HP BL460C G7 User Manual

HP ProLiant BL460c G7 Server Blade

User Guide

Abstract

This document is for the person who installs, administers, and troubleshoots servers and storage systems. HP assumes you are qualified in the servicing of computer equipment and trained in recognizing hazards in products with hazardous energy levels.

Part Number: 613018-002

March 2011

Edition: 2

© Copyright 2010, 2011 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, Windows NT, and Windows Server are U.S. registered trademarks of Microsoft Corporation. AMD Athlon is a trademark of Advanced Micro Devices, Inc.

Intel and Pentium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries. Java is a US trademark of Sun Microsystems, Inc.

Contents |

|

Component identification............................................................................................................... |

6 |

Front panel components ............................................................................................................................. |

6 |

Front panel LEDs ....................................................................................................................................... |

7 |

SAS and SATA hard drive LEDs................................................................................................................... |

8 |

SAS and SATA hard drive LED combinations ................................................................................................ |

8 |

System board components.......................................................................................................................... |

9 |

Mezzanine connector definitions ..................................................................................................... |

10 |

DIMM slot locations ....................................................................................................................... |

10 |

System maintenance switch............................................................................................................. |

10 |

HP c-Class Blade SUV Cable..................................................................................................................... |

11 |

Operations................................................................................................................................. |

12 |

Power up the server blade ........................................................................................................................ |

12 |

Power down the server blade.................................................................................................................... |

12 |

Remove the server blade .......................................................................................................................... |

13 |

Remove the access panel.......................................................................................................................... |

14 |

Install the access panel............................................................................................................................. |

14 |

Remove the DIMM baffle.......................................................................................................................... |

14 |

Setup......................................................................................................................................... |

15 |

Overview ............................................................................................................................................... |

15 |

Installing an HP BladeSystem c-Class enclosure ........................................................................................... |

15 |

Installing server blade options................................................................................................................... |

15 |

Installing interconnect modules .................................................................................................................. |

15 |

Interconnect bay numbering and device mapping.............................................................................. |

16 |

Connecting to the network........................................................................................................................ |

18 |

Installing a server blade ........................................................................................................................... |

18 |

Hardware options installation....................................................................................................... |

21 |

Introduction ............................................................................................................................................ |

21 |

Hard drive option.................................................................................................................................... |

21 |

Processor option...................................................................................................................................... |

22 |

Memory options ...................................................................................................................................... |

27 |

Memory subsystem architecture ....................................................................................................... |

28 |

Single-, dual-, and quad-rank DIMMs ............................................................................................... |

28 |

Low voltage DIMMs ....................................................................................................................... |

28 |

DIMM identification ....................................................................................................................... |

29 |

Memory configurations................................................................................................................... |

30 |

General DIMM slot population guidelines ......................................................................................... |

31 |

Installing a DIMM.......................................................................................................................... |

34 |

Mezzanine card option............................................................................................................................ |

35 |

Cache module and battery pack option...................................................................................................... |

36 |

HP Trusted Platform Module option ............................................................................................................ |

40 |

Installing the Trusted Platform Module board ..................................................................................... |

41 |

Retaining the recovery key/password .............................................................................................. |

44 |

Enabling the Trusted Platform Module............................................................................................... |

44 |

Cabling ..................................................................................................................................... |

46 |

Contents |

3 |

BBWC battery pack cabling ..................................................................................................................... |

46 |

Using the HP c-Class Blade SUV Cable ...................................................................................................... |

46 |

Connecting locally to a server blade with video and USB devices.................................................................. |

46 |

Accessing a server blade with local KVM ......................................................................................... |

47 |

Accessing local media devices ........................................................................................................ |

47 |

Software and configuration utilities ............................................................................................... |

49 |

Server blade deployment tools .................................................................................................................. |

49 |

HP BladeSystem c-Class Advanced management ............................................................................... |

49 |

Network-based PXE deployment ...................................................................................................... |

49 |

Deployment methods...................................................................................................................... |

51 |

Configuration tools .................................................................................................................................. |

55 |

SmartStart software........................................................................................................................ |

55 |

HP ROM-Based Setup Utility............................................................................................................ |

55 |

Array Configuration Utility .............................................................................................................. |

57 |

Option ROM Configuration for Arrays ............................................................................................. |

57 |

Re-entering the server serial number and product ID ........................................................................... |

58 |

Management tools................................................................................................................................... |

58 |

Automatic Server Recovery ............................................................................................................. |

58 |

ROMPaq utility.............................................................................................................................. |

59 |

Integrated Lights-Out 3 technology................................................................................................... |

59 |

Erase Utility .................................................................................................................................. |

59 |

Redundant ROM support ................................................................................................................ |

60 |

USB support.................................................................................................................................. |

60 |

Diagnostic tools ...................................................................................................................................... |

60 |

HP Insight Diagnostics.................................................................................................................... |

60 |

HP Insight Diagnostics survey functionality ........................................................................................ |

61 |

Integrated Management Log ........................................................................................................... |

61 |

Remote support and analysis tools ............................................................................................................. |

61 |

HP Insight Remote Support software ................................................................................................. |

61 |

Keeping the system current ....................................................................................................................... |

62 |

Drivers ......................................................................................................................................... |

62 |

ProLiant Support Packs ................................................................................................................... |

63 |

Operating System Version Support .................................................................................................. |

63 |

HP Smart Update Manager............................................................................................................. |

63 |

Change control and proactive notification ........................................................................................ |

63 |

Care Pack .................................................................................................................................... |

64 |

Troubleshooting .......................................................................................................................... |

65 |

Troubleshooting resources ........................................................................................................................ |

65 |

Pre-diagnostic steps ................................................................................................................................. |

65 |

Important safety information............................................................................................................ |

65 |

Symptom information ..................................................................................................................... |

67 |

Prepare the server for diagnosis ...................................................................................................... |

67 |

Loose connections ................................................................................................................................... |

69 |

Service notifications................................................................................................................................. |

69 |

Server health LEDs ................................................................................................................................... |

69 |

Troubleshooting flowcharts ....................................................................................................................... |

69 |

Start diagnosis flowchart ................................................................................................................ |

70 |

General diagnosis flowchart ........................................................................................................... |

71 |

Server blade power-on problems flowchart ....................................................................................... |

73 |

POST problems flowchart ............................................................................................................... |

75 |

OS boot problems flowchart ........................................................................................................... |

77 |

Server fault indications flowchart ..................................................................................................... |

79 |

Contents |

4 |

POST error messages and beep codes ....................................................................................................... |

81 |

Battery replacement .................................................................................................................... |

83 |

Regulatory compliance notices ..................................................................................................... |

85 |

Regulatory compliance identification numbers ............................................................................................. |

