John Deere AC2-80ES OPERATOR’S MANUAL

AC2-80ES

AIR COMPRESSOR

CAUTION

CAUTION

RISK OF INJURY! READ ENTIRE MANUAL BEFORE OPERATING! THIS MANUAL IS AN IMPORTANT PART OF THE AIR COMPRESSOR

AND MUST REMAIN WITH THIS UNIT!

Stationary Electric Air Compressor Manual

table of contents |

|

introduction................................................................................................................. |

3 |

important ................................................................................................................... |

3 |

INSPECTION...................................................................................................................... |

3 |

IMPORTANT safety INSTRUCTIONS........................................................................... |

4-7 |

RISK OF ELECTRIC SHOCK OR ELECTROCUTION................................................. |

4 |

RISK OF EXPLOSION OR FIRE.................................................................................. |

5 |

RISK OF BURSTING.................................................................................................... |

5 |

RISK TO BREATHING.................................................................................................. |

6 |

RISK OF BURNS.......................................................................................................... |

6 |

RISK OF FLYING OBJECTS........................................................................................ |

6 |

RISK FROM MOVING PARTS..................................................................................... |

7 |

RISK FROM NEGLIGENCE............. ........................................................................... |

7 |

RISK OF AIR COMPRESSOR DAMAGE..................................................................... |

7 |

FEATURE DRAWINGs & REVIEW............................................................................... |

8-11 |

PREPARATION INSTRUCTIONS................................................................................ |

12-13 |

INITIAL SET-UP.......................................................................................................... |

12 |

LOCATION ................................................................................................................. |

12 |

ELECTRICAL.............................................................................................................. |

13 |

PRE-START CHECKLIST........................................................................................... |

13 |

OPERATING INSTRUCTIONS......................................................................................... |

14 |

START-UP.................................................................................................................. |

14 |

SHUTDOWN............................................................................................................... |

14 |

MAINTENANCE INSTRUCTIONS.................................................................................... |

14 |

TROUBLESHOOTING................................................................................................. |

15-17 |

WARRANTY..................................................................................................................... |

18 |

NOTES.............................................................................................................................. |

21 |

Warning: This product contains lead, a chemical known to the State of California to cause birth defects or other reproductive harm.

Wash your hands after handling this product.

|

Stationary Electric Air Compressor Manual |

INTRODUCTION

Congratulations on the purchase of your new air compressor! You can be assured your air compressor was constructed with the highest level of precision and accuracy. Each component has been rigorously tested by technicians to ensure the quality, endurance and performance of this air compressor.

This operator's manual was compiled for your benefit. By reading and following the simple safety, installation and operation, maintenance and troubleshooting steps described in this manual, you will receive years of troublefree operation from your new Air Compressor. The contents of this manual are based on the latest product information available at the time of publication. The manufacturer reserves the right to make changes in price, color, materials equipment, specifications or models at any time without notice.

important!

A "DANGER, WARNING or CAUTION" safety warning will be surrounded by a "SAFETY ALERT BOX". This box is used to designate and emphasize Safety Warnings that must be followed when operating this air compressor. Accompanying the safety warnings are "Signal Words" which designate the degree or level of hazard seriousness. The "Signal Words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided MAY result in minor or moderate injury or damage to the air compressor.

The symbols set to the left of this paragraph are "Safety Alert Symbols". These symbols are used to call attention to items or procedures that could be dangerous to you or other persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ ALL INSTRUCTIONS IN THIS MANUAL AND ANY INSTRUCTIONS SUPPLIED BY MANUFACTURERS OF SUPPORTING EQUIPMENT BEFORE OPERATING THIS AIR COMPRESSOR AND ESPECIALLY POINT OUT THE "SAFETY WARNINGS" TO PREVENT THE POSSIBILITY OF PERSONAL INJURY TO THE OPERATOR.

