Heat Controller DXM2 User Manual

APPLICATION, OPERATION & MAINTENANCE MANUAL

DXM2 Digital

Heat Pump Controller

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Application, Operation, & Maintenance Manual |

DXM2 UNIT CONTROLS |

Heat Controller, Inc. |

Table of Contents

DXM2 Electronic Heat Pump Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 DXM2 Physical Dimensions & Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 DXM2 Layout and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 DXM2 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 DXM2 Service & Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Basic Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Advanced Troubleshooting and Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 DXM2 Wiring Diagram with Motorized Modulating Water Valve - Optional 96B0005N62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 DXM2 Wiring Diagram (Standard Installation) - 96B0005N56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Functional Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Performance Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

Heat Controller, Inc. |

DXM2 UNIT CONTROLS |

Application, Operation, & Maintenance Manual |

DXM2 Electronic Heat Pump Controls

DXM2 OVERVIEW

The manufacturer’s next generation control board, DXM2, is the geothermal industry’s first two-way communication.

The DXM2 electronic control is a robust, microprocessor based heat pump controller that is advanced and featureladen for maximum application flexibility. The DXM2 Control has relay outputs for Compressor, Compressor Speed, Reversing Valve, Alarm Relay, and 2 configurable relays for Fan, Fan Speed, HWG Pump, and Loop Pump, and 2 configurable accessory relay outputs. For on board diagnostics, there are 2 LED’s to provide status indication.

There are inputs for safety pressure switches, low temperature protection thermistors, condensate overflow sensor, DIP switch selection inputs, thermostat inputs, night setback inputs, and emergency shutdown input. Additional configurable temperature sensor inputs are available that may be used for hot water, compressor discharge, leaving air, leaving water, and entering water temperature sensors.

The DXM2 has an RS485 communications port to interface with a communicating thermostat or other compatible controls.

DXM2 Controller Part Number:

17B0002N02 DXM2 Control Board

General Operating Parameters

The following are general operating parameters for the DXM2 Control:

•Operating Environment: -40°F to 176°F and up to 95% relative humidity, non-condensing.

•Storage Environment: -40°F to 185°F and up to 95% relative humidity, non-condensing.

Power Requirements

DXM2 only power draw -

•Normally 8 VA draw at 24VAC

•Maximum 12 VA draw at 24VAC. A dedicated 24VAC, 50-60Hz, 1Ph, 40VA transformer minimum is required for typical WSHP application.

Relay and Connection Contact Ratings

The following relays are mounted on the DXM2 Control:

•Compressor Relay: 40VA at 24VAC

•Compressor Speed Relay: 28VA at 24VAC

•Alarm Relay: 28VA at 24VAC

•Reversing Valve: 28VA at 24VAC

•Accessory Relay 1: 28VA at 24VAC

•Accessory Relay 2: 28VA at 24VAC

•Fan Enable / Loop Pump Relay: 1 HP at 240VAC

•Fan Speed / HWG Pump Relay: 1 HP at 240VAC

•Connection ratings on the DXM2 Control:

•‘A’ terminal: 20VA at 24VAC. Larger solenoid valve draw should be controlled with accessory relays.

Grounding

The control board must be grounded from one of the C terminals.

Basic Control Features

•Single or two–stage compressor control

•Anti-short cycle protection

•High pressure cut-out

•Loss of charge cut-out

•High and low voltage cut-outs

•Water coil low temperature cut-out

•Air coil low temperature cut-out

•Random start

•Status LED and Fault LED

•Reset lockout at unit or disconnect

•Condensate overflow sensor

•Intelligent fault retry

•Test Mode

•Multiple blower configuration options

•Electric heat outputs

•Accessory water valve connection

Advanced Control Features

•Direct control of ECM blower

•Intelligent hot water generator control

•Two accessory relays configurable for multiple applications

•Internal Flow Center output

•Proportional valve output

•Night setback with override capability

•Emergency shutdown capability

•Removable thermostat connector for ease of installation and service

•Accepts conventional heat pump (Y,O) or heat/cool (Y,W) thermostat types

•RS–485 port to interface with a communicating thermostat or other compatible controls

