Hitachi SJ300 User Manual

SJ300 Series Inverter

Instruction Manual

• Three-phase Input |

200V Class |

• Three-phase Input |

400V Class |

U.S. Version Models |

European Version Models |

Manual Number: NB613XJ |

After reading this manual, |

September 2006 |

keep it handy for future reference. |

|

|

Hitachi Industrial Equipment Systems Co., Ltd.

i

SJ300 Inverter

Safety Messages

Definitions and

Symbols

For the best results with the SJ300 Series inverter, carefully read this manual and all of the warning labels attached to the inverter before installing and operating it, and follow the instructions exactly. Keep this manual handy for quick reference.

A safety instruction (message) includes a hazard alert symbol and a signal word, WARNING or CAUTION. Each signal word has the following meaning:

This symbol indicates HIGH VOLTAGE. It calls your attention to items or operations that could be dangerous to you and other persons operation this equipment. Read the message and follow the instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of two signal words: CAUTION or WARNING, as described below.

WARNING: Indicates a potentially hazardous situation that, if not avoided, can result in serious injury or death.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, can result in minor to moderate injury, or serious damage to the product. The situation described in the CAUTION may, if not avoided, lead to serious results. Important safety measures are described in CAUTION (as well as WARNING), so be sure to observe them.

STEP: A step is one of a series of action steps required to accomplish a goal. The

number of the step will be contained in the step symbol.

number of the step will be contained in the step symbol.

NOTE: Notes indicate an area or subject of special merit, emphasizing either the product’s capabilities or common errors in operation or maintenance.

TIP: Tips give a special instruction that can save time or provide other benefits while installing or using the product. The tip calls attention to an idea that may not be obvious to first-time users of the product.

Hazardous High Voltage

HIGH VOLTAGE: Motor control equipment and electronic controllers are connected to hazardous line voltages. When servicing drives and electronic controllers, there may be exposed components with housings or protrusions at or above line potential. Extreme care should be taken to protect against shock.

Stand on an insulating pad and make it a habit to use only one hand when checking components. Always work with another person in case an emergency occurs. Disconnect power before checking controllers or performing maintenance. Be sure equipment is properly grounded. Wear safety glasses whenever working on electronic controllers or rotating machinery.

ii

General Precautions - Read These First!

WARNING: This equipment should be installed, adjusted, and serviced by qualified electrical maintenance personnel familiar with the construction and operation of the equipment and the hazards involved. Failure to observe this precaution could result in bodily injury.

WARNING: The user is responsible for ensuring that all driven machinery, drive train mechanism not supplied by Hitachi Industrial Equipment Systems Co., Ltd., and process line material are capable of safe operation at an applied frequency of 150% of the maximum selected frequency range to the AC motor. Failure to do so can result in destruction of equipment and injury to personnel should a single-point failure occur.

WARNING: For equipment protection, install a ground leakage type breaker with a fast response circuit capable of handling large currents. The ground fault protection circuit is not designed to protect against personal injury.

HIGH VOLTAGE: HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING

POWER BEFORE WORKING ON THIS CONTROL.

WARNING: Wait at least five (5) minutes after turning OFF the input power supply before performing maintenance or an inspection. Otherwise, there is the danger of electric shock.

CAUTION: These instructions should be read and clearly understood before working on

SJ300 series equipment.

CAUTION: Proper grounds, disconnecting devices and other safety devices and their location are the responsibility of the user and are not provided by Hitachi Industrial Equipment Systems Co., Ltd.

CAUTION: Be sure to connect a motor thermal disconnect switch or overload device to the SJ300 series controller to assure that the inverter will shut down in the event of an overload or an overheated motor.

HIGH VOLTAGE: Dangerous voltage exists until power light is OFF. Wait at least 5 minutes after input power is disconnected before performing maintenance.

CAUTION: This equipment has high leakage current and must be permanently (fixed) hardwired to earth ground via two independent cables.

WARNING: Rotating shafts and above-ground electrical potentials can be hazardous. Therefore, it is strongly recommended that all electrical work conform to the National Electrical Codes and local regulations. Installation, alignment and maintenance should be performed only by qualified personnel.

Factory-recommended test procedures included in the instruction manual should be followed. Always disconnect electrical power before working on the unit.

iii

SJ300 Inverter

CAUTION:

a)Motor must be connected to protective ground via low resistive path (< 0.1Ω)

b)Any motor used must be of a suitable rating.

c)Motors may have hazardous moving parts. In this event suitable protection must be provided.

CAUTION: Alarm connection may contain hazardous live voltage even when inverter is disconnected. When removing the front cover for maintenance or inspection, confirm that incoming power for alarm connection is completely disconnected.

CAUTION: Hazardous (main) terminals for any interconnection (motor, contact breaker, filter, etc.) must be inaccessible in the final installation.

CAUTION: The end application must be in accordance with BS EN60204-1. Refer to the section “Step-by-Step Basic Installation” on page 2–6. The diagram dimensions are to be suitably amended for your application.