85 |

Federal Communications Commission notice............................................................................................... |

85 |

FCC rating label............................................................................................................................ |

85 |

Class A equipment......................................................................................................................... |

85 |

Class B equipment ......................................................................................................................... |

85 |

Declaration of conformity for products marked with the FCC logo, United States only....................................... |

86 |

Modifications.......................................................................................................................................... |

86 |

Cables................................................................................................................................................... |

86 |

Canadian notice (Avis Canadien).............................................................................................................. |

86 |

European Union regulatory notice ............................................................................................................. |

87 |

Disposal of waste equipment by users in private households in the European Union ......................................... |

87 |

Japanese notice ...................................................................................................................................... |

88 |

BSMI notice ............................................................................................................................................ |

88 |

Korean notice ......................................................................................................................................... |

88 |

Chinese notice ........................................................................................................................................ |

89 |

Laser compliance .................................................................................................................................... |

89 |

Battery replacement notice........................................................................................................................ |

89 |

Taiwan battery recycling notice................................................................................................................. |

90 |

Acoustics statement for Germany (Geräuschemission) .................................................................................. |

90 |

Electrostatic discharge................................................................................................................. |

91 |

Preventing electrostatic discharge .............................................................................................................. |

91 |

Grounding methods to prevent electrostatic discharge.................................................................................. |

91 |

Specifications............................................................................................................................. |

92 |

Environmental specifications ..................................................................................................................... |

92 |

Server blade specifications ....................................................................................................................... |

92 |

Technical support........................................................................................................................ |

93 |

Before you contact HP.............................................................................................................................. |

93 |

HP contact information............................................................................................................................. |

93 |

Customer Self Repair ............................................................................................................................... |

93 |

Acronyms and abbreviations...................................................................................................... |

101 |

Index....................................................................................................................................... |

103 |

Contents 5

Component identification

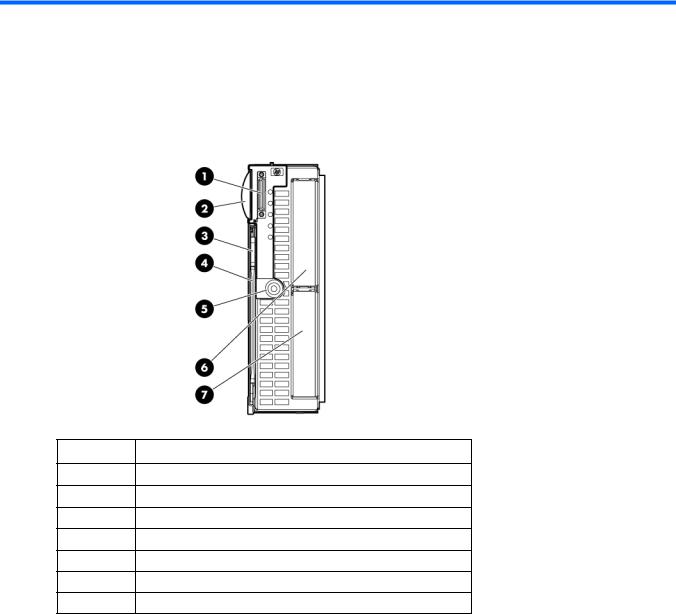

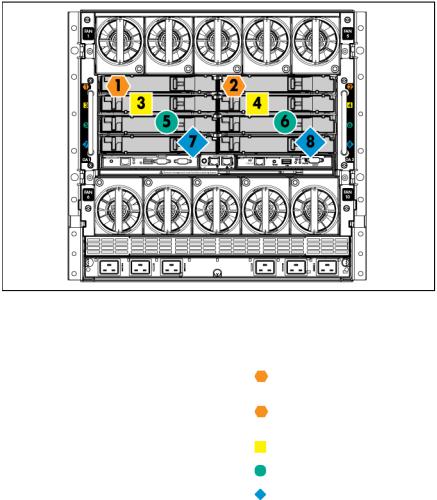

Front panel components

Item

1SUV connector*

2Serial label pull tab

3Release button

4Server blade release lever

5Power On/Standby button

6Hard drive bay 1

7Hard drive bay 2

*The SUV connector and the HP c-Class Blade SUV Cable are for some server blade configuration and diagnostic procedures.

Component identification 6

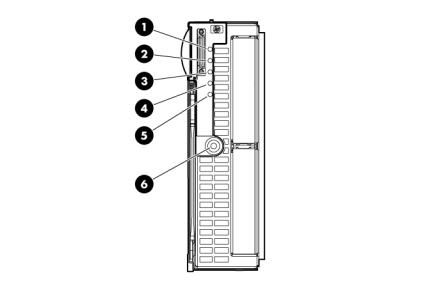

Front panel LEDs

Item |

Description |

Status |

|

|

|

1 |

UID LED |

Blue = Identified |

|

|

Blue flashing = Active remote management |

|

|

Off = No active remote management |

|

|

|

2 |

Health LED |

Green = Normal |

|

|

Amber flashing = Degraded condition |

|

|

Red flashing = Critical condition |

|

|

|

3 |

Flex 1 LED* |

Green = Network linked |

|

|

Green flashing = Network activity |

|

|

Off = No link or activity |

|

|

|

4 |

Flex 2 LED* |

Green = Network linked |

|

|

Green flashing = Network activity |

|

|

Off = No link or activity |

|

|

|

5 |

Reserved |

— |

6 |

System power LED |

Green = On |

|

|

Amber = Standby (auxiliary power available) |

|

|

Off = Off |

|

|

|

*Actual NIC numbers depend on several factors, including the operating system installed on the server blade.