•Boilerless electric heat

•Configurable inputs and outputs for advanced functions

3

Application, Operation, & Maintenance Manual |

DXM2 UNIT CONTROLS |

Heat Controller, Inc. |

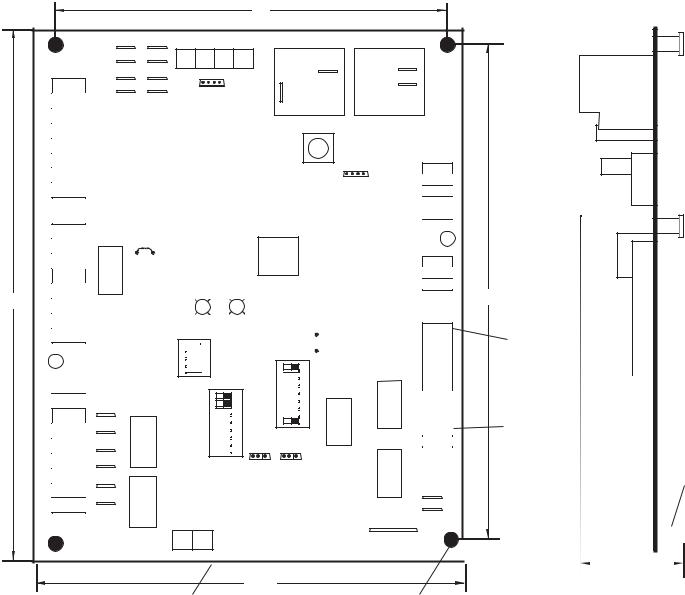

DXM2 Physical Dimensions & Layout

|

P1 |

|

|

Y1 |

|

|

Y2 |

|

|

W |

|

|

O |

|

|

G |

|

|

R |

|

|

C |

|

|

AL1 |

|

|

P2 |

|

|

AL2 |

|

|

R |

|

|

NSB |

Alarm |

|

C |

Relay |

|

|

|

7" |

ESD |

|

OVR |

|

|

|

|

|

|

H |

|

|

A |

|

|

P3 |

|

|

R |

|

|

NO1 |

|

|

NC1 |

|

|

COM |

Factory |

|

NC2 |

|

|

NO2 |

|

|

COM |

Use |

|

|

|

|

R |

|

COH

COM

5"

C |

Gnd B- |

A+ 24V |

P4 |

(240Vac) |

|

(240Vac) |

|||

R |

|

P5 |

N.O. |

N.C. |

|

N.O. |

|||

|

|

|

Com |

|

|

|

|

Fan Enable |

Fan Speed |

|

|

P8 |

Test |

P12 |

12V |

|

IN |

|

|

|

|

|

|

OUT |

|

|

Gnd |

|

|

NC |

JW1 |

Micro |

1 HP |

|

|

U1 |

|

|||

|

|

HP |

|

|

Fault |

Status |

LP |

6 1/2" |

|

LP |

||||

|

|

|||

|

|

LT1 |

|

|

|

|

LT1 |

|

Acc1

Relay

Off On

4 3 2 1

S3 Off On

8 7 6 5 4 3 2 1

S1

Off On

8 7 6 5 4 3 2 1

S2

A0-1 A0-2

JW3

JW3

CCH

Relay

Acc2

Relay

P11 |

|

|

|

|

|

P10 |

||

AO2 Gnd |

T1 |

T2 |

T2 |

T3 |

T3 |

T4 |

T4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 1/2" |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LT2 |