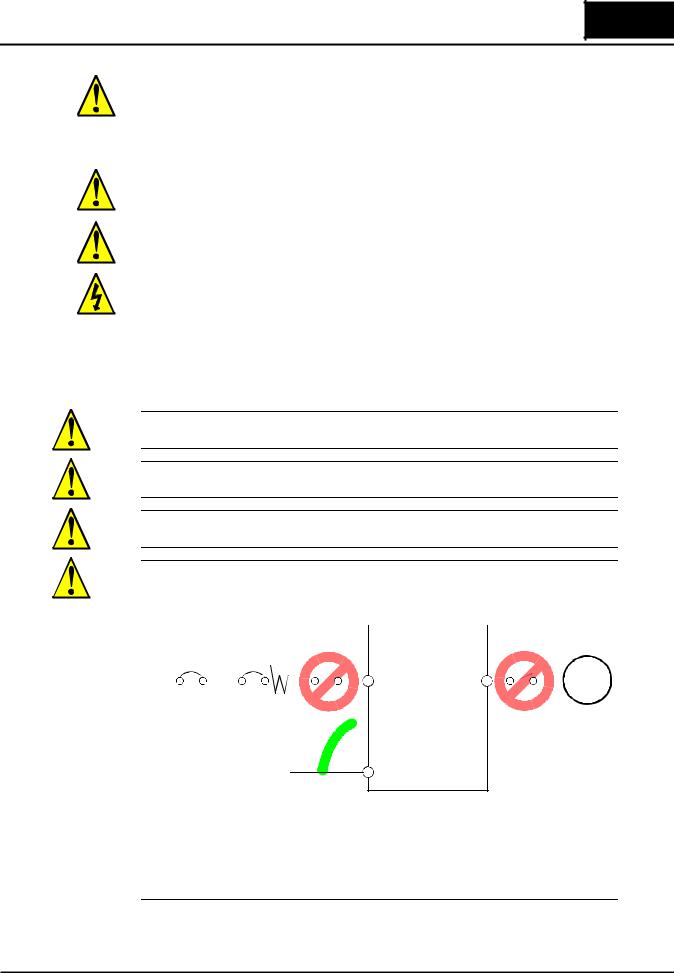

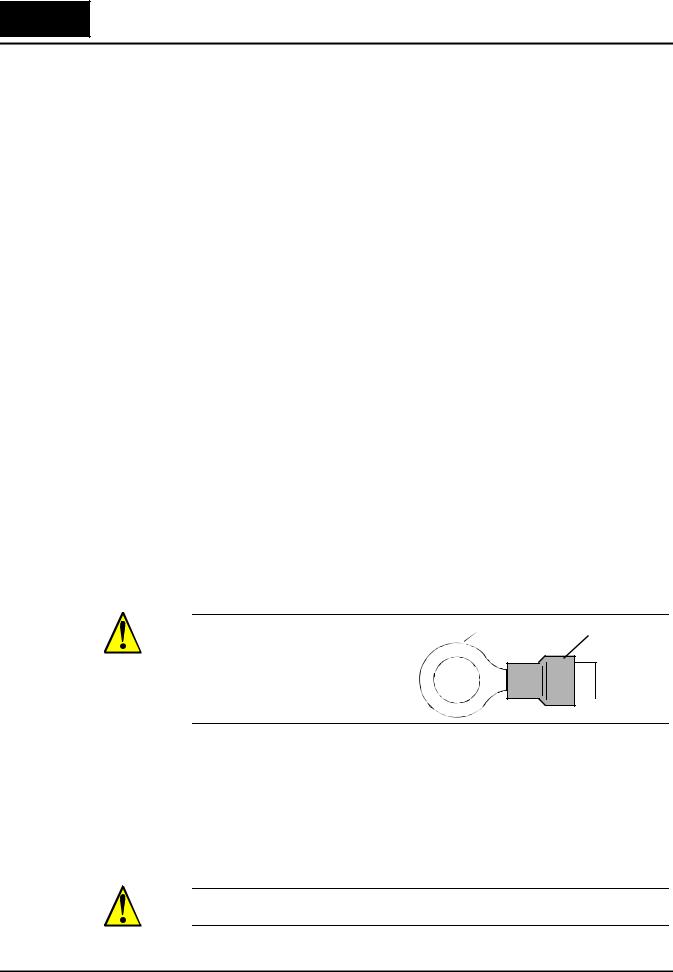

CAUTION: Connection to field wiring terminals must be reliably fixed having two independent means of mechanical support. Using a termination with cable support (figure below), or strain relief, cable clamp, etc.

Terminal (ring lug) |

Cable support |

Cable

Cable

CAUTION: A three-pole disconnection device must be fitted to the incoming main power supply close to the inverter. Additionally, a protection device meeting IEC947-1/IEC947-3 must be fitted at this point (protection device data shown in “Determining Wire and Fuse Sizes” on page 2–14).

NOTE: The above instructions, together with any other requirements are highlighted in this manual, and must be followed for continued LVD (European Low Voltage Directive) compliance.

iv

Index to Warnings and Cautions in This Manual

Installation—Cautions for Mounting Procedures

CAUTION: Be sure to install the unit on flame-resistant material such as a |

............... 2–6 |

steel plate. Otherwise, there is the danger of fire. |

|

CAUTION: Be sure not to place any flammable materials near the inverter. |

............... 2–6 |

Otherwise, there is the danger of fire. |

|

CAUTION: Be sure not to let the foreign matter enter vent openings in the |

............... 2–6 |

inverter housing, such as wire clippings, spatter from welding, metal |

|

shavings, dust, etc. Otherwise, there is the danger of fire. |

|

CAUTION: Be sure to install the inverter in a place that can bear the weight |

............... 2–6 |

according to the specifications in the text (Chapter 1, Specifications Tables). |

|

Otherwise, it may fall and cause injury to personnel. |

|

CAUTION: Be sure to install the unit on a perpendicular wall that is not |

............... 2–6 |

subject to vibration. Otherwise, it may fall and cause injury to personnel. |

|

CAUTION: Be sure not to install or operate an inverter that is damaged or |

............... 2–6 |

has missing parts. Otherwise, it may cause injury to personnel. |

|

CAUTION: Be sure to install the inverter in a well-ventilated room that |

............... 2–6 |

does not have direct exposure to sunlight, a tendency for high temperature, |

|

high humidity or dew condensation, high levels of dust, corrosive gas, |

|

explosive gas, inflammable gas, grinding-fluid mist, salt air, etc. Otherwise, |

|

there is the danger of fire. |

|

CAUTION: Be sure to maintain the specified clearance area around the |

............... 2–7 |

inverter and to provide adequate ventilation. Otherwise, the inverter may |

|

overheat and cause equipment damage or fire. |

|

Wiring—Warnings for Electrical Practices and Wire Specifications

|

|

WARNING: “Use 60/75°C Cu wire only” or equivalent. |

............. 2–13 |

|

|

WARNING: “Open Type Equipment.” For models SJ300–750H to SJ300– |

2–13 |

|

|

||

|

|

1500H. |

|

|

|

WARNING: “A Class 2 circuit wired with Class 1 wire” or equivalent. |

............. 2–13 |

|

|

||

|

|

WARNING: “Suitable for use on a circuit capable of delivering not more |

2–13 |

|

|

||

|

|

than 100,000 rms symmetrical amperes, 240 V maximum.” For models with |

|

|

|

suffix L. |

|

|

|

WARNING: “Suitable for use on a circuit capable of delivering not more |

............. 2–13 |

|

|

than 100,000 rms symmetrical amperes, 480 V maximum.” For models with |

|

|

|

suffix H. |

|

|

|

|

|

v

SJ300 Inverter

HIGH VOLTAGE: Be sure to ground the unit. Otherwise, there is a danger ............. |

2–13 |

of electric shock and/or fire. |

|

HIGH VOLTAGE: Wiring work shall be carried out only by qualified ............. |

2–13 |

personnel. Otherwise, there is a danger of electric shock and/or fire. |

|

HIGH VOLTAGE: Implement wiring after checking that the power supply ............. |

