Honeywell L6064A User Manual

L6064A

Universal Two Speed Fan and Limit Controllers

PRODUCT DATA

APPLICATION

These combination warm air fan and limit controllers

are suitable for all types of forced air heating systems.

The controllers have 2 switches with 3 individually adjustable set points. One switch opens the limit circuit if

the plenum temperature exceeds the preset safety limit;

most models reset automatically. The other switch

changes fan speeds. On all the L6064 the fan speed is

switched from low to high and vice versa according to

the plenum temperature. The fan speed is switched to

low if the plenum temperature falls below the fan off set

point. All the L6064 models are intended for use with

conventional warm air systems.

All models may be used as limit controls by wiring only

the limit side.

Limit controls are suitable for line voltage, low voltage, or millivoltage circuits.

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Follow furnace or burner manufacturer’s instructions, if available. Do not exceed the ratings and limitations given in this section.

ELECTRICAL RATINGS:

NOTE: The electrical rating is at maximum case tem-

perature of 88

O

C (190OF). Use high temperature insulating material, or a mounting bracket when mounting

surface temperature exceeds 88OC (190OF).

CAUTION

!

1. Disconnect power supply before beginning installation to prevent electrical shock or equipment

damage.

2. When connecting cable or conduit to control,

avoid straining the control case.

LOCATION

If this is a replacement installation, locate the

L6064 in the same location as the control being replaced. The L6064 sensing tube length should be

the same as the old control. If this is a new installation, the element should be installed only by a

trained, experienced service technician according

to the furnace manufacturer’s instructions. The element must not touch any internal part of the furnace.

MOUNTING

The device may be mounted as follows:

All models -- Surface or Bracket.

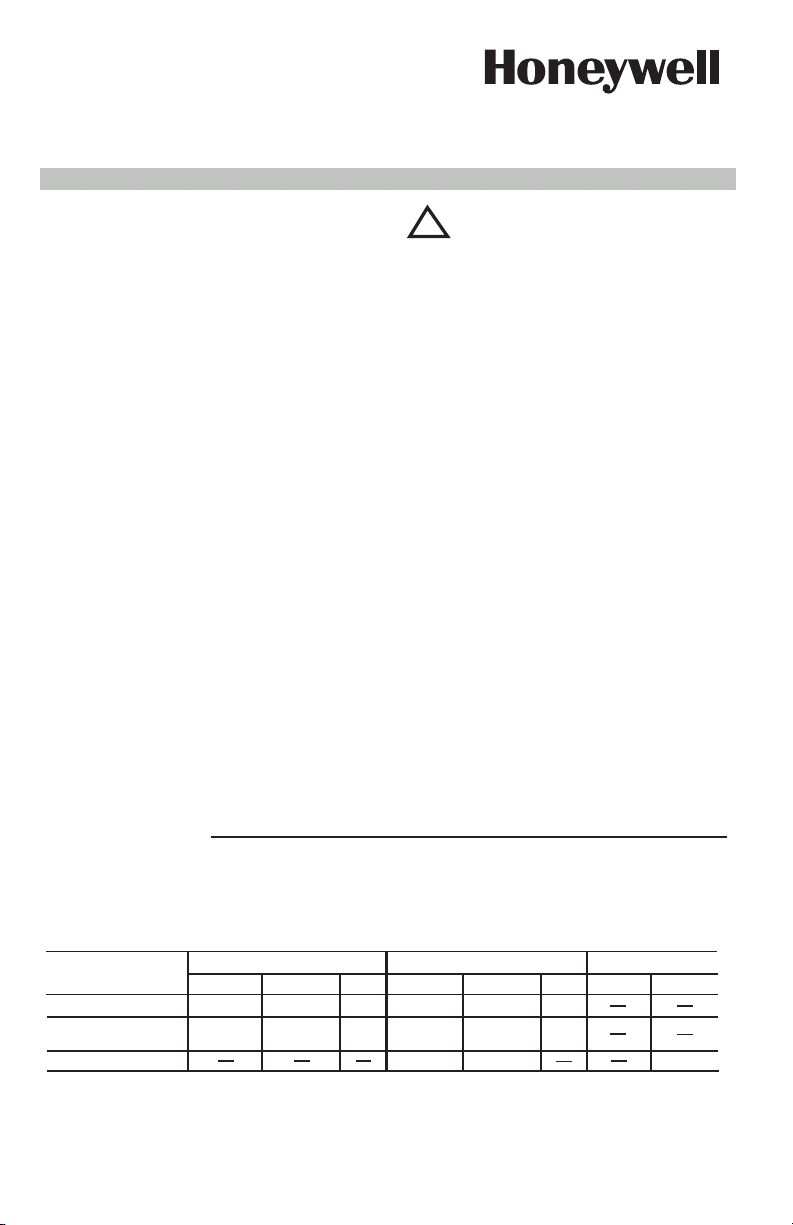

SURFACE MOUNTING

Hole in plenum should be just large enough to

accommodate the 20 mm (3/4 in.) diameter element

tube.