|

|

Factory low |

||||||||||

|

|

|

|

|

LT2 |

|

|

voltage molex |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

connection for |

|

|

|

|

|

|

|

|||

|

|

|

|

|

RV |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

unit harness |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

RV |

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

CO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

CO |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

RV |

|

P7 |

Factory low |

|

|

|

|

|

|

|

|||||||

|

Relay |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

voltage molex |

|

|

|

|

|

|

|

||||||

1 |

|

|

|

|

|

|

|

|

|

|

||||||||

|

24Vdc |

|

|

connection for |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

electric heat |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

4 |

|

EH1 |

|

|

harness |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

EH2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Comp |

|

P6 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

Relay |

|

|

|

|

|

|

|

|

|

|

|

|

|

3/8” standoff |

|||

|

|

|

|

CCG |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

P9 |

|

CC |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

T5 |

T5 |

T6 |

T6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.5 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Note: There is only |

Use 4 mounting screws |

one T1 connection |

#6 sheet metal screw 1” long |

4

Heat Controller, Inc. |

DXM2 UNIT CONTROLS |

Application, Operation, & Maintenance Manual |

DXM2 Layout and Connections

Service tool Communicating connection stat connection

|

P1 |

|

|

|

Y1 |

|

|

|

Y2 |

|

|

Conventional |

W |

|

|

stat connection |

O |

|

|

|

G |

|

|

|

R |

|

|

|

C |

|

|

|

AL1 |

|

|

|

P2 |

|

|

|

AL2 |

|

|

Cabinet |

R |

|

|

temperature |

NSB |

Alarm |

|

sensor |

C |

Relay |

|

(with variable |

ESD |

|

|

speed pump) |

|

||

OVR |

|

||

|

|

||

|

H |

|

|

|

A |

|

|

Communications |

|

|

|

and HWG |

P3 |

|

|

Settings |

R |

|

|

|

|

||

|

NO1 |

|

|

Accessory |

NC1 |

|

|

COM1 |

F |

||

relays refer |

|||

NO2 |

tca |

||

to DXM2 AOM |

|||

NC2 |

ro |

||

for configuration |

y |

||

|

|||

COM2 |

sU |

||

|

|||

|

|

e |

|

|

R |

|

COH

COM

C

R

JW1

Acc1

Relay

Acc2

Relay

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P4 |

|

|

|

|

|

|

|

|

(240Vac) |

|

|

|

|||||

|

Gnd |

|

B- |

|

A+ |

24V |

(240Vac) |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N.O. |

|

|

|

N.C. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

P5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Com |

|

|

|

|

|

N.O. |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fan Enable |

|

Fan Speed |

|

|

Test Button |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to Speed up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P8 |

|

Time Delays |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test |

|

P12 |

12V |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IN |

|

ECM Motor |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gnd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NC |

|

Water Coil |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Temp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Micro |

|

|

|

|

|

|

|

|

|

|

|

|

|

Limit Setting. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

JWT-LT1 jumper |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

U1 |

|

|

|

|

|

|

HP |

|

should be clipped |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

for low temp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Fault |

|

Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

LP |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(antifreeze) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LP |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LT1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LT1 |

|

Factory low |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LT2 |

|

|

|

Off |

On |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

voltage molex |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JW3 |

|

|

|

|

|

LT2 |

|

|||||||||

|

|

|

|

|

2 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connection for |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RV |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Off |

On |

|

|

|

|

|

|

|

|

unit harness |

||||||

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

CO |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

S3 Off |

|

|

On |

|

|

|

|

|

3 |

|

|

|

|

12 |

CO |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

RV |

P7 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

6 |

|

|

CCH |

|

|

Relay |

|

|

Electric heat |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

8 |

|

|

1 |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24Vdc |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay |

|

|

|

|

|

|

|

connection |

|

|

|

|

|

|

|

|

|

|

|

|

6 5 |

|

|

|

S2 |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EH1 |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

