Intel 945GZ, 945GC, 945P, 945G, 945PL User Manual

Intel® 945G/945GZ/945GC/ 945P/945PL Express Chipset Family

Thermal and Mechanical Design Guidelines (TMDG)

-For the Intel® 82945G/82945GZ/82945GC Graphics Memory Controller Hub (GMCH) and Intel® 82945P/82945PL Memory Controller Hub (MCH)

February 2008

Document Number: 307504-004

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CREATE A SITUATION WHERE PERSONAL INJURY OR DEATH MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

The Intel® 82945G/82945GZ/82945GC GMCH and Intel® 82945P/82945PL MCH may contain design defects or errors known as errata, which may cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order. Intel, Pentium, and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others. Copyright © 2005–2008, Intel Corporation. All rights reserved.

2 |

Thermal and Mechanical Design Guidelines |

Contents

1 |

Introduction ..................................................................................................... |

|

7 |

|

|

1.1 |

Terminology .......................................................................................... |

8 |

|

|

1.2 |

Reference Documents ............................................................................. |

9 |

|

2 |

Product Specifications...................................................................................... |

11 |

||

|

2.1 |

Package Description.............................................................................. |

11 |

|

|

|

2.1.1 |

Non-Grid Array Package Ball Placement ...................................... |

11 |

|

2.2 |

Package Loading Specifications............................................................... |

12 |

|

|

2.3 |

Thermal Specifications .......................................................................... |

13 |

|

|

2.4 |

Thermal Design Power (TDP).................................................................. |

13 |

|

|

|

2.4.1 |

Methodology........................................................................... |

14 |

|

|

2.4.2 |

Application Power.................................................................... |

14 |

|

|

2.4.3 |

Specifications ......................................................................... |

14 |

3 |

Thermal Metrology .......................................................................................... |

15 |

||

|

3.1 |

Case Temperature Measurements ........................................................... |

15 |

|

|

|

3.1.1 |

Thermocouple Attach Methodology............................................. |

15 |

|

3.2 |

Airflow Characterization ........................................................................ |

16 |

|

4 |

Reference Thermal Solution.............................................................................. |

19 |

||

|

4.1 |

Operating Environment ......................................................................... |

19 |

|

|

|

4.1.1 |

ATX Form Factor Operating Environment .................................... |

19 |

|

|

4.1.2 |

Balanced Technology Extended (BTX) Form Factor Operating |

|

|

|

|

Environment........................................................................... |

20 |

|

4.2 |

Mechanical Design Envelope................................................................... |

21 |

|

|

4.3 |

Thermal Solution Assembly.................................................................... |

21 |

|

|

4.4 |

Environmental Reliability Requirements ................................................... |

24 |

|

Appendix A |

Enabled Suppliers ........................................................................................... |

25 |

||

Appendix B |

Mechanical Drawings ....................................................................................... |

27 |

||

Thermal and Mechanical Design Guidelines |

3 |

Figures

Figure 1. (G)MCH Non-Grid Array ...................................................................... |

12 |

Figure 2. 0° Angle Attach Methodology (top view, not to scale).............................. |

16 |

Figure 3. 0° Angle Attach Heatsink Modifications (generic heatsink side and bottom |

|

view shown, not to scale)........................................................................... |

16 |

Figure 4. Airflow Temperature Measurement Locations ......................................... |

17 |

Figure 5. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on an |

|

ATX Platform............................................................................................ |

20 |

Figure 6. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on a |

|

Balanced Technology Extended (BTX) Platform.............................................. |

21 |

Figure 7. ATX GMCH Heatsink Installed on Board................................................. |

22 |

Figure 8. Balanced Technology Extended (BTX) GMCH Heatsink Installed on Board... |

23 |

Figure 9. (G)MCH Package Drawing ................................................................... |

28 |

Figure 10. (G)MCH Component Keep-Out Restrictions for ATX Platforms ................. |

29 |

Figure 11. (G)MCH Component Keep-Out Restrictions for Balanced Technology |

|

Extended (BTX) Platforms .......................................................................... |

30 |

Figure 12. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1 ....................... |

31 |

Figure 13. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2 ....................... |

32 |

Figure 14. (G)MCH Reference Heatsink for ATX Platforms – Anchor ........................ |

