John Deere HR-2500GH, HR-2700GH OPERATOR'S MANUAL

hr-2500gh hr-2700gh

High Pressure Washers

AC-Series Operator’s Manual-E/F |

|

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate and service your machine correctly. Failure to do so could result in personal injury or equipment damage. This manual and safety signs on your machine may also be available in other languages. (See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your machine and should remain with the machine when you sell it.

MEASUREMENTS in this manual are given in both metric and customary U.S. unit equivalents. Use only correct replacement parts and fasteners. Metric and inch fasteners may require a specific metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by the direction the machine will travel when going forward.

WRITE SERIAL NUMBER in the Specification or

Identification Numbers section. Accurately record all the numbers to help in tracing the machine should it be stolen. Your dealer also needs these numbers when you order parts. File the identification numbers in a secure place off the machine.

WARRANTY is provided from your John Deere dealer for customers who operate and maintain their equipment as described in this manual. The warranty is explained on the warranty certificate shown in this manual.

This warranty provides you the assurance that your John Deere dealer will back products where defects appear within the warranty period. Should the equipment be abused, or modified to change its performance beyond the original factory specifications, the warranty will become void. Setting fuel delivery above specifications or otherwise overpowering the machine will result in such action.

Warranty and product support for the engines is provided by Honda®. The Honda engine warranty is explained in the Honda Warranty Certificate that accompanies this pressure washer. Additional copies of the Engine Warranty

Certificate are available from your John Deere dealer.

|

|

AC-Series Operator’s Manual-E/F |

|

Contents

|

Page |

Safety .................................................................................. |

5 |

Safety Signs ...................................................................... |

10 |

Controls ............................................................................ |

11 |

Preparing the Washer |

|

Check Engine Oil................................................................. |

12 |

Gasoline Engine Oil............................................................. |

12 |

Filling Fuel Tank................................................................... |

13 |

Inlet Water Supply Requirements ........................................ |

14 |

Pump Oil.............................................................................. |

15 |

Connect Hoses and Prime Pump......................................... |

15 |

Installing Nozzle................................................................... |

16 |

Final Checklist...................................................................... |

16 |

Operating the Washer |

|

Starting and Operating Engine ............................................ |

17 |

Stopping the Engine............................................................. |

17 |

Locking Trigger Gun............................................................. |

17 |

Water Pressure.................................................................... |

18 |

Changing Nozzle.................................................................. |

18 |

Selecting the Proper Nozzle................................................. |

18 |

15° Nozzle-Yellow................................................................ |

19 |

25°Nozzle-Green.................................................................. |

19 |

Detergent Injector Nozzle-Black (Brass).............................. |

19 |

Cleaning Horizontal Surfaces............................................... |

20 |

Cleaning Vertical Surfaces................................................... |

20 |

Removing Paint.................................................................... |

20 |

Cleaning Radiator Fins......................................................... |

20 |

Detergent Usage Guide....................................................... |

21 |

Cleaning with Detergents..................................................... |

22 |

Shut-down............................................................................ |

22 |

Troubleshooting ............................................................... |

23 |

Maintenance Chart ............................................................ |

25 |

Service |

|

Cleaning Water Inlet Screen................................................ |

26 |

Cleaning Detergent Hose Strainer....................................... |

26 |

Water Pump Oil.................................................................... |

26 |

Check Engine Oil................................................................. |

27 |

Changing Engine Oil............................................................ |

27 |

Gasoline Engine Oil............................................................. |

27 |

Servicing Air Cleaner ........................................................... |

28 |

Cleaning and Gapping Spark Plug....................................... |

28 |

Adjusting Idle Speed............................................................ |

28 |

Storage |

|

Storing Washer..................................................................... |

29 |

Removing Washer from Extended Storage.......................... |

29 |

Specifications |

|

Specifications ...................................................................... |

30 |

Record Serial Number.......................................................... |

30 |

|

Page |

Accessories |

|

High Pressure Hose ............................................................ |

31 |

Rotating Brush..................................................................... |

31 |

0° Nozzle-Red...................................................................... |

31 |

40° Nozzle-White................................................................. |

31 |

Rotating Nozzle.................................................................... |

32 |

All-Purpose Cleaning........................................................... |

32 |

Surface Preparation............................................................. |

32 |

Degreasing........................................................................... |

32 |

Spray Wax............................................................................ |

33 |

Rust Inhibiting Antifreeze..................................................... |

33 |

Detergent Booster................................................................ |

33 |

Plus-4 Motor Oil................................................................... |

34 |

Gasoline Conditioner & Stabalizer....................................... |

34 |

Warranty ............................................................................. |

35 |

All information, illustrations and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice.

AC-Series Operator’s Manual-E/F |

|

Contents

AC-Series Operator’s Manual-E/F

Safety

Recognize safety information

This is the safety alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

understand signal words

A signal word--DANGER, WARNING or CAUTION--is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER or WARNING safety signs are located near specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to safety messages in this manual.

follow safety instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in good condition. Replace missing or damaged safety signs. Be sure new equipment components and repair parts include the current safety signs. Replacement safety signs are available from your John Deere dealer.

Learn how to operate the machine and how to use controls properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition. Unauthorized modifications to the machine may impair the function and/or safety and affect machine life.

If you do no understand any part of this manual and need assistance, contact your John Deere dealer.

