Gemini PT 2100 User Manual

Page 1

OPERATIONS MANUAL

BEDIENUNGSHANDBUCH

MANUAL DEL OPERADOR

MANUEL D’INSTRUCTIONS

PT-2100

HIGH-TORQUE DIRECT-DRIVE

PROFESSIONAL TURNTABLE

PROFESSIONELLER PLATTENSPIELER MIT

DREHMOMENTSTARKEM DIREKTANTRIEB

GIRADISCOS PROFESIONAL DE ACCIONAMIENTO DIRECTO Y

DE ALTO PAR MOTOR

PLATINE VINYLE PROFESSIONNELLE HI-TORQUE À

ENTRAÎNEMENT DIRECT PILOTÉE PAR QUARTZ

GIRADISCHI PROFESSIONALE A COMANDO DIRETTO ED A

ALTA COPPIA MOTRICE

MULTI LANGUAGE INSTRUCTIONS:

English.....................................................................................................Page 4

Deutsch...................................................................................................Page 7

Español...................................................................................................Page 10

Francais.................................................................................................Page 13

Italiano...................................................................................................Page 16

Page 2

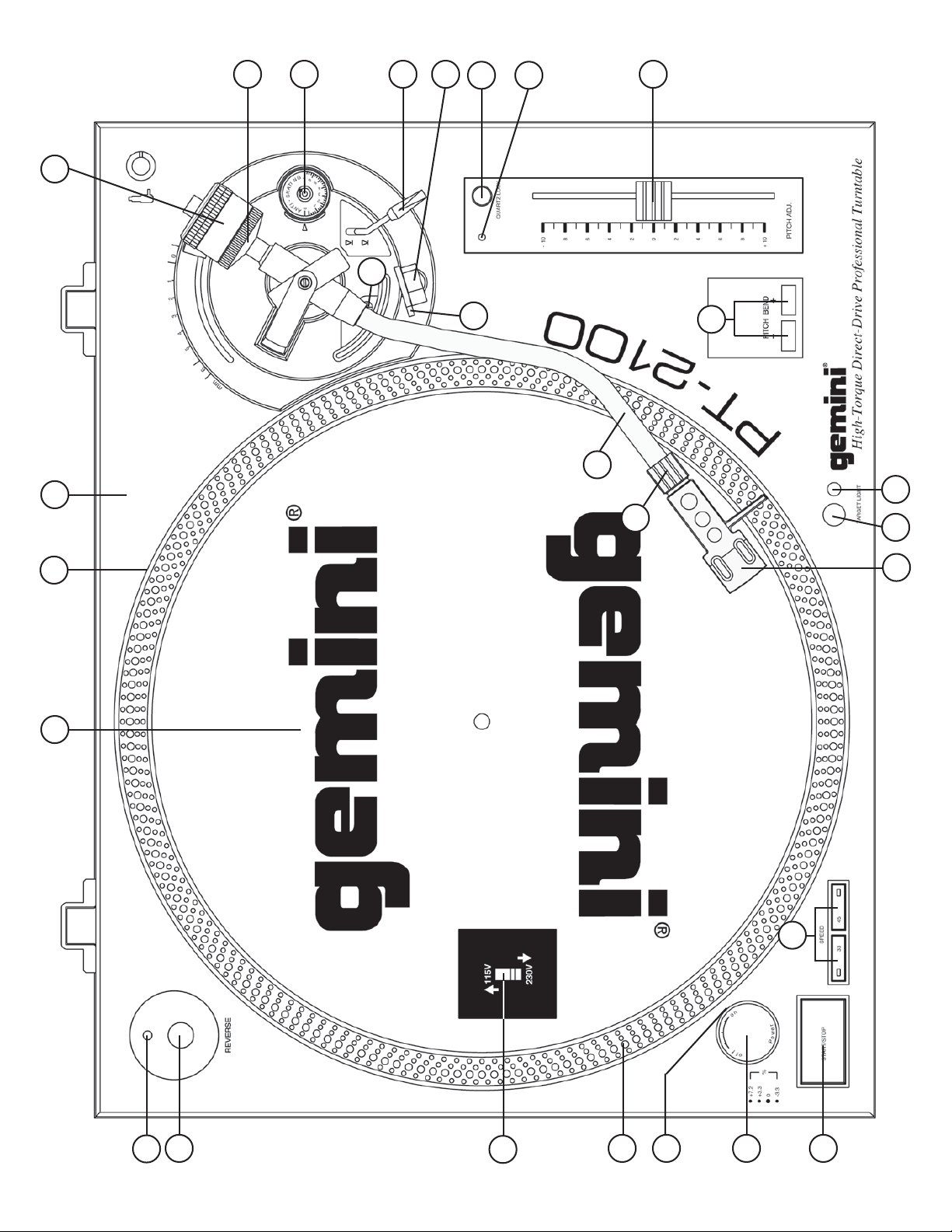

12 16 10

7

17

4

1

8

9

5

18

19

14132524

11

6

20

15

26

23 22

2

Figure 1

17A

3

21

Page 3

Figure 2

Figure 3

Page 4

Introduction

Congratulations on purchasing a Gemini PT-2100 high-torque direct drive

professional turntable. This state of the art turntable includes the latest

features in modern direct drive turntable technology. Prior to use, we

suggest that you carefully read all the instructions.

Features

• Quartz locked speed

• +/- 10% Pitch control

• Fully electronic braking

• Strobe illuminator

• Soft-touch start/stop switch

• Platter Reverse

Precautions

1. Read all operating instructions before using this equipment.

2. To reduce the risk of electrical shock, do not open the unit. There

are NO USER REPLACEABLE PARTS INSIDE. Please contact the

Gemini Service Department or your authorized dealer to speak to a

qualified service technician.

In the U.S.A., if you have any problems with this unit, call

1-732-969-9000 for customer service. Do not return

equipment to your dealer.

3. Tone arm bearings are factory set and sealed. Any attempt at