Once the unit has been uncrated, immediately write in the serial number of your unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim with the transportation company immediately. Be sure that all damaged parts are replaced an that the mechanical and electrical problems

are corrected prior to operation of the unit. If you require service, contact your customer service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235 Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls: |

|

. |

Model Number |

. |

Serial Number |

3. |

Date and Place of Purchase |

Stationary Electric Air Compressor Manual

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using this product basic precautions should always be observed, including the following:

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

HAZARD |

POTENTIAL CONSEQUENCE |

PREVENTION |

|

RISK OF ELECTRIC SHOCK |

Serious injury or death could occur |

Installation of this unit, including all |

||

|

OR ELECTROCUTION |

if the air compressor is not properly |

electrical connections, must comply |

|

|

grounded. Your air compressor is |

with all local, state and national |

||

|

|

|

||

|

|

|

poweredbyelectricityandmaycause |

codes. |

|

|

|

electric shock or electrocution if not |

This product must be grounded. |

|

|

|

used properly. |

Connect to a GFCI circuit breaker |

|

|

|

when available. If the unit should |

|

|

|

|

|

|

|

|

|

|

malfunction or breakdown, grounding |

|

|

|

|

provides a path of least resistance |

|

|

|

|

for electric current to reduce the risk |

|

|

|

|

of electric shock. Do not ground to a |

|

|

|

|

gas supply line. |

|

|

|

|

Improperconnectionoftheequipment- |

|

|

|

|

groundingconductorcanresultinarisk |

|

|

|

|

ofelectrocution. Checkwithaqualified |

|

|

|

|

electrician or service personnel if you |

|

|

|

|

are in doubt as to whether the system |

|

|

|

|

is properly grounded. |

|

|

|

|

Always be certain the unit is receiving |

|

|

|

|

proper voltage (+/- 5% of the voltage |

|

|

|

|

listed on the nameplate). Before |

|

|

|

|

installing electrical connections, be |

|

|

|

|

certain the power switches are in the |

|

|

|

|

"OFF" position. |

|

|

|

|

Keep all connections dry and off the |

|

|

|

|

ground. |

|

|

|

Electrical shock may occur if the |

Never operate air compressor in wet |

|

|

|

air compressor is not operated |

conditions. |

|

|

|

properly. |

Never operate air compressor with |

|

|

|

|

safety guards/covers removed or |

|

|

|

|

damaged. |

|

|

|

Serious injury or death may occur if |

Any electrical wiring or repairs |

|

|

|

electrical repairs are attempted by |

performed on this air compressor |

|

|

|

unqualified persons. |

should be done byAuthorized Service |

|

|

|

PersonnelinaccordancewithNational |

|

|

|

|

|

|

|

|

|

|

and Local electrical codes. |

|

|

|

|

Before opening any electrical |

|

|

|

|

enclosure, always shut off the air |

|

|

|

|

compressor, relieve pressure and |

|

|

|

|

unplug the air compressor from the |

|

|

|

|

power source. Allow air compressor |

|

|

|

|

to cool down. Never assume the air |

|

|

|

|

compressor is safe to work on just |

|

|

|

|

because it is not operating. It could |

|

|

|

|

restart at any time! Service in a clean, |

|

|

|

|

dry, flat area. |

Stationary Electric Air Compressor Manual

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

HAZARD |

POTENTIAL CONSEQUENCE |

PREVENTION |

|

RISK OF |

Serious injury or death may occur |

Always operate air compressor in a |

|

EXPLOSION OR FIRE |

from normal electrical sparks in |

well ventilated area free of flammable |

|

motor and pressure switch |

vapors, combustible dust, gases or |

|

|

|

||

|

|

|

other combustible materials. |

|

|

|

|

|

DONOTSMOKEifsprayingflammable |

|

|

|

material. Locate the air compressor |

|

|

|

at least 20 feet away from the spray |

|

|

|

area. (An additional hose may be |

|

|

|

required.) |

|

|

Serious injury may occur if any air |

Never place objects against or on |

|

|

compressor ventilation openings |

top of air compressor. |

Operate air |

|

are restricted, causing the air |

compressor at least 12 inches away |

|

|

compressor to overheat and start |

from any wall or obstruction that would |

|

|

a fire. |

restrict proper ventilation. |

|

RISK OF |

Serious injury or death may occur |

Drain air tank daily or after each use |

|

BURSTING |

from an air tank explosion if air tanks |

to prevent moisture buildup in the air |

|

|

are not properly maintained. |

tank. |

|

|

|

|

|

If air tank develops a leak, replace the airtankimmediately. Neverrepair,weld or make modifications to the air tank or its attachments. Use only genuine manufacturer repair parts for your air compressor.