AC-Series Operator’s Manual-E/F

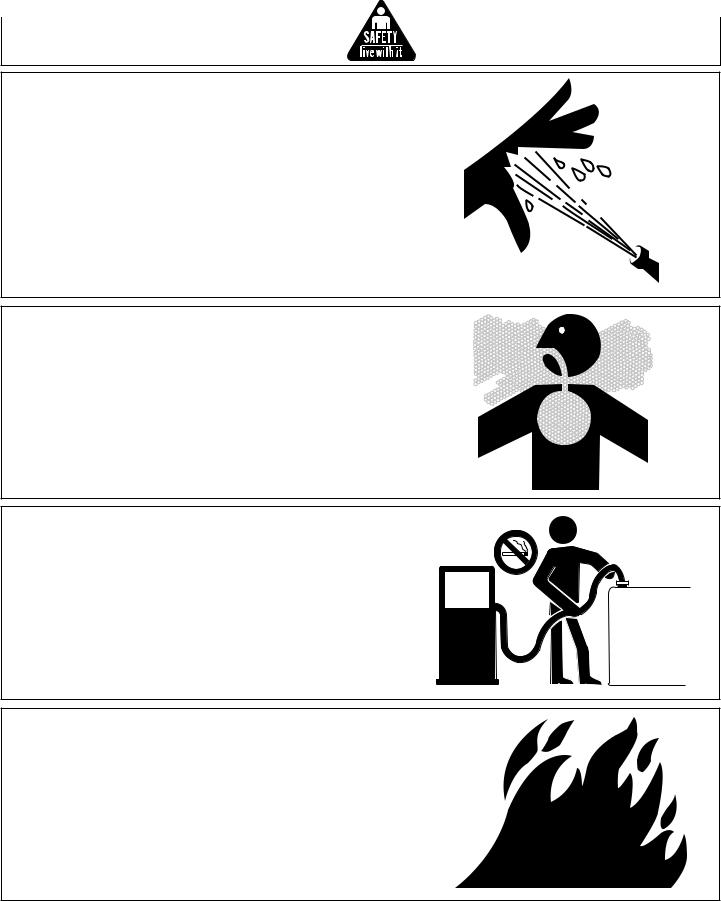

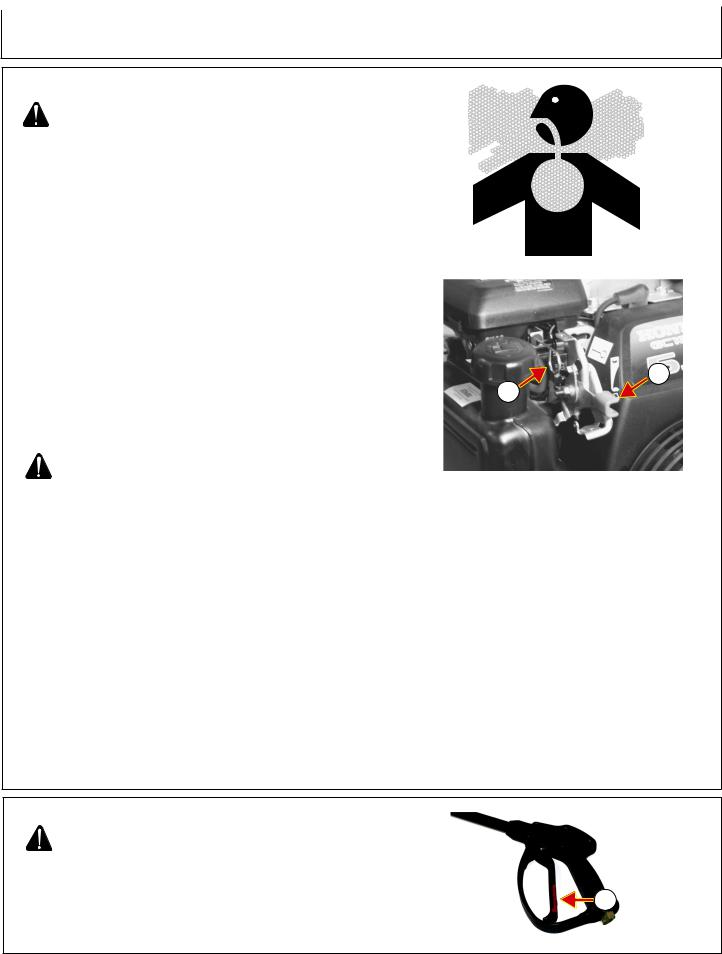

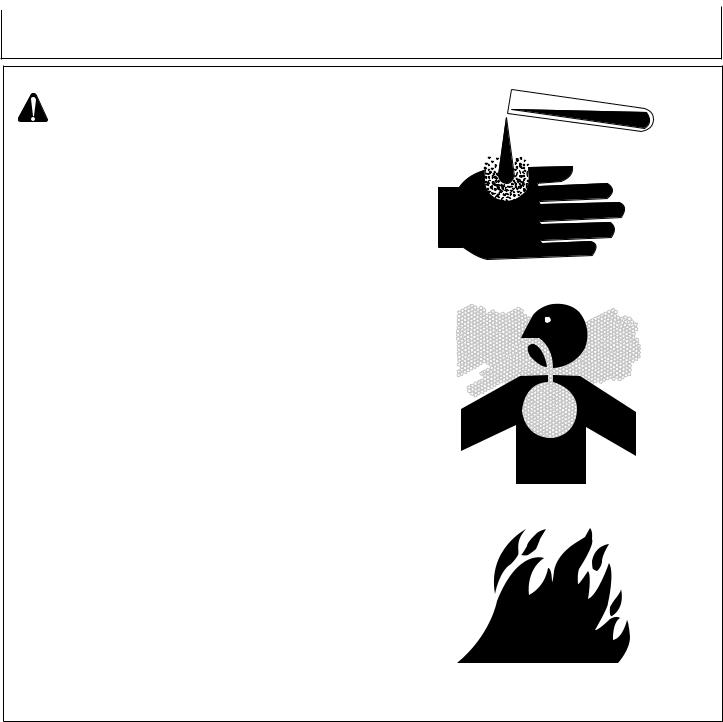

protect against high pressure spray

Spray from high pressure nozzles can penetrate the skin and cause serious injury. Keep spray from contacting hands or body.

If an accident occurs, see a doctor immediately. Any high pressure spray injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

work in a ventilated area

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area,

remove the exhaust fumes from the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

handle fuel safely-avoid fires

Handle fuel with care: it is highly flammable. Do not refuel the machine while smoking or when near open flame or sparks.

Always stop engine before refueling machine. Fill fuel tank outdoors.

