Husqvarna 225L-LD, 232L, 225L Lite User Manual

225L/LD 225L Lite 232L

Operator's manual |

(CARB, EPA) |

Read through the Operator‘s Manual carefully and understand the content before using the machine.

101 89 12-95

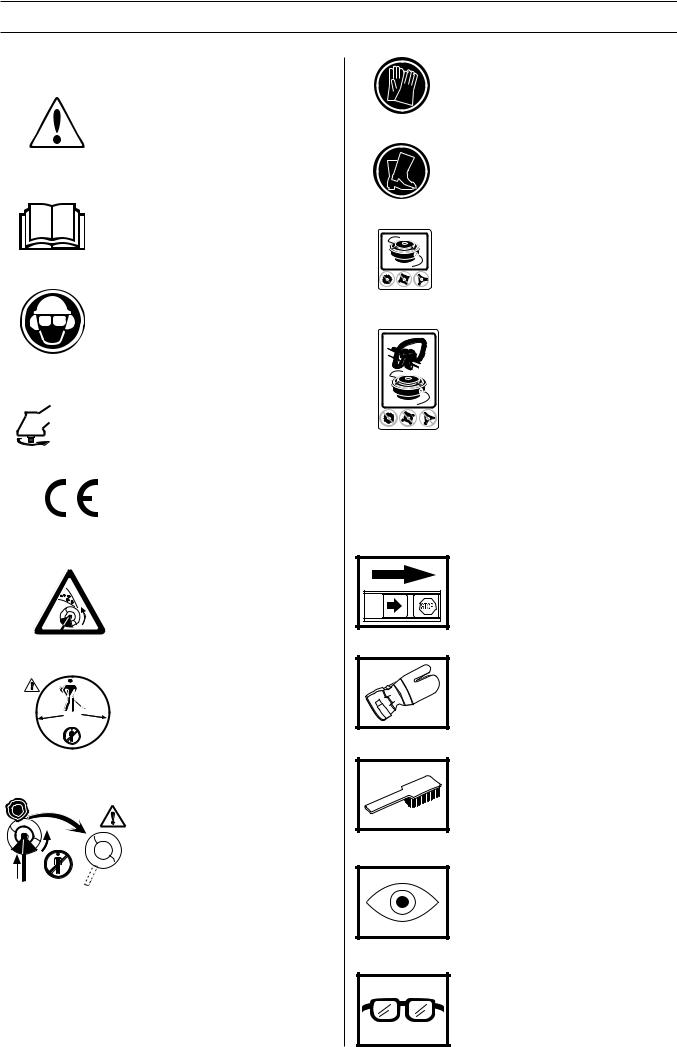

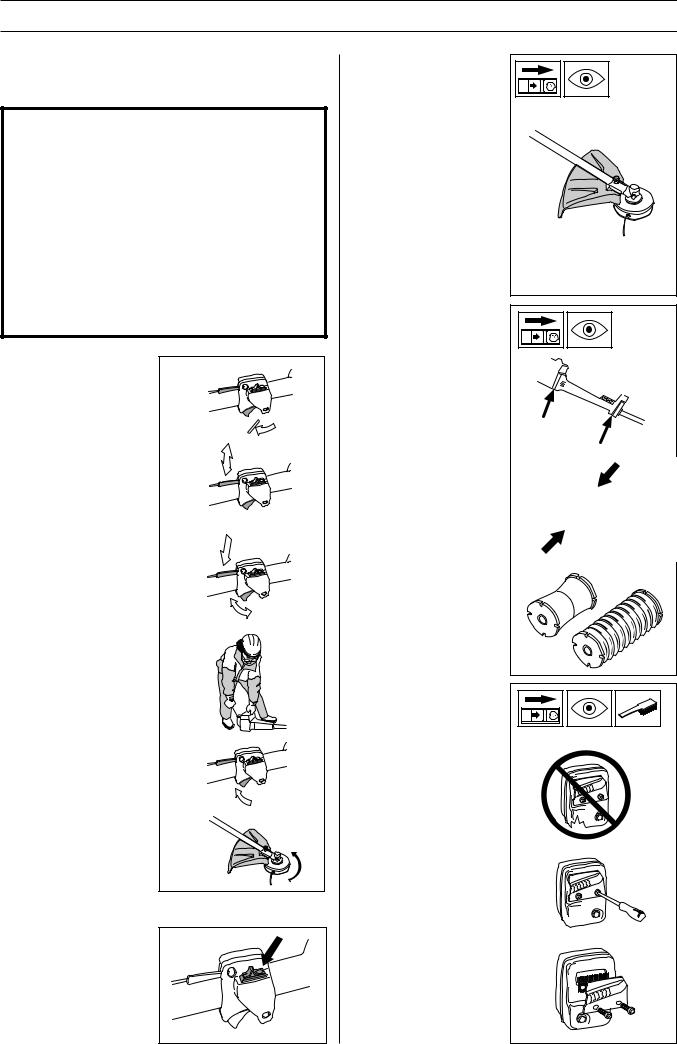

SYMBOL EXPLANATION

Symbols

max 10000 rpm

WARNING! Clearing saws, brushcutters and trimmers can be dangerous!

Careless or incorrect use can result in serious or fatal injury to the operator or others.

Read through the Operator‘s Manual carefully and understand the content before using the machine.

Always use

•A protective helmet where there is a risk of falling objects

•Ear protection

•Approved eye protection

•Max. speed of output axle, rpm

•This product is in accordance with applicable CE directives.

•Beware of thrown objects and ricochets.

15 m  50FT

50FT

15 m 50FT

15 m 50FT

•The operator of the machine shall ensure, while working, that no persons or animals come closer than 15 metres.

•Blade can thrust violently when coming in contact with any object. Blade thrust can cause amputation of arms or legs. Keep people and animals 50 feet away. Never use blades unless recommended handlebar, shoulder strap, attaching hardware and blade deflector are installed.

•Always wear approved protective gloves.

•Use anti-slip and stable boots.

•Only use non-metallic, flexible cutting elements, that is trimmer head with trimmer cord.

•Only intended for the trimmer head.

Checks and/or maintenance should be carried out with the engine switched off, with the stop switch in the STOP position.

Always wear approved protective gloves.

Regular cleaning required.

Ocular control.

Approved eye protection must always be used.

2 – English

CONTENTS

Before using a new machine

•Read the Operator‘s Manual carefully.

•Check the assembly and adjustment of the cutting equipment. See page 13.

•Start the machine and check the carburettor settings. See page 16-17.

IMPORTANT! A too lean carburettor adjustment significantly increases the risk of an engine breakdown.

Insufficient care of the air filter will cause deposits on the spark plug resulting in starting difficulties.

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual.

!WARNING!

Under no circumstances may the design of the machine be modified without the permission of the manufacturer. Always use genuine accessories. Non-authorised modifications and/or accessories can result in serious personal injury or the death of the operator or others.

Your warranty does not cover damage or liability caused by the use of nonauthorized accessories or replacement parts.