Serious injury may occur from |

Never make adjustments to the factory |

an air compressor malfunction or |

set pressures. |

exploding accessories if incorrect |

Never exceed manufacturers |

system components, attachments |

maximum allowable pressure rating |

or accessories are used. |

of attachments. |

|

|

|

Because of extreme heat, do not use |

|

plastic pipe or lead tin soldered joints |

|

for a discharge line. |

|

Never use air compressor to inflate |

|

small, low pressure objects such as |

|

toys. |

Stationary Electric Air Compressor Manual

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

HAZARD |

POTENTIAL CONSEQUENCE |

PREVENTION |

|

RISK TO BREATHING |

Serious injury or death could occur |

Never inhale air from the air |

|

|

from inhaling compressed air. The |

compressor either directly or from |

|

|

air stream may contain carbon |

a breathing device connected to the |

|

|

monoxide, toxic vapors or solid |

air compressor. |

|

|

particles. |

|

|

|

Sprayed materials such as paint, |

Operate air compressor only in |

|

|

paint solvents, paint remover, |

a well ventilated area. Follow all |

|

|

insecticides,weedkillers,etc.contain |

safety instructions provided with the |

|

|

harmful vapors and poisons. |

materials you are spraying. Use of |

|

|

|

a respirator may be required when |

|

|

|

working with some materials. |

|

RISK OF BURNS |

Serious injury could occur from |

Never allow any part of your body |

|

touching exposed metal parts. |

or other materials to make contact |

||

|

|||

|

These areas can remain hot for |

with any exposed metal parts on the |

|

|

some time after the air compressor |

air compressor. |

|

|

is shutdown. |

|

RISK FROM |

Serious injury can occur from loose |

Always wear safety glasses to shield |

FLYING OBJECTS |

debris being propelled at a high |

the eyes from flying debris. |

|

speed from the compressed air |

|

|

stream. |

Never point the air stream at any |

|

||

|

Soft tissue damage can occur from |

|

|

the compressed air stream. |

part of your body, anyone else or |

|

|

animals. |

|

|

Never leave pressurized air in the air |

|

|

compressor. Shut off air compressor |

|

|

and relieve pressure when storing or |

|

|

attempting maintenance. |

|

|

Alwaysmaintainasafedistancefrom |

|

|

people and animals while operating |

|

|

|

|

|

the air compressor. |

Stationary Electric Air Compressor Manual

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

|

|

HAZARD |

POTENTIAL CONSEQUENCE |

|

PREVENTION |

|

|

||||

|

|

|

|

|

|

|||||||

|

|

|

RISK FROM |

Risk of bodily injury from moving |

Before performing maintenance, |

|||||||

|

|

MOVING PARTS |

parts. This air compressor cycles |

always turn off air compressor. |

||||||||

|

|

|

|

|

|

|

|

(Starts/Stops) automatically when |

Bleed pressure from the air hose and |

|||

|

|

|

|

|

|

|

|

the pressure switch is in the "On/ |

disconnectfromtheelectricalsource. |

|||

|

|

|

|

|

|

|

|

Auto" position. |

All repairs to the air compressor |

|||

|

|

|

|

|

|

|

|

|

should be made by an Authorized |

|||

|

|

|

|

|

|

|

|

|

Service person. Never assume the |

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

air compressor is safe to work on just |

|||

|

|

|

|

|

|

|

|

|

because it is not operating. It could |

|||

|

|

|

|

|

|

|

|

|

restart at any time! |

|

|

|

|

|

|

|

|

|

|

|

|

Do not operate without protective |

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

covers/guards. Always unplug the |

|||

|

|

|

|

|

|

|

|

|

air |

compressor before |

removing |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

any |

guard. Replace |

damaged |

|

|

|

|

|

|

|

|

|

|

covers/guards before using the air |

|||

|

|

|

|

|

|

|

|

|

compressor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RISK FROM |

Risk of injury from negligent use. |

Never allow children or adolescents |

|||||||

|

|

NEGLIGENCE |

|

|||||||||

|

|

|

to operate this air compressor! |

|||||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Stay alert-watch what you are doing. |

|||

|

|

|

|

|

|

|

|

|

Do not operate the air compressor |

|||

|

|

|

|

|

|

|

|

|

whenfatiguedorundertheinfluence |

|||

|

|

|

|

|

|

|

|

|

of alcohol or drugs. |

|

|

|

|

|

|

|

|

|

|

|

|

Knowhowtostoptheaircompressor. |

|||

|

|

|

|

|

|

|

|

|

Be |

thoroughly familiar with |

||

|

|

|

|

|

|

|

|

|

controls. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

RISK OF DAMAGE TO |

Risk of major repair. |

Do not operate air compressor |

|||||||||

|

AIR COMPRESSOR |

|

without an air filter. |

|

|

|||||||

|

|

Do not operate air compressor in a |

||||||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

corrosive environment. |

|

|

|

|

|

|

|

|

|

|

|

|

Always operate the air compressor |

|||

|

|

|

|

|

|

|

|

|

secured to a concrete surface to |

|||

|

|

|

|

|

|

|

|

|

prevent the air compressor from |

|||

|

|

|

|

|

|

|

|

|

falling. |

|

|

|

|

|

|

|

|

|

|

|

|

Follow all maintenance instructions |

|||

|

|

|

|

|

|

|

|

|

listed in this manual. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! save these instructions !