Prevent fires by keeping machine clean of accumulated trash, grease and debris. Always clean up spilled fuel.

drain gasoline when storing machine

Gasoline stored in fuel tank can explode.

Never store equipment with gasoline in the tank inside a building where fumes may reach an open flame or spark.

Always drain gasoline from fuel tank and carburetor bowl when storing machine. Allow engine to cool before storing.

AC-Series Operator’s Manual-E/F

CLEANING DETERGENT PRECAUTIONS

Know the detergent being used. Be prepared to tell a physician exactly what you are using in the event of an emergency. Read all detergent labels and follow all instructions exactly regarding preparation, use, safety, transportation, and disposal. Keep all detergents out of the reach of children, pets and livestock.

NEVER spray combustible liquids of any kind.

Do not use highly corrosive detergents or acid-type cleaners with this washer.

handle chemical products safely

Direct exposure to hazardous chemicals can cause injury. Potentially hazardous chemicals used with the pressure washer includes such items as detergents.

A Material Safety Data Sheet (MSDS) provides specific details on detergents; physical and health hazards, safety procedures and emergency response techniques. Check the MSDS before you start any job using a detergent. That way you will know exactly what the risks are and how to do the job safely. Then follow procedures and recommended equipment. (See your John Deere dealer for MSDS Sheets on products used with this equipment.)

MSDS

AC-Series Operator’s Manual-E/F

important safety instructions

WARNING: To reduce the risk of injury, read this operator’s manual completely. When using this product, the following basic precautions should always be followed:

1.Read all the instructions before using the product.

2.High pressure water spray can cut skin. Do not “lock” trigger in the open position. Do not direct spray at persons. Keep operating area clear of all persons and pets. Warn children that the water spray can cut. Supervise children closely.

3.Do not allow children or untrained persons to operate the washer.

4.Do not spray electrical switches, receptacles or light bulbs, or glass or fragile objects that may shatter

5.Dirt and debris removed by spray can cause eye injury. Wear eye protection.

6.Do not move washer with engine running. Always stop engine and allow washer to cool before handling.

7.Wet surfaces can be slippery. Wear shoes and keep both feet on the ground. Do not climb on items being cleaned. Do not overreach or stand on unstable support. Keep good footing and balance at all times.

8.When the spray trigger is released, water pressure is trapped in the discharge hose. Release trapped pressure by triggering the spray gun after the washer is turned off.

9.Do not operate the washer when fatigued or under the influence of drugs or chemicals. Stay alert.

Watch what you are doing.

10.Do not operate the washer if fuel, pump oil or water leaks are visible. Resume operation ONLY after washer has been inspected and repaired.

11.Follow the maintenance instruction specified in this manual.

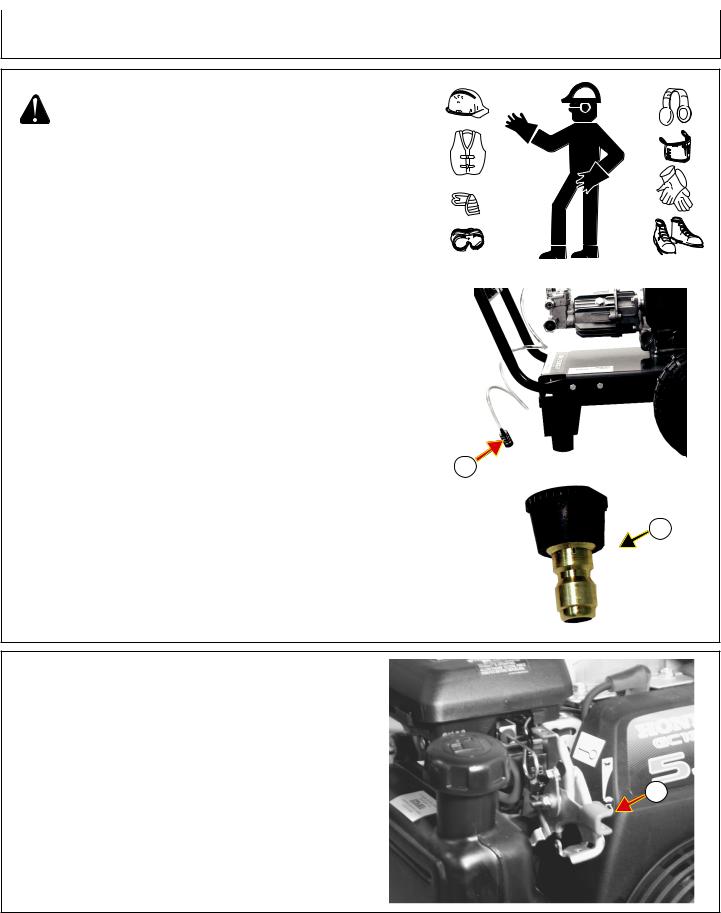

wear protective clothing

Wear close fitting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine.

AC-Series Operator’s Manual-E/F

prepare for emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital and fire department near your telephone.

inspect high pressure washer

Be sure all covers, guards and shields are in place. Locate all operating controls and safety labels.

Keep all hardware and plumbing fittings tight.

service high pressure washer safely

Before servicing washer, disconnect spark plug wire, relieve water pressure and allow unit to cool down.

Service washer in a clean dry flat area. If applicable, block wheels to prevent unit from rolling.

