Kohler SV710, SV820, SV725, SV830, SV740 User Manual

...

OWNER'S MANUAL

COURAGE SV710-740

COURAGE SV710-740

COURAGE PRO SV810-840

COURAGE PRO SV810-840

VERTICAL CRANKSHAFT

Safety Precautions

To ensure safe operation please read the following statements and understand their meaning. Also refer to your equipment owner's manual for other important safety information. This manual contains safety precautions which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause severe personal injury, death, or substantial property damage if the warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can cause minor personal injury or property damage if the caution is ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow these precautions could result in injury to yourself and others.

WARNING

WARNING

Explosive Fuel can cause fires and severe burns.

Do not fill the fuel tank while the engine is hot or running.

Explosive Fuel!

Gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well ventilated, unoccupied buildings, away from sparks or flames. Do not fill the fuel tank while the engine is hot or running, since spilled fuel could ignite if it comes in contact with hot parts or sparks from ignition. Do not start the engine near spilled fuel. Never use gasoline as a cleaning agent.

WARNING

WARNING

Rotating Parts can cause severe injury.

Stay away while engine is in operation.

Rotating Parts!

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the engine with covers, shrouds, or guards removed.

CAUTION

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is running.

Electrical Shock!

Never touch electrical wires or components while the engine is running. They can be sources of electrical shock.

WARNING

WARNING

Hot Parts can cause severe burns.

Do not touch engine while operating or just a er stopping.

Hot Parts!

Engine components can get extremely hot from operation. To prevent severe burns, do not touch these areas while the engine is running, or immediately a er it is turned o . Never operate the engine with heat shields or guards removed.

California

Proposition 65 Warning

Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

2

WARNING

WARNING

Accidental Starts can cause severe injury or death.

Disconnect and ground spark plug leads before servicing.

Accidental Starts!

Disabling engine. Accidental starting can cause severe injury or death. Before working on the engine or equipment, disable the engine as follows: 1) Disconnect the spark plug lead(s). 2) Disconnect negative (-)

ba ery cable from ba ery.

Safety Precautions (Cont.)

WARNING

WARNING

Carbon Monoxide can cause severe nausea, fainting or death.

Avoid inhaling exhaust fumes, and never run the engine in a closed building or confined area.

Lethal Exhaust Gases!

Engine exhaust gases contain poisonous carbon monoxide. Carbon monoxide is odorless, colorless, and can cause death if inhaled. Avoid inhaling exhaust fumes, and never run the engine in a closed building or confined area.

WARNING

WARNING

Explosive Gas can cause fires and severe acid burns.

Charge ba ery only in a well ventilated area. Keep sources of ignition away.

Explosive Gas!

Ba eries produce explosive hydrogen gas while being charged. To prevent a fire or explosion, charge ba eries only in well ventilated areas. Keep sparks, open flames, and other sources of ignition away from the ba ery at all times. Keep ba eries out of the reach of children. Remove all jewelry when servicing ba eries.

Before disconnecting the negative

(-) ground cable, make sure all switches are OFF. If ON, a spark will occur at the ground cable terminal which could cause an explosion if hydrogen gas or gasoline vapors are present.

Congratulations – You have selected a fine four-cycle, twin cylinder, air-cooled engine. Kohler designs long life strength and on-the-job durability into each engine...making a Kohler engine dependable...dependability you can count on. Here are some reasons why:

•E cient overhead valve design, and pressure lubrication provide maximum power, torque, and reliability under all operating conditions.

•Dependable, maintenance-free electronic ignition ensures fast, easy starts time a er time.

•Kohler engines are easy to service. All routine service areas (like the dipstick and oil fill, air cleaner, spark plugs, and carburetor) are easily and quickly accessible.

•Parts subject to the most wear and tear (like the cylinder liner and camsha ) are made from precision formulated cast iron.

•Every Kohler engine is backed by a worldwide network of over 10,000 distributors and dealers. Service support is just a phone call away. Call 1-800-544-2444 (U.S. & Canada) for Sales & Service assistance. Or visit www.KohlerEngines.com.

