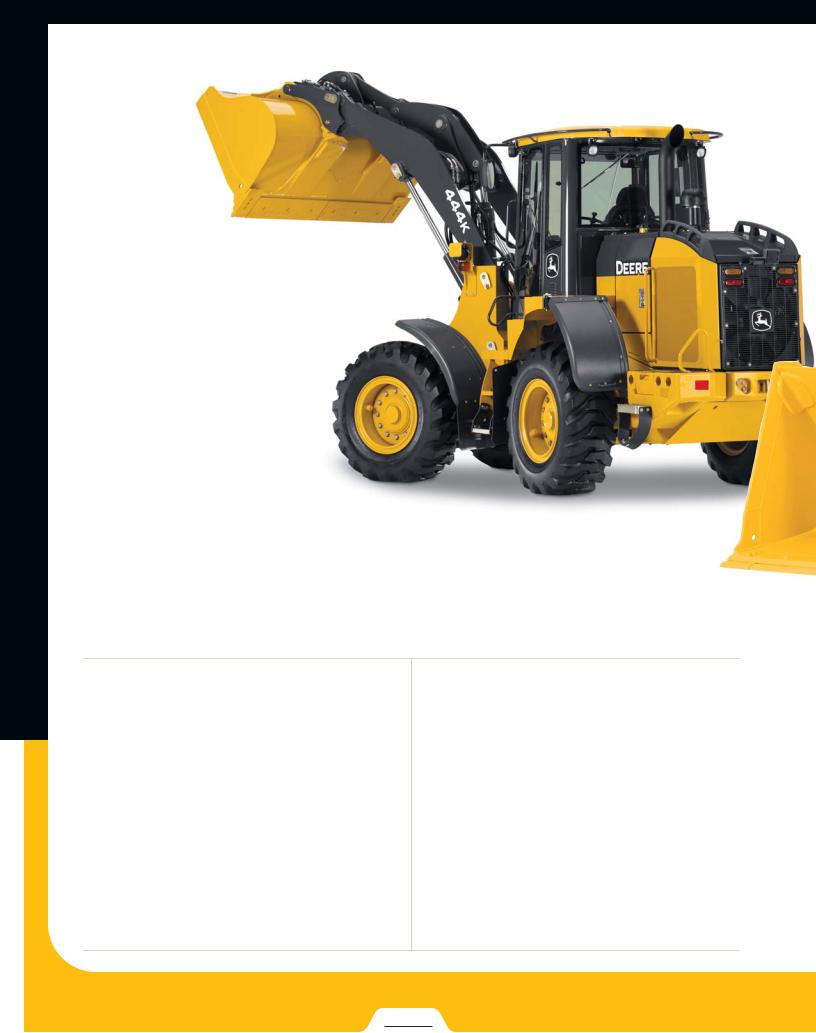

John Deere 524K, 444K, 544K SPECIFICATIONS

9 5 – 1 4 7 K W ( 1 2 8 – 1 9 8 N E T H P )