AC-Series Operator’s Manual-E/F

SAFETY SIGNS

|

|

34-1608 |

|

CAUTION/PRECAUCION |

WARNING |

ADVERTENCIA |

|

RISK OF FIRE |

RIESGO DE FUEGE |

RISK OF BURNS |

RIESGO DE QUEMAR |

Do not add fuel when |

No ponga combustible cuando |

MUFFLER AND |

EL AMORTIGUADOR Y LAS |

product is operating. Allow |

el producto este en operacion. |

ADJACENT AREAS |

AREAS ADYACENTES PUEDEN |

engine to cool for two ( ) |

Permita que el motor se enfrie |

MAY EXCEED 50°F. |

TENER TEMPERATURAS POR |

por minutos antes de |

ARRIBA DE 50°F. |

||

minutes before refueling. |

reablastecer de combustible. |

4-0598-0 0699-E/S-ENG. |

|

|

|

34-0598 |

|

|

4-0599-E/S-0 0600-ENG |

|

|

|

|

|

|

34-0599 |

|

|

|

10 |

AC-Series Operator’s Manual-E/F |

Controls

hr-2500gh and hr-2700gh

b

a

2500

A-- Water Supply Inlet

B-- High Pressure Outlet c

C-- Detergent Strainer

D-- Choke

E-- Throttle

D

E

p02-013107

gun, wand, hose

p03-013107

AC-Series Operator’s Manual-E/F |

11 |

Preparing the Washer

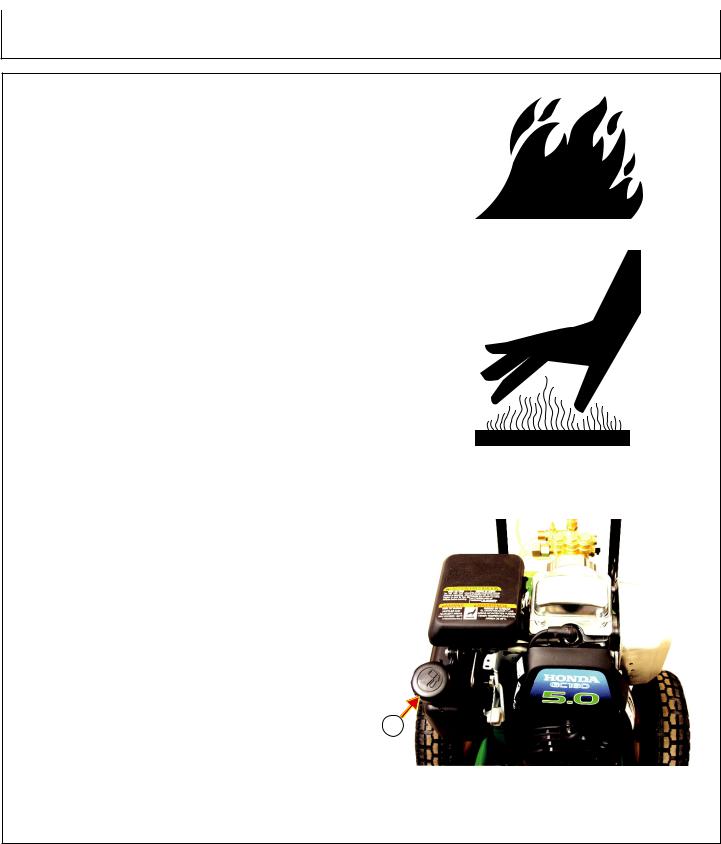

check engine oil

NOTE: All washers are shipped with engine oil. Check proper level.

1.Place unit on level surface.

2.Remove oil filler cap/dipstick (A) and wipe it clean.

3.Insert filler cap/dipstick into oil filler neck, but DO NOT screw it in.

4.Remove dipstick. Proper oil level is at midpoint of dipstick (A). Add oil if necessary to bring oil level to top of threads (B).

5.Install and tighten cap.

A 013107-p04

gasoline engine oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere TURF-GARDTM is preferred. Also recommended is John Deere PLUS-4®.

Other oils may be used if they meet one or more of the following:

•API Service Classification SH

•API Service Classification SG •CCMC Specification G4 •CCMC Specification G5

B

p05-013107

|

|

|

|

|

|

|

|

|

50°C |

122°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

40°C |

104°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

30°C |

86°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

68°f |

|

|

|

|

|

|

||

|

-10W sae |

|

|

|

30-10Wsae |

|

20°C |

|

|

|

|

|

|

|||

|

|

|

|

|

10°C |

50°f |

|

30-5Wsae |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

0°C |

32°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

-10°C |

14°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

-20°C |

-4°f |

|

|

|

|

|

-102299r0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

-30°C |

-22°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

-40°C |

-40°f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

dwg13 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

AC-Series Operator’s Manual-E/F |

Preparing the Washer

filling fuel tank

CAUTION: Risk of fire. Handle fuel carefully.

CAUTION: Risk of fire. Handle fuel carefully.

-Do not add fuel when product is operating. Stop engine and allow engine to cool for two minutes before refueling. Hot surfaces can cause burns and ignite spilled fuel. Do not touch muffler.

-Fill fuel tank outdoors away from flames and open sparks.

-Do not smoke when filling fuel tank.

-Do not overfill fuel tank. (There should be no fuel in filler neck.)

-Avoid spilling fuel. Wipe clean after refueling. -Move from refueling area before starting.

-Prevent fires by keeping engine clean of accumulation, grease, trash and debris.

IMPORTANT: Do not permit dirt or other foreign matter to enter the fuel system. This will cause hard starting, poor performance and engine damage. Always use clean fuel storage containers and funnels.

Use clean, fresh, lead-free gasoline. Do not use stale gasoline or gasoline that has been stored for a long time. Stale gasoline does not vaporize properly, causing hard starts. Use of TY15977 gasoline stabilizer is highly

recommended . Use of leaded gasoline or gasohol is NOT recommended.

IMPORTANT: Do not mix oil with gasoline.

1. |

Wipe dust and dirt from around fuel tank. Remove |

|

|

filler cap (A) and place cap in a clean area away from |

|

|

muffler. |

|

2. |

Slowly fill the fuel tank to bottom of filler neck with lead |

|

|

free gasoline. Do not overfill, leave approximately 5mm |

|

|

(0.19 in.) of open space at the top of the tank for fuel |

A |

|

expansion. |

|

3. |

Replace and tighten filler cap. |

|

Fuel Tank Capacity

HR-2500GH, HR-2700GH............. 1.72L (0.46 gal)

AC-Series Operator’s Manual-E/F |

13 |

Preparing the Washer

Inlet water supply requirements

1.Inlet water supply must be a minimum of 20 PSI (1.4 bar).