To keep your engine in top operating condition, follow the maintenance procedures in this manual.

3

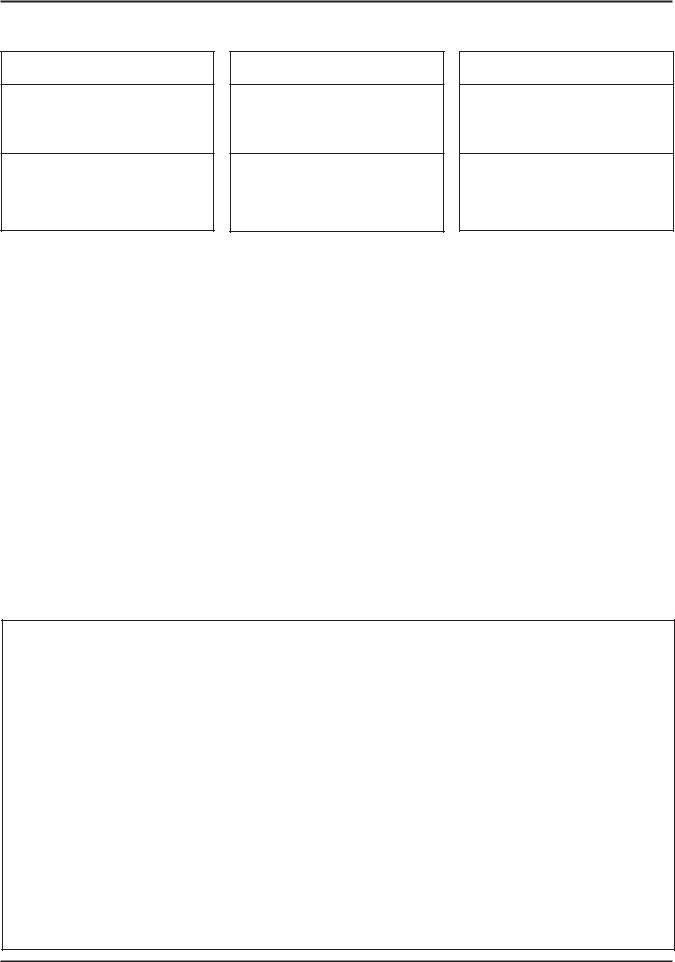

Courage® |

|

Courage PRO™ |

|

Air Cleaner Access |

|

Raised Air Cleaner |

|

Door Handle |

Dipstick |

||

Access Door |

|||

|

|||

|

|

Rectifier-Regulator

Fuel

Pump Electric

Starter

Identification Plate |

Oil Filter |

Spark Plug |

Figure 1. Typical Courage® and Courage PRO™ Series Vertical Shaft Engines.

Oil Recommendations

Using the proper type and weight of oil in the crankcase is extremely important. So is checking oil daily and changing oil regularly. Failure to use the correct oil, or using dirty oil, causes premature engine wear and failure.