2–13 |

is OFF. Otherwise, you may incur electric shock and/or fire. |

|

HIGH VOLTAGE: Do not connect wiring to an inverter or operate an ............. |

2–13 |

inverter that is not mounted according the instructions given in this manual. |

|

Otherwise, there is a danger of electric shock and/or injury to personnel. |

|

Wiring—Cautions for Electrical Practices

CAUTION: Be sure that the input voltage matches the inverter specifica- ............. |

2–19 |

tions: • Three phase 200 to 240V 50/60Hz • Three phase 380 to 480V 50/ |

|

60Hz |

|

CAUTION: Be sure not to power a three-phase-only inverter with single ............. |

2–19 |

phase power. Otherwise, there is the possibility of damage to the inverter |

|

and the danger of fire. |

|

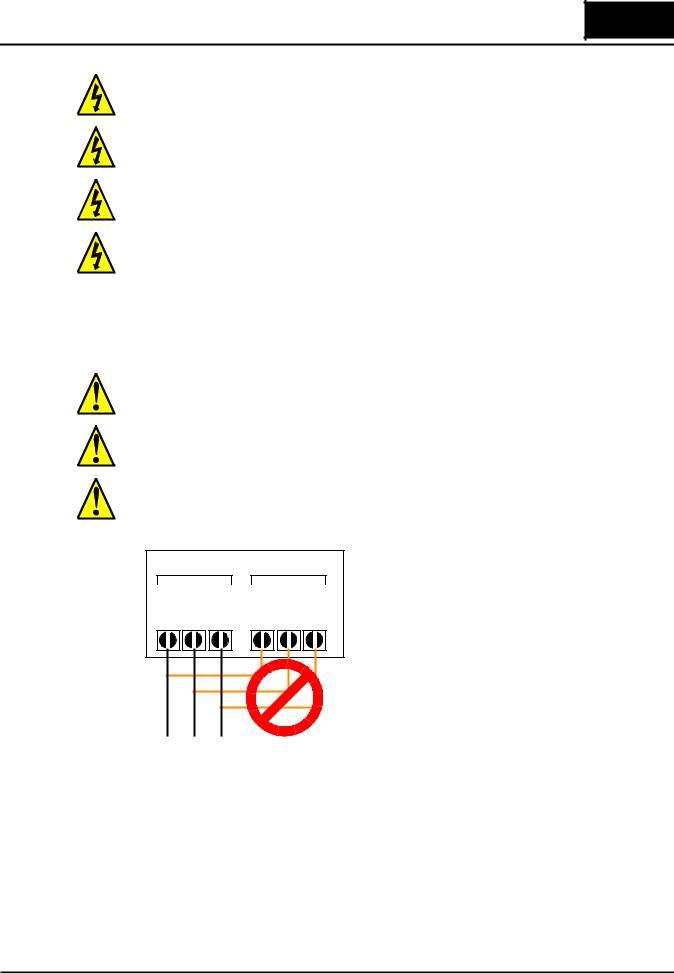

CAUTION: Be sure not to connect an AC power supply to the output termi- ............. |

2–19 |

nals. Otherwise, there is the possibility of damage to the inverter and the |

|

danger of injury and/or fire. |

|

Power Input |

Power Output |

NOTE: |

|

||||

|

|

||||||

L1 |

L2 |

L3 |

T1 |

T2 |

T3 |

L1, L2, L3: |

Three-phase 200 to 240V 50/60 Hz |

|

Three-phase 380 to 480V 50/60 Hz |

||||||

R |

S |

T |

U |

V |

W |

|

|

vi

CAUTION: Fasten the screws with the specified fastening torque in the |

............. 2–16 |

table below. Check for any loosening of screws. Otherwise, there is the |

|

danger of fire. |

|

CAUTION: Remarks for using ground fault interrupter breakers in the main |

............. 2–19 |

power supply: Adjustable frequency inverters with CE-filters (RFI-filter) |

|

and shielded (screened) motor cables have a higher leakage current toward |

|

Earth GND. Especially at the moment of switching ON this can cause an |

|

inadvertent trip of ground fault interrupter breakers. Because of the rectifier |

|

on the input side of the inverter there is the possibility to stall the switch-off |

|

function through small amounts of DC current. Please observe the follow- |

|

ing: • Use only short time-invariant and pulse current-sensitive ground fault |

|

interrupter breakers with higher trigger current. • Other components should |

|

be secured with separate ground fault interrupter breakers. • Ground fault |

|

interrupter breakers in the power input wiring of an inverter are not an |

|

absolute protection against electric shock. |

|

CAUTION: Be sure to install a fuse in each phase of the main power supply |

............. 2–19 |

to the inverter. Otherwise, there is the danger of fire. |

|

CAUTION: For motor leads, ground fault interrupter breakers and electro- |

............. 2–19 |

magnetic contactors, be sure to size these components properly (each must |

|

have the capacity for rated current and voltage). Otherwise, there is the |

|

danger of fire. |

|

CAUTION: Failure to remove all vent opening covers before electrical |

............. 2–20 |

operation may result in damage to the inverter. |

|

Powerup Test Caution Messages

CAUTION: The heat sink fins will have a high temperature. Be careful not |

............. 2–21 |

to touch them. Otherwise, there is the danger of getting burned. |

|

CAUTION: The operation of the inverter can be easily changed from low |

............. 2–21 |

speed to high speed. Be sure to check the capability and limitations of the |

|

motor and machine before operating the inverter. Otherwise, there is the |

|

danger of injury. |

|

CAUTION: If you operate a motor at a frequency higher than the inverter |

............. 2–22 |

standard default setting (50Hz/60Hz), be sure to check the motor and |

|

machine specifications with the respective manufacturer. Only operate the |

|

motor at elevated frequencies after getting their approval. Otherwise, there |

|

is the danger of equipment damage and/or injury to personnel. |

|

CAUTION: Check the following before and during the powerup test. Other- |

............. 2–22 |

wise, there is the danger of equipment damage. • Is the shorting bar between |

|

the [P] and [PD] terminals installed? DO NOT power or operate the inverter |

|

if the jumper is removed. • Is the direction of the motor rotation correct? • Did the inverter trip during acceleration or deceleration? • Were the rpm and frequency meter readings as expected? • Were there any abnormal motor vibrations or noise?