8 7 |

A0-1 |

A0-2 |

|

|

4 |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

EH2 |

|

|

||||||||||||||||

|

|

|

|

|

|

|

S1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Comp |

P6 |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay |

CCG |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Configurefigure |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

modulating valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modulating Valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CC |

|

or variable |

P11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P10 |

|

|

|

|

P9 |

|

(Optional) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

speed pump |

|||||||||||

AO2 Gnd |

|

|

T1 |

T2 |

T2 |

T3 |

T3 |

|

T4 |

T4 |

|

T5 |

T5 |

T6 |

T6 |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24V to compressor second-stage solenoid for Y2/full

load capacity

Variable pump speed |

Entering temp water |

Leaving temp water |

Leaving temp air |

water Hot Entering Temperature |

Discharge Compressor temperature |

|

|

|

|

Use 4 mounting screws #6 sheet metal screw 1” long

5

Application, Operation, & Maintenance Manual |

DXM2 UNIT CONTROLS |

Heat Controller, Inc. |

DXM2 Controls

THERMOSTAT COMPATABILITY - IT IS STRONGLY RECOMMENDED THAT A COMMUNICATING THERMOSTAT (7602-443) BE USED WITH GEOMAX COMMUNICATING SYSTEMS FOR:

1.Four-wire connections between the thermostat, compressor section (HTS), and air handler (WDG).

2.Configuring, monitoring and diagnosing the system in PLAIN ENGLISH on the thermostat.

FIELD SELECTABLE INPUTS

Test mode: Test mode allows the service technician to check the operation of the control in a timely manner. By momentarily pressing the TEST pushbutton, the DXM2 control enters a 20 minute test mode period in which all time delays are sped up 15 times. Upon entering test mode, the Status and Fault LED displays will change. The Status LED will either flash rapidly to indicate the control is in the test mode, or display a numeric flash code representing the current airflow if an ECM blower is connected and operating. The Fault LED will display the most recent fault condition in memory. Note: A flash code of 1 indicates there have been no faults stored in memory.

For diagnostic ease at conventional thermostats, the alarm relay will also cycle during test mode. The alarm relay will cycle on and off similar to the Fault LED to indicate a code representing the last fault, at the thermostat.

The test mode can be exited by pressing the TEST pushbutton for 3 seconds. The test Mode can also be entered and exited by cycling the G input, 3 times within a 60 second time period.

During Test Mode, the control monitors to see if the LT1 and LT2 thermistors are connected and operating properly. If the control is in Test Mode, the control will lockout, with Code 9, after 60 seconds if:

a)the compressor is On in Cooling Mode and the LT1 sensor is colder than the LT2 sensor. or,

b)the compressor is On in Heating Mode and the LT2 sensor is colder than the LT1 sensor.

Retry Mode: If the control is attempting a retry of a fault, the Fault LED will slow flash (slow flash = one flash every 2 seconds) to indicate the control is in the process of retrying.

Field Configuration Options - Note: In the following field configuration options, jumper wires should be clipped ONLY when power is removed from the DXM2 control.

Note: Jumper 3 must not be clipped prior to adding antifreeze to the water loop. Antifreeze protection to 10°F required. Clipping JW3 without antifreeze may result in freeze damage and will void the unit warranty.

Water coil low temperature limit setting: Jumper 3 (JW3LT1 Low Temp) provides field selection of temperature limit

setting for LT1 of 30°F or 10°F [-1°F or -12°C] (refrigerant temperature).

Not Clipped = 30°F. Clipped = 10°F.

Alarm Relay Setting - Jumper 1 (JW1-AL2 Dry) provides field selection of alarm function when Alarm Relay is energized.

Not Clipped = AL1 connected to R (24VAC) with Alarm Relay active.

Clipped = Dry contact connection between AL1 and AL2 with Alarm Relay active.

JUMPERS (Set at Factory)

A0-2: Configure Modulating Valve (Optional)

Set A0-2 jumper (see Figure on page 5) to “IOV” if using Internal Modulating Motorized Valve (optional).