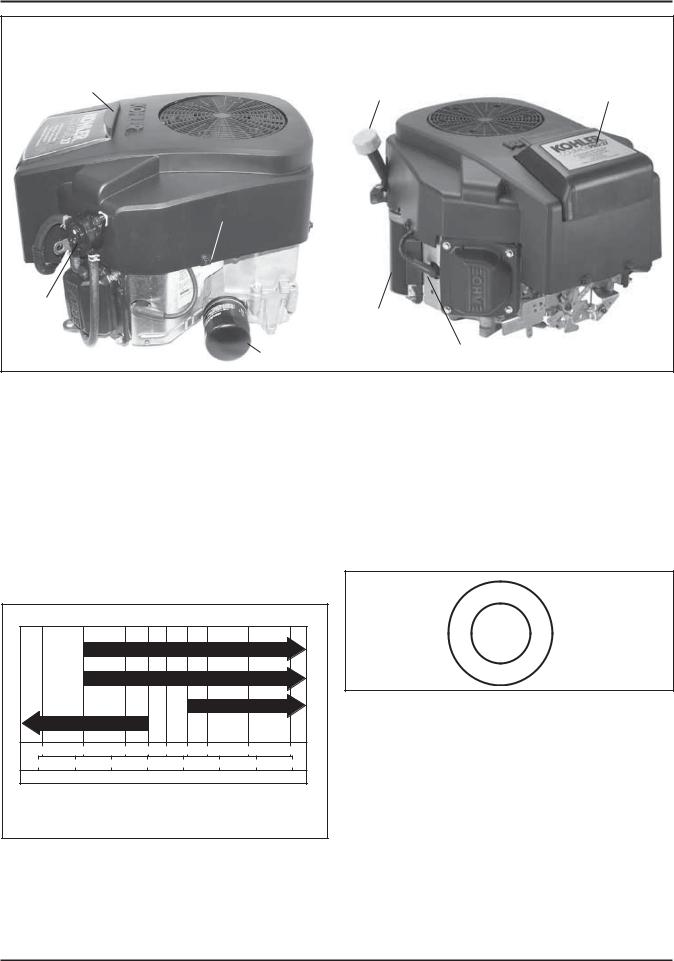

Oil Type

Use high quality detergent oil of API (American Petroleum Institute) service class SG, SH, SJ or higher. Select the viscosity based on the air temperature at the time of operation as shown in the following table.

RECOMMENDED SAE VISCOSITY GRADES

|

** |

|

|

|

Kohler 10W-30 |

|

|||

|

|

|

|

|

10W-30 |

|

|

||

|

|

|

|

|

|

|

|

||

|

|

5W-20, 5W-30 |

* |

|

|

|

SAE 30 |

|

|

|

|

|

|

|

|

|

|

||

°F |

-20 |

0 |

20 |

32 |

40 |

50 |

60 |

80 |

100 |

°C -30 |

-20 |

-10 |

0 |

|

10 |

20 |

30 |

40 |

|

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

*Use of synthetic oil having 5W-20 or 5W-30 rating is acceptable, up to 4°C (40°F).

**Synthetic oils will provide better starting in extreme cold below

23°C (-10°F).

Figure 2. Viscosity Grades Table.

NOTE: Using other than service class SG, SH, SJ or higher oil or extending oil change intervals longer than recommended can cause engine damage.

NOTE: Synthetic oils meeting the listed classifications may be used with oil changes performed at the recommended intervals. However to allow piston rings to properly seat, a new or rebuilt engine should be operated for at least 50 hours using standard petroleum based oil before switching to synthetic oil.

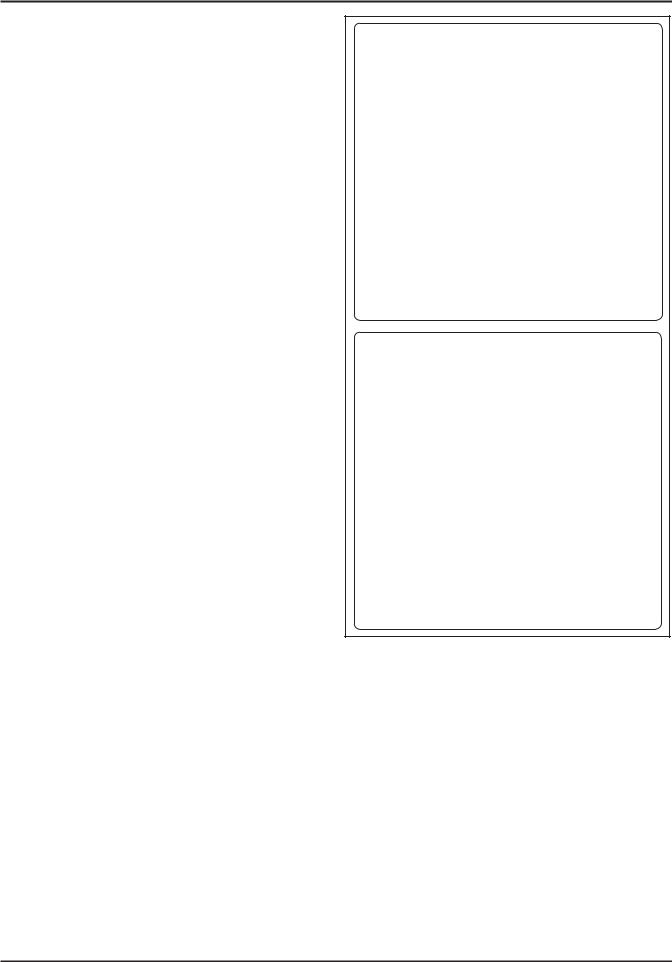

A logo or symbol on oil containers identifies the API service class and SAE viscosity grade. See Figure 3.