List of contents |

|

SYMBOL EXPLANATION |

|

Symbols ............................................................................... |

2 |

CONTENTS |

|

Before using a new machine ................................................. |

3 |

List of contents .................................................................... |

3 |

SAFETY INSTRUCTIONS |

|

Personal protective equipment ............................................. |

4 |

The machine‘s safety equipment .......................................... |

4 |

Control, maintenance and service of the machine‘s safety |

|

equipment ...................................................................... |

6 |

Cutting equipment .............................................................. |

7 |

General safety instructions ................................................... |

8 |

General working instructions ............................................... |

9 |

Basic working techniques ..................................................... |

9 |

WHAT IS WHAT? |

|

What is what on the trimmer?............................................ |

11 |

ASSEMBLY |

|

Assembling the loop handlebar .......................................... |

12 |

Assembling and dismantling the two-part shaft (225LD) ... |

12 |

Assembling the spray guard and |

|

trimmer head Superauto II ........................................... |

13 |

Assembling other guards and cutting equipment ................ |

13 |

FUEL HANDLING |

|

Fuel mixture ...................................................................... |

14 |

Fuelling.............................................................................. |

14 |

START AND STOP |

|

Control before starting ....................................................... |

15 |

Start and stop ..................................................................... |

15 |

MAINTENANCE |

|

Carburettor ........................................................................ |

16 |

Muffler .............................................................................. |

18 |

Cooling system .................................................................. |

18 |

Air filter ............................................................................. |

18 |

Spark plug .......................................................................... |

19 |

Angle gear .......................................................................... |

19 |

Two-part shaft .................................................................... |