DIP SWITCHES

Note: In the following field configuration options, DIP switches should only be moved when power is removed from the DXM2 Control to ensure proper operation.

DIP Package #1 (S1)

DIP Package #1 is 8 position and provides the following setup selections.

DIP 1.1: Unit Performance Sentinel Disable - Provides field selection to disable the UPS feature.

On = Enabled. Off = Disabled.

DIP 1.2: Compressor Relay Staging Operation - Provides selection of Compressor Relay staging operation. The Compressor Relay can be selected to turn on with Stage 1 or Stage 2 call from the thermostat. This is used with Dual Stage units (2 compressors where 2 DXM2 Controls are being used) or with master/slave applications. In master/slave applications, each compressor and fan will stage according to its appropriate DIP 1.2. If set to stage 2, the compressor will have a 3 second on-delay before energizing during a Stage 2 demand. Also, if set for stage 2, the Alarm Relay will NOT cycle during Test Mode.

On = Stage 1. Off = Stage 2.

DIP 1.3: Thermostat Type (Heat/Cool) - Provides selection of thermostat type. Heat Pump or Heat/Cool thermostats can be selected. When in Heat/Cool Mode, Y1 is input call for Cooling Stage 1, Y2 is input call for Cooling Stage 2, W1 is input call for Heating Stage 1, and O/W2 is input call for Heating Stage 2. In Heat Pump Mode, Y1 is input call for Compressor Stage 1, Y2 is input call for Compressor Stage 2, W1 is input call for Heating Stage 3 or Emergency Heat, and O/W2 is the input call for RV (heating or cooling dependent upon DIP 1.4).

6

Heat Controller, Inc. |

DXM2 UNIT CONTROLS |

Application, Operation, & Maintenance Manual |

DXM2 Controls

On = Heat Pump. Off = Heat/Cool. |

DIP Package #3 (S3) |

DIP 1.4: Thermostat Type (O/B) - Provides selection of thermostat type. Heat pump thermostats with “O” output on with Cooling or “B” output on with Heating can be selected.

On = HP Stat with O output with cooling. Off = HP Stat with B output with heating.

DIP 1.5: Dehumidification Mode - Provides selection of normal or Dehumidification Fan Mode. In Dehumidification Mode, the fan speed will be adjusted for Cooling. In Normal Mode, the fan speed will be normal during Cooling.

On = Normal Fan Mode. Off = Dehumidification Mode.

DIP 1.6: DDC Output at EH2 - DIP Switch 1.6 provides selection for DDC operation. If set to DDC Output at EH2, the EH2 terminal will continuously output the last fault code of the controller. If set to EH2 normal, then the EH2 will operate as standard electric heat output.

On = EH2 Normal. Off = DDC Output at EH2.

DIP 1.7: Boilerless Operation - Provides selection of Boilerless Operation. In Boilerless Mode, only the

compressor is used for Heating Mode when LT1 is above the temperature specified by the setting of DIP 1.8. If DIP 1.8 is set for 50°F, then the compressor is used for heating as long as LT1 is above 50°F. Below 50°F, the compressor is not used and the control goes into Emergency Heat Mode, staging on EH1 and EH2 to provide heating.

On = normal. Off = Boilerless operation.

DIP 1.8: Boilerless Changeover Temperature - Provides selection of boilerless changeover temperature setpoint.

On = 50°F. Off = 40°F.

DIP Package #2 (S2)

DIP Package #2 (S2) - A combination of dip switches 2.1, 2.2, 2.3, and 2.4, 2.5, 2.6 deliver configuration of ACC1 and ACC2 relay options respectively. See Table 2 for description and functionality.

DIP 2.7: Auto Dehumidification Fan Mode or High Fan Mode - Provides selection of Auto Dehumidification Fan Mode or High Fan Mode. In Auto Dehumidification Mode, the Fan Speed will be adjusted during Cooling IF the H input is active. In High Fan Mode, the Fan will operate on high speed when the H input is active.