adjustment will void the warranty.

4. Be sure that all AC power is OFF while making connections.

5. Cables should be low capacitance, shielded and of proper length. Make

sure that all plugs and jacks are tight and properly connected.

6. Always begin with the audio level faders/volume controls set at

minimum and the speaker volume control(s) set to OFF. Wait 8 to 10

seconds prior to turning up the speaker volume to prevent the transient

“POP” that could result in speaker/crossover damage.

7. DO NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE.

8. DO NOT USE ANY SPRAY CLEANER OR LUBRICANT ON ANY

CONTROLS OR SWITCHES.

Parts Checklist

Turntable unit.................................................................................1

Dust cover hinge............................................................................2

Turntable platter.............................................................................1

45 RPM adapter...............................................................................1

Neoprene mat....................................................................................1

Counter balance.............................................................................1

Dust cover......................................................................................1

Headshell.......................................................................................1

Assembly and Set-Up

NOTE: SEE FIG. 1 (PAGE 1) FOR PART NUMBERS AND

LOCATIONS.

TURNTABLE INSTALLATION:

1. Set the TURNTABLE BASE (1) on a flat, level surface free of vibration.

Try to place the unit as far away from the speakers as possible. Keep

the unit away from direct exposure to the sun, heat, moisture or dirt.

Keep the unit well ventilated. Use the turntable feet to horizontally

stabilize the unit.

2. Make sure that the VOLTAGE SELECTOR (3) switch (located on the

TURNTABLE BASE) is set to the correct voltage. WARNING: If you try

to operate the turntable with the incorrect voltage setting, it can damage

your turntable.

3. After checking to ensure that all packing materials have been removed,

gently place the PLATTER (2) on the center spindle of the TURNTABLE

BASE (1).