Attempting to operate the washer with less than adequate water supply will cause rapid wear of packings, valves and bearings that will dramatically shorten pump life. Symptoms of inadequate water supply are pump shuddering and flattening of the supply hose.

2.Inlet water flow must be at least 125% of pump rated flow (see table below). Check volume by timing how long it takes to fill a 5 gallon (19 L) container. For example, a flow rate of 3.0 GPM would fill a 5 gallon container in 5/3 minute (100 seconds).

3.Water supply hose should be a good grade of garden hose with a minimum I.D. 5/8 in. (16mm) and no longer than 50 ft. (15.24 m). If longer supply hose must be used, check to be certain flow is at least equal to the

“GPM Supply Required” value listed at the bottom of this page for your washer.

4.If non-pressurized (static draw) water supply is used, check to be certain flow is at least 125% of pump rated flow (see table below). In static draw situations, water flow rate (GPM) can be increased by elevating the water supply tank or changing to a larger inside diameter water supply hose.

5.Adding on extension to the supply hose will reduce water flow rates. Check for adequate water flow rate each time an extension is added. Water flow rates can be increased by using the largest possible internal diameter supply hose.

IMPORTANT: Inlet water temperature must not be more than 125° F (60° C). Damage to the pump may result.

Washer |

Rated Flow |

GPM Supply |

|

(GPM) |

Required |

HR-2500GH |

............... 2.3............................ |

3 |

HR-2700GH............... |

2.3............................ |

3 |

pic4-092299r0

14 |

AC-Series Operator’s Manual-E/F |

Preparing the Washer

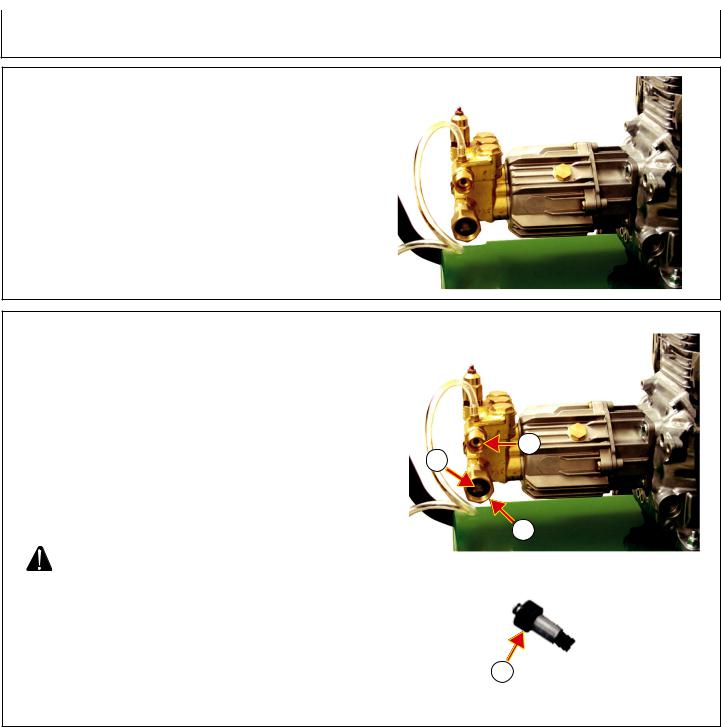

pump oil

This pump does not require periodic changing of the oil. It uses a high grade synthetic oil which will last for the life of the pump.

Connect hoses and prime pump

IMPORTANT: Besurethatinletwaterscreen(C)iscleanandin place before connecting water supply hose to washers. The water pump and valves could be damaged from contaminants.