Component identification 7

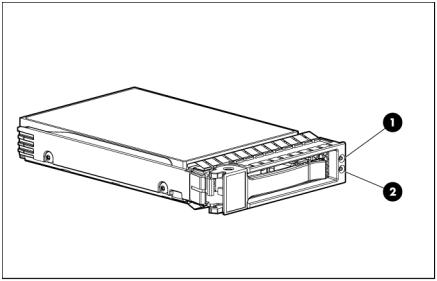

SAS and SATA hard drive LEDs

Item |

Description |

|

|

1 |

Fault/UID LED (amber/blue) |

2 |

Online LED (green) |

SAS and SATA hard drive LED combinations

Online/activity |

Fault/UID LED |

Interpretation |

LED (green) |

(amber/blue) |

|

|

|

|

On, off, or flashing |

Alternating amber |

The drive has failed, or a predictive failure alert has been received |

|

and blue |

for this drive; it also has been selected by a management |

|

|

application. |

|

|

|

On, off, or flashing |

Steadily blue |

The drive is operating normally, and it has been selected by a |

|

|

management application. |

|

|

|

On |

Amber, flashing |

A predictive failure alert has been received for this drive. |

|

regularly (1 Hz) |

Replace the drive as soon as possible. |

|

|

|

On |

Off |

The drive is online, but it is not active currently. |

Flashing regularly |

Amber, flashing |

Do not remove the drive. Removing a drive may terminate the |

(1 Hz) |

regularly (1 Hz) |

current operation and cause data loss. |

|

|

The drive is part of an array that is undergoing capacity expansion |

|

|

or stripe migration, but a predictive failure alert has been received |

|

|

for this drive. To minimize the risk of data loss, do not replace the |

|

|

drive until the expansion or migration is complete. |

|

|

|

Flashing regularly |

Off |

Do not remove the drive. Removing a drive may terminate the |

(1 Hz) |

|

current operation and cause data loss. |

|

|

The drive is rebuilding, erasing, or it is part of an array that is |

|

|

undergoing capacity expansion or stripe migration. |

|

|

|

Flashing irregularly |

Amber, flashing |

The drive is active, but a predictive failure alert has been received |

|

regularly (1 Hz) |

for this drive. Replace the drive as soon as possible. |

|

|

|

Flashing irregularly |

Off |

The drive is active, and it is operating normally. |

Component identification 8

Online/activity |

Fault/UID LED |

Interpretation |

LED (green) |

(amber/blue) |

|

|

|

|

Off |

Steadily amber |

A critical fault condition has been identified for this drive, and the |

|

|

controller has placed it offline. Replace the drive as soon as |

|

|

possible. |

|

|

|

Off |

Amber, flashing |

A predictive failure alert has been received for this drive. Replace |

|

regularly (1 Hz) |

the drive as soon as possible. |

Off |

Off |

The drive is offline, a spare, or not configured as part of an array. |

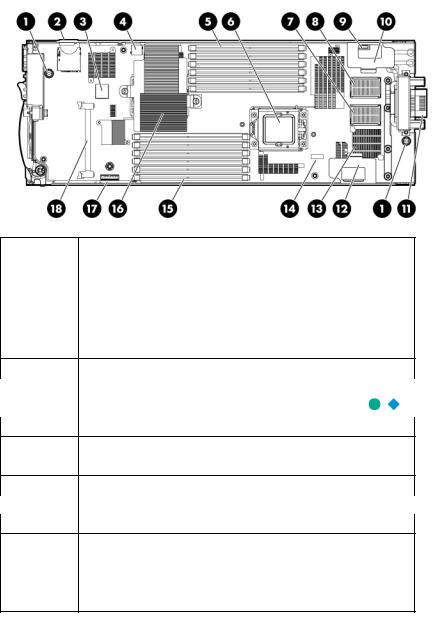

System board components

Item |

Description |

|

|

1 |

System board thumbscrews (2) |

2 |

SD card slot |

3 |

Internal USB connector |

4 |

Hard drive backplane connector |

5 |

Processor 2 DIMM slots (6) |

6Processor socket 2

7Mezzanine connector 1 (Type I mezzanine only)

8Mezzanine connector 2 (Type I or Type II mezzanine)

9System battery

10 |

Tray for optional embedded RAID controller battery |

11 |

Enclosure connector |

12Tray for optional mezzanine card battery

13Embedded FlexFabric adapters (2)

14System maintenance switch

15 |

Processor 1 DIMM slots (6) |

16 |

Processor socket 1 (populated) |

17 |

TPM connector |

18 |

Cache module connector |

The symbols

correspond to the symbols located on the interconnect bays. For more information, see the

correspond to the symbols located on the interconnect bays. For more information, see the

HP ProLiant BL460c G7 Server Blade Installation Instructions that ship with the server blade.

Component identification 9

Mezzanine connector definitions

A PCIe x8 mezzanine connector supports x16 cards at up to x8 speeds.

Item |

PCIe |

|

|

Mezzanine connector 1 |

x8, Type I mezzanine card only |

Mezzanine connector 2 |

x8, Type 1 or II mezzanine card |

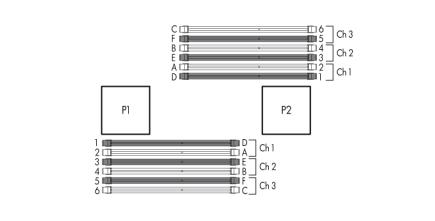

DIMM slot locations

DIMM slots are numbered sequentially (1 through 6) for each processor. The supported AMP modes use the letter assignments for population guidelines.

System maintenance switch

Position |

Function |

Default |

|

|

|

1* |

iLO 3 security override |

Off |

2 |

Configuration lock |

Off |

3 |

Reserved |

Off |

4 |

Reserved |

Off |

5* |

Password disabled |

Off |

6* |

Reset configuration |

Off |

7 |

Reserved |

Off |

8 |

Reserved |

Off |

*To access redundant ROM, set S1, S5, and S6 to ON.

Component identification 10

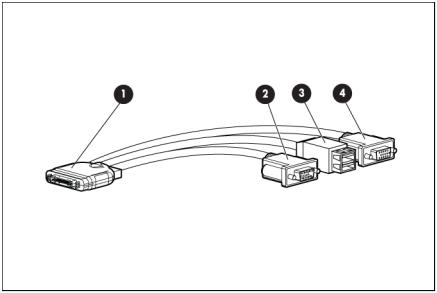

HP c-Class Blade SUV Cable

Item |

Connector |

Description |

|

|

|

1 |

Server blade |

For connecting to the SUV connector on the |

|

|

server blade front panel |

2 |

Video |

For connecting a video monitor |

3 |

USB |

For connecting up to two USB devices |

4 |

Serial |

For trained personnel to connect a null modem |

|

|

serial cable and perform advanced diagnostic |

|

|

procedures |

|

|

|

Component identification 11

Operations

Power up the server blade

The Onboard Administrator initiates an automatic power-up sequence when the server blade is installed. If the default setting is changed, use one of the following methods to power up the server blade:

•Use a virtual power button selection through iLO 3.

•Press and release the Power On/Standby button.

When the server blade goes from the standby mode to the full power mode, the system power LED changes from amber to green.

For more information about the Onboard Administrator, see the enclosure setup and installation guide on the HP website (http://www.hp.com/support).

For more information about iLO 3, see "Integrated Lights-Out 3 technology (on page 59)."

Power down the server blade

Before powering down the server blade for any upgrade or maintenance procedures, perform a backup of critical server data and programs.

Depending on the Onboard Administrator configuration, use one of the following methods to power down the server blade:

•Use a virtual power button selection through iLO 3.

This method initiates a controlled remote shutdown of applications and the OS before the server blade enters standby mode.

•Press and release the Power On/Standby button.