4. Put the NEOPRENE MAT (4) on the PLATTER (2).

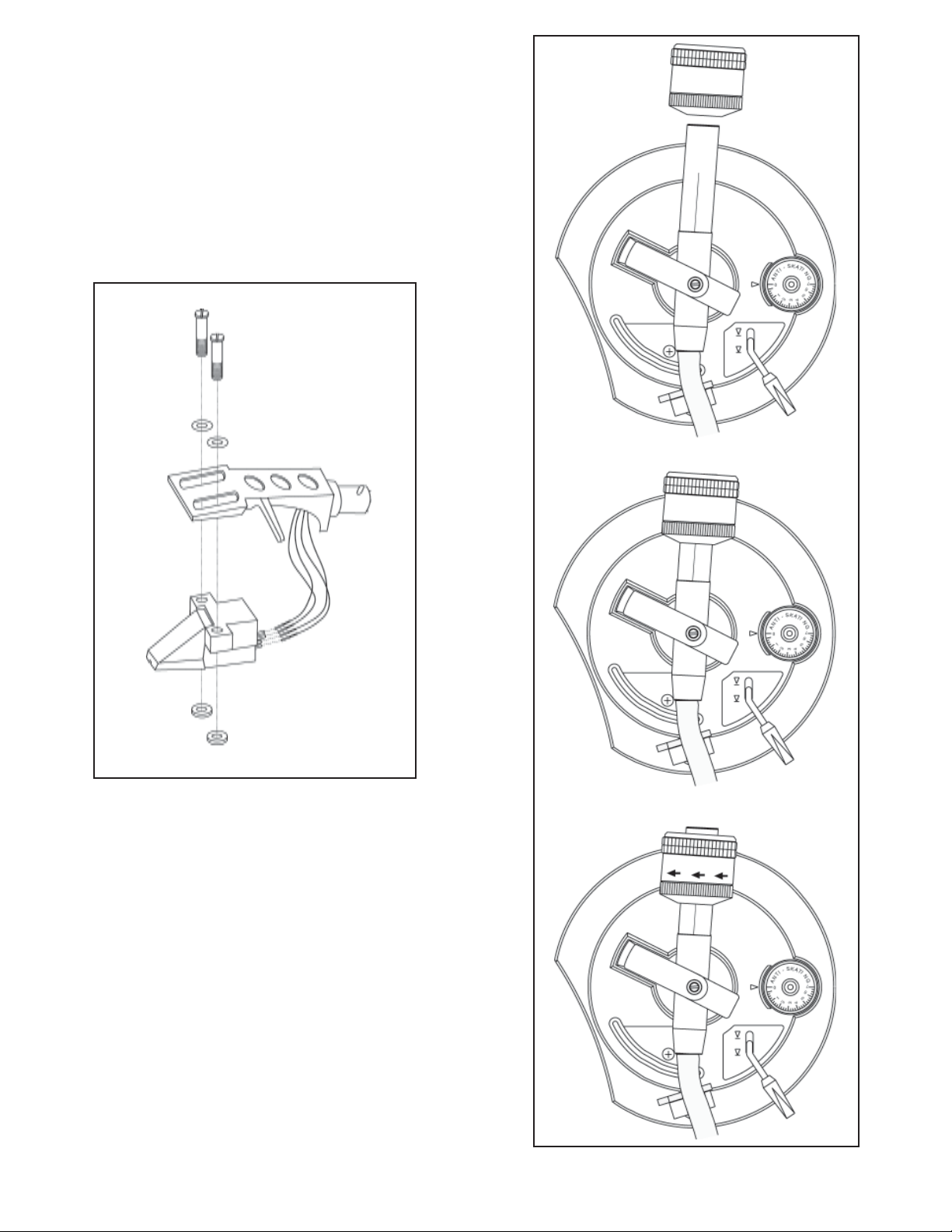

CARTRIDGE INSTALLATION: (SEE FIG. 2)

Because all cartridges have their own designs, please refer to your

particular cartridge’s instructions to insure proper installation.

1. Connect the lead wires to the cartridge terminals. For your convenience,

the terminals of most cartridges are color coded. Connect each lead

wire to the terminal of the same color.

White (L+).................................................Left Channel +

Blue (L-)...................................................Left Channel -

Red (R+).................................................Right Channel +

Green (R-)..............................................Right Channel -

2. Mount the cartridge in the HEADSHELL (5) and tighten it with the

screws included with the cartridge.

ATTENTION STANTON 680 CARTRIDGE USERS

When using a Stanton 680 or similar cartridge, where the body

is grounded to a cartridge terminal, remove the grounding strap

from the cartridge body to the cartridge ground terminal. Failure

to do this may result in excessive hum.

HEADSHELL INSTALLATION:

Insert the HEADSHELL (5) into the front of the tubular TONE ARM (6).

While holding the HEADSHELL firmly in a horizontal position, turn the

LOCKING NUT (7) counter clockwise until the HEADSHELL is locked in

place.

COUNTERWEIGHT INSTALLATION: (SEE FIG. 3)

1. Slide the COUNTERWEIGHT (8) onto the rear of the TONE ARM (6)

with the numbered stylus gauge facing forward.