vii

SJ300 Inverter

Warnings for Operations and Monitoring

WARNING: Be sure to turn ON the input power supply only after closing |

............... 4–3 |

the front case. While the inverter is energized, be sure not to open the front |

|

case. Otherwise, there is the danger of electric shock. |

|

WARNING: Be sure not to operate electrical equipment with wet hands. |

............... 4–3 |

Otherwise, there is the danger of electric shock. |

|

WARNING: While the inverter is energized, be sure not to touch the |

............... 4–3 |

inverter terminals even when the motor is stopped. Otherwise, there is the |

|

danger of electric shock. |

|

WARNING: If the Retry Mode is selected, the motor may suddenly restart |

............... 4–3 |

after a trip stop. Be sure to stop the inverter before approaching the machine |

|

(be sure to design the machine so that safety for personnel is secure even if |

|

it restarts.) Otherwise, it may cause injury to personnel. |

|

WARNING: If the power supply is cut OFF for a short period of time, the |

............... 4–3 |

inverter may restart operation after the power supply recovers if the Run |

|

command is active. If a restart may pose danger to personnel, so be sure to |

|

use a lock-out circuit so that it will not restart after power recovery. Other- |

|

wise, it may cause injury to personnel. |

|

WARNING: The Stop Key is effective only when the Stop function is |

............... 4–3 |

enabled. Be sure to enable the Stop Key separately from the emergency |

|

stop. Otherwise, it may cause injury to personnel. |

|

WARNING: During a trip event, if the alarm reset is applied and the Run |

............... 4–3 |

command is present, the inverter will automatically restart. Be sure to apply |

|

the alarm reset only after verifying the Run command is OFF. Otherwise, it |

|

may cause injury to personnel. |

|

WARNING: Be sure not to touch the inside of the energized inverter or to |

............... 4–3 |

put any conductive object into it. Otherwise, there is a danger of electric |

|

shock and/or fire. |

|

WARNING: If power is turned ON when the Run command is already |

............... 4–3 |

active, the motor will automatically start and injury may result. Before |

|

turning ON the power, confirm that the RUN command is not present. |

|

WARNING: When the Stop key function is disabled, pressing the Stop key |

............... 4–3 |

does not stop the inverter, nor will it reset a trip alarm. |

|

WARNING: Be sure to provide a separate, hard-wired emergency stop |

............... 4–3 |

switch when the application warrants it. |

|

WARNING: If the power is turned ON and the Run command is already |

............. 4–12 |

active, the motor starts rotation and is dangerous! Before turning power ON, |

|

confirm that the external Run command is not active. |

|

WARNING: After the Reset command is given and the alarm reset occurs, |

............. 4–27 |

the motor will restart suddenly if the Run command is already active. Be |

|

sure to set the alarm reset after verifying that the Run command is OFF to |

|

prevent injury to personnel. |

|

WARNING: You may need to disconnect the load from the motor before |

............. 4–67 |

performing auto-tuning. The inverter runs the motor forward and backward |

|

for several seconds without regard to load movement limits. |

|

viii

Cautions for Operations and Monitoring

CAUTION: The heat sink fins will have a high temperature. Be careful not to touch them. Otherwise, there is the danger of getting burned.

CAUTION: The operation of the inverter can be easily changed from low speed to high speed. Be sure check the capability and limitations of the motor and machine before operating the inverter. Otherwise, it may cause injury to personnel.

CAUTION: If you operate a motor at a frequency higher than the inverter standard default setting (50Hz/60Hz), be sure to check the motor and machine specifications with the respective manufacturer. Only operate the motor at elevated frequencies after getting their approval. Otherwise, there is the danger of equipment damage.

CAUTION: It is possible to damage the inverter or other devices if your application exceeds the maximum current or voltage characteristics of a connection point.

CAUTION: Be careful not to turn PID Clear ON and reset the integrator sum when the inverter is in Run Mode (output to motor is ON). Otherwise, this could cause the motor to decelerate rapidly, resulting in a trip.

CAUTION: When the motor runs at lower speeds, the cooling effect of the motor’s internal fan decreases.

CAUTION: If the inverter capacity is more than twice the capacity of the motor in use, the inverter may not achieve its full performance specifications.

Warnings and Cautions for Troubleshooting and Maintenance

WARNING: Wait at least five (5) minutes after turning OFF the input power supply before performing maintenance or an inspection. Otherwise, there is the danger of electric shock.

WARNING: Make sure that only qualified personnel will perform maintenance, inspection, and part replacement. Before starting to work, remove any metallic objects from your person (wristwatch, bracelet, etc.). Be sure to use tools with insulated handles. Otherwise, there is a danger of electric shock and/or injury to personnel.

WARNING: Never remove connectors by pulling on its wire leads (wires for cooling fan and logic P.C. board). Otherwise, there is danger of fire due to wire breakage and/or injury to personnel.

CAUTION: Do not connect the megger to any control circuit terminals such as intelligent I/O, analog terminals, etc. Doing so could cause damage to the inverter.

CAUTION: Never test the withstand voltage (HIPOT) on the inverter. The inverter has a surge protector between the main circuit terminals above and the chassis ground.

............... 4–2

............... 4–2

............... 4–2

............... 4–7

............. 4–30

............. 4–55

............. 4–70

............... 6–2

............... 6–2

............... 6–2

............. 6–11

............. 6–11

ix

SJ300 Inverter

WARNING: The screws that retain the capacitor bank assembly are part of ............. |

6–13 |

the electrical circuit of the high-voltage internal DC bus. Be sure that all |

|

power has been disconnected from the inverter, and that you have waited at |

|

least 5 minutes before accessing the terminals or screws. Be sure the charge |

|

lamp is extinguished. Otherwise, there is the danger of electrocution to |

|

personnel. |

|

CAUTION: Do not operate the inverter unless you have replaced the two ............. |

6–13 |

screws that connect the capacitor bank assembly to the internal DC bus. |

|

Otherwise, damage to the inverter may occur. |

|

CAUTION: Remove the fan assembly carefully, since it is attached to the ............. |

6–14 |

unit via connecting wires. |

|

HIGH VOLTAGE: Be careful not to touch wiring or connector terminals ............. |

6–16 |

when working with the inverters and taking measurements. Be sure to place |

|

the measurement circuitry above in an insulated housing before using them. |

|

General Warnings and Cautions

WARNING: Never modify the unit. Otherwise, there is a danger of electric shock and/or injury.

CAUTION: Withstand voltage tests and insulation resistance tests (HIPOT) are executed before the units are shipped, so there is no need to conduct these tests before operation.

CAUTION: Do not attach or remove wiring or connectors when power is applied. Also, do not check signals during operation.