K LOADERS

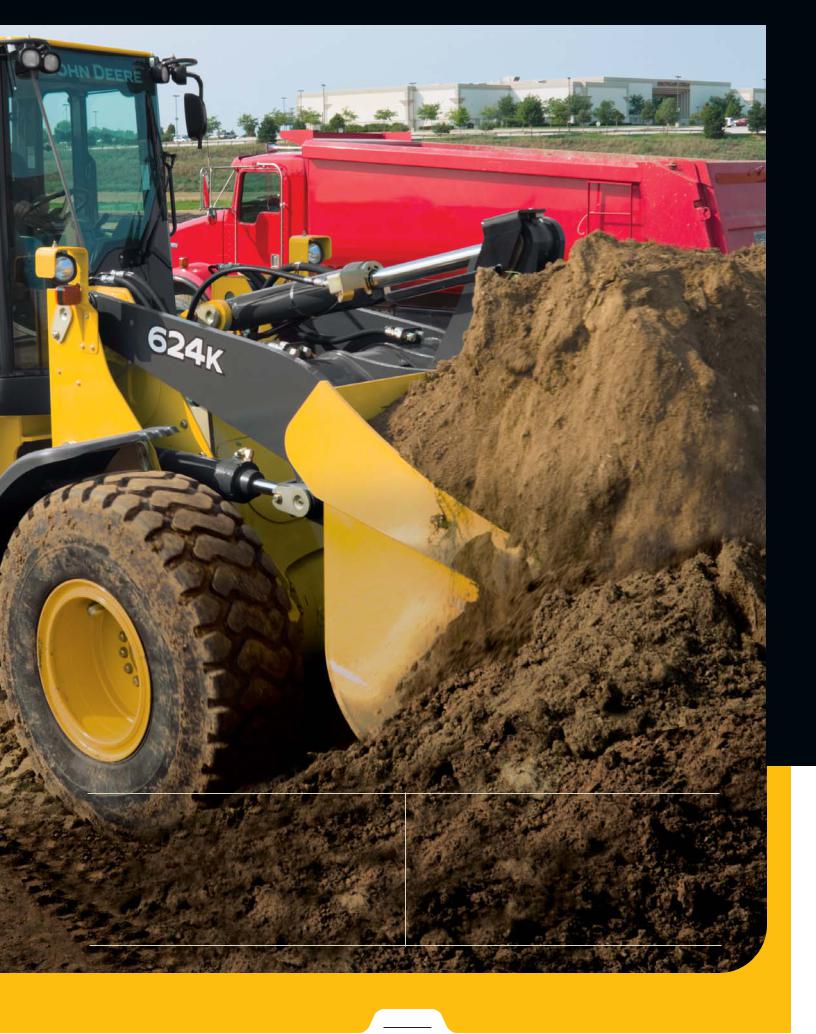

444K | 524K | 544K | 624K

UTILITY LOADERS

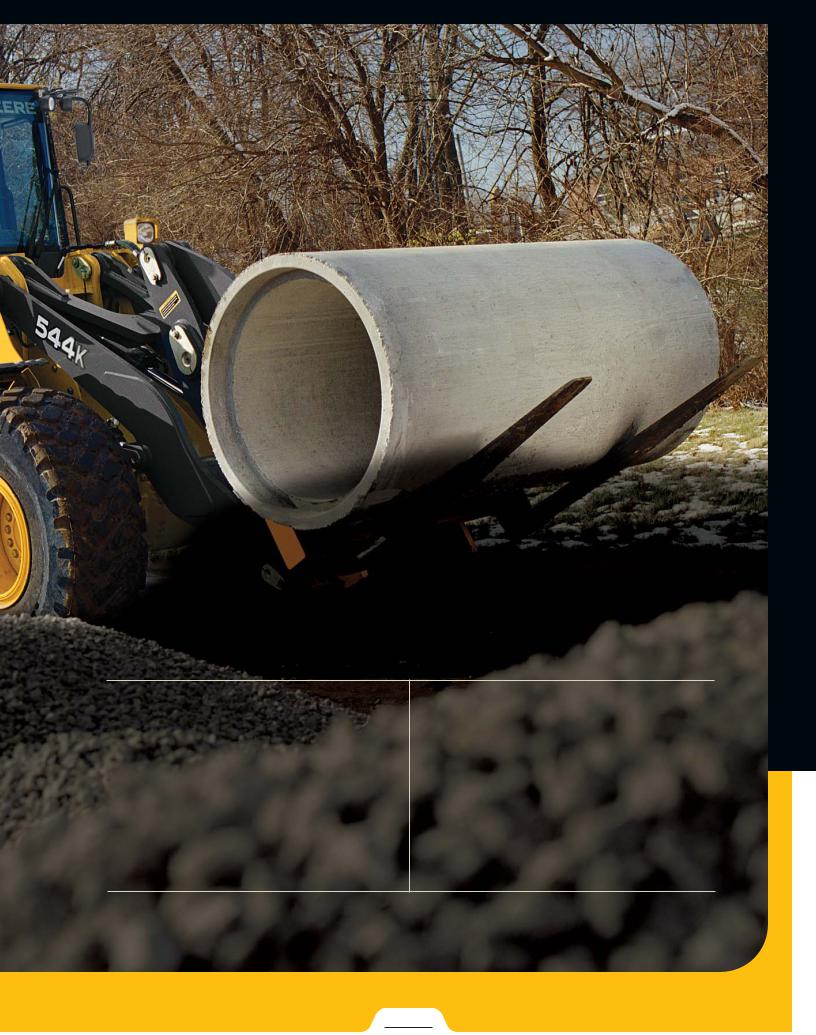

transmission. The J-Series Loaders introduced a lot of innovative thinking — and began a tradition that continues in the new K-Series. Although they don’t appear all that different from their standard-setting predecessors, these next-generation loaders are loaded throughout with even more customer-inspired

to-read LCD monitors with advanced onboard diagnostics. You have more choices, too, including the 2.1-m3 (2.75 cu. yd.) 524K, NeverGrease™ pins, and automatic diff-lock axles, to list just a few. Exceptional productivity, long-term durability, unparalleled versatility — you get it all in the John Deere K-Series.

