Husqvarna 450 User Manual

Operator’s Manual

Read these instructions carefully and make sure

you understand them before using the 450.

Manuel d’utilisation

Veuillez lire attentivement ces instructions et assurez-vous de

bien les comprendre avant d’utiliser la machine modèle 450.

Manual

del operador

Lea cuidadosamente estas instrucciones y asegúrese

de que las comprende bien antes de usar el 450.

450

CONTENTS

Content Page

Table of contents ………………………….. 2

Unpacking .................................................. 2

Transporting ............................................... 2

Sound Data ................................................ 2

Introduction, personal safety ...................... 3

Registration of the product ………………… 4

General safety message ............................ 4

Safety warnings ......................................... 5

Excel series blades ................................... 6

Blade and skid plate installation ................ 6

What is what? ............................................ 7

Operating instructions ............................... 8

Fuel and fuel safety warnings …….…….... 9

Recommended fuels ................................. 9

Recommended oils …….......……….…..… 9

Maintenance .............................................. 10

Sawing contraction joints …………....….… 11

Maximizing the Soff-Cut system .......…..... 12

Troubleshooting ......................................... 13

Technical specications ............................. 14

Conformity certicates ............................... 14

Warranty .................................................... 15

Your 450 saw has been shipped from the factory thoroughly

inspected. Only minimal assembly is required to start using the

saw. Remove the saw from the container using proper lifting

techniques. Discard or recycle the packing material per your

regional laws. In your container will be the 450 saw, blade

shaft wrench, an owner’s manual, an engine owner’s manual,

a part list, a warranty card, a joint protector sample pack, a

diamond blade, a skid plate, and a ramp for unloading the saw.