This method initiates a controlled shutdown of applications and the OS before the server blade enters standby mode.

•Press and hold the Power On/Standby button for more than 4 seconds to force the server blade to enter standby mode.

This method forces the server blade to enter standby mode without properly exiting applications and the OS. It provides an emergency shutdown method if an application stops responding.

•Execute one of the following commands using the Onboard Administrator CLI: poweroff server [bay number]

or

poweroff server [bay number] force

The first command initiates a controlled shutdown of applications and the OS before the server blade enters standby mode. The second form of the command forces the server blade to enter standby mode without exiting applications and the OS. This emergency method forces a shutdown if an application stops responding.

•Use the Onboard Administrator GUI to initiate a shutdown:

Operations 12

a.Select the Enclosure Information tab, and then select the Overall checkbox in the Device Bays item.

b.Initiate a shutdown from the Virtual Power menu:

—Select Momentary Press to initiate a controlled shutdown of applications and the OS.

—Select Press and Hold to initiate an emergency shutdown of applications and the OS.

IMPORTANT: When the server blade is in standby mode, auxiliary power is still being provided. To remove all power from the server blade, remove the server blade from the enclosure.

After initiating a virtual power down command, be sure that the server blade is in standby mode by observing that the system power LED is amber.

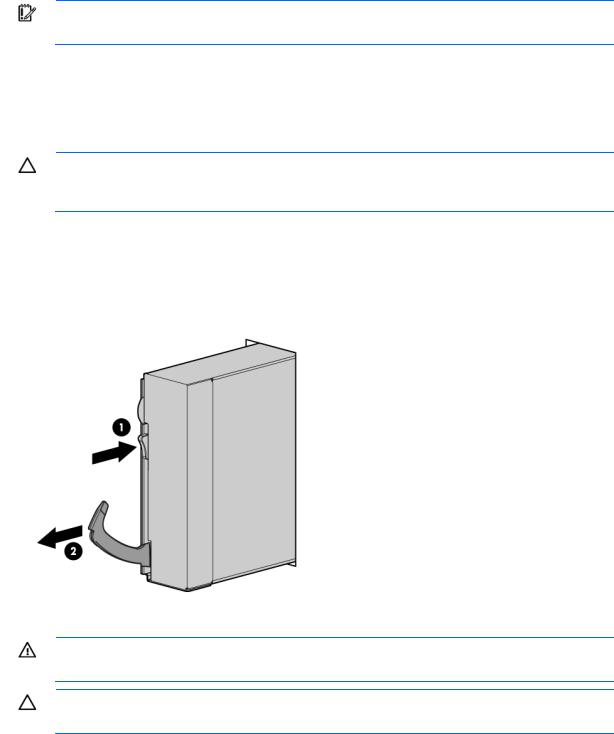

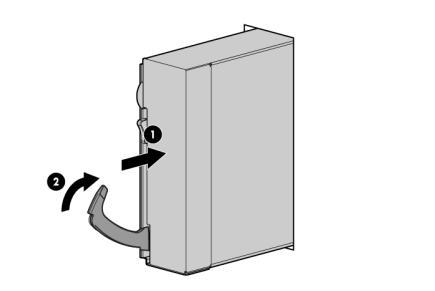

Remove the server blade

CAUTION: Do not use the server blade release lever to lift or carry the server blade. Always support the weight of the server blade by handling the chassis directly. Improper use can damage the release lever and the server blade.

To remove the component:

1.Identify the proper server blade.

2.Power down the server blade (on page 12).

3.Remove the server blade.

4.Place the server blade on a flat, level work surface.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server blade before beginning any installation procedure. Improper grounding can cause ESD.

Operations 13

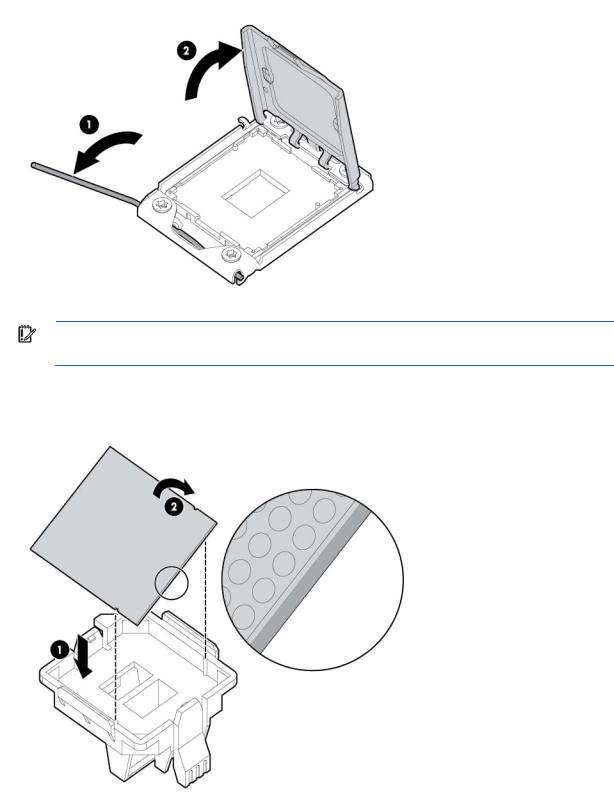

Remove the access panel

To remove the component:

1.Power down the server blade (on page 12).

2.Remove the server blade (on page 13).

3.Lift the access panel latch and slide the access panel to the rear.

4.Remove the access panel.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server blade before beginning any installation procedure. Improper grounding can cause ESD.

Install the access panel

1.Place the access panel on top of the server blade with the hood latch open. Allow the panel to extend past the rear of the server blade approximately 0.8 cm (0.2 in).

2.Engage the anchoring pin with the corresponding hole in the latch.

3.Push down on the hood latch. The access panel slides to a closed position.

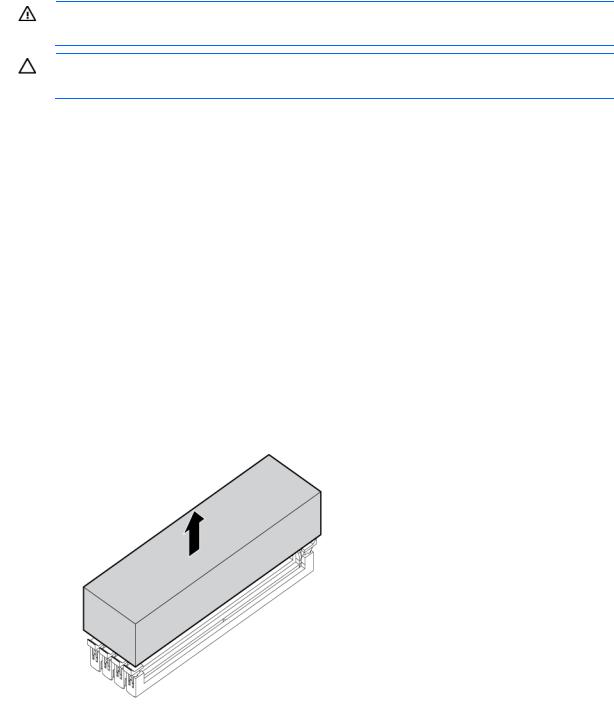

Remove the DIMM baffle

To remove the component:

1.Power down the server blade (on page 12).