PAGES

2–3

K-SERIES SPECIFICATIONS

Rated Net Power |

444K |

524K |

544K |

624K |

95 kW (128 hp) |

110 kW (146 hp) |

125 kW (167 hp) |

147 kW (198 hp) |

|

Bucket Capacity |

1.9 m3 (2.5 cu. yd.) |

2.1 m3 (2.75 cu. yd.) |

2.3 m3 (3.0 cu. yd.) |

2.7 m3 (3.5 cu. yd.) |

Z-bar: |

|

|

|

|

Tipping Load |

8072 kg |

8935 kg |

9434 kg |

12 031 kg |

40-degree full turn |

(17,796 lb.) |

(19,698 lb.) |

(20,799 lb.) |

(26,542 lb.) |

Breakout Force |

8023 kg (17,688 lb.) |

9193 kg (20,267 lb.) |

10 188 kg (22,461 lb.) |

12 920 kg (28,484 lb.) |

Operating Weight |

11 055 kg |

12 282 kg |

12 820 kg |

15 185 kg |

|

(24,372 lb.) |

(27,077 lb.) |

(28,263 lb.) |

(33,477 lb.) |

Powerllel™: |

|

|

|

|

Tipping Load |

6226 kg |

N/A |

7554 kg |

9257 kg |

40-degree full turn |

(13,726 lb.) |

|

(16,654 lb.) |

(20,408 lb.) |

Breakout Force |

6056 kg (13,352 lb.) |

N/A |

8604 kg (18,968 lb.) |

10 759 kg (23,719 lb.) |

Operating Weight |

12 074 kg |

N/A |

13 840 kg |

16 454 kg |

|

(26,619 lb.) |

|

(30,511 lb.) |

(36,275 lb.) |

Tool Carrier: |

|

|

|

|

Tipping Load |

N/A |

N/A |

N/A |

10 739 kg |

40-degree full turn |

|

|

|

(23,675 lb.) |

Breakout Force |

N/A |

N/A |

N/A |

10 978 kg (24,202 lb.) |

Operating Weight |

N/A |

N/A |

N/A |

15 499 kg (34,169 lb.) |

|

|

|

|

|

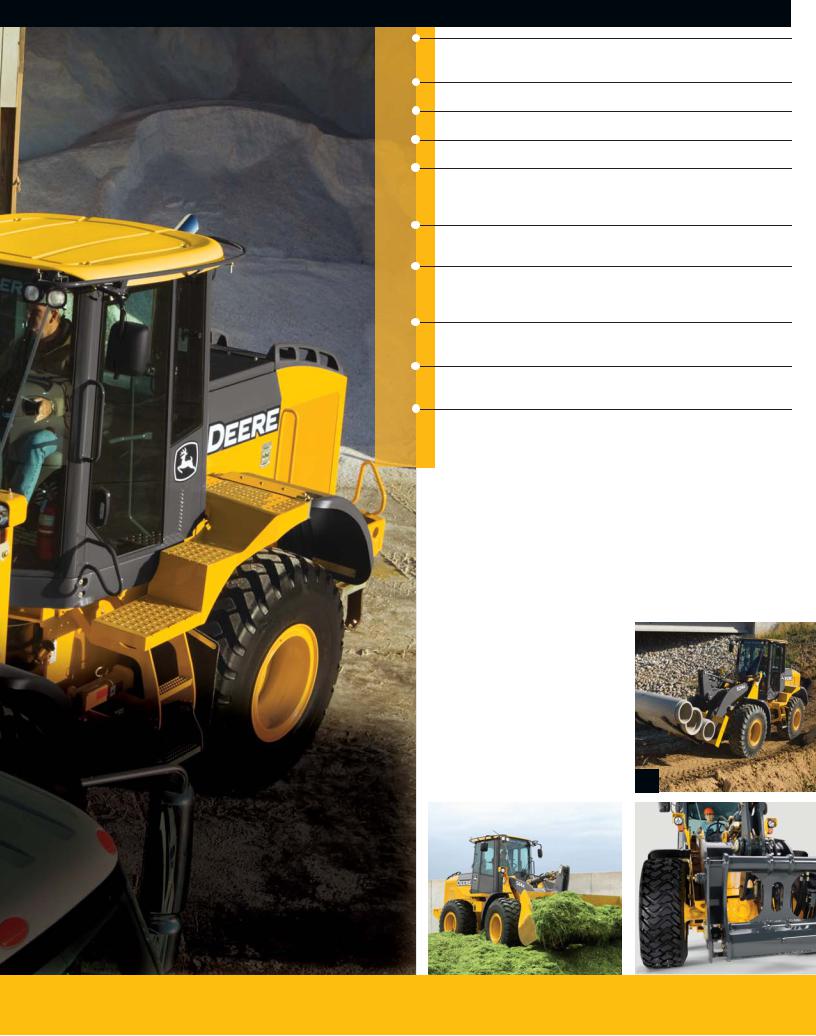

impressive torque reserves that top out at a whopping 55 percent in the 624K. For power without compromise in all conditions.