2. Twist the COUNTERWEIGHT (8) lightly counter clockwise, to screw it

onto the rear of the TONE ARM (6).

ADJUSTING HORIZONTAL ZERO (0) BALANCE AND

STYLUS PRESSURE:

1. Without touching the stylus tip, remove the stylus protector (if your

cartridge has a detachable one).

2. Release the ARM CLAMP (9) and lift the TONE ARM (6) off the ARM

REST (10).

3. Counter clockwise advancement of the COUNTERWEIGHT (8) will

cause the cartridge side of the TONE ARM (6) to be lowered. Clockwise

will cause the opposite. Turn the COUNTERWEIGHT clockwise or

counter clockwise as needed until the TONE ARM is balanced horizon-

tally. You can easily tell this by watching for the point where the TONE

ARM “floats” freely.

4. Place TONE ARM (6) on ARM REST (10) and lock it in place with the

ARM CLAMP (9).

5. With the TONE ARM (6) locked on the ARM REST (10), hold the

COUNTERWEIGHT (8) steady with one hand while rotating the STYLUS

PRESSURE RING (11) until the numeral “0” on the ring aligns with the

center line on the TONE ARM (6) rear shaft. The horizontal zero (0)

balance should be completed.

6. Refloat the TONE ARM to ensure horizontal zero (0) balance. If zero

balance has not been maintained, repeat counterweight steps 3 - 5.

7. After adjusting the horizontal zero (0) balance, turn the balanced

COUNTERWEIGHT (8) counter clockwise until the cartridge

manufacturer’s recommend stylus pressure appears on the STYLUS

PRESSURE RING (11) where it meets the center line of the TONE ARM

(6) rear shaft.

ADJUSTING THE ANTI-SKATING CONTROL:

Set the ANTI-SKATING CONTROL (12) to the same value as the stylus

pressure.

Page 5

L (WHITE)

R (RED)

GND (Spade Lug)

MIXER OR

RECEIVER

OUTPUT CONNECTORS

PHONO L CHANNEL

PHONO R CHANNEL

GND Screw

INSTALLING THE DUSTCOVER:

1. Mount the hinges onto the dustcover.

2. Hold the dustcover in position, directly above the turntable, and slide the

hinge bases into the holders mounted on the rear panel.

3. Always raise the dustcover before removal.

4. Avoid opening and closing the dustcover during play. Undesirable

vibration and stylus skipping can result.

CONNECTIONS:

1. Plug the AC power plug into an appropriate outlet.

2. See Table A for proper connection of the output RCA plugs and ground

connector. Make sure that all the plugs are firmly plugged into the

appropriate jacks (phono inputs). To reduce hum, make sure the ground

lug is firmly connected to the ground screw.

TABLE A

Operating Instructions

BASIC OPERATION:

1. Place a record on the NEOPRENE MAT (4) which sits on the

PLATTER (2).

2. Select the desired speed by depressing the 33 or 45 SPEED

SELECTOR (15) button.

3. Turn the POWER (13) switch to the “ON” position, at which point the

strobe illuminator (built into the POWER switch and the speed indicator

(for the selected speed) will illuminate.

4. Remove the stylus protector (if applicable to your cartridge).

5. Release the ARM CLAMP (9) found on the ARM REST (10).

6. Push the START STOP (14) button. The turntable PLATTER (2) will

start to spin.

7. Push the CUE LEVER (16) to the “UP” position.

8. Position the tone arm over the desired position on the record and push

the CUE LEVER to the “DOWN” position. The TONE ARM (6) will

slowly lower onto the record at which time play will begin.

9. When play is over, raise the TONE ARM (6), move it to the ARM REST

(10), and secure it with the ARM CLAMP (9).

10.You now have the option of turning off the power by turning the POWER

(13) switch to the “OFF” position, or stopping the PLATTER (2) by

pushing the START STOP (14) button and engaging the electronic

brake.

INTERRUPTING PLAY:

1. Pushing the CUE LEVER (16) to the “UP” position will cause the TONE

ARM (6) to lift, stopping play.

2. Pushing the CUE LEVER to the “DOWN” position will cause the TONE

ARM to slowly lower onto the record at the point where play was

interrupted.