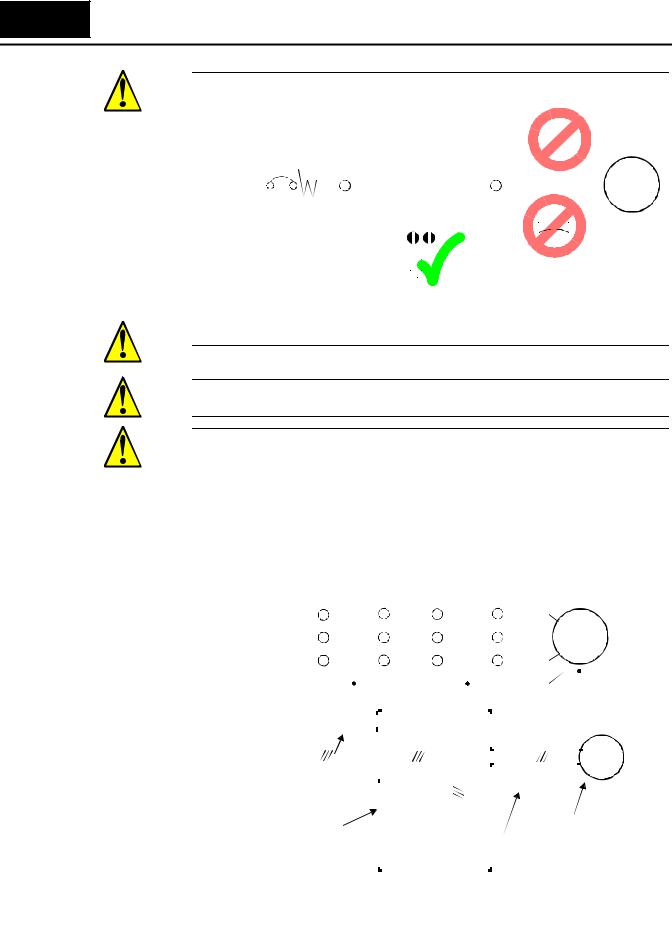

CAUTION: Do not stop operation by switching OFF electromagnetic contactors on the primary or secondary sides of the inverter.

Power |

Ground fault |

|

|

|

|

|

|

|||||||||

Input |

interrupter |

|

|

|

|

|

|

|

|

|||||||

|

Inverter |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

MCCB |

GFI |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

R, S, T |

U, V, W |

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

L1, L2, L3

FW

FW

When there has been a sudden power failure while a Run command is active, then the unit may restart operation automatically after the power failure has ended. If there is a possibility that such an occurrence may harm humans, then install an electromagnetic contactor on the power supply side, so that the circuit does not allow automatic restarting after the power supply recovers. If an optional remote operator is used and the retry function has been selected, this will also allow automatic restarting when a Run command is active. So, please be careful.

x

CAUTION: Do not insert leading power factor capacitors or surge absorbers between the output terminals of the inverter and motor.

|

|

Ground fault |

|

|

|

|

|

|

|

|

|

|

|

|

Surge absorber |

||||||||||||

|

|

|

interrupter |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power |

|

GFI |

|

Inverter |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Input |

|

|

|

|

|

|

R, S, T |

|

|

|

|

|

|

|

|

|

U, V, W |

|

|

|

|

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

L1, L2, L3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND lug |

|

|

|

|

|

|

Leading power |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

factor capacitor |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION: Be sure to connect the grounding terminal to earth ground.

CAUTION: When inspecting the unit, be sure to wait five minutes after tuning OFF the power supply before opening the cover.

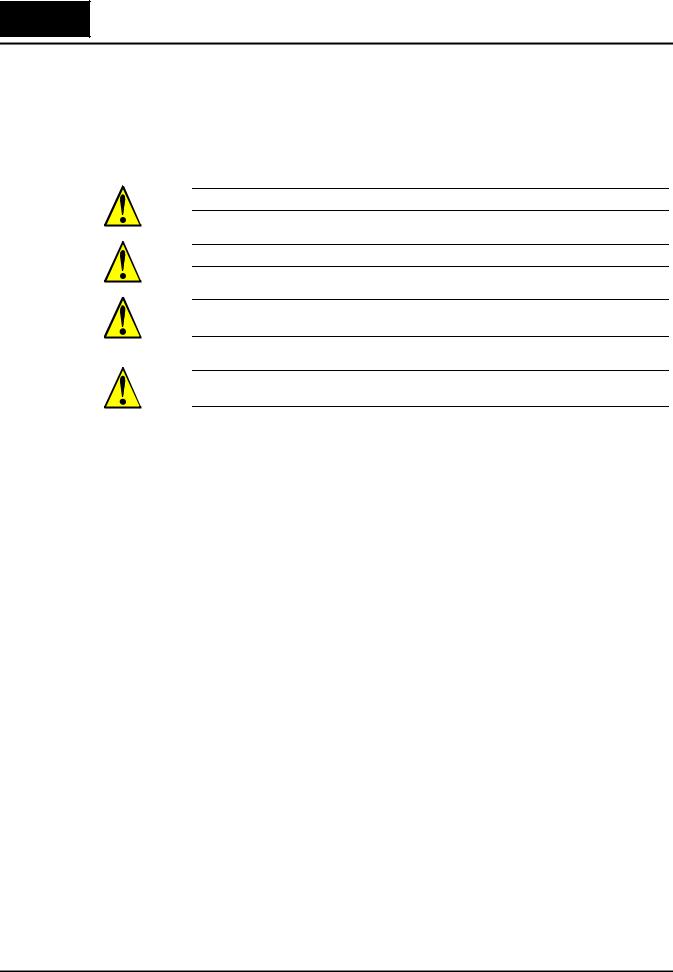

CAUTION: SUPPRESSION FOR NOISE INTERFERENCE FROM INVERTER

The inverter uses many semiconductor switching elements such as transistors and IGBTs. Thus, a radio receiver or measuring instrument located near the inverter is susceptible to noise interference.

To protect the instruments from erroneous operation due to noise interference, they should be used well away from the inverter. It is also effective to shield the whole inverter structure. The addition of an EMI filter on the input side of the inverter also reduces the effect of noise from the commercial power line on external devices.