19 |

Maintenance schedule ........................................................ |

20 |

TECHNICAL DATA |

|

225L/LD ........................................................................... |

21 |

225L Lite ........................................................................... |

21 |

232L .................................................................................. |

21 |

FEDERAL AND CALIFORNIA EMISSION CONTROL |

|

WARRANTY STATEMENT |

|

Your warranty rights and obligations .................................. |

22 |

English – 3

SAFETY INSTRUCTIONS

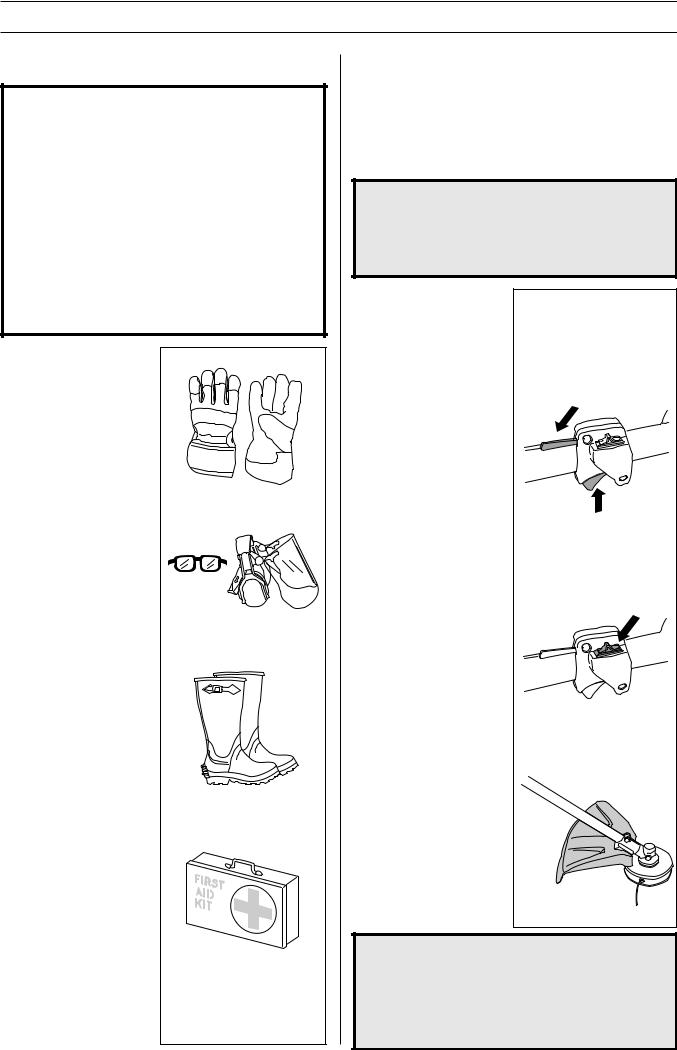

Personal protective equipment

IMPORTANT INFORMATION

•A clearing saw, brushcutter or trimmer used incorrectly or carelessly can become a dangerous tool, that can cause serious or fatal injury to the operator or others. It is extremely important that you read and understand the content of this manual.

•When using a trimmer, personal protective equipment approved by the appropriate authorities must be used. Personal protective equipment does not eliminate the risk of accidents, however, it can reduce the effects of an injury in the event of an accident. Ask your dealer for help when choosing protective equipment.

GLOVES

Gloves should be worn when necessary, e.g., when assembling cutting equipment.

EAR PROTECTION Ear protection offering sufficient dampening effect should be used.

EYE PROTECTION Blows from branches or objects thrown by the rotating cutting equipment can damage the eyes.

BOOTS

Use anti-slip and stable boots.

CLOTHING

Wear clothes made of a strong fabric and avoid loose clothing that can catch on shrubs and branches.

FIRST AID KIT

A first aid kit should be carried by operators of clearing saws, brushcutters or trimmers.

The machine‘s safety equipment

This section describes the machine‘s safety equipment, its function and how checks and maintenance are carried out to ensure that it operates correctly. (See the chapter “What is what“ to locate where this equipment is positioned on your machine.)

!WARNING!

Never use a machine with defective safety equipment. Follow the control, maintenance and service instructions described in this section.