33 |

Figure 15. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1 .. |

34 |

Figure 16. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2 .. |

35 |

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip .......... |

36 |

Figure 18. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) |

|

Platforms................................................................................................. |

37 |

Figure 19. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) |

|

Platforms – Clip ........................................................................................ |

38 |

Figure 20. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) |

|

Platforms – Heatsink Assembly ................................................................... |

39 |

Tables

Table 1. (G)MCH Loading Specifications.............................................................. |

12 |

|

Table 2. (G)MCH Case Temperature Specifications ............................................. |

13 |

|

Table 3. |

(G)MCH Thermal Design Power Specifications........................................ |

14 |

Table 4. |

Reference Thermal Solution Environmental Reliability Requirements ......... |

24 |

Table 5. |

(G)MCH ATX Intel Reference Heatsink Enabled Suppliers......................... |

25 |

Table 6. |

(G)MCH Balanced Technology Extended (BTX) Intel Reference Heatsink |

|

Enabled Suppliers ..................................................................................... |

26 |

|

4 |

Thermal and Mechanical Design Guidelines |

Revision History

Revision |

Description |

Date |

Number |

|

|

|

|

|

-001 |

•Initial Release |

May 2005 |

|

|

|

-002 |

•Added Intel® 82945PL specifications |

October 2005 |

-003 |

•Added Intel® 82945GZ specifications |

December |

|

|

2005 |

|

|

|

-004 |

•Added Intel® 82945GC specifications |

February 2008 |

§

Thermal and Mechanical Design Guidelines |

5 |

6 |

|

Thermal and Mechanical Design Guidelines |

Introduction

1 Introduction

As the complexity of computer systems increases, so do power dissipation requirements. The additional power of next generation systems must be properly dissipated. Heat can be dissipated using improved system cooling, selective use of ducting, and/or active/passive heatsinks.

The objective of thermal management is to ensure that the temperatures of all components in a system are maintained within functional limits. The functional temperature limit is the range within which the electrical circuits can be expected to meet specified performance requirements. Operation outside the functional limit can degrade system performance, cause logic errors, or cause component and/or system damage. Temperatures exceeding the maximum operating limits may result in irreversible changes in the operating characteristics of the component. The goal of this document is to provide an understanding of the operating limits of the Intel® 82945G/82945GZ/82945GC Graphics and Memory Controller Hub (GMCH) and Intel® 82945P/82945PL Memory Controller Hub (MCH), and discuss a reference thermal solution.

The simplest and most cost-effective method to improve the inherent system cooling characteristics of the (G)MCH is through careful design and placement of fans, vents, and ducts. When additional cooling is required, component thermal solutions may be implemented in conjunction with system thermal solutions. The size of the fan or heatsink can be varied to balance size and space constraints with acoustic noise.

This document presents the conditions and requirements to properly design a cooling solution for systems that implement the 82945G/82945GZ/82945GC GMCH or 82945P/82945PL MCH. Properly designed solutions provide adequate cooling to maintain the (G)MCH case temperature at or below thermal specifications. This is accomplished by providing a low local-ambient temperature, ensuring adequate local airflow, and minimizing the case to local-ambient thermal resistance. By maintaining the (G)MCH case temperature at or below those recommended in this document, a system designer can ensure the proper functionality, performance, and reliability of these components.

Note: Unless otherwise specified, the information in this document applies to the Intel® 82945G/82945GZ/82945GC Graphics and Memory Controller Hub (GMCH) and the Intel® 82945P/82945PL Memory Controller Hub (MCH). The term (G)MCH refers to the 82945G GMCH, 82945GZ GMCH, 82945GC GMCH, 82945P MCH, and 82945PL MCH.

Note: Unless otherwise specified, ICH7 refers to the Intel® 82801GB ICH7 and 82801GR ICH7R I/O Controller Hub 7 components.