Note that the external dispersion of noise from the power line can be minimized by connecting an EMI filter on the primary side of inverter.

|

|

|

|

|

EMI filter |

|

|

Inverter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

L1 |

|

R1 |

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

U |

|

|

|

|

|

|

|

|

|

|

|

|

T1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

Power L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

S1 |

|

|

S2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

||||||||||||||||||||||||||||||||||||||||

|

source |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T3 |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

L3 |

|

T1 |

|

|

T2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

noise |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

EMI filter |

|

|

|

|

|

|

|

Inverter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Completely ground the enclosed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grounded frame |

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Conduit or shielded cable— |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

operator |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

panel, metal screen, etc. with as |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to be grounded |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

short a wire as possible. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

xi

SJ300 Inverter

CAUTION: MOTOR TERMINAL VOLTAGE SURGE SUPPRESSION FILTER (For 400 V CLASS Inverters)

In a system using an inverter with the voltage control PWM system, a voltage surge caused by the cable constants such as the cable length (especially when the distance between the motor and inverter is 10 m or more) and cabling method may occur at the motor terminals. A dedicated filter of the 400 V class for suppressing this voltage surge is available. Be sure to install a filter in this situation. (See “LCR filter” on page 5–2, part type HRL–xxxC.)

CAUTION: EFFECTS OF POWER DISTRIBUTION SYSTEMS ON INVERTERS

In the cases below involving a general-purpose inverter, a large peak current can flow on the power supply side, sometimes destroying the converter module:

1.The unbalance factor of the power supply is 3% or higher.

2.The power supply capacity is at least 10 times greater than the inverter capacity (or the power supply capacity is 500 kVA or more).

3.Abrupt power supply changes are expected, due to conditions such as:

a.Several inverters are interconnected with a short bus.

b.A thyristor converter and an inverter are interconnected with a short bus.

c.An installed phase advance capacitor opens and closes.

Where these conditions exist or when the connected equipment must be highly reliable, you MUST install an input-side AC reactor of 3% (at a voltage drop at rated current) with respect to the supply voltage on the power supply side. Also, where the effects of an indirect lightning strike are possible, install a lightning conductor.

CAUTION: Do not install inverters in a corner-grounded Delta distribution system. The resulting line imbalance will cause premature line fuse failure and failure of the inverter input bridge rectifier. Install in a balanced Delta or Wye distribution system only.

CAUTION: When the EEPROM error E8 occurs, be sure to confirm the setting values again.

CAUTION: When using normally closed active state settings (C011 to C019) for externally commanded Forward or Reverse terminals [FW] or [RV], the inverter may start automatically when the external system is powered OFF or disconnected from the inverter! So, do not use normally closed active state settings for Forward or Reverse terminals [FW] or [RV] unless your system design protects against unintended motor operation.

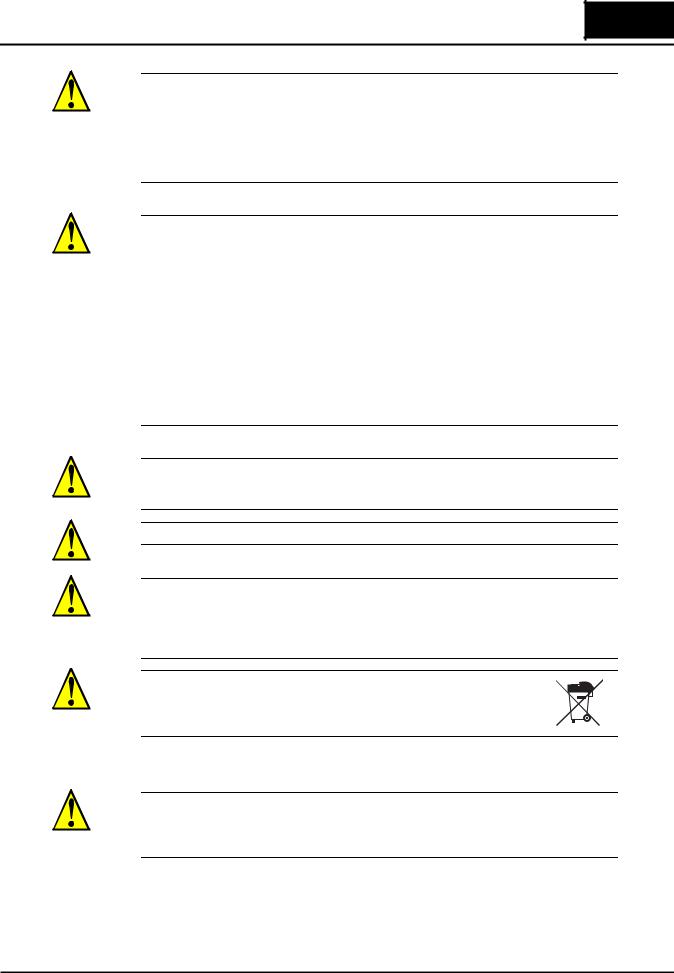

CAUTION: Do do not discard the inverter with household waste. Contact an industrial waste management company in your area who can treat industrial waste without polluting the environment.

General Caution

CAUTION: In all the illustrations in this manual, covers and safety devices are occasionally removed to describe the details. While operating the product, make sure that the covers and safety devices are placed as they were specified originally and operate it according to the instruction manual.

xii

UL® Cautions, Warnings, and Instructions

Wiring Warnings for Electrical Practices and Wire Sizes

The Cautions, Warnings, and instructions in this section summarize the procedures necessary to ensure an inverter installation complies with Underwriters Laboratories® guidelines.

WARNING: “Use 60/75°C Cu wire only” or equivalent.

WARNING: “Open Type Equipment.” For models SJ300–750H to SJ300–1500H.

WARNING: “Suitable for use on a circuit capable of delivering not more than 100,000 rms symmetrical amperes, 240 V maximum.” For models with suffix L.

WARNING: “Suitable for use on a circuit capable of delivering not more than 100,000 rms symmetrical amperes, 480 V maximum.” For models with suffix H.