1. Throttle trigger lock

The throttle trigger lock is designed to prevent the throttle from accidentally being engaged. When the trigger lock (A) is pressed into the handle (= when you hold the handle) the throttle

(B) is released. When the grip on the handle is released the throttle and the throttle trigger lock return to their original positions. This takes place via two independent return spring systems. This means that the throttle is automatically locked in its “idling“ position.

2. Stop switch

The stop switch should be used to stop the engine.

3. Cutting attachment guard

This guard is intended to prevent objects from being thrown towards the operator and to protect the operator from unintentionel contact with the cutting attachment.

A |

B |

" |

!WARNING!

Under no circumstances may the cutting equipment be used without an approved guard fitted. See the chapter “Technical data” . If the wrong guard or a defective guard is fitted this can cause serious personal injury.

4 – English

SAFETY INSTRUCTIONS

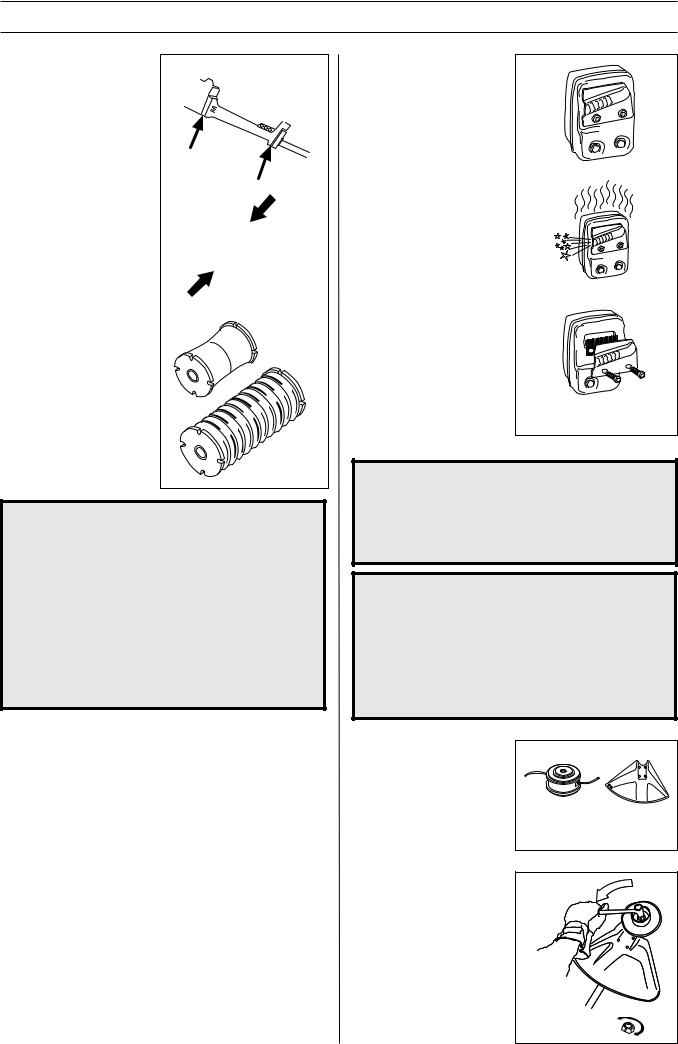

4. Vibration damping system

Your machine is equipped with a vibration damping system, which is designed to give as vibration-free and comfortable use as possible.

Use of incorrectly wound cord or incorrect cutting equipment increases the level of vibration.

The machine‘s vibration damping system reduces the transfer of vibrations between the engine unit/ cutting equipment and the machine‘s handles. The engine body including the cutting equipment is suspended on the handlebar system via a vibration damping element.

225L Lite |

!WARNING!

Over exposure to vibrations can result in blood-vessel or nerve injury to persons suffering with blood circulation problems. Seek medical attention if you experience physical symptoms that can be related to over exposure to vibrations. Examples of such symptoms are “numbness“, lack of feeling, “tickling“, “pricking“, “pain“ lack of or a reduction in normal strength, changes in the colour of the skin or its surfaces. These symptoms normally appear in the fingers, hands or wrists.

5. Muffler

The muffler is designed to give the lowest possible noise level and to direct the engine‘s exhaust fumes away from the operator. Muffler fitted with catalytic converter is also designed to reduce harmful exhaust components.

In countries that have a warm and dry climate the risk of fire is obvious. We have therefore fitted certain mufflers with a spark arrest screen. Make sure that your muffler is fitted with this kind of screen.