On = Auto Dehumidification Mode (default). Off = High Fan

Mode.

DIP 2.8: Factory Setting - Normal position is On. Do not change selection unless instructed to do so by the Factory.

DIP Package #3 is 4 position and provides the following setup selections.

DIP 3.1: Communications configuration: Provides selection of the DXM2 operation in a communicating system. The DXM2 may operate as a communicating master or slave device depending on the network configuration. In most configurations, the DXM2 will operate as a master device.

On = Communicating Master device (default). Off = communicating Slave device.

Table 1: Accessory Relay 1 Configuration

DIP 2.1 |

DIP 2.2 |

DIP 2.3 |

|

ACC1 Relay Option |

|

|

|

|

|

ON |

ON |

ON |

|

Cycle with fan |

|

|

|

|

|

OFF |

ON |

ON |

|

Digital night setback |

|

|

|

|

|

ON |

OFF |

ON |

|

Water valve – Slow opening |

|

|

|

|

|

ON |

ON |

OFF |

|

Outside air damper |

|

|

|

|

|

OFF |

ON |

OFF |

|

Whole House Dehumidification |

|

option – Dehumidistat |

|||

|

|

|

|

|

|

|

|

|

|

OFF |

OFF |

OFF |

|

option – Humidistat |

|

|

|

|

|

OFF |

OFF |

ON |

|

Hydronic Economizer – 1st Stage |

|

|

|

|

|

ON |

OFF |

OFF |

|

Hydronic Economizer – Both |

|

Stages |

|||

|

|

|

|

|

|

|

|

|

|

All other DIP combinations are invalid |

|

|||

Table 2: Accessory Relay 2 Configuration

DIP 2.4 |

DIP 2.5 |

DIP 2.6 |

ACC2 Relay Option |

|

|

|

|

ON |

ON |

ON |

Cycle with compressor |

|

|

|

|

OFF |

ON |

ON |

Digital night setback |

|

|

|

|

ON |

OFF |

ON |

Water valve – Slow opening |

|

|

|

|

OFF |

OFF |

ON |

Humidifier |

|

|

|

|

ON |

ON |

OFF |

Outside air damper |

|

|

|

|

All other DIP combinations are invalid

DIP 3.2: HWG Test Mode: Provides forced operation of the HWG pump output, activating the HWG pump output for up to five minutes.

On = HWG test mode. Off = Normal HWG mode (default).

DIP 3.3: HWG Temperature: Provides the selection of the HWG operating setpoint.

On = 150°F [66°C]. Off = 125°F [52°C] (default).

DIP 3.4: HWG Status: Provides HWG operation control.

On = HWG mode enabled. Off = HWG mode disabled (default)

7

Application, Operation, & Maintenance Manual |

DXM2 UNIT CONTROLS |

Heat Controller, Inc. |

DXM2 Controls

SAFETY FEATURES

The following safety features are provided to protect the compressor, heat exchangers, wiring and other

components from damage caused by operation outside of design conditions.

Anti-Short Cycle Protection - The control features a 5 minute anti-short cycle protection for the compressor.

Note: The 5 minute anti-short cycle also occurs at power up.

Random Start - The control features a 5-80 second random start upon power up. The random start delay will be present after a control power up and after returning from Night Setback or Emergency Shutdown modes.

Extended Compressor Operation Monitoring - If the compressor relay has been on for 4 continuous hours, then the control will automatically turn off the compressor relay and wait the short cycle protection time. All appropriate safeties will be monitored during the off time. If all operation is normal, and if the compressor demand is still present, the control will turn the compressor back on.

Fault Retry - In Fault Retry Mode, the Fault LED begins slow flashing to signal that the control is trying to recover from a fault input. The DXM2 Control will stage off the outputs and then “try again” to satisfy the thermostat call for compressor. Once the thermostat input calls are satisfied, the control will continue on as if no fault occurred. If 3 consecutive faults occur without satisfying the thermostat call for compressor, then the control will go to Lockout Mode. The last fault causing the lockout will be stored in memory and is displayed at the Fault LED by entering the Test mode.