Stationary Electric Air Compressor Manual

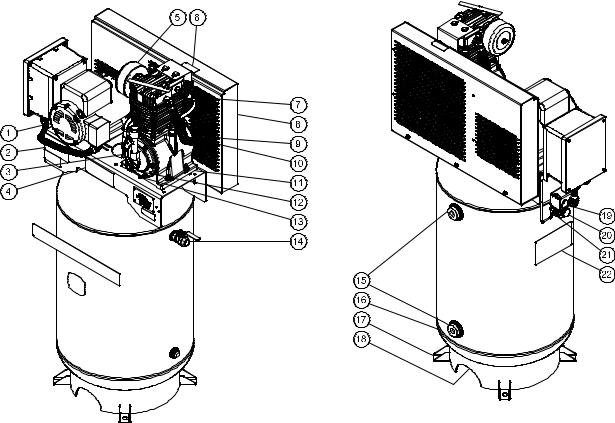

ELECTRIC AIR COMPRESSOR FEATURES

TWO STAGE

(DOES NOT INCLUDE POWER CORD, POWER PLUG, PRESSURE REGULATOR)

AM2-SE05-80J FEATURES

ItemDescription |

12 |

Oil Sight Glass |

|

1 |

Electric Motor |

13 |

Oil Drain Plug |

2 |

Decal - Maintenance Instructions |

14 |

Outlet Fitting |

3 |

Check Valve |

15 |

Tank Inspection Openings |

4 |

Decal - Operating Instructions |

16 |

Air Tank Assembly |

5 |

Air Intake Filter |

17 |

Foot |

6 |

Decal - Warning: Hot Surface |

18 |

Air Tank Drain Valve |

7 |

Pump Discharge Line |

19 |

Motor Pressure Switch |

8 |

Beltguard |

20 |

Air Tank Pressure Gauge |

9 |

Ventilation Openings |

21 |

Safety Relief Valve |

10 |

Oil Fill Port/vent |

22 |

Decal - Danger/warning/caution |

11 |

Air Compressor Pump |

|

|

Stationary Electric Air Compressor Manual

exploded view & explanation of air compressor features

AIR TANK DRAIN VALVE: The drain valve is used to remove moisture from the air tank(s) after the air compressor is shut off. NEVER attempt to open the drain valve when more than 10 PSI of air pressure is in the air tank! To open the drain valve, turn the knob counterclockwise.

OIL SIGHT GLASS: The Oil Sight Glass displays the oil level in the pump. The oil level should be at the center of the Oil Sight Glass. If low, add SAE 30W non-detergent oil.

OIL FILL PORT/VENT: Pour oil into the Oil Fill Port/Vent when required.

AIR INTAKE FILTER: This filter is designed to clean air coming into the pump. To ensure the pump continually receives a clean, cool, dry air supply this filter must always be clean and ventilation opening free from obstructions. Replace filter element when necessary.

AIR COMPRESSOR PUMP: To compress air, the pistons move up and down in the cylinders. On the downstroke, air is drawn in through the air intake valves while the exhaust valves remain closed. On the upstroke, air is compressed, the intake valves close and compressed air is forced out through the exhaust valves, into the discharge line, through the check valve and/or the pilot valve and into the air tank.

MOTOR/PRESSURE SWITCH: This switch is used to start or stop the air compressor. Moving the switch to the "Auto" (On) position will provide automatic power

to the pressure switch which will allow the motor to start when the air tank pressure is below the factory set "cut-in" pressure. When in the Start/Stop Option, the pressure

switch stops the motor when the air tank pressure reaches the factory set "cut-out" pressure. For safety purposes, this switch also has a pressure release valve located

on the side of the switch designed to automatically release compressed air from the air compressor pump head and its discharge line when the air compressor reaches

"cut-out" pressure or is shut off. This allows the motor to restart freely. Moving the switch to the "Off" position will remove power from the pressure switch and stop the air compressor.