It is extremely important that the instructions for checking, maintaining and servicing the muffler are followed. (see the section “Control, maintenance and service of the machine‘s safety equipment“).

!WARNING!

Mufflers fitted with catalytic converters become extremely hot during use and after stopping. This also applies at idling speeds. Contact can result in burns to the skin. Be observant to the risk of fire!

!WARNING!

Bear in mind that exhaust fumes:

•contain carbon monoxide, which can cause carbon monoxide poisoning. Therefore never start or run the machine indoors.

•are hot and can contain sparks that can cause fires. Never start the machine indoors or close to inflammable material.

6.Cutting

equipment

The trimmer head is intended for trimming grass.

7. Locking nut

The locking nut secures the cutting equipment on the output shaft.

English – 5

SAFETY INSTRUCTIONS

Control, maintenance and service of the machine‘s safety equipment

IMPORTANT INFORMATION

•All service and repairs to the machine require special training.

•This applies especially to the machine‘s safety equipment. If the machine does not meet any of the controls listed below you should contact your service workshop.

•The purchase of one of our products guarantees that professional repair and servicing will be carried out on it. If the point of purchase is not one of our servicing dealers, please ask for details of the closest service workshop.

1.Throttle trigger

lock

• Check that the throttle is locked in the “idling position“ when the throttle trigger lock is in its original position.

•Press in the throttle trigger lock and make sure it returns to its original

position when released.

• Ensure that the throttle and throttle trigger lock move easily and that their return spring systems function.

• See section "Start". Start the machine and apply full throttle. Release the throttle and check that the cutting equipment stops and remains at a standstill. If the cutting equipment rotates with the throttle in the idling position then the carburettor‘s idling

setting must be checked. # See chapter

“Maintenance“.

2. Stop switch

• Start the engine and make sure that the engine stops when the stop switch is moved to the stop position.

3. Cutting attachment guard

•Ensure that the spray guard is undamaged and is not cracked.

•Replace the guard if it has been exposed to impact or is cracked.

•Always use the prescribed blade an guard combination, see chapter

"Technical data".

4. Vibration damping system

•Check the vibration damping element regularly for material cracks and distortion.

•Check that the vibration damping element is securely attached between the engine unit and the handlebar unit.

5. Muffler

1.Never use a machine that has a defective muffler.

2.Check regularly that the muffler is secure.

3.If your muffler is fitted with a spark arrest screen then it should be cleaned regularly. A blocked screen leads to the engine overheating with serious damage as a result. Never use a muffler with a defective spark arrest screen.

225L Lite |

6 – English

SAFETY INSTRUCTIONS

6. Cutting equipment

The section describes how through correct maintenance and through using the right type of cutting equipment you can:

•Obtain maximum clearing capacity.

•Increase the service life of the cutting equipment.

Two basic rules:

1)Only use the cutting and guard equipment we recommend! See chapter “Technical data“.

2)Check the cutting equipment with regard to damage and crack formation. Damaged cutting equipment should always be replaced.

7. Locking nut

• Protect your hand from injury when assembling, use the blade guard as protection when tightening with a socket spanner. Tighten the nut by turning against the direction of rotation. Loosen the nut by turning in the direction of rotation. (NOTE! the nut has a left-hand thread).

• Tighten the nut using a socket spanner, 35 - 50 Nm (3.5 - 5 kpm).

NOTE!

The locking nut‘s nylon lock must not be so worn that it can be turned by hand. The lock shall hold at least 1.5 Nm. The nut should be replaced after it has been put on approx. 10 times.

!WARNING!

Never use a machine with defective safety equipment. The safety equipment should be maintained as described in this section. If your machine does not meet any of these controls you should contact your service workshop.

Cutting equipment

IMPORTANT INFORMATION

The section describes how through correct maintenance and through using the right type of cutting equipment you can obtain maximum clearing capacity and increase the service life of the cutting equipment.

•Only use the cutting and guard equipment we recommend! See chapter “Technical data“.

•Refer to the instructions for the cutting equipment for the correct winding of cord

and for the selection of the right cord diameter.