2.Remove the server blade (on page 13).

3.Remove the access panel (on page 14).

4.Remove the DIMM baffle.

Operations 14

Setup

Overview

Installation of a server blade requires the following steps:

1.Install and configure an HP BladeSystem c-Class enclosure.

2.Install any server blade options.

3.Install interconnect modules in the enclosure.

4.Connect the interconnect modules to the network.

5.Install a server blade.

6.Complete the server blade configuration.

For definitions of the acronyms used in this document, refer to "Acronyms and abbreviations" in the server blade user guide.

Installing an HP BladeSystem c-Class enclosure

Before performing any server blade-specific procedures, install an HP BladeSystem c-Class enclosure.

The most current documentation for server blades and other HP BladeSystem components is available at the HP website (http://www.hp.com/go/bladesystem/documentation).

Documentation is also available in the following locations:

•Documentation CD that ships with the enclosure

•HP Business Support Center website (http://www.hp.com/support)

Installing server blade options

Before installing and initializing the server blade, install any server blade options, such as an additional processor, hard drive, or mezzanine card.

Installing interconnect modules

For specific steps to install interconnect modules, see the documentation that ships with the interconnect module.

Setup 15

Interconnect bay numbering and device mapping

•HP BladeSystem c7000 Enclosure

To support network connections for specific signals, install an interconnect module in the bay corresponding to the embedded NIC or mezzanine signals.

Server blade signal |

Interconnect bay |

Interconnect bay labels |

Flex adapter 1 |

1 |

|

(embedded) |

|

|

Flex adapter 2 |

2 |

|

(embedded) |

|

|

Mezzanine 1 |

3 and 4 |

|

Mezzanine 2 |

5 and 6 |

|

|

||

|

7 and 8 |

|

|

|

|

|

|

|

For detailed port mapping information, see the HP BladeSystem enclosure installation poster or the HP BladeSystem enclosure setup and installation guide on the HP website (http://www.hp.com/go/bladesystem/documentation).

Setup 16

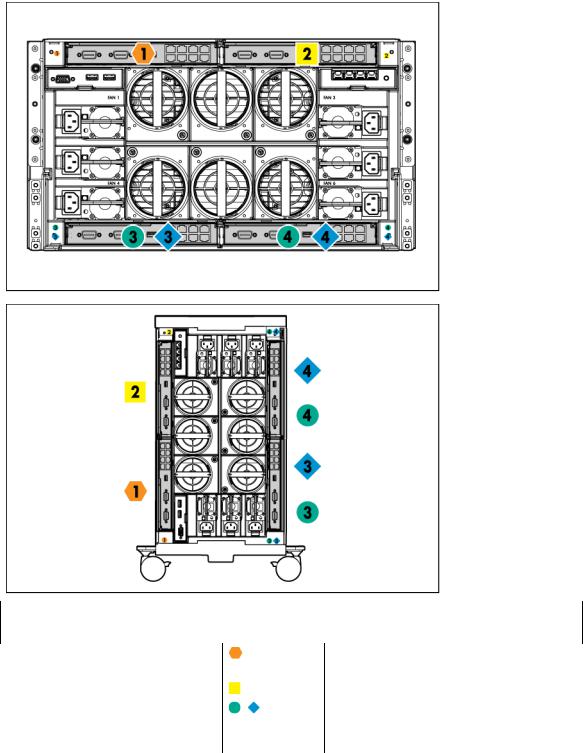

•HP BladeSystem c3000 Enclosure and Tower Enclosure

Server blade signal |

Interconnect |

Interconnect |

Notes |

|

bay number |

bay label |

|

|

|

|

|

Flex adapter 1, 2 |

1 |

(embedded) |

|

Mezzanine 1 |

2 |

Mezzanine 2 |

3 and 4 |

|

|

—

Four port cards connect to bay 2.

•Four port cards

•Ports 1 and 3 connect to bay 3.

•Ports 2 and 4 connect to bay 4.

•

Setup 17

Connecting to the network

To connect the HP BladeSystem to a network, each enclosure must be configured with network interconnect devices to manage signals between the server blades and the external network.

Two types of interconnect modules are available for HP BladeSystem c-Class enclosures: Pass-Thru modules and switch modules. For more information about interconnect module options, see the HP website (http://www.hp.com/go/bladesystem/interconnects).

IMPORTANT: To connect to a network with a Pass-Thru module, always connect the Pass-Thru module to a network device that supports Gigabit speed.

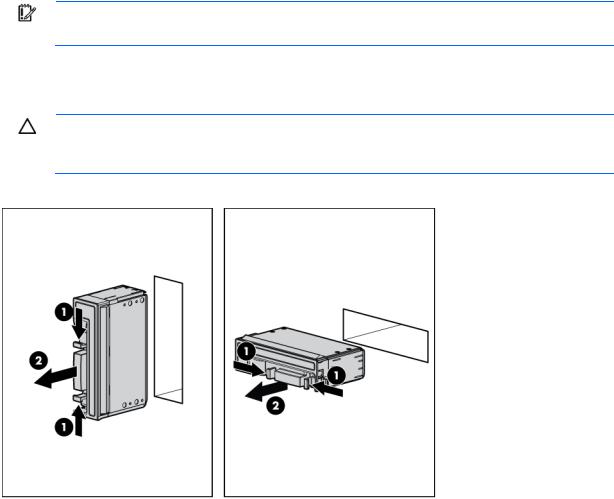

Installing a server blade

CAUTION: To prevent improper cooling and thermal damage, do not operate the server blade or the enclosure unless all hard drive and device bays are populated with either a component or

ablank.

1.Remove the device bay blank.

Setup 18

2.Remove the enclosure connector cover.

3.Prepare the server blade for installation.

Setup 19

4.Install the server blade.

Setup 20

Hardware options installation

Introduction

If more than one option is being installed, read the installation instructions for all the hardware options and identify similar steps to streamline the installation process.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system components to cool before touching them.

CAUTION: To prevent damage to electrical components, properly ground the server before beginning any installation procedure. Improper grounding can cause electrostatic discharge.