Terminal Tighten- The wire size range and tightening torque for field wiring terminals are presented in the table

ing Torque and |

below. |

|

|

|

|

|

|

|

Wire Size |

|

|

|

|

|

|

|

|

|

|

Input |

Motor |

200V |

|

Torque |

||

|

|

Output |

Wire Size Range (AWG) |

|||||

|

|

|

|

|||||

|

|

Voltage |

|

|

Inverter Model |

|

|

|

|

|

HP |

kW |

|

ft-lbs |

(N-m) |

||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

0.4 |

SJ300-004LFU |

20 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

0.75 |

SJ300-007LFU |

18 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1.5 |

SJ300-015LFU |

14 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

2.2 |

SJ300-022LFU |

14 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

3.7 |

SJ300-037LFU |

10 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

7.5 |

5.5 |

SJ300-055LFU |

8 |

1.8 |

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

7.5 |

SJ300-075LFU |

6 |

1.8 |

2.5 |

|

|

200V |

|

|

|

|

|

|

|

|

15 |

11 |

SJ300-110LFU |

4 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

15 |

SJ300-150LFU |

2 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

|

|

|

|

25 |

18.5 |

SJ300-185LFU |

1 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

|

|

|

|

30 |

22 |

SJ300-220LFU |

1/0 AWG |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

|

|

|

|

40 |

30 |

SJ300-300LFU |

1/0 || 1/0 AWG |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

|

|

|

|

50 |

37 |

SJ300-370LFU |

1/0 || 1/0 AWG |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

|

|

|

|

60 |

45 |

SJ300-450LFU |

1/0 || 1/0 AWG |

10.1 |

13.7 |

|

|

|

|

|

|

|

|

|

|

|

|

75 |

55 |

SJ300-550LFU |

2/0 || 2/0 AWG |

10.1 |

13.7 |

|

|

|

|

|

|

|

|

|

xiii

SJ300 Inverter

|

Motor |

|

|

Torque |

||

Input |

Output |

400V |

|

|||

Wire Size Range (AWG) |

|

|

||||

Voltage |

|

|

Inverter Model |

|

|

|

HP |

kW |

|

ft-lbs |

(N-m) |

||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

0.75 |

SJ300-007HFU/E |

20 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

2 |

1.5 |

SJ300-015HFU/E |

18 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

3 |

2.2 |

SJ300-022HFU/E |

16 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

5 |

4.0 |

SJ300-040HFU/E |

14 |

1.1 |

1.5 |

|

|

|

|

|

|

|

|

7.5 |

5.5 |

SJ300-055HFU/E |

12 |

1.8 |

2.5 |

|

|

|

|

|

|

|

|

10 |

7.5 |

SJ300-075HFU/E |

10 |

1.8 |

2.5 |

|

|

|

|

|

|

|

|

15 |

11 |

SJ300-110HFU/E |

8 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

20 |

15 |

SJ300-150HFU/E |

6 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

25 |

18.5 |

SJ300-185HFU/E |

6 |

3.6 |

4.9 |

400V |

|

|

|

|

|

|

30 |

22 |

SJ300-220HFU/E |

4 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

|

40 |

30 |

SJ300-300HFU/E |

3 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

50 |

37 |

SJ300-370HFU/E |

1 |

3.6 |

4.9 |

|

|

|

|

|

|

|

|

60 |

45 |

SJ300-450HFU/E |

1 AWG (75°C) |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

75 |

55 |

SJ300-550HFU/E |

1/0 || 1/0 AWG |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

100 |

75 |

SJ300-750HFU/E |

3/0 (1/0 || 1/0 AWG) |

6.5 |

8.8 |

|

|

|

|

|

|

|

|

125 |

90 |

SJ300-900HFU/E |

3/0 (1/0 || 1/0 AWG) |

10.1 |

13.7 |

|

|

|

|

|

|

|

|

150 |

110 |

SJ300-110HFU/E |

1/0 || 1/0 AWG |

10.1 |

13.7 |

|

|

|

|

|

|

|

|

175 |

132 |

SJ300-1320HFE |

3/0 || 3/0 |

10.1 |

13.7 |

|

|

|

|

|

|

|

|

200 |

150 |

SJ300-1500HFU |

3/0 || 3/0 |

10.1 |

13.7 |

|

|

|

|

|

|

|

xiv

Fuse and Circuit The inverter’s input power wiring must include UL Listed, dual-element, 600V fuses, or UL

Breaker Sizes |

Listed, inverse-time, 600V circuit breakers. |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Input |