NOTE:Filling supply hose with water before attaching to pump |

|

|

A |

|

|

will greatly reduce priming time. |

|

|

|

|

|

|

||

1. |

Prime water supply hose. Shut off water. |

c |

||

|

|

|

||

2. |

Connect water supply hose to washer inlet (B). Be sure |

|

|

|

|

water supply and hose meet specifications. Do not turn |

|

|

b |

|

water on at this time. |

|

|

|

|

CAUTION: Check pressure rating printed on the |

|

|

|

|

hose. Use proper hoses. |

|

|

|

3. |

Connect high pressure hose screw connect (D) to washer |

|

|

|

|

outlet (A). Screw clockwise to tighten. |

|

|

p10-013107 |

4. |

Open water supply. Squeeze trigger on gun. Allow water to |

|

|

|

|

|

|

||

|

run (without engine running) until water runs out of pressure |

|

|

|

|

hose. Start engine and cycle trigger on gun until “crackling” |

|

D |

|

|

sound (air in lines) stops. Turn off water supply. |

|

|

|

P07-013107

p07-013107

AC-Series Operator’s Manual-E/F |

15 |

Preparing the Washer

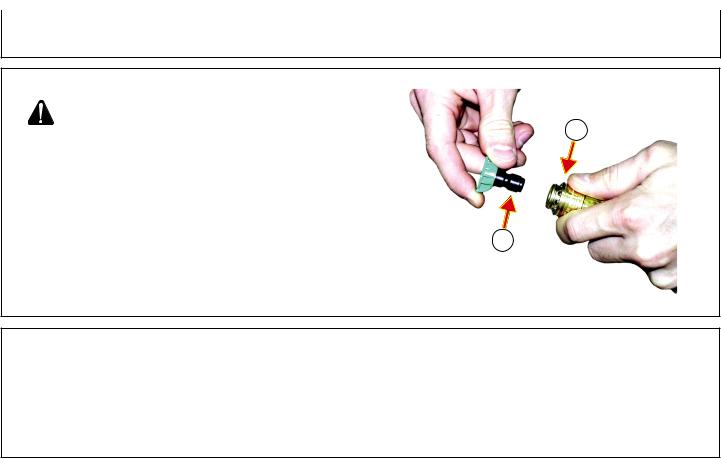

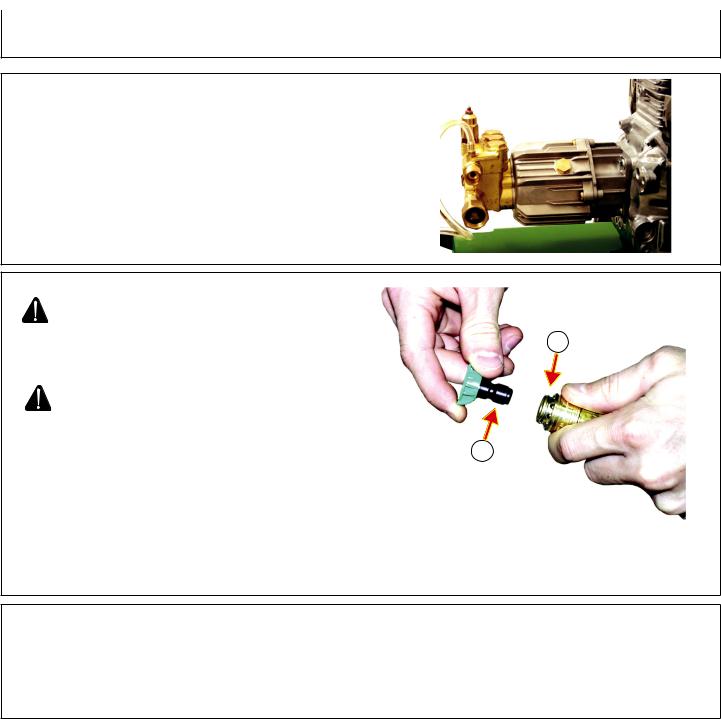

installing nozzle

CAUTION: To avoid injury from escaping fluids |

|

|

under pressure, relieve the pressure in the |

A |

|

system by stopping the washer and depressing |

||

|

||

gun trigger. Lock trigger before changing or |

|

|

adjusting nozzle. |

|

|

Be sure nozzle is tightly attached before operating |

|

|

to help prevent nozzle release. |

|

|

1. Retract locking ring (A) of quick-connect fitting and |

B |

|

insert male quick-connect fitting of nozzle (B). |

|

2.Push ring forward and lock nozzle in place. Be sure nozzle is fastened to wand.

final checklist

1.Check engine oil and fuel.

2.Open water supply completely.

3.Check all hose connections.

4.Check hoses for kinks.

pic81•102299r0

16 |

AC-Series Operator’s Manual-E/F |

Operating the Washer

starting and operating engine

CAUTION: Do not run engine in an enclosed area.

Exhaust gas contains carbon monoxide, an odorless and poisonous gas that can cause sickness or death.

IMPORTANT: To prevent possible pump damage, do not allow washer pump to run in bypass (with gun trigger released) for longer than 3 minutes.

IMPORTANT: Duringfirsttwohoursofengineoperation,engine may operate at low or erratic RPM as the engine moving parts break in.

dwg14-102299r0

1. Pull choke control lever (B) out to “CHOKE” position.

NOTE: A warm engine requires less choking than a cold engine.

2. Move throttle lever (C) up to the fast (or high) position.

NOTE: Forbestengineperformanceitisrecommendedtheengine |

|

|

|

be operated with the throttle in the FAST or HIGH position |

C |

3. |

Place foot on washer frame. |

|

4. |

Point nozzle away from people, animals or fragile materials |

B |

and squeeze gun trigger. If trigger is not squeezed while pulling recoil starter, pressure will build up until recoil starter can not be pulled over.

CAUTION: Be sure nozzle output end is not directed at bystander or objects. Pressurized output spray will start almost instantaneously at engine start-up and can cause serious personal injury or property damage. Release trigger immediately upon engine start.

5.Pull recoil starter grip lightly until resistance is felt, then pull briskly until engine starts.

IMPORTANT: Do not allow starter grip to snap back against engine. Return it gently to prevent damage to starter.

6.Push “CHOKE” control lever (B) in as soon as engine warms up enough to run smoothly. If engine is warm, push choke lever in as soon as engine starts.

stopping the engine

IMPORTANT: To stop engine in emergency, turn throttle (C) down to “STOP” position.

1.Move throttle lever (C) down to “STOP” position.

2.Trigger gun to relieve spray.

locking gun trigger

CAUTION: Gun trigger should be locked when not in use or whenever adjustments are being made to gun or nozzle. This will help prevent accidental

discharge of high pressure fluid.

1.Pivot lock (A) out to prevent trigger engagement.

2.Pivot lock in to release trigger.

A 102299r1

pic73-

pic158•113099r0

AC-Series Operator’s Manual-E/F |

17 |

Operating the Washer

water pressure

Water pressure is preset on washers and should only be serviced by an authorized dealer.

p07-013107

changing nozzle

CAUTION: High pressure spray can cause serious |

|

|

injury. Keep away from spray. Never point the gun |

|

|

at yourself or anyone else. Never put your hand, |

A |

|

fingers, eyes or body directly over spray. Do not |

||

|

||

point spray toward fragile materials. |

|

|

CAUTION: To avoid injury from escaping fluids |

|

|

under pressure, relieve the pressure in the system |

|

|

by stopping the washer and depressing gun |

|

|

trigger. Lock trigger before changing or adjusting |

B |

|

nozzle. |

||

Be sure nozzle is tightly attached before operating |

|

|

to help prevent nozzle release. |

|

1.Retract locking ring (A) of quick-connect fitting and remove nozzle (B).

2.Insert nozzle and push ring forward and lock nozzle in place. Be sure nozzle is fastened to wand.

selecting the proper nozzle

Pressure and volume are partially determined by the size of the orifice in the nozzle. Standard numbers are on the nozzles to indicate spray pattern and orifice size. For example, a nozzle stamped 2503 has a 25° spray pattern and a 3.0 orifice.

pic81-102299r0

18 |

AC-Series Operator’s Manual-E/F |

Operating the Washer

15° NOzzle-yellow

This nozzle provides a chiseling effect suitable for surface preparation. The spray should be directed at a 45° angle to the surface. Recommended uses are:

-Removing peeling paint.