PLAYING 45 RPM RECORDS:

1. When playing a 45 RPM record with a large center hole, first place the

45 ADAPTER on the center spindle.

2. Be sure that the 45 SPEED SELECTOR (15) button is pushed and the

45 speed indicator is illuminated.

TARGET LIGHT:

1. Push the TARGET LIGHT SWITCH (18) firmly and the TARGET LIGHT

(19) will raise into position and illuminate the stylus tip.

2. To lower the TARGET LIGHT, push down on it until it locks in the

casing.

3. When not being used, the TARGET LIGHT should be kept in the

lowered position.

ADJUSTING THE PITCH CONTROL:

1. The PT-2100 is equipped with PITCH CONTROL (21) and QUARTZ

LOCK (23). When the QUARTZ LOCK is activated, the QUARTZ

LOCK LED (22) lights GREEN, and the speed will be exactly 33 1/3 or

45 RPM depending on which SPEED SELECTOR (15) button is pushed

regardless of the position of the pitch control. PITCH CONTROL

automatically disengages when QUARTZ LOCK is activated.

2. When the QUARTZ LOCK is off, you can adjust the PITCH CONTROL.

When you move PITCH CONTROL off center, the pitch can vary +/-

10% depending on the position of the PITCH CONTROL.

3. Push the QUARTZ LOCK (23) button to bring the speed back to exactly

33 1/3 or 45 RPM when the PITCH CONTROL is positioned off center.

Disengaging the QUARTZ LOCK will bring the platter speed back to the

original pitch setting.

4. The PLATTER (2) is equipped with a STROBE RPM INDICATOR

STRIP (24) and the POWER (13) switch contains built in STROBE

LIGHTS (25). When the PLATTER (2) is spinning, the STROBE

LIGHTS illuminate the STROBE RPM INDICATOR STRIP. The bottom

row of dots will appear to be stationary when the pitch is -3.3%. The

second row of dots from the bottom will appear to be stationary when

the speed is exactly 33 1/3 or 45 RPM depending on which SPEED

SELECTOR (15) button is pushed. The third row of dots from the

bottom will appear to be stationary when the pitch is +3.3%. The top

row of dots will appear to be stationary when the pitch is +7.2%.

PITCH BEND:

1. Pushing the PITCH BEND (20) buttons will temporarily raise or lower

the pitch without changing the slide setting. Releasing the buttons will

return the pitch to the slide setting.

USING THE REVERSE BUTTON:

1. Press the REVERSE (17) button to reverse the rotation of the

PLATTER (2) (the REVERSE LED (17A) will light while in reverse

mode). Press the REVERSE BUTTON a second time to return to

normal play.

ARM-LIFT HEIGHT ADJUSTMENT:

If the pre-adjusted distance that the CUE LEVER (16) raises the stylus off

the record surface is inadequate, it can be adjusted by turning the ARM-

LIFT HEIGHT ADJUSTMENT SCREW (26) while simultaneously pushing

down on the TONE ARM (6). Clockwise rotation of the screw will decrease

the distance and counter clockwise rotation will increase the distance.