Thermal and Mechanical Design Guidelines |

7 |

Introduction

1.1Terminology

|

Term |

Description |

|

|

|

|

BGA |

Ball Grid Array. A package type defined by a resin-fiber substrate where a die is |

|

|

mounted and bonded. The primary electrical interface is an array of solder balls |

|

|

attached to the substrate opposite the die and molding compound. |

|

|

|

|

FC-BGA |

Flip Chip Ball Grid Array. A package type defined by a plastic substrate where a |

|

|

die is mounted using an underfill C4 (Controlled Collapse Chip Connection) |

|

|

attach style. The primary electrical interface is an array of solder balls attached |

|

|

to the substrate opposite the die. Note that the device arrives at the customer |

|

|

with solder balls attached. |

|

|

|

|

Intel® ICH7 |

Intel® I/O Controller Hub 7. The chipset component that contains the primary |

|

|

PCI interface, LPC interface, USB, ATA, and/or other legacy functions. |

|

|

|

|

GMCH |

Graphic Memory Controller Hub. The chipset component that contains the |

|

|

processor and memory interface and integrated graphics device. |

|

|

|

|

MCH |

Memory Controller Hub. The chipset component that contains the processor |

|

|

and memory interface. It does not contain an integrated graphics device. |

|

|

|

|

TA |

The measured ambient temperature locally to the component of interest. The |

|

|

ambient temperature should be measured just upstream of airflow for a |

|

|

passive heatsink or at the fan inlet for an active heatsink. |

|

|

|

|

TC |

The measured case temperature of a component. For processors, TC is |

|

|

measured at the geometric center of the integrated heat spreader (IHS). For |

|

|

other component types, it is generally measured at the geometric center of the |

|

|

die or case. |

|

|

|

|

TC-MAX |

The maximum case/die temperature with an attached heatsink. This |

|

|

temperature is measured at the geometric center of the top of the package |

|

|

case/die. |

|

|

|

|

TC-MIN |

The minimum case/die temperature with an attached heatsink. This |

|

|

temperature is measured at the geometric center of the top of the package |

|

|

case/die. |

|

|

|

|

TDP |

Thermal Design Power. TDP is specified as the highest sustainable power level |

|

|

of most or all of the real applications expected to be run on the given product, |

|

|

based on extrapolations in both hardware and software technology over the life |

|

|

of the component. Thermal solutions should be designed to dissipate this target |