Motor |

200V |

Ampere Rating |

Input |

|

Motor |

400V |

Ampere Rating |

||

Output |

|

Output |

||||||||

for Fuse or |

|

for Fuse or |

||||||||

Voltage |

|

|

Inverter Model |

Voltage |

|

|

|

Inverter Model |

||

HP |

kW |

Breaker |

|

HP |

kW |

Breaker |

||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2 |

0.4 |

SJ300-004LFU |

10 |

|

|

1 |

0.75 |

SJ300-007HFU/E |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

0.75 |

SJ300-007LFU |

10 |

|

|

2 |

1.5 |

SJ300-015HFU/E |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1.5 |

SJ300-015LFU |

10 |

|

|

3 |

2.2 |

SJ300-022HFU/E |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

2.2 |

SJ300-022LFU |

15 |

|

|

5 |

4.0 |

SJ300-040HFU/E |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

3.7 |

SJ300-037LFU |

20 |

|

|

7.5 |

5.5 |

SJ300-055HFU/E |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

7.5 |

5.5 |

SJ300-055LFU |

30 |

|

|

10 |

7.5 |

SJ300-075HFU/E |

20 |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

7.5 |

SJ300-075LFU |

40 |

|

|

15 |

11 |

SJ300-110HFU/E |

30 |

200V |

|

|

|

|

|

|

|

|

|

|

15 |

11 |

SJ300-110LFU |

60 |

|

|

20 |

15 |

SJ300-150HFU/E |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

15 |

SJ300-150LFU |

80 |

|

|

25 |

18.5 |

SJ300-185HFU/E |

50 |

|

|

|

|

|

400V |

|

|

|

|

|

|

25 |

18.5 |

SJ300-185LFU |

100 |

|

30 |

22 |

SJ300-220HFU/E |

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

22 |

SJ300-220LFU |

125 |

|

|

40 |

30 |

SJ300-300HFU/E |

70 |

|

|

|

|

|

|

|

|

|

|

|

|

40 |

30 |

SJ300-300LFU |

150 |

|

|

50 |

37 |

SJ300-370HFU/E |

90 |

|

|

|

|

|

|

|

|

|

|

|

|

50 |

37 |

SJ300-370LFU |

175 |

|

|

60 |

45 |

SJ300-450HFU/E |

125 |

|

|

|

|

|

|

|

|

|

|

|

|

60 |

45 |

SJ300-450LFU |

225 |

|

|

75 |

55 |

SJ300-550HFU/E |

125 |

|

|

|

|

|

|

|

|

|

|

|

|

75 |

55 |

SJ300-550LFU |

250 |

|

|

100 |

75 |

SJ300-750HFU/E |

175 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

125 |

90 |

SJ300-900HFU/E |

200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150 |

110 |

SJ300-110HFU/E |

250 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

175 |

132 |

SJ300-1320HFE |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 |

150 |

SJ300-1500HFU |

300 |

|

|

|

|

|

|

|

|

|

|

|

Wire Connectors

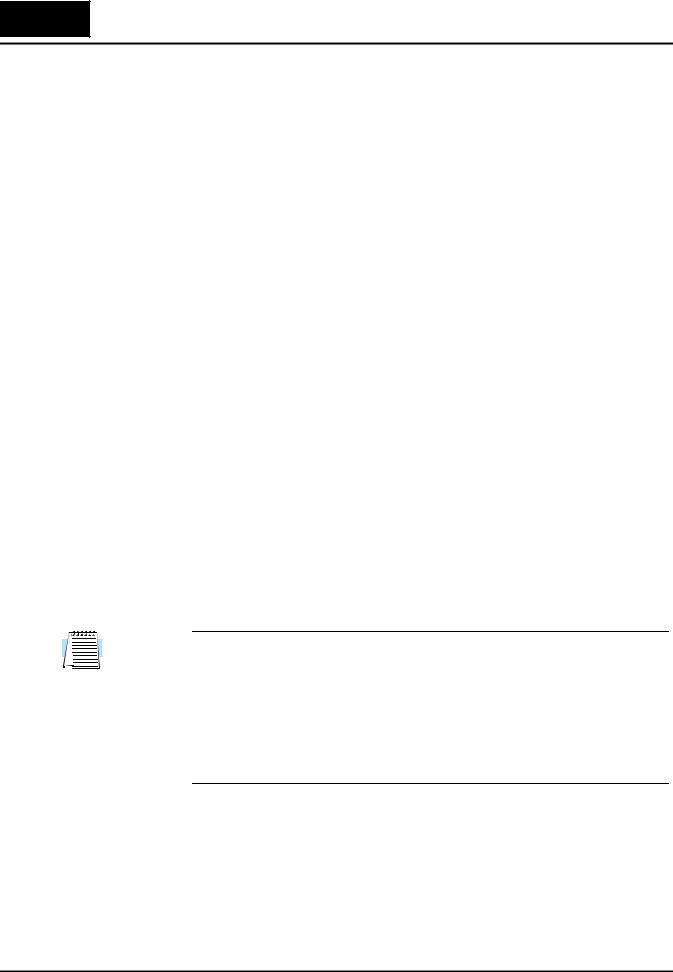

WARNING: Field wiring connections must be made by a UL Listed and CSA Certified ring lug terminal connector sized for the wire gauge being used. The connector must be fixed using the crimping tool specified by the connector manufacturer.

Terminal (ring lug) |

Cable support |

Cable

Cable

Motor Overload

Protection

Hitachi SJ300 inverters provide solid state motor overload protection, which depends on the proper setting of the following parameters:

•B012 “electronic overload protection”

•B212 “electronic overload protection, 2nd motor”

•B312 “electronic overload protection, 3rd motor”

Set the rated current [Amperes] of the motor(s) with the above parameters. The setting range is 0.2 * rated current to 1.2 * rated current.

WARNING: When two or more motors are connected to the inverter, they cannot be protected by the electronic overload protection. Install an external thermal relay on each motor.

xv

SJ300 Inverter

Table of Contents

Safety Messages

Hazardous High Voltage |

|

|

|

|

i |

|||

General Precautions - Read These First! |

|

|

|

|

ii |

|||

Index to Warnings and Cautions in This Manual |

|

|

iv |

|||||

General Warnings and Cautions |

|

|

|

ix |

||||

UL® Cautions, Warnings, and Instructions |

|

|

xii |

|||||

Table of Contents

Revisions |

|

|

|

xvii |

Contact Information |

|

xviii |

||

Chapter 1: Getting Started

Introduction |

|

|

|

1–2 |

||

SJ300 Inverter Specifications |

|

|

|

1–6 |

||

Introduction to Variable-Frequency Drives |

|

1–13 |

||||

Frequently Asked Questions |

|

|

1–17 |

|||

Chapter 2: Inverter Mounting and Installation

Orientation to Inverter Features |

|

|

2–2 |

||||

Basic System Description |

|

|

|

2–5 |

|||

Step-by-Step Basic Installation |

|

|

|

2–6 |

|||

Powerup Test |

|

|

2–21 |

||||

Using the Front Panel Keypad |

|

|

2–23 |

||||

Chapter 3: Configuring Drive Parameters

Choosing a Programming Device |

|

|

3–2 |

||||||||||

Using Keypad Devices |

|

|

3–3 |

||||||||||

“D” Group: Monitoring Functions |

|

|

3–6 |

||||||||||

“F” Group: Main Profile Parameters |

|

|

3–8 |

||||||||||

“A” Group: Standard Functions |

|

|

3–9 |

||||||||||

“B” Group: Fine-Tuning Functions |

|

3–29 |

|||||||||||

“C” Group: Intelligent Terminal Functions |

|

3–47 |

|||||||||||

“H” Group: Motor Constants Functions |

|

3–62 |

|||||||||||

“P” Group: Expansion Card Functions |

|

3–65 |

|||||||||||

“U” Group: User-selectable Menu Functions |

|

3–67 |

|||||||||||

Programming Error Codes |

|

3–68 |

|||||||||||

Chapter 4: Operations and Monitoring

Introduction |

|

|

|

4–2 |

||||||||

Optional Controlled Decel and Alarm at Power Loss |

|

|

4–4 |

|||||||||

Connecting to PLCs and Other Devices |

|

|

|

4–7 |

||||||||

Using Intelligent Input Terminals |

|

|

4–11 |

|||||||||

Using Intelligent Output Terminals |

|

|

4–42 |

|||||||||

Analog Input Operation |

|

|

4–59 |

|||||||||

Analog Output Operation |

|

|

4–62 |

|||||||||

Setting Motor Constants for Vector Control |

|

|

4–65 |

|||||||||

PID Loop Operation |

|

|

4–71 |

|||||||||

Configuring the Inverter for Multiple Motors |

|

4–72 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

xvi

Chapter 5: Inverter System Accessories

Introduction |

|

5–2 |

||

Component Descriptions |

|

5–3 |

||

Dynamic Braking |

|

5–6 |

||

Chapter 6: Troubleshooting and Maintenance

Troubleshooting |

|

|

|

6–2 |

|||

Monitoring Trip Events, History, & Conditions |

|

|

6–5 |

||||

Restoring Factory Default Settings |

|

|

|

6–9 |

|||

Maintenance and Inspection |

|

|

6–10 |

||||

Warranty |

|

|

6–18 |

||||

Appendix A: Glossary and Bibliography

Glossary |

|

A–2 |

|

Bibliography |

|