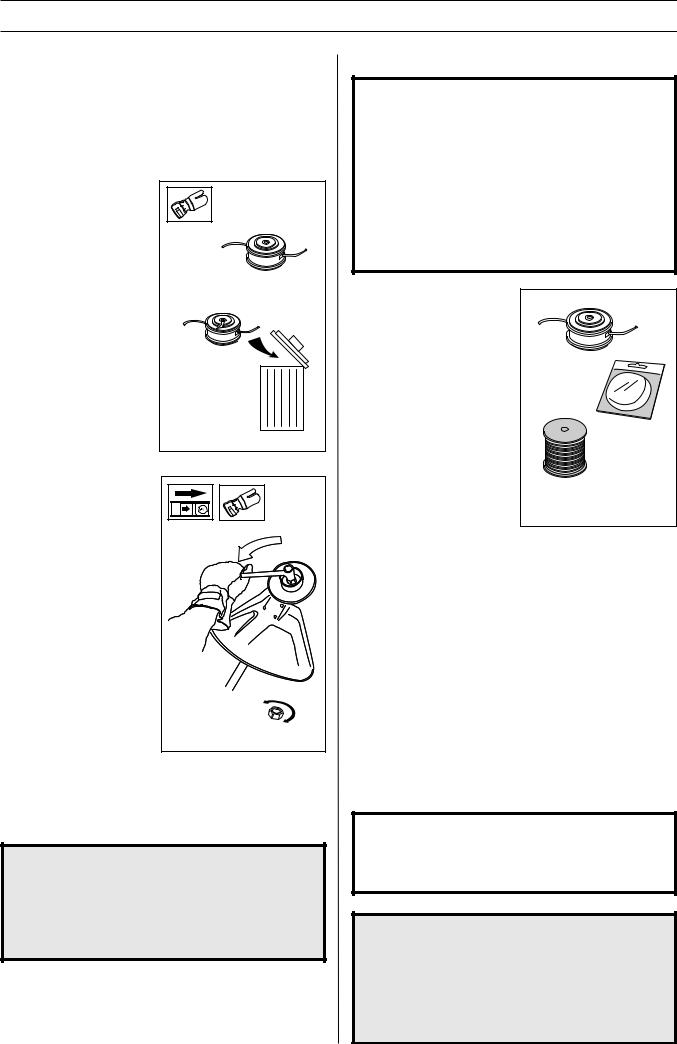

Trimmer head

• Only use a trimmer head and trimmer cord that is recommended. These have been tested by the manufacturer to suit a particular engine size. This is especially important when a fully automatic trimmer head is used. Only use the cutting equipment we recommend! See chapter

“Technical data“.

•Generally smaller machines require a small trimmer head and vice versa. This is because when clearing using a cord the engine must throw out the cord radially from the trimmer head and also meet resistance from the grass being cleared.

•The length of the cord is also important. A longer cord requires greater engine power than a shorter cord of the same diameter.

•Make sure the knife positioned on the trimmer guard is intact. This is used to cut the cord to the correct length.

•To increase the life of the cord it can be soaked in water for a few days. This will make the line tougher and it will keep longer.

IMPORTANT INFORMATION

Always ensure the trimmer cord is wound tightly and evenly around the drum, otherwise harmful vibrations will occur.

!WARNING!

Always stop the engine before starting work on any part of the cutting equipment. This continues to rotate even after the throttle has been released. Ensure that the cutting equipment has stopped completely and remove the cable from the spark plug before you start to work on it.

English – 7

SAFETY INSTRUCTIONS

General safety instructions

IMPORTANT INFORMATION

•The machine is only designed for trimming grass.

•The only accessories to be used with the engine unit as a drive source are the cutting units we recommend in the chapter “Technical data“ .

•Never use the machine if you are tired, if you have consumed alcohol, or if you are taking medicines that can affect your sight, your judgement or the control of your body.

•Use personal protective equipment. See the section “Personal protective equipment“.

•Never use a machine that has been modified so that it no longer corresponds with the original design.

•Never use a machine that is faulty. Follow the maintenance, control and service instructions in this Operator‘s Manual. Some maintenance and service actions should be carried out by trained and qualified specialists. See the chapter “Maintenance“ .

•The machine operator shall ensure, while working, that no persons or animals come closer than 15 metres (50 feet). When several operators are working in the same area the safety distance should be at least double tree length, however, at least 15 metres (50 feet).

!WARNING!

Faulty cutting equipment increases the risk of accidents.