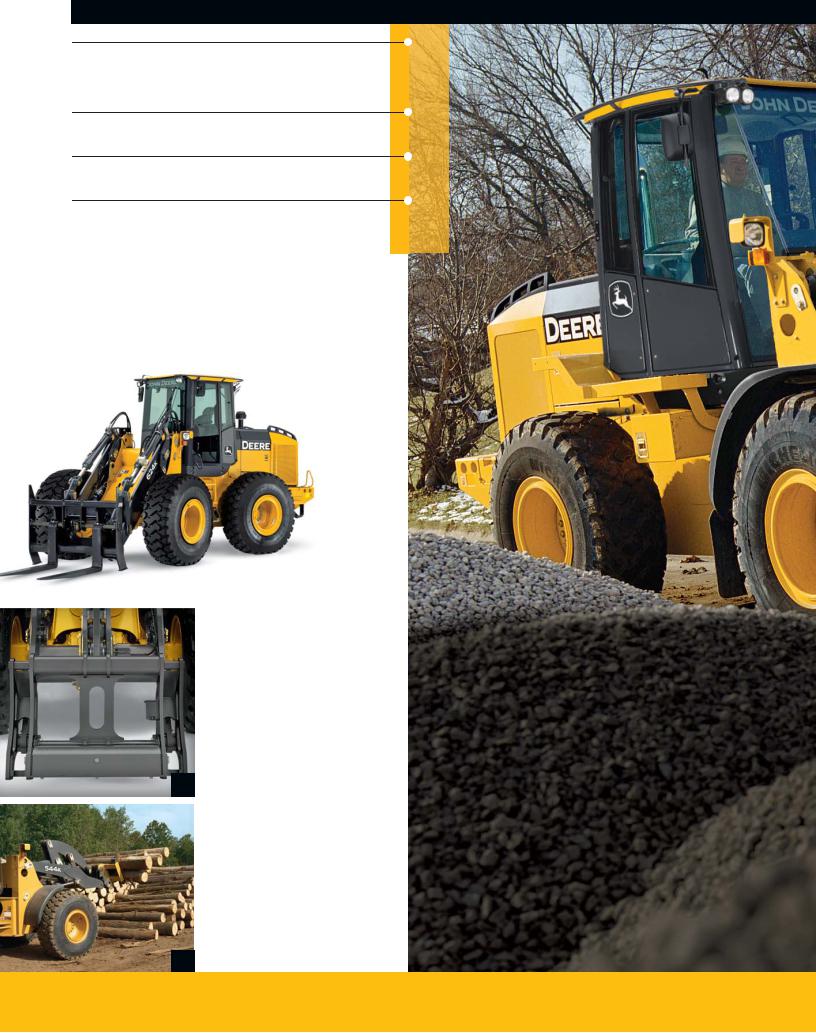

K-Series Loaders ride on a wide stance that provides additional lateral stability for handling heavy loads and working on rough terrain. Overall balance is exceptional.

Same-side ground-level service access makes the daily routine quick and easy. Enhanced onboard diagnostics and extended service intervals further maximize uptime.