Note: LT1 and LT2 faults are factory set for one try, so there will be no “retries” for LT1 and LT2 faults. The control will only try one time for these faults.

FAULT CODES

Lockout - In Lockout Mode, the Fault LED will begin fast flashing. The compressor relay is turned off immediately. The fan output will be turned off after the current blower off delay unless auxiliary heat is active. The Lockout Mode can be “soft” reset via the thermostat by removing the call for compressor, or by a “hard” reset (disconnecting power to the control). The fault code will be stored in non-volatile memory that can be displayed by the Fault LED by entering the Test mode, even if power was removed from the control.

Lockout with Emergency Heat - If the DXM2 is configured for Heat Pump thermostat Mode (see DIP 1.3),

CAUTION!

CAUTION! Do not restart units without inspection and remedy of faulting condition. Equipment damage may occur.

the DXM2 is in Lockout Mode, and the W input becomes active, then Emergency Heat Mode will occur during Lockout. For Emergency Heat, the fan and auxiliary heat outputs will be activated.

Fault Code 2: High Pressure Switch – When the High Pressure switch opens due to high refrigerant pressures, the compressor relay is de–energized immediately. The High Pressure fault recognition is immediate (does not delay for 30 continuous seconds before de–energizing the compressor). When the Test mode is activated, the Fault LED will display a fault code of 2 for a High Pressure fault.

Fault Code 3: Loss of Charge Switch – The Loss of Charge Switch must be open and remain open for 30 continuous seconds during a compressor “on” cycle to be recognized as a Loss of Charge fault. If the Loss of Charge switch is open for 30 seconds prior to compressor

power up it will be considered a Loss of Charge fault. The Loss of Charge Switch input is bypassed for the initial 120 seconds of a compressor run cycle. When the Test mode is active, the Fault LED will display a fault code of 3 for a Loss of Charge fault.

Fault Code 4: Water Coil Low Temperature Cut-Out Limit (LT1) - The control will recognize an LT1 fault, during a compressor run cycle if:

a)the LT1 thermistor temperature is below the selected low temperature protection limit setting for at least 50 seconds, AND

b)the LT1 thermistor temperature is rising (getting warmer) at a rate LESS than 2°F per 30 second time period.

The LT1 input is bypassed for the initial 120 seconds of a compressor run cycle. When the Test mode is active, the Fault LED will display a fault code of 4 for a LT1 fault.

Fault Code 5: Air Coil Low Temperature Cut-Out (LT2) - The control will recognize an LT2 fault, during a compressor run cycle if:

a)the LT2 thermistor temperature is below the low temperature protection limit setting for at least 50 seconds, AND

b)the LT2 thermistor temperature is rising (getting warmer) at a rate LESS than 2°F per 30 second time period.

The LT2 input is bypassed for the initial 120 seconds of a

8

Heat Controller, Inc. |

DXM2 UNIT CONTROLS |

Application, Operation, & Maintenance Manual |

DXM2 Controls

compressor run cycle. When the Test mode is active, the Fault LED will display a fault code of 5 for a LT2 fault.

Fault Code 6: Condensate Overflow - The Condensate Overflow sensor must sense overflow levels for 30 continuous seconds to be recognized as a CO fault. Condensate Overflow will be monitored at all times during the compressor run cycle. When the Test mode is active, the Fault LED will display a fault code of 6 for a Condensate Overflow fault.

Fault Code 7: Over/Under Voltage Shutdown - An Over/Under Voltage condition exists when the control voltage is outside the range of 18VAC to 31.5VAC. Over/ UnderVoltage Shutdown is self-resetting in that if the voltage comes back within range of 18.5VAC to 31VAC for at least 0.5 seconds, then normal operation is restored. This is not considered a fault or lockout. If the DXM2 is in over/under voltage shutdown for 15 minutes, the Alarm Relay will close. When the Test mode is active, the Fault LED will display a fault code of 7 for an Over/Under Voltage Shutdown.