-Removing mildew stains. 102299r0 pic86-

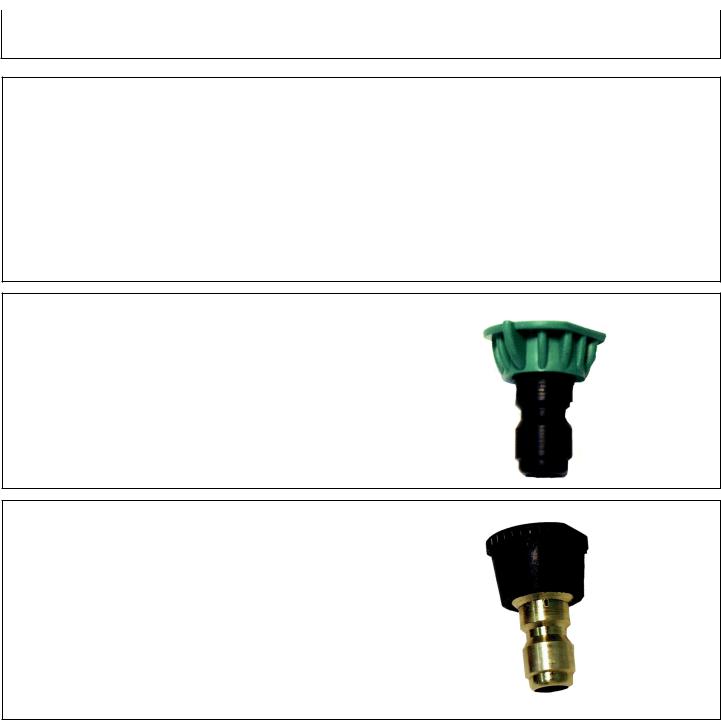

25° NOzzle-green

This is a flushing nozzle. It produces a brush effect with a wider spray pattern and less concentrated spray pressure than a 15° nozzle. Recommended uses are:

-Wet sweeping leaves from walks and drives. |

-pic87092299r0 |

-Cleaning barbecue grill. |

|

-Cleaning stable floors. |

|

-Cleaning swimming pool bottoms. |

|

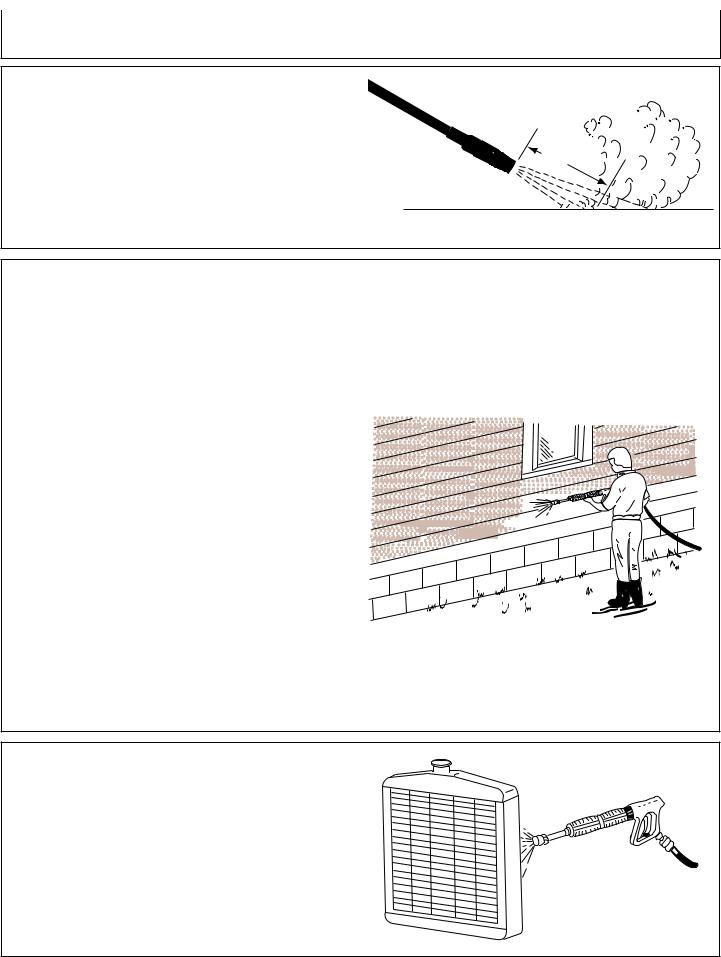

detergent injector nozzle-black

(brass)

This nozzle must be used with and is included in the detergent injector kit. This nozzle will allow a soft spray to soak on a surface with a liquid detergent. It is

recommended for applying cleaning solution for removing

mildew and oxidation stain from houses; or cleaning

effervescent brick. 102299r0 pic89-

AC-Series Operator’s Manual-E/F |

19 |

Operating the Washer

cleaning horizontal surfaces

Move nozzle wand from side to side. Direct spray at an angle to force debris ahead and away from the cleared area.

Depending on the material to be removed and nozzle pressure, hold nozzle end 8 to 10 inches (20 to 25 cm) from the surface and use slow, overlapping strokes. If debris is easy to remove, move nozzle back to cover more area for faster cleaning.

8" - 10"

(20-25 cm)

cleaning vertical surfaces

IMPORTANT: Remember that the washer can deliver a high pressure spray that can break glass and gouge soft wood and other materials.

When cleaning building interiors or exteriors without detergents, work from top to bottom. This will help eliminate streaks. In interiors, start with the ceiling first, then the walls and the floor last.

Clean around windows carefully. If glass panes are not well-caulked and puttied, the high pressure spray could break the glass.

Never spray directly overhead. Always spray ahead to avoid dripping or falling debris.

removing paint

IMPORTANT: Remember that high pressure spray can gouge soft woods and other materials, as well as loosen grout.

1. Direct spray at a 45° angle about 4 to 12 inches (10 to 30 cm) from surface.

2. Spray in a back and forth motion, try to get beneath the loose and bubbled paint.

3.Do not be concerned with the paint that remains. It should be sufficiently bonded so as not to cause repainting problems.