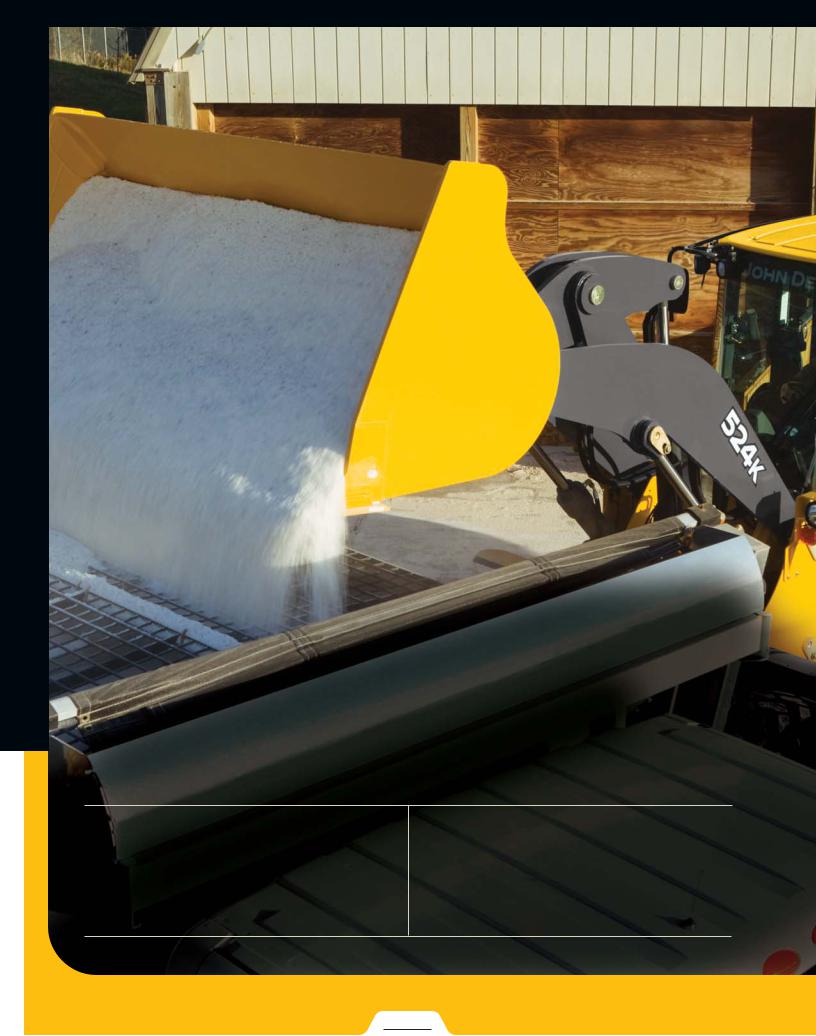

Z-bar or parallel lift? If you can’t decide which configuration is best for you, the 444K, 544K, and 624K Powerllel’s patented design delivers the best of both.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and high-traffic areas. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

4 |

|

|

|

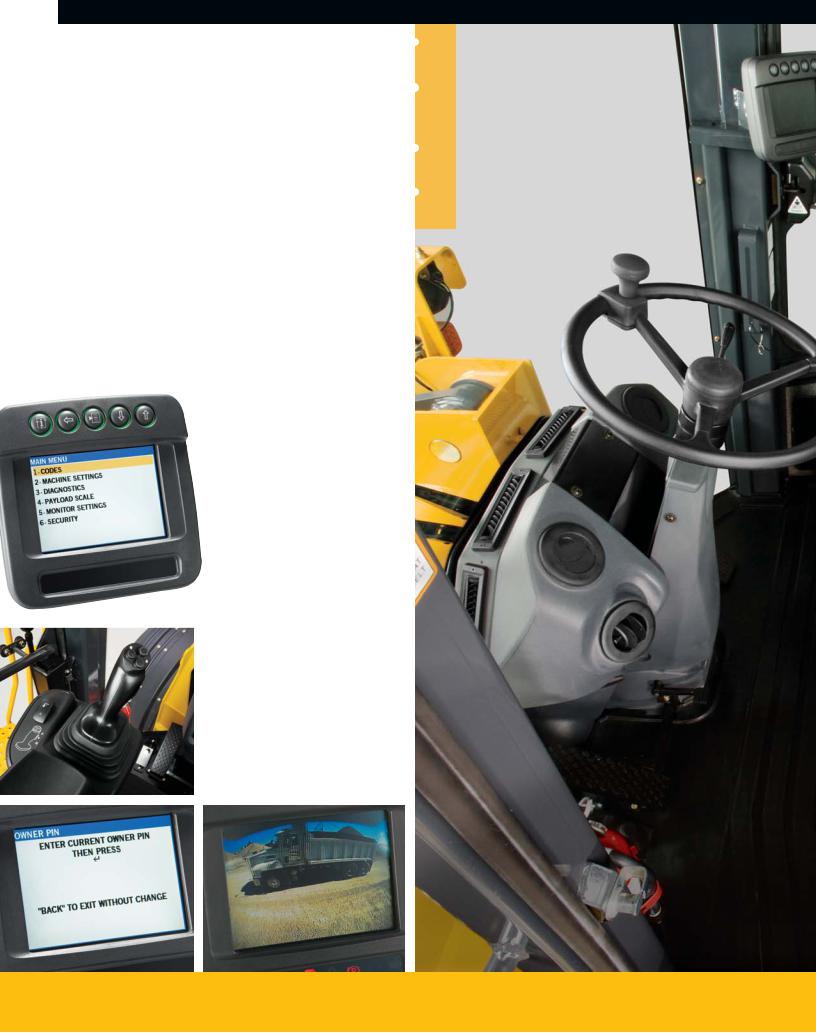

2.Backlit touchpad in the expanded sealedswitch module controls key-less start and

24 other machine functions. Enables the |

2 |

operator to adjust boom-height kick-out and return-to-carry, and activate return- to-dig from the seat.