1. Remove cover by squeezing sides and pulling

off. Insert element in plenum and mark location of

mounting holes. Make sure the case is snug against

the plenum before marking the mounting holes.

2. Punch or drill holes for mounting screws.

3. Place insulation between plenum and case if

necessary, or use a mounting bracket.

4. Fasten controller securely with mounting

screws.

90OC field wiring may be required.

NOTE: For applications under DIN or BEAB jurisdiction ambient temperatures must not exceed

O

70

C (158OF).

FAN

24 Vac

LIMIT

2

Full Load (Amps)

Locked Rotor

(Amps)

Max. Amp.

FAN LOW

6 14

120 Vac 240 Vac

FAN HIGH

LIMIT

FAN LOW

8

48

84

FAN HIGH

3

LIMIT

4

7

42

24

Pilot Duty: 2 A at 24 Vac; 0.25 to 12 Vdc. (Limit)

Maximum Combined Connected Load: 2000 VA. ac. Load capacity at terminal points must not exceed the rated

capacity of connected wire at its rated insulation temperature. 75

O

C minimum field wiring is required.

FURNACE

MA

T

RIAU

THERMO-ISOLANT

SI N

CESSAIRE

PL

NUM DE

L’APP

AREIL

DE

CHAUFF

AGE

2697C

!

VIS DE MONT

AGE

APPAREIL

DE

CHAUFF

AGE

PL NUM

SUPPORT RIGIDE

50

100

150

200

250

ON/OFF

FAN LIMIT

FAN

LIMIT

BORNES-

PRESSION POUR

CONDUCTEURS

STANDARDS

(4)

PRISE FEMELLE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE M LE DE

6,4 MM (1/4 PO)

(4)

PROTØGE-FILS

POUR RETIRER UN

CONDUCTEUR

STANDARD,

POUSSER AVEC UN

TOURNE-VIS ET

TIRER LE FIL

CONDUCTEUR

STANDARD DE

COMMANDE

D’ QUIPEMENT

CONDUCTEUR AVEC

BORNE ¸ COSSE M LE

DE 6,4 MM (1/4 PO)

(POUSSER LA COSSE AU

FOND DE LA CAVIT .)

Low

CONNECTEUR

M LE RAPIDE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE FEMELLE

DE 6,4 MM (1/4 PO)

CONDUCTEUR

AVEC BORNE

EMBROCHABLE

M LE DE 6,4 MM

(1/4 PO) (POUSSER

LA COSSE AU FOND

DE LA CAVIT .)

LOAD

LINE

HIGH LINE

STRIPE GAUGE

ERS

BORNE-PRESSION

VERROUILLABLE

ORIFICE

POUR FIL

PLENUM

HEAT

INSULATING

MATERIAL IF

NEEDED

2697C

Fig. 1 - Surface mounting L6064. Requires hole

20 mm (3/4 in.) diameter in the plenum.