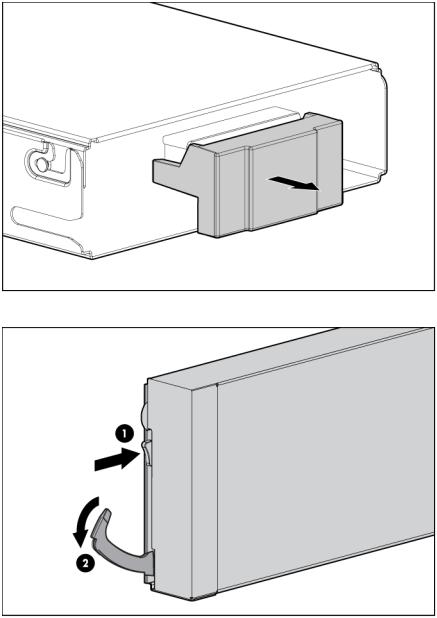

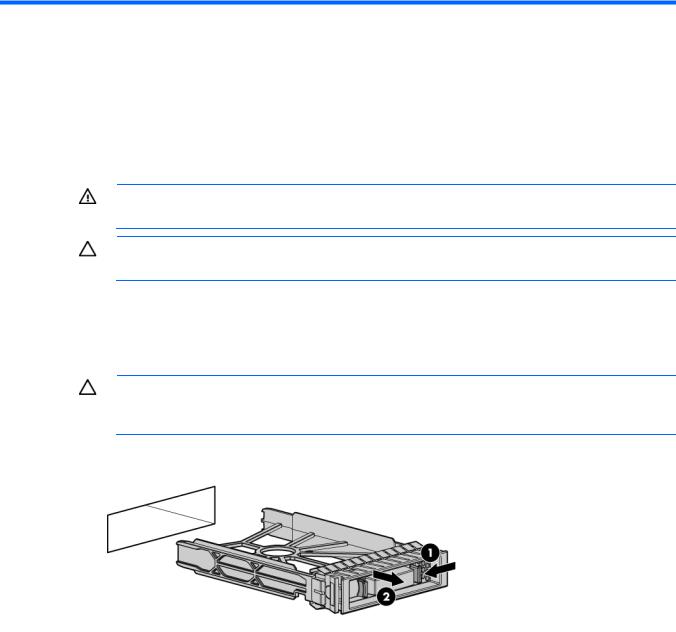

Hard drive option

The server blade supports up to two SAS or SATA drives.

CAUTION: To prevent improper cooling and thermal damage, do not operate the server blade or the enclosure unless all hard drive and device bays are populated with either a component or

ablank.

1.Remove the SAS hard drive blank.

Hardware options installation 21

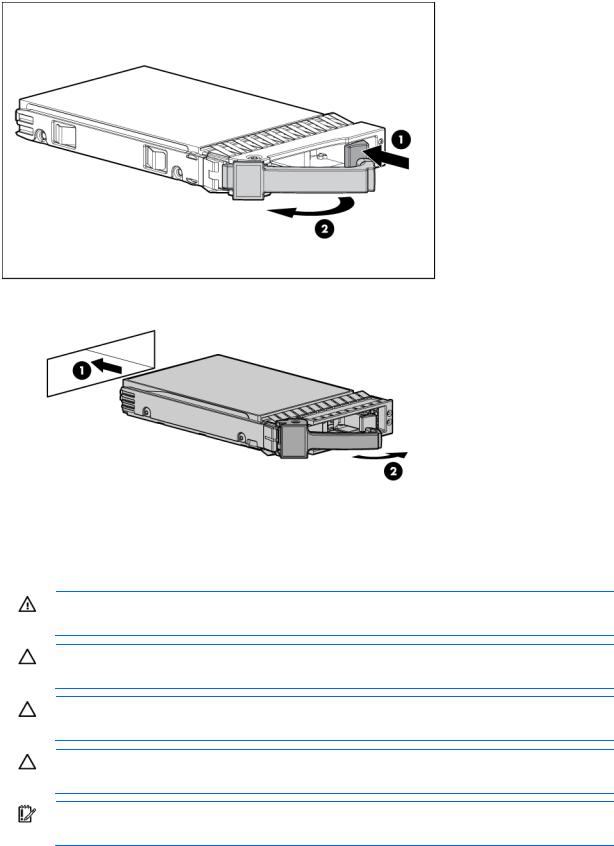

2.Prepare the hard drive.

3.Install the hard drive.

4.Determine the status of the hard drive from the hot-plug SAS hard drive LED combinations ("SAS and SATA hard drive LED combinations" on page 8).

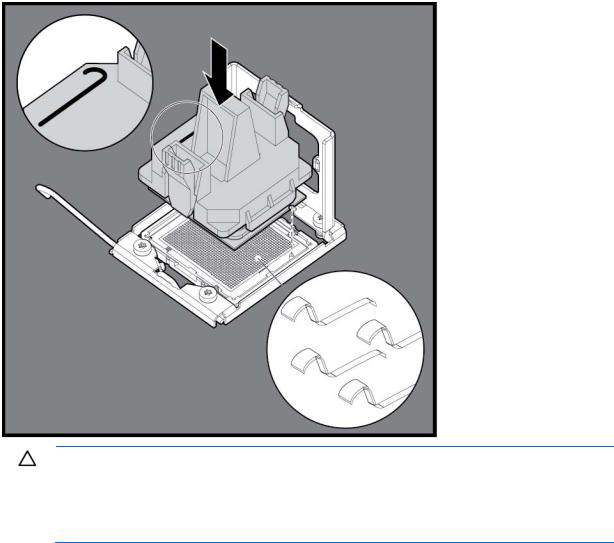

Processor option

WARNING: To reduce the risk of personal injury from hot surfaces, allow the drives and the internal system components to cool before touching them.

CAUTION: To prevent possible server blade malfunction and damage to the equipment, multiprocessor configurations must contain processors with the same part number.

CAUTION: To prevent possible server blade overheating, always populate processor socket 2 with a processor and a heatsink or a processor socket cover and a heatsink blank.

CAUTION: The heatsink thermal interface media is not reusable and must be replaced if the heatsink is removed from the processor after it has been installed.

IMPORTANT: When installing the heatsink, align the guide pins on the processor retention bracket with the alignment holes in the heatsink.

Hardware options installation 22

IMPORTANT: Processor socket 1 must always be populated. If processor socket 1 is empty, the server blade does not power up.

To install the component:

1.Update the system ROM using any standard ROM flash mechanism.

2.Power down the server blade (on page 12).

3.Remove the server blade (on page 13).

4.Remove the access panel (on page 14).

5.Remove all DIMM baffles ("Remove the DIMM baffle" on page 14).