3.Programmable clutch cutoff increases productivity in all kinds of terrain. Simply select the slope of your dumpsite — level, small, or steep. Depressing the brake pedal disconnects the transmission while maintaining engine speed for fast boom cycles.

3

breakout throughout the entire bucket and

2angle range. To conquer tough tasks such as loading logs.

3

10–11

inexperienced operators or applications requiring high traction, such as stockpiling

silage, plowing snow, and handling pipe. |

1 |

|

3 |

|

2 |

|

|

|

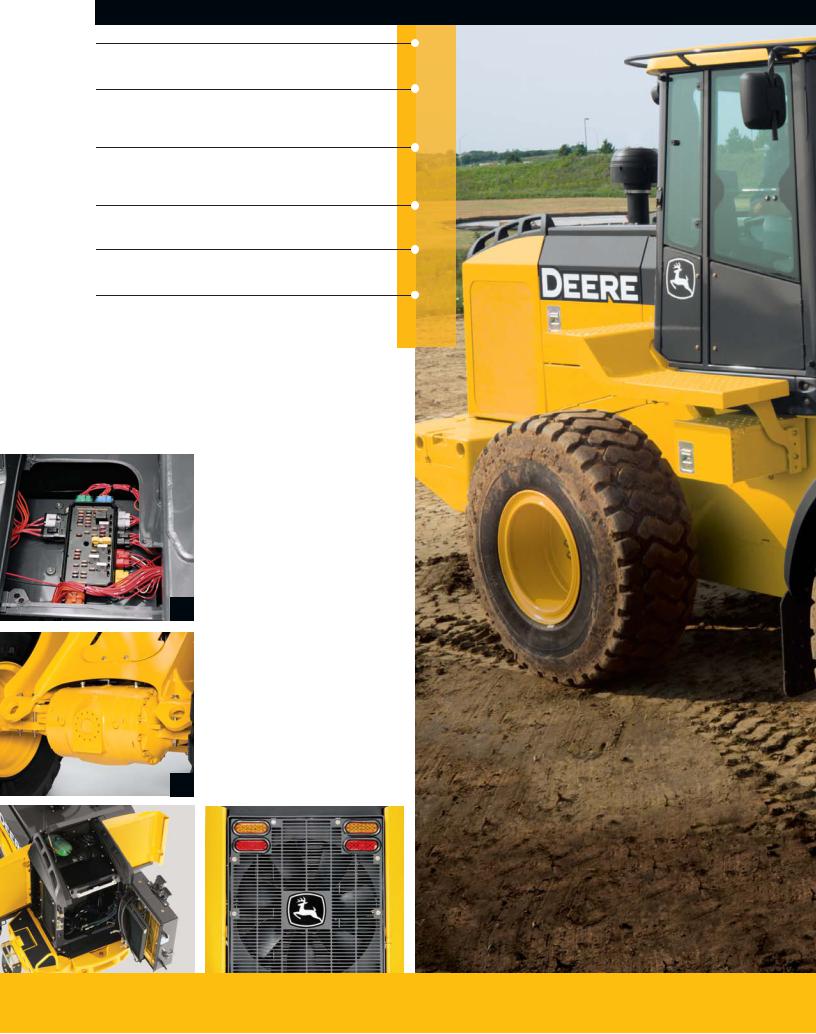

Four steel plates support the loader tower, extending pin life and protecting the boom-cylinder hoses.

Sealed-switch module keeps out dust, moisture, and debris, and virtually never wears out. Proven marine-grade touchpad eliminates rocker switches and nearly 100 wires, and unsealed connections provide even longer life.