Page 6

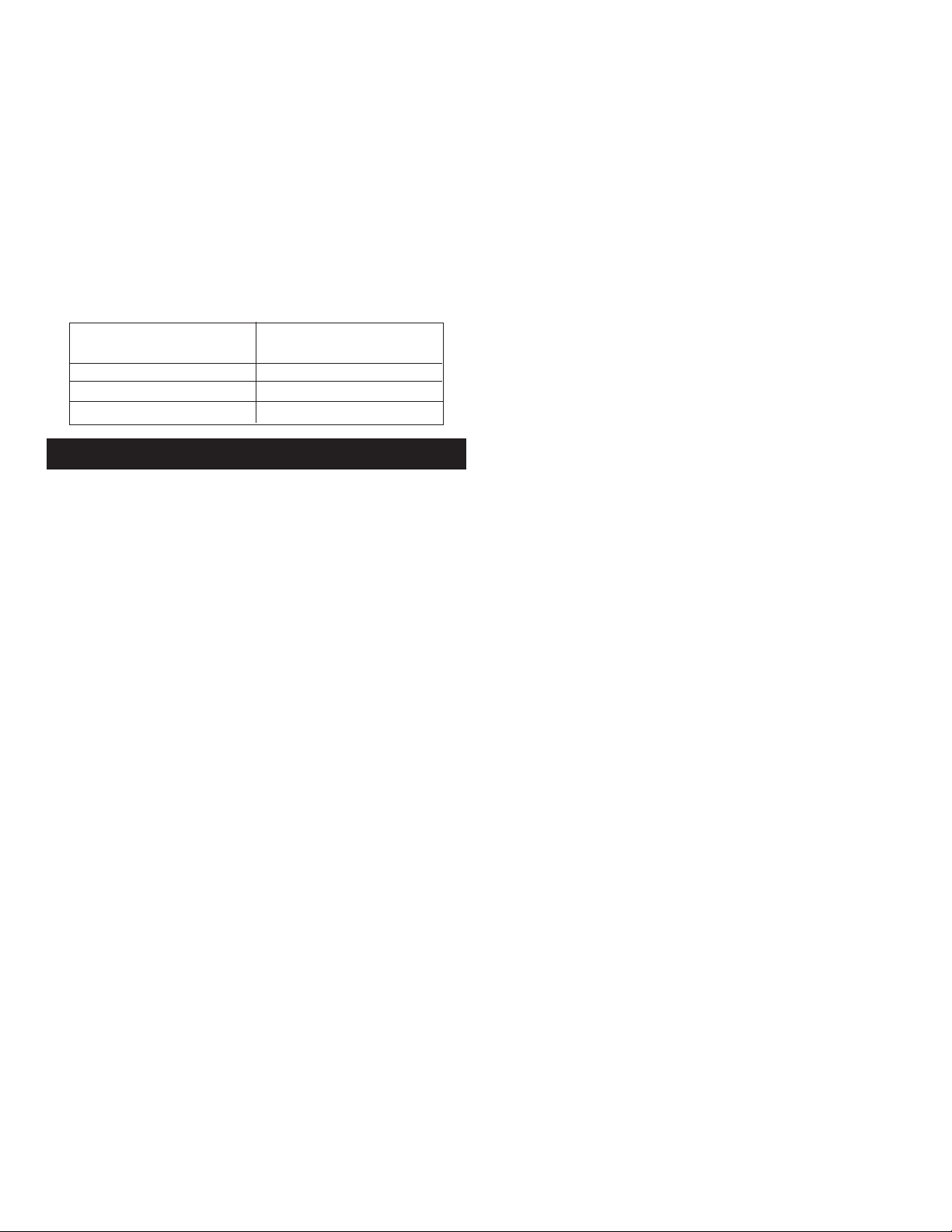

Specifications

TURNTABLE SECTION:

Type...................................................Quartz Direct Drive Manual Turntable

Drive Method...............................................................................Direct Drive

Motor.....................................................................Brushless DC Motor 18V

Platter..................................................Aluminum Diecast 13” (332mm) Dia.

Speed............................................................................33 1/3 or 45 RPM

Starting Torque................................................................................2.2 Kg/cm

Build-up Characteristics............................0.6 sec. standstill to 33 1/3 RPM

Braking System....................................................................Electronic Brake

Wow and Flutter.......................................................................0.01% WRMS*

* This rating refers to the turntable assembly and platter only and excludes

effects of records, cartridges or tonearms.

Rumble...........................................................................78 dB (IEC 98A WTD)

TONEARM SECTION:

Type.........................................................Universal S-Shaped Tubular Arm

Effective Length................................................................9 1/16” (230.1 mm)

Overhang............................................................................19/32" (15.2 mm)

Effective Mass...........................................................9 g (Without Cartridge)

Offset Angle...........................................................................................22°

Friction...................................................Less Than 7 mg (Lateral, Vertical)

Tracking Error Angle........Within 2°32' at the outer groove and within

0°32' at the inner groove of a 30 cm (12") record

Stylus Pressure Adjust Range...........................................................0 - 5 g

Applicable Cartridge Weight Range....................................................6 - 10 g

Headshell Weight....................................................................................5.6 g

GENERAL:

Power Supply............................................................115V~60Hz/230V~50Hz

Power Consumption........................................................................15 Watts

Dimensions.....................................17 3/4” x 6" x 14" (450 x 152 x 352 mm)

Weight...............................................................................25.5 lbs. (11.6 kg)

Specifications are subject to change without notice. The weight and

dimensions shown are approximate.

Loading...

Loading...