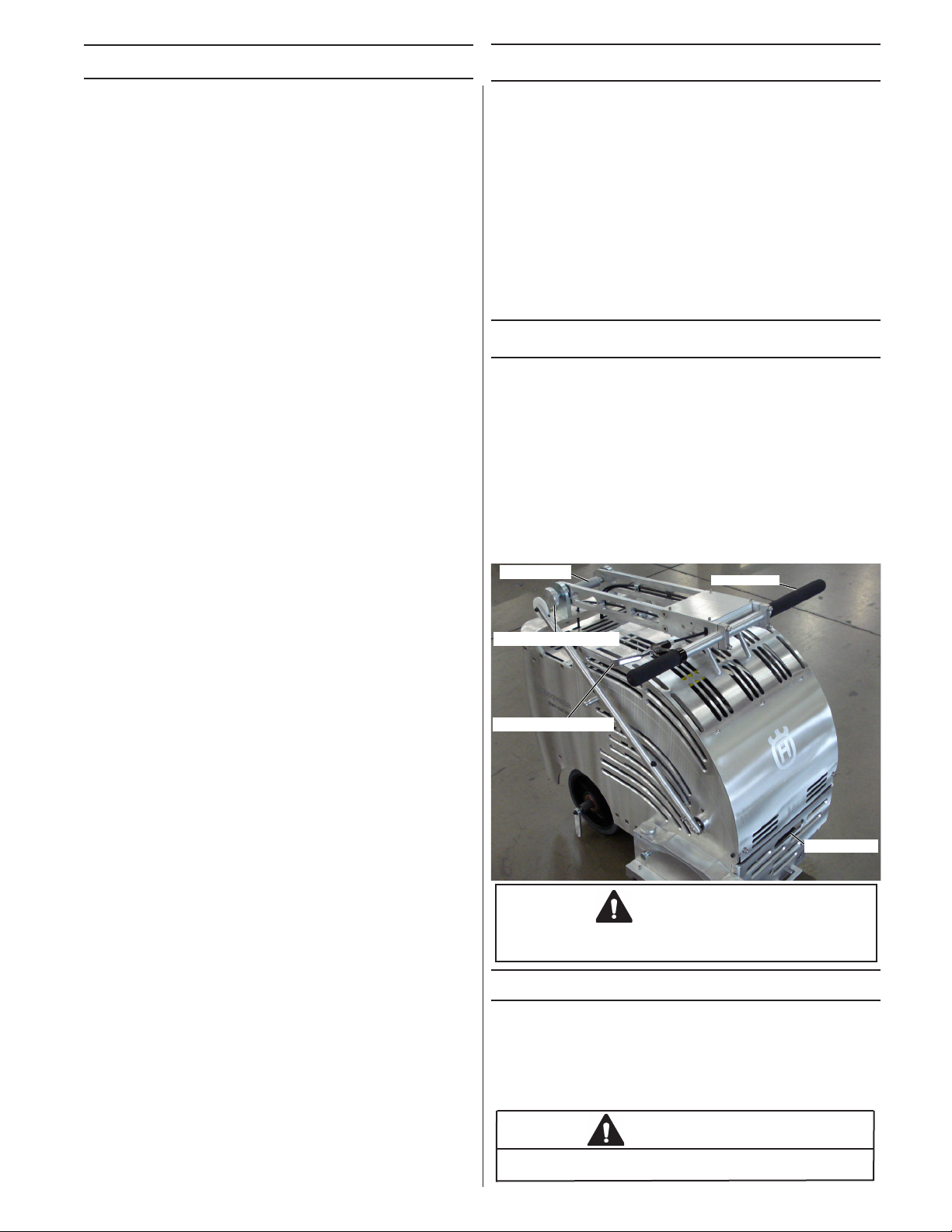

Raise the saw to its full height by pressing down on the handle

bar. Place the unloading ramp at the edge of the container and

roll the saw out of the container. Lower the saw by pressing

down on the handle bar and squeezing the lever on the handle

bar.

CAUTION

Only use the center of the handle or the

handle bar when lifting the 450.

The 450 saw weights approximately 139 pounds (63 kilo-

grams) when ready to use . Use safe lifting practices when

handling the saw. Always remove the diamond blade when

transporting the saw. Always transport the saw with a skid

plate installed. Raise the guide arm to the back position.

Loosen the handle locking knob and fold the handle forward.

Tighten the handle locking knob and make sure the handle is

locked in the keyways. The saw can be lifted from the center of

the handle. If two (2) people are lifting the saw, use the handle

bar and lift with two hands on each side of the saw. Always

store and transport the saw in a completely lowered position

and secured from moving.

UNPACKING

2

TRANSPORTING

According to Standard ISO 3744:1998 and Directive 2000/14/

EC for environmental sound level and according to Standard

ISO 11201:1995 for sound level at the operator’s position, the

450 saw emits the following:

Sound power level Lwa 102 dB (A)

Sound pressure level Lpa 86 dB (A)

SOUND DATA

WARNING

Always wear safety approved hearing protection.

Handle bar

Lifting point

Handle locking knob

Lifting point

Blade release lever

INTRODUCTION

Common sense:

The focus of this manual is HOW to operate and service the equipment safely.

It is not possible to cover every conceivable situation you can face when using this equipment. Therefore use this

product only in a manner described in this manual. Operation or handling the machine in any other manner can

lead to serious injury or death.

If a situation is not described in this manual it should be considered dangerous - and not be done.

If you are unfamiliar with this product make sure that you carefully understand how it functions and practice all

operations and handling before putting the machine to use. Familiarize yourself in the presence of an experienced

operator. Avoid all situations that are beyond your capability.

If you still feel uncertain about the operating procedures after reading these instructions DO NOT operate the

machine until you have consulted an experienced operator.

If you have further questions you can contact the closest Husqvarna Construction Products location by writing or

calling, see information below. You can also nd the closest location by searching the internet at;

www.husqvarnacp.com . Husqvarna Construction Products will willingly be of service and provide you with advice

as well as help you to use your product both efciently and safely.

Additional manuals are available at NO CHARGE and can also be obtained on the internet site.

Husqvarna Construction Products

265 Radio Road

Corona, California 92879

USA

Toll Free no: 800 776 3328 (USA & Canada)

Phone no: 951 272 2330

Telefax no: 951 272 2338

Internet Site: www.husqvarnacp.com

PERSONAL SAFETY EQUIPMENT

When working and operating the saw the following

approved personal safety items should be used:

Head

Protection

Hearing

Protection

Eye

Protection

Safety

Shoes

Protective

Gloves

The 450 is designed as a residential and light commercial Ultra Early Entry concrete saw. The pat-

ented Soff-Cut Ultra Early Entry dry cutting system controls random cracking of concrete through the early

timing of the saw cutting usually within one to two hours after nishing process is completed. The patented

low noise and low dust blade block and skid plate technology in conjunction with the Husqvarna blades al-

lows for Ultra Early Entry sawing the same day while minimizing chipping and spalling. The saw is a manual

push style with manual controls for all functions.

3

4

REGISTER THE PRODUCT

Please register your new 450 with Husqvarna Construction Products by mailing

in the registration card that came with the machine or you can register on the internet site

www.husqvarnawarranty.com

Registration will allow us to contact in case of any critical updates or recalls on this machine.

Warranty registration has also been found to be helpful in tracing stolen equipment.

Record the following information for your records:

PURCHASE DATE: ________________

MODEL No: ________________ SERIAL No: __________________

ENGINE MODEL: _____________ ENGINE TYPE: ______________ ENGINE CODE: ________________

The 450 model and serial number as well as the engine model number, engine type and code are critical in order to

obtain the correct service parts.

SAFETY HAZARDS

CAUTION

HEARING HAZARD

During the normal use of this

machine, operator may be

exposed to a noise level equal

to or higher than 85 dB(A). Use

hearing protection.

WARNING

ASPHYXIATION HAZARD

Running an engine in a con-

ned or badly ventilated area

can result in injury or death due

to asphyxiation or carbon

monoxide poisoning.