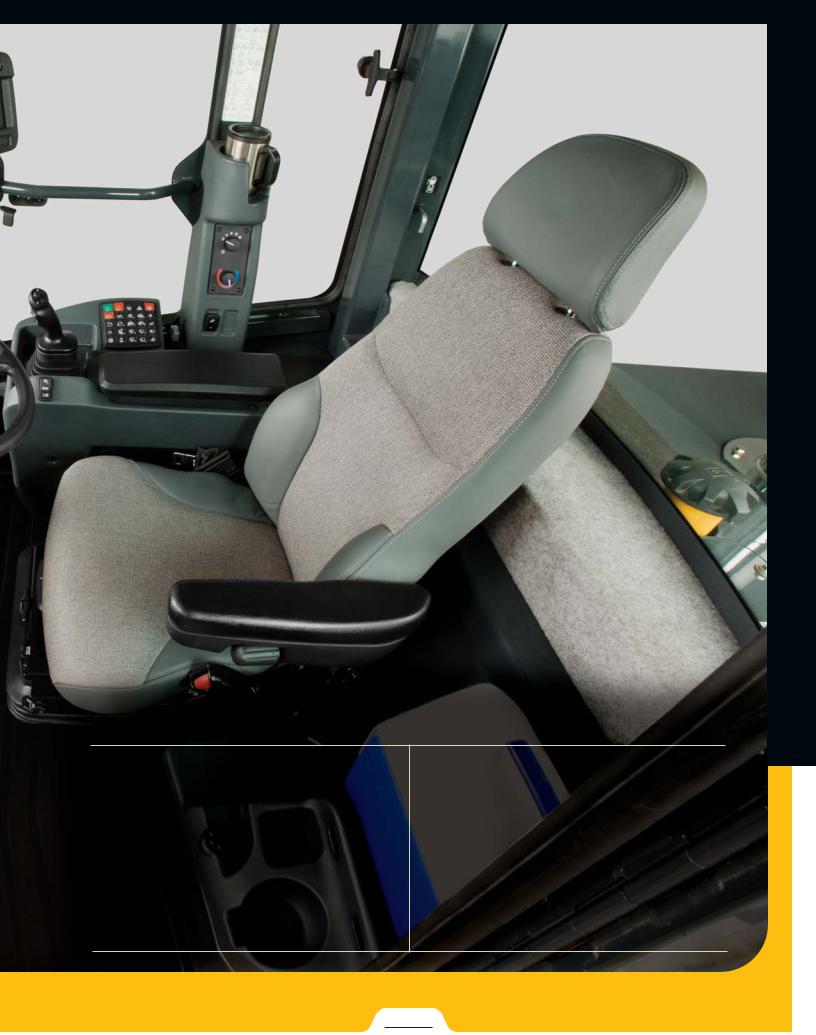

Standard features such as bypass-start protection, automatic park brake, convenient handholds, and slip-resistant steps help keep the operator out of harm’s way.

Wet-sleeve engine liners provide uniform engine cooling for less oil breakdown and longer durability than cast-in-block designs.

500-, 2,000-, and 4,000-hour engine, transmission, and hydraulic oil and filter service intervals mean more uptime.

Wide-mouth fuel tank allows quick and convenient ground-level fill-ups. Generous capacity lets you work longer.

1.Electrical-distribution center employs highly reliable circuit-board technology and solid-state switches that eliminate numerous wiring harnesses, fuses, relays, and connectors. Sealed gold-pin electrical connectors resist corrosion for superior long-term integrity.

2.524K, 544K, and 624K planetary final drives are mounted inboard. Hydraulic wet-disc brakes on all models self-adjust.

3.Quad-Cool places the radiator, air-conditioner condenser, intercooler, and hydraulic, transmission, and optional axle coolers in a unique boxed configuration that’s isolated from engine heat. For increased efficiency and durability.

4.Optional programmable fan automatically reverses at predetermined intervals, ejecting debris from the radiator and cooler cores. Or choose your own cleaning cycles through the monitor.

2

3 |

|

4 |

|

|

|

12–13

Loading...

Loading...