Fault Code 8: Unit Performance Sentinel – UPS – The UPS feature warns when the heat pump is operating inefficiently. A UPS condition exists when:

a)In Heating Mode with compressor energized, if LT2 is greater than 125°F for 30 continuous seconds, or

b)In Cooling Mode with compressor energized, if LT1 is greater than 125°F for 30 continuous seconds, OR LT2 is less than 40°F for 30 continuous seconds.

If a UPS condition occurs, the control will immediately go to UPS warning. The status LED will remain on as if the control is in Normal Mode. (see “LED and Alarm Relay Operation Table”). Outputs of the control, excluding Fault LED and Alarm Relay, will NOT be affected by UPS. The UPS condition cannot occur during a compressor off cycle. During UPS warning, the Alarm Relay will cycle on and off. The cycle rate will be On for 5 seconds, Off for 25 seconds, On for 5 seconds, Off for 25 seconds, etc. When the Test mode is active, the Fault LED will display a fault code of 8 for an UPS condition.

Fault Code 9: Swapped LT1/LT2 Thermistors - During Test Mode, the control monitors to see if the LT1 and LT2 thermistors are connected and operating properly. If the control is in Test Mode, the control will lockout, with Code 9, after 60 seconds if:

a)the compressor is On in Cooling Mode and the LT1 sensor is colder than the LT2 sensor. Or,

b)the compressor is On in Heating Mode and the LT2 sensor is colder than the LT1 sensor.

When the Test mode is active, the Fault LED will display a fault code of 9 for a Swapped Thermistor fault.

Fault Code 10: ECM Blower Fault – When operating an ECM blower, there are two types of ECM Blower fault conditions that may be detected.

a)An ECM blower fault will be detected and the control will lockout after 15 seconds of blower operation with the blower feedback signal reading less than 100 RPM.

b)An ECM blower fault will be detected when the ECM configuration is incorrect or incomplete. For this fault condition, the control will continue to operate using default operating parameters.

When the Test mode is active, the Fault LED will display a fault code of 10 for an ECM Blower fault.

Fault Code 11: Low Air Coil Pressure Switch (Whole House Dehumidification Units Only) – When the Low Air Coil Pressure switch opens due to low refrigerant pressure in the cooling or reheat operating mode, the

compressor relay is de–energized immediately. The Low Air Coil Pressure fault recognition is immediate (does not delay for 30 continuous seconds before de–energizing the compressor). When the Test mode is activated, the Fault LED will display a fault code of 11 for a Low Air Coil Pressure fault. Note: Low Air Coil Pressure fault will keep the unit from operating in the cooling or reheat modes, but heating operation will still operate normally.

Fault Code 12: Low Air Temperature (Whole House Dehumidification Units Only) – The control will recognize an Low Air Temperature fault, during cooling, reheat, or constant fan operation if the LAT thermistor temperature is below 35 degrees for 30 continuous seconds. When the Test mode is activated, the Fault LED will display a fault code of 12 for a Low Air Temperature fault. Note: Low Air Temperature fault will keep the unit from operating in the cooling, reheat, or constant fan modes, but heating operation will still operate normally.

Diagnostic Features

The green Status LED and red Fault LED on the DXM2 Control advise service personnel of the current status of the DXM2 Control. The LED’s will indicate the current operating status of the DXM2, as well as the LAST fault in memory. If there is no fault in memory and the fault display is selected, the Fault LED will flash Code 1. See Table 3 for a complete listing of codes.

UNIT OPERATION DESCRIPTION

Power Up - The unit will not operate until all the inputs and safety controls are checked for normal conditions.

9

Loading...

Loading...