6.Remove the heatsink blank. Retain the heatsink blank for future use.

CAUTION: Failure to completely open the processor locking lever prevents the processor from seating during installation, leading to hardware damage.

Hardware options installation 23

7.Open the processor locking lever and the processor socket retaining bracket. Do not remove the processor socket cover.

IMPORTANT: Be sure the processor remains inside the processor installation tool.

8.If the processor has separated from the installation tool, carefully re-insert the processor in the tool. Handle the processor by the edges only, and do not touch the bottom of the processor, especially the contact area.

Hardware options installation 24

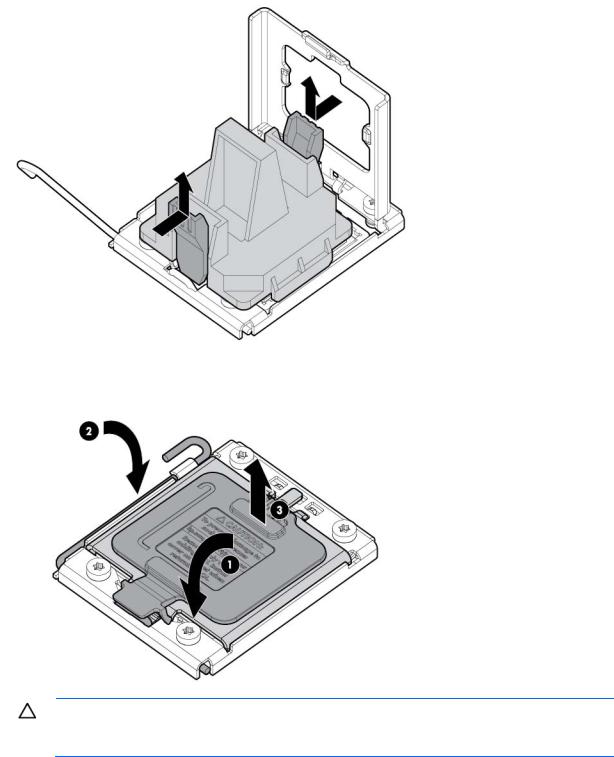

9.Align the processor installation tool with the socket, and then install the processor. THE PINS ON THE SYSTEM BOARD ARE VERY FRAGILE AND EASILY DAMAGED.

CAUTION: THE PINS ON THE SYSTEM BOARD ARE VERY FRAGILE AND EASILY DAMAGED. To avoid damage to the system board:

•Never install or remove a processor without using the processor installation tool.

•Do not touch the processor socket contacts.

•Do not tilt or slide the processor when lowering the processor into the socket.

Hardware options installation 25

10.Press the tabs on the processor installation tool to separate it from the processor, and then remove the tool.

11.Close the processor socket retaining bracket and the processor locking lever. The processor socket cover is automatically ejected. Remove the cover.

CAUTION: Be sure to close the processor socket retaining bracket before closing the processor locking lever. The lever should close without resistance. Forcing the lever closed can damage the processor and socket, requiring system board replacement.

Hardware options installation 26

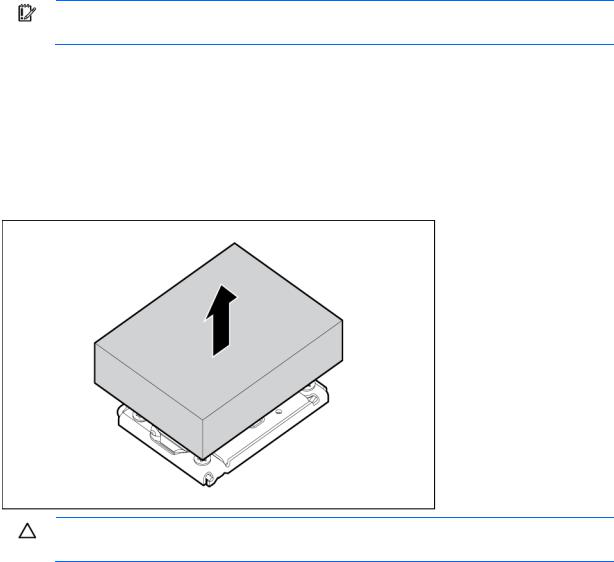

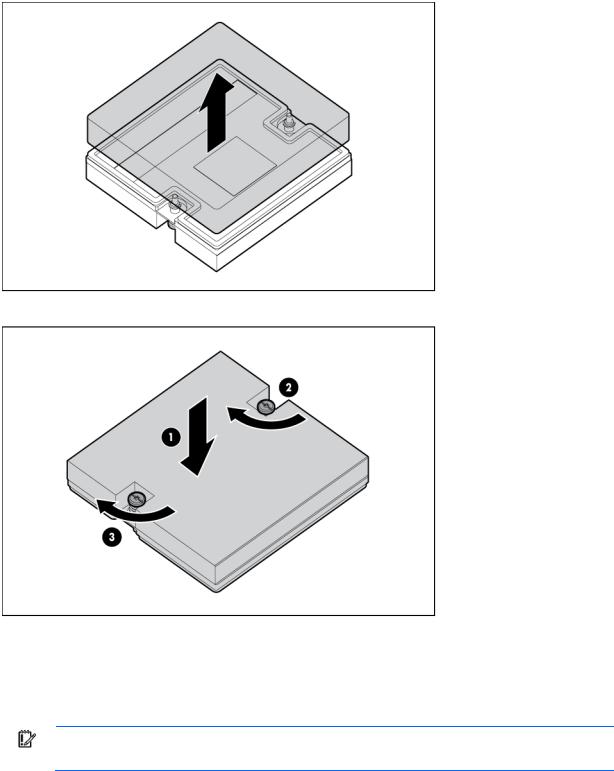

12. Remove the thermal interface protective cover from the heatsink.

13. Align and install the heatsink. Alternate tightening the screws until the heatsink is seated properly.

14.Install all DIMM baffles.

15.Install the access panel (on page 14).

Memory options

IMPORTANT: This server blade does not support mixing RDIMMs and UDIMMs. Attempting to mix these two types causes the server to halt during BIOS initialization.

The memory subsystem in this server blade can support RDIMMs or UDIMMs. Both types are referred to as DIMMs when the information applies to both types. When specified as RDIMM or UDIMM, the information applies to that type only. All memory installed in the server blade must be the same type.

The server blade supports the following DIMM speeds:

Hardware options installation 27

•Singleand dual-rank PC3-10600 (DDR-1333) DIMMs operating at 1333 and 1066 MHz

•Quad-rank PC3-8500 (DDR-1066) DIMMs operating at 1066 MHz

Depending on the processor model, the number of DIMMs installed, and whether UDIMMs or RDIMMs are installed, the memory clock speed may be reduced to 1066 or 800 MHz. For more information on the effect of DIMM slot population, see "General DIMM slot population guidelines (on page 31)."