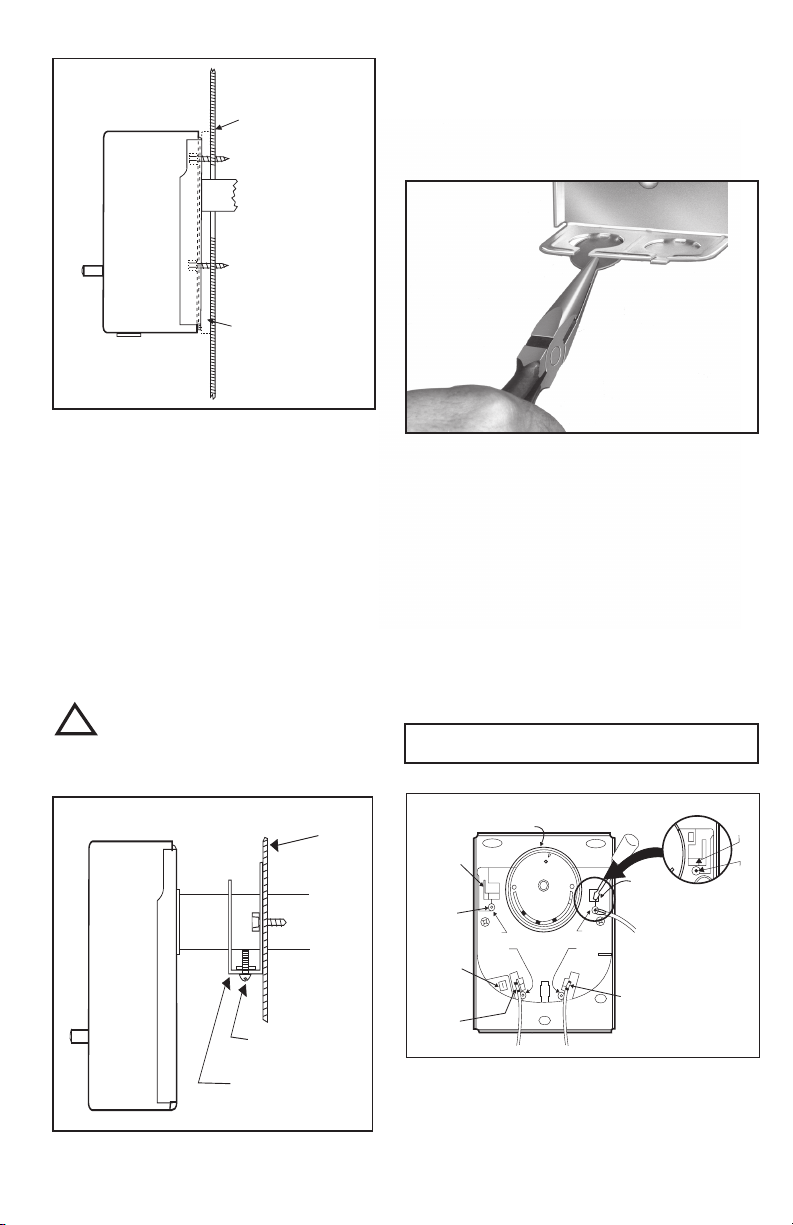

RIGID BRACKET MOUNTING

All models of the L6064 may be mounted using a

rigid bracket. The rigid bracket requires a hole 20

mm (3/4 in.) diameter for mounting.

1. Use bracket as a template to mark the location

of mounting holes in plenum. Drill or punch holes for

mounting screws.

2. Fasten bracket in place with screws furnished.

Tighten the screws securely.

3. Insert element tube through bracket, straighten

controller, and fasten by tightening setscrew.

WARNING

!

Be sure screw strikes tube frame and does not strike

inner sensing element.

WIRING

Disconnect power supply before beginning installation

to prevent electrical shock and equipment damage.

All wiring must comply with local electrical codes and

ordinances. See Fig. 5 for typical hookups.

1. To remove the slotted knockouts, bend down and

break off with a long hose pliers. See Fig. 3.

Fig. 3 - Removing slotted knockouts.

2. Pass wires through bushing before connecting.

3. Connect wire to push-in terminals, and insert the

bushing into knockout slot.

PUSH-IN TERMINALS

1. No. 14, 16, or 18 solid or No. 14 or 16 fused stranded

wire may be connected to the terminals.

2. Strip insulation from wires the distance shown by

the strip guage on the controller.

3. Solid or solder dipped wire may be inserted by pushing into the terminal holes. If stranded wire is used, insert a small screwdriver into the slot next to the terminal. Push in and hold while inserting wire in terminal.

Then remove screwdriver.

All wires must be clear of rotating scaleplate.

IMPORTANT

RIGID BRACKET

SETSCREW

Fig. 2 - Rigid bracket mounting requires a hole 20

mm (3/4 in.) diameter for mounting.

FURNACE

PLENUM

FEMALE

RECEPTACLE FOR

CONNECTION OF

6.4MM (1/4 ") MALE

FLAG TERMINAL

(4)

STANDARD

WIRE PUSH IN

CONNECTORS

(4)

MALE

QUICKCONNECT

FOR CONNECTION

OF 6.4MM (1/4")

FEMALE FLAG

TERMINAL

LEADWIRE WITH

1/4 IN. (6.4MM)

MALE FLAG

TERMINAL (FORCE

FLAG TO BOTTOM

OF CAVITY)

WIRING GUARD

50

FAN LIMIT

ON/OFF

100

200

150

LINE

FAN

HIGH LINE

Low

250

LOAD

LIMIT

STRIPE GAUGE

ERS

TO RELEASE

STANDARD WIRE -

PUSH SCREW

DRIVER IN AND PULL

WIRE OUT

STANDARD

WIRE TO

CONTROLLED

EQUIPMENT

LEADWIRE WITH 1/4 IN.