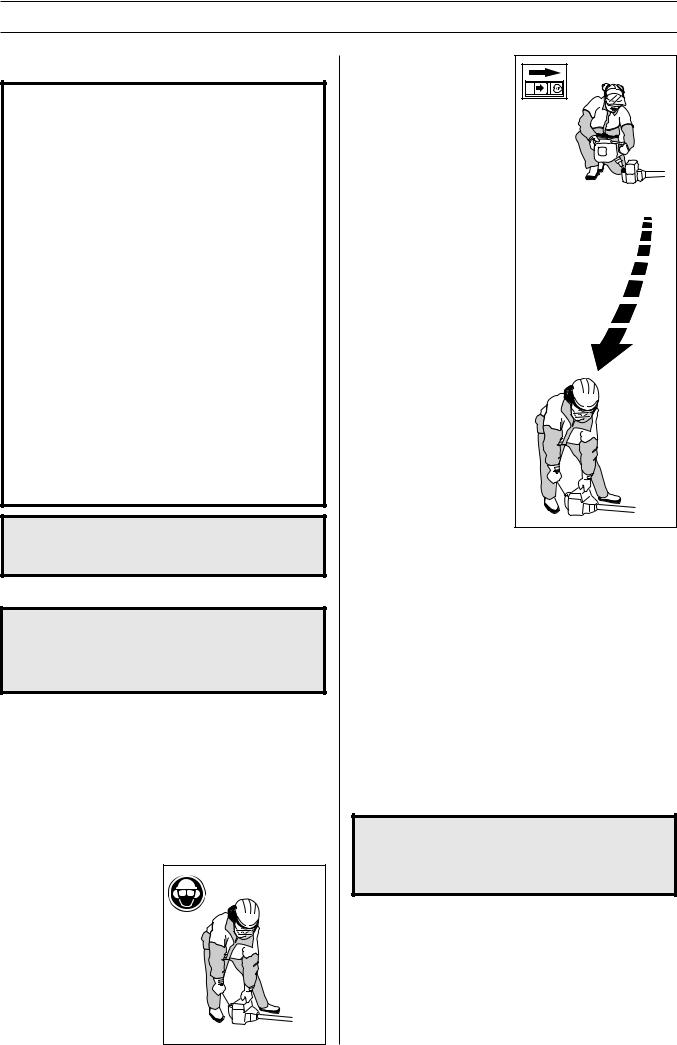

Start

!WARNING!

When the engine is started with the choke in either the choke or start throttle positions the cutting equipment starts to rotate immediately.

•The complete clutch cover with shaft must be fitted before the machine is started, otherwise the clutch can become loose and cause personal injury.

•Never start the machine indoors. Bear in mind the dangers of inhaling the engine‘s exhaust fumes.

•Observe your surroundings and make sure that there is no risk of people or animals coming into contact with the cutting equipment.

•Place the machine on the

ground, ensure the cutting equipment runs free of twigs and stones. Push the machine body towards the ground using your left hand. (NOTE! Not with your foot). Grip the starter handle with your right hand and pull the starter cord.

Fuel safety |

|

|

• |

Never fill the machine |

|

|

while the engine is |

|

|

running. Always stop the |

|

|

engine and let it cool for a |

|

|

few minutes before |

|

|

refuelling. |

|

• |

Provide good ventilation |

|

|

when filling or mixing fuel |

|

|

(petrol and 2-stroke oil). |

|

• Move the machine at least |

Min. 3 m |

|

(10 ft) |

||

|

3 m from the filling |

|

|

position before starting. |

|

• |

Never start the machine: |

|

a) If you have spilt fuel on it. |

|

|

|

Wipe up all spillage. |

|

b)If you have spilt fuel on |

|

|

|

yourself or your clothes. |

|

|

Change your clothes. |

|

c) If there is a fuel leak. |

|

|

|

Make regular checks for |

|

|

leakage from the fuel cap |

|

|

and the fuel supply pipes. |

|

Transport and storage

•Store and transport the machine and fuel so that any leakage or fumes do not risk coming into contact with sparks or naked flames. For example, electric machines, electric motors, electrical switches/power switches, heaters or the like.

•When storing and transporting fuel approved containers intended for this purpose must be used.

•When storing the machine for long periods the fuel tank must be emptied. Contact your local petrol station to find out how to dispose of excess fuel.

!WARNING!

Exercise great care when handling fuel. Bear in mind the risk of fire, explosions and inhaling fumes.

8 – English

Loading...

Loading...