|

|

RV |

|

|

|

|

|

|

E |

I |

|

|

|

|

|

S |

|

C |

|

|

P |

I |

|

E |

|||

|

|

|||||

A |

|

SAE |

|

S |

||

|

|

|

J |

|||

|

|

10W-30 |

|

|||

|

|

|

|

|||

Figure 3. Oil Container Logo.

Refer to Maintenance Instructions beginning on page 7 for detailed oil check, oil change, and oil filter change procedures.

Fuel Recommendations

WARNING: Explosive Fuel!

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well ventilated, unoccupied buildings, away from sparks or flames. Do not fill the fuel tank while the engine is hot or running, since spilled fuel could ignite if it comes in contact with hot parts or sparks from ignition. Do not start the engine near spilled fuel. Never use gasoline as a cleaning agent.

4

General Recommendations

Purchase gasoline in small quantities and store in clean, approved containers. A container with a capacity of 2 gallons or less with a pouring spout is recommended. Such a container is easier to handle and helps eliminate spillage during refueling.

Do not use gasoline le over from the previous season, to minimize gum deposits in your fuel system and to ensure easy starting.

Do not add oil to the gasoline.

Do not overfill the fuel tank. Leave room for the fuel to expand.

Fuel Type

For best results use only clean, fresh, unleaded gasoline with the pump sticker octane rating of 87 or higher. In countries using the Research method, it should be 90 octane minimum.

Unleaded gasoline is recommended as it leaves less combustion chamber deposits and reduces harmful exhaust emissions. Leaded gasoline is not recommended.

Gasoline/Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by volume) is approved as a fuel for Kohler engines. Other gasoline/alcohol blends including E20 and E85 are not to be used and not approved. Any failures resulting from use of these fuels will not be warranted.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline blends (up to a maximum of 15% MTBE by volume) are approved as a fuel for Kohler engine. Other gasoline/ether blends are not approved.

Engine Identification Numbers

When ordering parts, or in any communication involving an engine, always give the Model, Specification, and Serial Numbers of the engine.

The engine identification numbers appear on a decal (or decals) a xed to the engine shrouding. Include le er su xes, if there are any.

Record your engine identification numbers on the identification label (Figure 4) for future reference.

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPA PH2 AND EC STAGE II (SN:4) EMISSION REGS FOR SI SORE. NOT FOR SALE IN

CALIFORNIA UNLESS PREEMPT PER SEC. 209 (e) (1) OF CAA.

FAMILY TYPE APP

DISPL. (CC) N11236

MODEL NO.

SPEC. NO.

SERIAL NO.

BUILD DATE OEM PROD. NO.

EMISSION COMPLIANCE PERIOD:

EPA: CARB: CERTIFIED ON:

REFER TO OWNER'S MANUAL FOR HP RATING, SAFETY, MAINTENANCE AND ADJUSTMENTS

1-800-544-2444 KohlerEngines.com

KOHLER CO. KOHLER, WISCONSIN USA

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPA PH2 AND CA 2008 AND

LATER EXH EMISSION REGS FOR SI SORE. USING DELEGATED ASSEMBLY FOR AFTERTREATMENT.

FAMILY

TYPE APP

DISPL. (CC)

MODEL NO.

SPEC. NO. N11236

SERIAL NO.

BUILD DATE OEM PROD. NO.

EMISSION COMPLIANCE PERIOD:

EPA: CARB: CERTIFIED ON:

REFER TO OWNER'S MANUAL FOR HP RATING, SAFETY, MAINTENANCE AND ADJUSTMENTS

1-800-544-2444 KohlerEngines.com

KOHLER CO. KOHLER, WISCONSIN USA

Figure 4. Engine Identification Label.