(6.4 MM) MALE SPADE

TERMINAL (FORCE

FLAG TO BOTTOM OF

CAVITY)

Fig. 4 - Internal view of L6064 showing use of

screwdriver to connect or disconnect

wires at push-in terminals.

NOTE: Because the dial turns when the

element temperature changes, the lettering

on the dial may not be horizontal.

2

PUSH-IN

LOCK

TERMINAL

HOLE

FOR WIRE

A

L6064

LIMIT

FAN

SIDE

SIDE

(HOT)

L1

1

L2

LOW SPEED

HIGH SPEED

L1

(HOT)

2

1

ADD DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED

TO CONTROL LOW VOLTAGE EQUIPMENT

2

1

L2

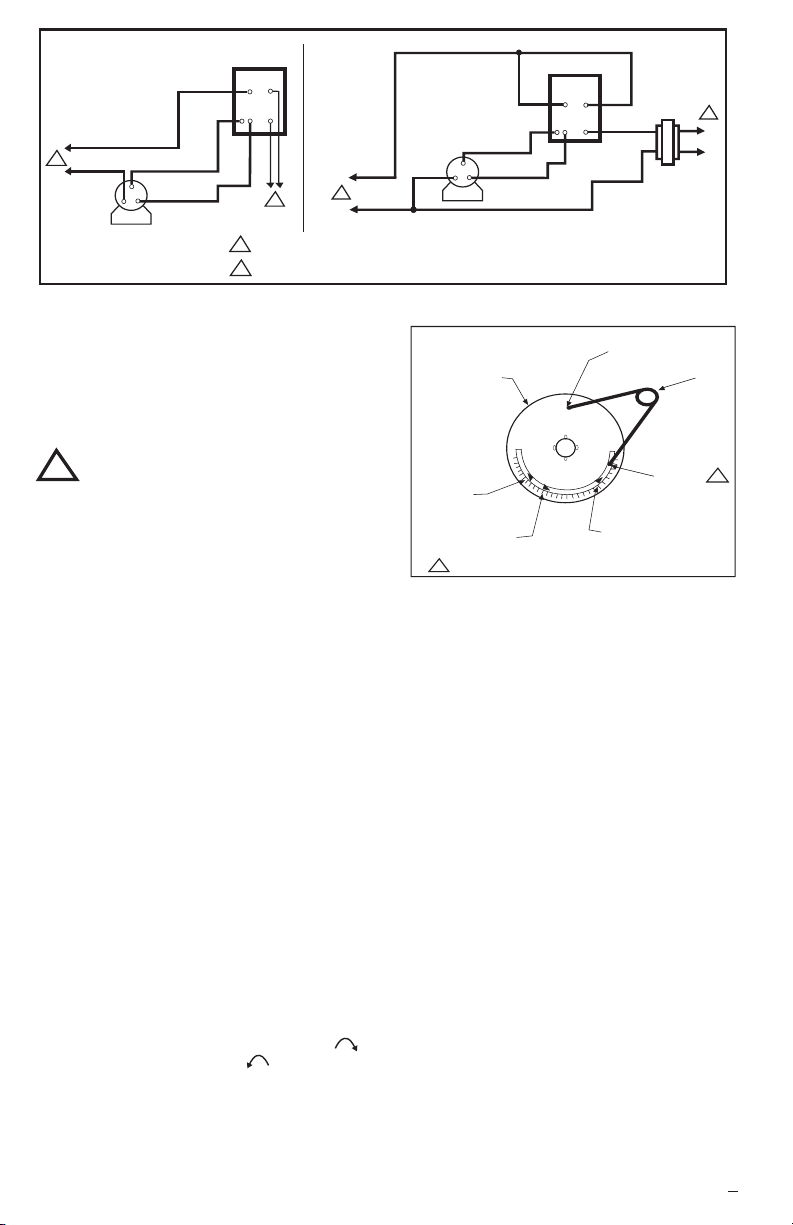

Fig. 5 - A: Limit in low voltage circuit.