4.Some remaining paint may curl up at the edges. These edges should be scraped with a steel brush or scraper just before painting.

cleaning radiator fins

IMPORTANT: Some engine and radiator manufacturers may not permit cleaning radiators with a high pressure washer. See equipment Operator’s Manual.

1. Use clean water without detergent.

IMPORTANT: Spray straight into the radiator to prevent bending fins.

2.If possible, direct spray in the direction opposite to normal air flow through the radiator.

20 |

AC-Series Operator’s Manual-E/F |

Operating the Washer

detergent usage guide

CAUTION: Use detergents carefully. Read labels thoroughly and follow all instructions for preparation, use, safety, transportation and disposal. Be prepared to tell a physician exactly what detergents you are using in the event of an emergency. Keep all detergents out of reach of children.

Be aware that two detergents can be mixed on the sprayed surface. In this regard, some detergents may give off harmful fumes or start an unpredictable chemical reaction when mixed with another detergent.

NEVER SPRAY FLAMMABLE LIQUIDS such as gasoline, fuel oil, alcohol, naptha, etc.

The washers are designed to dispense John Deere approved cleaners and degreasers.

IMPORTANT: Using detergents other than John Deere approved cleaners and degreasers is

NOT recommended.

If the use of detergents other than those approved by John Deere is desired, be sure to read and follow all detergent labels exactly regarding preparation, use, safety, transportation, and disposal. Keep in mind that the washer’s detergent system further dilutes the detergent with water, and that some detergents may not be concentrated enough to properly work with the system.

Some detergents may not give premix instructions and may require experimenting to determine proper dilution for your application.

If you are not familiar with the detergent, always test a small area of the surface to be cleaned for adverse reaction. Do this a day in advance. Thoroughly rinse area with water.

AC-Series Operator’s Manual-E/F |

21 |

Operating the Washer

cLEANING WITH detergents

CAUTION: Wear goggles, respirator, and protective clothing

to help prevent injury from detergents and spray.

IMPORTANT: DO NOT direct pressure washer spray at the washer.

1.Mix detergent as instructed by the manufacturer.

2.Be sure that water supply is adequate and turned on fully.

3. Insert detergent strainer into solution (A). Be sure that hose is clear and fully submerged in solution.

IMPORTANT: The detergent system will work only if the detergent nozzle is installed.

4. |

Install detergent nozzle (B). (Black nozzle with brass body.) |

|

5. |

Start washer and squeeze gun trigger. If detergent does not spray |

|

|

within one minute, check to make sure the detergent hose is in the |

|

|

solution and is not plugged. |

|

6. |

To help avoid streaking, apply detergent to the lowest surface first, |

|

|

and move up, using long overlapping strokes. Allow solution to |

|

|

soak for several minutes. |

|

IMPORTANT: Remember that high pressure spray can gouge soft |

A |

|

|

woods, damage other materials and loosen grout. |

|

7.Install a pressure nozzle. With the nozzle approximately 6 to 10 inches (15 to 25 cm) and at an angle to the surface, power rinse the area from the top down.

8.If surface is not clean, repeat the above procedures.

IMPORTANT: To avoid damage and contamination with other detergents, siphon a gallon (3.78 L) of clear water through the system after each use.

shutdown

IMPORTANT: Shutdown procedures should be followed at the end of each cleaning operation.

1.If a detergent was used, place detergent inlet strainer in CLEAN water and operate trigger to spray water for a period of three minutes. This will flush the system of detergents and help prevent the detergent valve from sticking or corrosion.

2.Run engine at idle for 2-3 minutes.

3.Turn engine off by moving throttle lever (A) down to “STOP”.

p11-013107

B

B

pic89-102299r0

A

pic158•113099r0

22 |

AC-Series Operator’s Manual-E/F |

Troubleshooting

Symptom |

Problem |

solution |

No discharge at nozzle when |

Low pressure or no water supply. |

Ensure hose is 5/8 in. inside diameter |

trigger mechanism is squeezed. |

|

and incoming water supply is turned |

|

|

on. |

|

Obstruction in nozzle. |

Clean or replace nozzle. |

Low or fluctuating discharge |

Inadequate water supply. |

Use larger I.D. size of hose and |

pressure. |

|

provide specified inlet water pressure |

|

|

and volume. |

Kink in water inlet hose or in high pressure discharge hose.

Water inlet screen obstructed. Pump sucking air. (Pump prime lost.)

Remove kink.

Remove screen, clean or replace.

Tighten all water intake connections. Eliminate leaks in intake line.

|

Not in high pressure mode. |

Install high pressure nozzle. |

|

Obstructed or worn spray nozzle. |

Remove and clean or replace. |

|

Bypass valve not operating correctly. |

See your John Deere dealer. |

Water flows from nozzle when |

Gun malfunction. |

DO NOT USE!! See your John Deere |

trigger is released. |

|

dealer. |

Pump oil is white or milky color. |

Water in oil. |

Change oil. Avoid directing water |

|

|

spray at pump. |

Detergent will not siphon into |

Strainer not completely submerged |

Check, submerge if necessary. |

Low Pressure Detergent mode. |

in solution. |

|

|

Strainer obstructed. |

Inspect, clean or replace. |

|

Siphon hose cut, obstructed or |

Inspect, clean or replace. |

|

kinked. |

|

|

Not in Low Pressure mode. |

Install detergent nozzle. |

|

Too many high pressure hose |

Use only one extension hose |

|

extensions attached to outlet. |

maximum. |

|

Detergent valve stuck closed. |

See your John Deere dealer. |

Water flows back into detergent |

Detergent valve jammed, missing |

See your John Deere dealer. |

container. |

or corroded. |

|

Oil leaking from pump. |

Pump failed. |

DO NOT USE!! See your John Deere |

|

|

dealer. |

Water leaks from brass valve on pump.

Thermal Relief Valve opening to protect pump.

Do not run washer with gun trigger closed for more than 3 minutes. Trigger gun to close valve.

AC-Series Operator’s Manual-E/F |

23 |

Loading...

Loading...