|

|

power level. |

|

|

|

|

TIM |

Thermal Interface Material. TIM is the thermally conductive material installed |

|

|

between two surfaces to improve heat transfer and reduce interface contact |

|

|

resistance. |

|

|

|

|

lfm |

Linear Feet per Minute. Unit of airflow speed. |

|

|

|

|

ΨCA |

Case-to-ambient thermal characterization parameter (Psi). This is a measure of |

|

|

thermal solution performance using total package power. It is defined as (TC – |

|

|

TA) / Total Package Power. Heat source size should always be specified for Ψ |

|

|

measurements. |

|

|

|

8 |

|

Thermal and Mechanical Design Guidelines |

Introduction

1.2 |

Reference Documents |

|

|

|

|

|

|

|

|

Document |

Comments |

|

|

|

|

|

|

Intel® 945G/945GZ/945P/945PL Express Chipset Family |

http://developer.intel.com/des |

|

|

Datasheet |

ign/chipsets/datashts/307502. |

|

|

|

htm |

|

|

|

|

|

|

Intel® I/O Controller Hub 7 (ICH7) Datasheet |

http://developer.intel.com//de |

|

|

|

sign/chipsets/datashts/30701 |

|

|

|

3.htm |

|

|

|

|

|

|

Intel® I/O Controller Hub 7 (ICH7) Thermal Design Guidelines |

http://developer.intel.com//de |

|

|

|

sign/chipsets/designex/30701 |

|

|

|

5.htm |

|

|

|

|

|

|

Intel® Pentium® 4 Processor 670, 660, 650, 640, and 630 and |

http://developer.intel.com |

|

|

Intel® Pentium® 4 Processor Extreme Edition Datasheet |

/design/pentium4/datashts |

|

|

|

/306382.htm |

|

|

|

|

|

|

Intel® Pentium®4 Processors 570/571, 560/561, |

http://developer.intel.com |

|

|

550/551,540/541, 530/531 and 520/521 Supporting Hyper- |

/design/Pentium4/datashts |

|

|

Threading Technology Datasheet |

/302351.htm |

|

|

|

|

|

|

Intel® Pentium® D Processor 840, 830 and 820 Datasheet |

http://developer.intel.com |

|

|

|

/design/PentiumD//datasht |

|

|

|

s/307506.htm |

|

|

|

|

|

|

Intel® Pentium® 4 Processor on 90 nm Process in the 775– |

http://developer.intel.com |

|

|

Land LGA Package Thermal and Mechanical Design Guidelines |

/design/Pentium4/guides/3 |

|

|

|

02553.htm |

|

|

|

|

|

|

Intel® Pentium® D® Processor and Intel® Pentium® Processor |

http://developer.intel.com/ |

|

|

Extreme Edition 830 Thermal and Mechanical Design Guidelines |

design/pentiumXE/designe |

|

|

|

x/306830.htm |

|

|

|

|

|

|

LGA775 Socket Mechanical Design Guide |

http://developer.intel.com/ |

|

|

|

design/pentium4/guides/3 |

|

|

|

02666.htm |

|

|

|

|

|

|

Various System Thermal Design Suggestions |

http://www.formfactors.or |

|

|

|

g |

|

|

|

|

§

Thermal and Mechanical Design Guidelines |

9 |

Introduction

10 |

Thermal and Mechanical Design Guidelines |

Product Specifications

2 Product Specifications

This chapter provides the package description and loading specifications. The chapter also provides component thermal specifications and thermal design power descriptions for the (G)MCH.

2.1Package Description

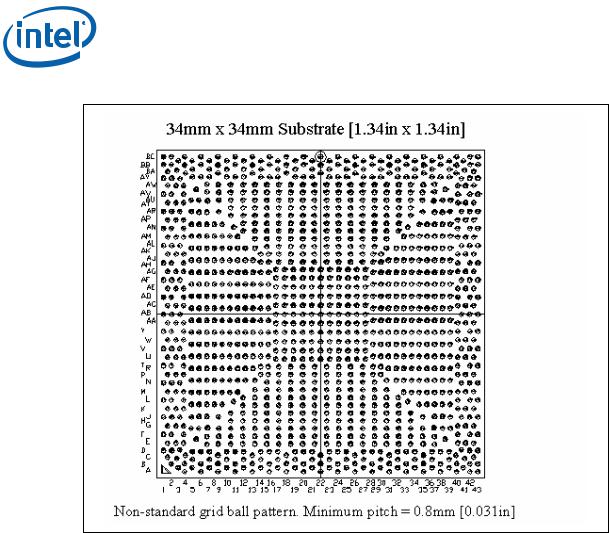

The (G)MCH is available in a 34 mm [1.34 in] x 34 mm [1.34 in] Flip Chip Ball Grid Array (FC-BGA) package with 1202 solder balls. The die size is currently 9.6 mm [0.378in] x 10.6 mm [0.417in]. A mechanical drawing of the package is shown in Figure 9, Appendix B.

2.1.1Non-Grid Array Package Ball Placement

The (G)MCH package uses a “balls anywhere” concept. The minimum ball pitch is 0.8 mm [0.031 in], but ball ordering does not follow a 0.8-mm grid. Board designers should ensure correct ball placement when designing for the non-grid array pattern. For exact ball locations relative to the package, contact your Field Sales Representative.

Thermal and Mechanical Design Guidelines |

11 |

Product Specifications

Figure 1. (G)MCH Non-Grid Array

2.2Package Loading Specifications

Table 1 provides static load specifications for the chipset package. This mechanical maximum load limit should not be exceeded during heatsink assembly, shipping conditions, or standard use conditions. Also, any mechanical system or component testing should not exceed the maximum limit. The chipset package substrate should not be used as a mechanical reference or load-bearing surface for the thermal and mechanical solution.

Table 1. (G)MCH Loading Specifications

Parameter |

Maximum |

Notes |

|

|

|

Static |

15 lbf |

1,2,3 |

|

|

|

NOTES:

1.These specifications apply to uniform compressive loading in a direction normal to the (G)MCH package.

2.This is the maximum force that can be applied by a heatsink retention clip. The clip must also provide the minimum specified load on the (G)MCH package.

3.These specifications are based on limited testing for design characterization. Loading limits are for the package only.

12 |

Thermal and Mechanical Design Guidelines |

Loading...

Loading...