WARNING

CALIFORNIA PROP 65

Use of this product can expose

you to materials known to the

State of California to cause

cancer and/or birth defects or

other reproductive harm.

WARNING

DO NOT MODIFY THE PRODUCT

Under no circumstances may the design of the machine be modied without the permission of the manu-

facturer. Always use genuine accessories. Unauthorized modications and/or accessories can result in

serious personal injury or the death of the operator or others. Your warranty may not cover damage or

liability caused by the use of unauthorized accessories or replacement parts.

SAFETY DEFINITIONS

In this manual a Safety Alert Symbol followed by the signal words WARNING and CAUTION are used to

identify safety information about hazards which can result in death, serious injury and/or property damage.

These signal words mean:

WARNING indicates a hazard which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might result in minor or moderate injury.

NOTICE indicates a message not related to personal injury.

5

SAFETY WARNINGS

WARNING

Failure to comply with the following warnings could

result in serious bodily injury or death!

PERSONAL SAFETY

• Read and understand instructions before operating saw.

• Always wear safety approved hearing, eye, head and

respiratory protection.

• Wear boots with non-slip soles to provide proper footing.

Steel-toed safety boots are recommended.

• Wear rubber work gloves to avoid contact with wet concrete

which can cause serious skin irritation.

• Know how to stop the saw quickly in case of emergency.

• Keep all parts of your body away from blade and other

moving parts. Do not wear loose clothing or jewelry which

can be caught in moving parts. Wear protective hair covering

to contain long hair.

• Use caution when loading and unloading saw.

• Stay alert. Maintain awareness of saw operation. Use

common sense. Do not operate saw when tired or after

consumption of any substance that would impair physical

function or rational judgment.

• Do not over reach. Keep proper footing and balance.

WORK AREA SAFETY

• Never operate the saw in any application or job where you

are not trained or supervised.

• Keep visitors, children and animals out of the work area.

• Observe all safety regulations for the safe handling of fuel.

Gasoline is extremely ammable and its vapors can explode

if ignited. Do not refuel indoors or in poorly ventilated areas.

Handle fuel in safety containers. Shut off the engine and

allow it to cool before refueling. Wipe the saw dry if fuel is

spilled on it. Always move away from the fueling area before

starting the engine. Do not smoke while refueling.

• Do not operate the saw while smoking or near an open ame.

• Do not operate the saw in areas of combustible material or

fumes. Sparks may occur from the saw that could cause a

re or explosion.

• Operate only in well ventilated areas. Engine exhaust contain

carbon monoxide which can cause loss of consciousness and

possible death.

• The mufer and engine become very hot during operation.

Keep all body parts and foreign material away from the

engine while running.

• Avoid dangerous environments. Do not expose saw to rain.

Keep work area well lit and clean.

SAW SAFETY

• Do not leave saw unattended while the engine is running.

• Do not alter the saw. Any alteration or modication is misuse

and may result in a dangerous condition.

• All safety guards must be in place before starting the engine.

• Only operate the saw from behind the machine with both

hands on the handle.

• Do not use damaged equipment, blades, guards or personal

protection equipment. Do not disable safety equipment or kill

switches.

• Do not operate the saw if there is a fuel leak.

• Use extreme caution when maneuvering the saw on ramps

or loading and unloading from trucks or trailers.

• Use only Husqvarna Construction Products replacement

parts. Use of unauthorized parts may create a danger.

• Do not use the saw as vehicle for transporting personnel or

equipment.

• Remove the ignition cable from the spark plug before

performing saw maintenance or changing blades to prevent

accidental engine starting.

• Remove all wrenches from the saw before starting.

• Never stand on the saw.

• When the saw is not in use or transporting, remove the blade

and lower the saw completely. Properly secure the saw to

prevent accidental movement.

BLADE SAFETY

• Examine cutting blades before each use. Do not use any

blades that has cracks, nicks, or aws. Tri-arbor hole should

be undamaged. Use only dry cut, steel centered, tri-arbor

diamond blades made for cutting green concrete.

• Husqvarna Excel Series diamond blades are designed to

only cut green concrete. Cutting any other material may result

in blade failure or a dangerous condition.

• Inspect blade anges for damage, excessive wear and

cleanliness before mounting the blade. The blade should t

snugly on clean, undamaged, tri-arbor shaft.

• Use only Husqvarna Excel Series blades or blades marked

with a maximum operating speed greater than 3200 rpm.

• Never operate the saw without the blade block assembly

securely in place including blade cover, lexan shields and

skid plate installed in working order. A damaged blade block

assembly must be replaced to protect the operator.

• Make sure the blade does not make contact with the ground

or any other surface when maneuvering the saw.

• Avoid getting in direct line with the blade or contacting the

blade while it is rotating.

Loading...

Loading...