Memory subsystem architecture

The memory subsystem in this server blade is divided into channels. Each processor supports three channels, and each channel supports two DIMM slots, as shown in the following table.

Channel |

Slot |

Slot number |

|

|

|

1 |

D |

1 |

|

A |

2 |

2 |

E |

3 |

|

B |

4 |

|

|

|

3 |

F |

5 |

|

C |

6 |

|

|

|

This multi-channel architecture provides enhanced performance in Advanced ECC mode. This architecture also enables the Mirrored Memory and Lockstep memory modes. This server blade supports both Registered PC3 DIMMs (RDIMMs) and Unbuffered DIMMs (UDIMMs).

DIMM slots in this server are identified by number and by letter. Letters identify the slots to populate for specific AMP modes. Slot numbers are reported by ROM messages during boot and for error reporting.

Single-, dual-, and quad-rank DIMMs

To understand and configure memory protection modes properly, an understanding of single-, dual-, and quad-rank DIMMs is helpful. Some DIMM configuration requirements are based on these classifications.

A single-rank DIMM has one set of memory chips that is accessed while writing to or reading from the memory. A dual-rank DIMM is similar to having two single-rank DIMMs on the same module, with only one rank accessible at a time. A quad-rank DIMM is, effectively, two dual-rank DIMMs on the same module. Only one rank is accessible at a time. The server blade memory control subsystem selects the proper rank within the DIMM when writing to or reading from the DIMM.

Dualand quad-rank DIMMs provide the greatest capacity with the existing memory technology. For example, if current DRAM technology supports 2-GB single-rank DIMMs, a dual-rank DIMM would be 4-GB, and a quad-rank DIMM would be 8-GB.

Low voltage DIMMs

Low Voltage DDR3 DIMMs operate at a lower voltage (1.35V) than standard voltage DDR3 DIMMs (1.5V), and therefore consume less power. However, LVDIMMs are configured to operated at standard voltage levels (1.5V) under the following conditions:

•If LVDIMMs are mixed with standard DDR3 DIMMs on the same server, the LVDIMMs operate at 1.5V.

•If there are two dual-rank LVDIMMs per channel on any populated memory channel in the system running at 1333 MHz, the LVDIMMs operate at 1.5V.

Hardware options installation 28

This setting preserves maximum memory subsystem performance. To have DIMMs operate at 1.35V, configure the Maximum Memory Bus Frequency option in the ROM-Based Setup Utility to 1066 MHz.

•If there is one quad-rank LVDIMM per channel on any populated memory channel in the system running at 1066 MHz, the LVDIMMs operate at 1.5V.

This setting preserves maximum memory subsystem performance. To have DIMMs operate at 1.35V, configure the Maximum Memory Bus Frequency option in the ROM-Based Setup Utility to 800 MHz.

LVDIMMs are only supported for use with the Intel® Xeon® 5600 series of processors.

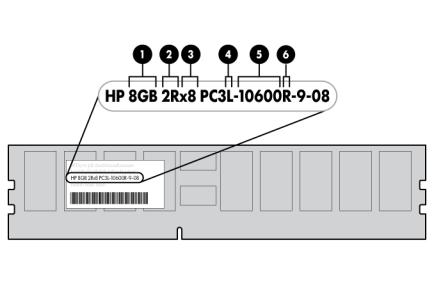

DIMM identification

To determine DIMM characteristics, use the label attached to the DIMM and the following illustration and table.

Item |

Description |

Definition |

|

|

|

|

|

1 |

Size |

— |

|

2 |

Rank |

1R |

= Single-rank |

|

|

2R |

= Dual-rank |

|

|

4R |

= Quad-rank |

|

|

|

|

3 |

Data width |

x4 = 4-bit |

|

|

|

x8 = 8-bit |

|

4 |

Voltage rating |

L = Low voltage (1.35v) |

|

|

|

Blank or omitted = Standard |

|

|

|

|

|

5 |

Memory speed |

10600 = 1333-MHz |

|

|

|

8500 = 1066-MHz |

|

|

|

|

|

6 |

DIMM type |

R = RDIMM (registered) |

|

|

|

E = UDIMM (unbuffered with ECC) |

|

|

|

|

|

For the latest supported memory information, see the QuickSpecs on the HP website (http://www.hp.com).

Hardware options installation 29

Memory configurations

To optimize server blade availability, the server blade supports the following AMP modes:

•Advanced ECC—provides the greatest memory capacity for a given DIMM size, while providing up to 4-bit error correction. This mode is the default option for this server blade.

•Lockstep—provides enhanced protection over Advanced ECC mode while continuing to make all installed memory available to the operating system. The server blade can continue to function if a singleor mulit-bit memory failure within a single DRAM device occurs.

•Online spare memory—provides protection against failing or degraded DIMMs. Certain memory is reserved as spare, and automatic failover to spare memory occurs when the system detects a DIMM that is degrading and receiving a high rate of correctable memory errors. This allows DIMMs that have a higher probability of receiving an uncorrectable memory error (which would result in system downtime) to be removed from operation.

•Mirrored Memory—provides maximum protection against failed DIMMs. Uncorrectable errors in one channel are corrected by the mirror channel.

Advanced Memory Protection options are configured in RBSU. If the requested AMP mode is not supported by the installed DIMM configuration, the server blade boots in Advanced ECC mode. For more information, see "HP ROM-Based Setup Utility (on page 55)."

For the latest memory configuration information, see the QuickSpecs on the HP website (http://www.hp.com).

RDIMM maximum memory configurations

The server blade supports a maximum of 96 GB of memory with one processor (6 x 16 GB), or 192 GB of memory with two processors (12 x 16 GB).

UDIMM maximum memory configurations

The server blade supports a maximum of 24 GB of memory with one processor and 48 GB of memory with two processors using 4-GB dual-rank UDIMMs.

Advanced ECC memory configuration

Advanced ECC memory is the default memory protection mode for this server blade. Standard ECC can correct single-bit memory errors and detect multi-bit memory errors. When multi-bit errors are detected using Standard ECC, the error is signaled to the server blade and causes the server blade to halt.

Advanced ECC protects the server blade against some multi-bit memory errors. Advanced ECC can correct both single-bit memory errors and 4-bit memory errors if all failed bits are on the same DRAM device on the DIMM.

Advanced ECC provides additional protection over Standard ECC because it is possible to correct certain memory errors that would otherwise be uncorrected and result in a server blade failure. The server blade provides notification that correctable error events have exceeded a pre-defined threshold rate.

Hardware options installation 30

Loading...

Loading...