B: Limit in line voltage circuit.

OPERATION

During normal operation, the L6064 sensing element

will rotate and close the fan switch for high speed once

plenum temperature reaches the factory-set fan on set

point.

SETTINGS AND ADJUSTMENTS

CAUTION

!

When adjusting the fan and limit setting levers, hold

the scalepale dial to keep it from turning and straining

the sensing element.

Move the setting levers to the control points recommended by the burner or furnace manufacturer. Use

gentle finger pressure.

1. Move the FAN OFF (continuous low speed) setting

lever to the temperature at which the fan is to run low

speed for continuous air circulation.

All L6064 models - FAN ON (heating fan speed) range

is from 8.3

O

C (15OF) above the FAN OFF (continuous

low speed) setting to 17OC (30OF) below the LIMIT OFF

setting.

2. Move the LIMIT setting lever to the temperature at

which the high limit switch is to break the primary control circuit.

All L6064 models - limit range is 35

O

to 250

F).

O

C to 120OC (95OF

LIMIT SETTING ADJUSTMENT

These controllers have a limit stop which prevents the

limit indicator lever from being adjusted beyond the equipment manufacturer’s specifications.

1. Push the small end of Limit Adjust Tool (196722)

through hole in scaleplate (located at caution marking) to

depress the stop disc not more than 1/16 in. (1.6 mm) to

release stop lock (Fig. 10). Stop disc is on back of

scaleplate.

2. While depressing the stop disc, insert the long end of

Limit Adjust Tool next to limit stop (Fig. 10) and move the

stop to desired setting.

If the L4064 is a replacement control, high limit stop setting should be the same as that of

the control being replaced.

(Move stop clockwise to

lower the setting, counterclockwise to raise it.) Then

remove the limit stop adjust tool.

3. Set the LIMIT OFF lever to the temperature at which

the high limit switch is to open to stop the burner. If the

high limit stop has been properly set, the LIMIT OFF lever

should be as high as the stop permits.

B

L6064

LIMIT

FAN

SIDE

SIDE

LIMIT STOP

ADJUSTABLE

LIMIT STOP

O

C)

TOOL

O

F

2

24V

1

LOW SPEED

HIGH SPEED

SCALEPLATE

CAUTION

DO NOT ROTATE - HOLD DIAL

WHEN SETTING POINTERS

50

FAN

AN

F

OFF

OFF

100

ON

FAN OFF SET

POINT LEVER

FAN ON SET

POINT LEVER

HOMEOWNER: THIS IS A "SAFETY STOP". DO NOT ALTER

1

150

L1

120V

TO RELEASE STOP,

PRESS STIFF WIRE

IN HOLE

250

200

LIMIT SET POINT LEVER

(FACTORY-SET AT 200

L2

(93

Fig. 6 - Changing the high limit stop.

CHECKOUT

Always conduct a thorough checkout immediately following completion of the installation. Operate the system

through at least one complete cycle to ensure that the system operates as intended, especially with respect to the

proper function of the limit control.

The recommended method of checking out the limit control function without disturbing any of the furnace manufacturer’s fan or limit settings is as follows:

1. To stimulate fan motor failure, a broken fan belt, or a

plugged filter, remove the belt driving the fan. On direct

drive fans disconnect the wiring to the fan motor - at the

motor terminal panel - and insulate any live conductors

which might result.

2. Turn the thermostat to the highest setting to ensure

that the burner will run continuously.

3. Watch the operation of the furnace to be sure that

the limit control shuts off the burner when the plenum temperature reaches the limit setting, and that the fan motor

continues to operate. On direct drive fans check to be

sure that voltage is evident on the disconnected leads to

the fan motor when the limit stops the burner.

4. If the installation checks out satisfactorily, replace the

fan belt-or reconnect any direct drive fan wiring-and lower

the thermostat temperature adjustment to the normal setting.

5. If the installation does not check out satisfactorily,

recheck the wiring, correct any wiring discrepancies, and

repeat items 1 through 4. If the installation cannot be made

to function properly DO NOT LEAVE THE FURNACE

OPERATIONAL, PARTICULARLY IF THE LIMIT OR FAN

CONTROLS DO NOT FUNCTION CORRECTLY. REMOVE THE FUSE IN THE CIRCUIT POWERING THE

FURNACE until assistance can be enlisted to correct the

installation.

3

95C-10617B 1

Loading...

Loading...