The Emission Compliance Period referred to on the Emission Control or Air Index label indicates the number of operating hours for which the engine has been shown to meet Federal and CARB emission requirements. The following table provides the Engine Compliance Period (in hours) associated with the category descriptor found on the certification label.

Emission Compliance Period (Hours)

EPA |

Category C |

Category B |

Category A |

|

250 hours |

500 hours |

1000 hours |

||

|

||||

|

|

|

|

|

CARB |

Moderate |

Intermediate |

Extended |

|

125 hours |

250 hours |

500 hours |

||

|

||||

|

|

|

|

Refer to certification label for engine displacement.

Exhaust Emission Control System for models SV710-SV840 is EM for U.S. EPA and Europe; PAIR for California Tier III.

5

Operating Instructions

Also read the operating instructions of the equipment this engine powers.

Pre-Start Checklist

•Check oil level. Add oil if low. Do not overfill.

•Check fuel level. Add fuel if low.

•Check cooling air intake areas and external surfaces of engine. Make sure they are clean and unobstructed.

•Check that the air cleaner components and all shrouds, equipment covers, and guards are in place and securely fastened.

•Check that any clutches or transmissions are

disengaged or placed in neutral. This is especially important on equipment with hydrostatic drive. The shi lever must be exactly in neutral to prevent resistance which could keep the engine from starting.

WARNING: Lethal Exhaust Gases!

WARNING: Lethal Exhaust Gases!

Engine exhaust gases contain poisonous carbon monoxide. Carbon monoxide is odorless, colorless, and can cause death if inhaled. Avoid inhaling exhaust fumes, and never run the engine in a closed building or confined area.

Cold Weather Starting Hints

1.Be sure to use the proper oil for the temperature expected. See Figure 2 on page 4.

2.Declutch all possible external loads.

3.Be sure the ba ery is in good condition. A warm ba ery has much more starting capacity than a cold ba ery.

4.Use fresh winter grade fuel. NOTE: Winter grade gasoline has higher volatility to improve starting.

Do not use gasoline le over from summer.

Starting

1.Place the thro le control midway between the slow and fast positions. Place the choke control into the on position.

2.Start the engine by activating the key switch. Release the switch as soon as the engine starts.

NOTE: Do not crank the engine continuously for more than 10 seconds at a time. If the engine does not start, allow a 60 second cool down period between starting a empts. Failure to follow these guidelines can burn out the starter motor.

NOTE: If the engine develops su cient speed to disengage the starter but does not keep running (a false start), engine rotation must be allowed to come to a complete stop before a empting to restart the engine.

If the starter is engaged while the flywheel is rotating, the starter pinion and flywheel ring gear may clash, resulting in damage to the starter.

If the starter does not turn the engine over, shut o starter immediately. Do not make further a empts to start the engine until the condition is corrected. Do not jump start using another ba ery (refer to Ba ery). See your Kohler Engine Service Dealer for service assistance.

3.For a Cold Engine – Gradually return the choke control to the o position a er the engine starts and warms up.

The engine/equipment may be operated during the warm-up period, but it may be necessary to leave the choke partially on until the engine warms up.

4.For a Warm Engine – Return choke to o position as soon as engine starts.

Stopping

1.Remove the load by disengaging all PTO driven a achments.

2.For Engines without a Shutdown Solenoid:

Move the thro le to the slow or low idle position. Allow the engine to run at idle for 30-60 seconds; then stop the engine.

For Engines Equipped with a Shutdown Solenoid: Position the thro le control between half and full thro le; then stop the engine.

Battery

A 12 volt ba ery is normally used. Refer to the operating instructions of the equipment this engine powers for specific ba ery requirements.

If the ba ery charge is not su cient to crank the engine, recharge the ba ery.

Operating

Angle of Operation

This engine will operate continuously at angles up to 25°. Check oil level to assure crankcase oil level is at the FULL or “F” mark on the dipstick.

6

Loading...

Loading...