SAFETY RELIEF VALVE: This valve is designed to prevent system failures by relieving pressure from the system when the compressed air reaches a predetermined level. The valve is preset by the manufacturer and must not be modified in any way. To verify the valve is working properly, pull on the ring. Air pressure should escape. When the ring is released, it will reseat.

AIR TANK PRESSURE GAUGE: The air tank pressure gauge indicates the reserve air pressure in the air tank.

STARTER: the Motor starter provides thermal overload protection. The starter is required from on motors 5 Hp and above.

Stationary Electric Air Compressor Manual

nOTES

10 |

Stationary Electric Air Compressor Manual |

warning

warning

THE FOLLOWING PAGES CONTAIN OPERATING AND MAINTENANCE INSTRUCTIONS.

do not attempt to operate this AIR COMPRESSOR until you have read and understood all safety precautions and instructions listed in this manual.

incorrect operation of this unit can cause serious injury!!

do not alter or modify this equipment in any manner!

Stationary Electric Air Compressor Manual |

11 |

WARNING

WARNING

RISK OF EXPLOSION OR FIRE CAUSING SERIOUS INJURY OR DEATH!

Do not allow the motor or Motor/ Pressure Switch to come in contact with flammable vapors, combustible dust, gases or other combustiblematerials. Anelectric spark may cause an explosion or fire.

When using the air compressor for spray painting, place the air compressor as far away from the work area as possible.

preparation INSTRUCTIONS

INITIAL SET-UP:

1.Read safety warnings before setting-up air compressor.

2.Ensure the oil level in the air compressor pump is adequate. If low, add SAE-30W non-detergent oil.

LOCATION:

1.In order to avoid damaging the air compressor, do not incline the air compressor transversely or longitudinally more than 10°.

2.Place air compressor on a concrete surface at least 12 inches away from obstacles that may prevent proper ventilation. Place the flywheel side of the unit toward the wall. Do not place air compressor in an area:

-where there is evidence of oil or gas leaks.

-where flammable gas vapors or materials may be present.

-where air temperatures fall below 32°F or exceed 104°F.

-where extremely dirty air or water could be drawn into the air compressor.

3.Distribute air compressor weight evenly. Excessive vibration can weaken the air tank creating a hazard of explosion.

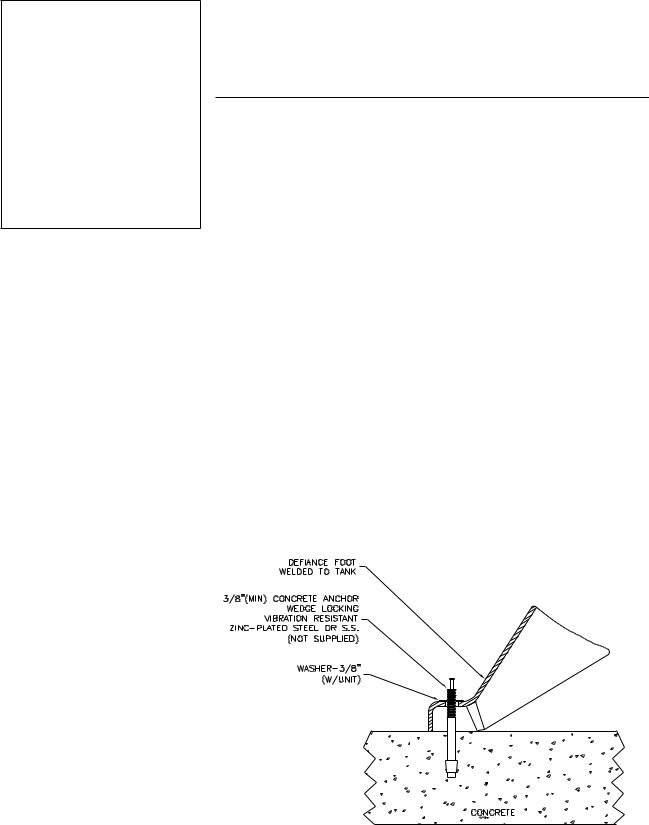

4.Bolt the air compressor to the concrete surface.

a.Mark the areas through the feet of the air compressor where anchor bolts will be placed.

b.Move the air compressor and drill holes in the marked areas to accept the anchor bolts.

c.With the nut attached, pound the anchor bolts into the pre-drilled holes.

d.Remove the nuts and place the air compressor over the anchor bolts.

e.Replace and tighten the nuts.

ANCHOR-DCE

12 |

Stationary Electric Air Compressor Manual |

Loading...

Loading...