GE TPX24PBDWW, TPS24PBDBS, TPX24PBDAA, TPX24PBDCC, TPX24PBDBB User Manual

GE Appliances

Side by side

Refrigerators

Côte à côte

Réfrigérateurs

Lado a lado

Refrigeradores

Owner’s Manual

Profile Models 24 CustomStyle, 28 and 30

Manuel d’utilisation

Modèle Profile «CustomStyle» 24,

Modèles Profile 28 et 30

Manual del propietario

Modelo Profile 24 “CustomStyle,” Modelos Profile 28 y 30

English section begins on page 2

La section française commence à la page 40

La sección en español empieza en la página 74

www.geappliances.com |

Part No. 162D9617P009 Pub. No. 49-60064 11-99 JR |

Troubleshooting Tips Installation Instructions Operating Instructions Safety Instructions

Customer Service

Safety Information

Safety Precautions . . . . . . . . . . . .3 Use of Extension Cords . . . . . . . . .3 How to Connect Electricity . . . . . .4 Use of Adapter Plugs . . . . . . . . . .4

Operating Instructions

Controls . . . . . . . . . . . . . . . . . .5–8

Features . . . . . . . . . . . . . . . . . .5–12

Refreshment Center . . . . . . .13–15

Care and Cleaning . . . . . . . . .16–18

Installation Instructions

Preparing to

Install the Refrigerator . . . . .19, 20 Trim Kits . . . . . . . . . . . . . . . .21–25 Water Line Installation . . . . .26–28

Troubleshooting Tips

Normal Operating Sounds . . . . . .29

Before You

Call For Service . . . . . . . . . . .29–32

Customer Service

Warranty for Canadian Customers .32 Warranty for U.S. Customers . . . .33

FXRC Cartridge

Performance Data Sheet . . . . . . .34

State of California Water Treatment Device Certificate . . .35

Product Registration . . . . . . . . . .37

Service Telephone

Numbers . . . . . . . . . . . .Back Cover

2

Congratulations!

You Are Now Part of the GE Family

Welcome to the GE family. We’re proud of our quality products and we are committed to providing dependable service. You’ll see it in this easy-to-use Owner’s Manual and you’ll hear it in the friendly voices of our customer service department.

Best of all, you’ll experience these values each time you use your refrigerator. That’s important, because your new refrigerator will be part of your family for many years. And we hope you will be part of ours for a long time to come.

We thank you for buying GE. We appreciate your purchase, and hope you will continue to rely on us whenever you need quality appliances for your home.

GE & You, A Service Partnership.

IMPORTANT!

IMPORTANT!

Fill out the Consumer Product Registration Card.

Two Easy Ways To Register Your Appliance!

■Through the internet at www.geappliances.com.

■Complete and mail the enclosed Product Registration Card.

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

You can find them on a label inside the fresh food compartment on the top.

Staple sales slip or cancelled check here.

Proof of the original purchase date is needed to obtain service under the warranty.

READ THIS MANUAL

Inside you will find many helpful hints on how to use and maintain your refrigerator properly. Just a little preventive care on your part can save you a great deal of time and money over the life of your refrigerator.

IF YOU NEED SERVICE

You’ll find many answers to common problems in the Before You Call For Service section. If you review our chart of Troubleshooting Tips first, you may not need to call for service at all.

If you do need service, you can relax knowing help is only a phone call away. A list of toll-free customer service numbers is included in the back section. Or, in the U.S., you can always call the GE Answer Center® at 800.626.2000, 24 hours a day, 7 days a week. In Canada, call 1-800-361-3400.

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

WARNING!

Use this appliance only for its intended purpose as described in this Owner’s Manual.

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

■This refrigerator must be properly installed and located in accordance with the Installation Instructions before it is used.

■Do not allow children to climb, stand or hang on the shelves in the refrigerator. They could damage the refrigerator and seriously injure themselves.

■Do not allow anyone to climb, sit, stand or hang on the Refreshment Center door. They could damage the refrigerator and maybe even tip it over, causing severe personal injury.

■Do not touch the cold surfaces in the freezer compartment when hands are damp or wet. Skin may stick to these extremely cold surfaces.

■Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

■In refrigerators with automatic icemakers, avoid contact with the moving parts of the ejector mechanism, or with the heating element that releases the cubes. Do not place fingers or hands on the automatic icemaking mechanism while the refrigerator is plugged in.

■Keep fingers out of the “pinch point” areas; clearances between the doors and between the doors and cabinet are necessarily small. Be careful closing doors when children are in the area.

■Unplug the refrigerator before cleaning and making repairs.

NOTE: We strongly recommend that any servicing be performed by a qualified individual.

■Turning the control to the OFF or position does not remove power to the light circuit.

■Do not refreeze frozen foods which have thawed completely.

DANGER! RISK OF CHILD ENTRAPMENT

DANGER! RISK OF CHILD ENTRAPMENT

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems of the past. Junked or abandoned refrigerators are still dangerous…even if they will sit for “just a few days.” If you are getting rid of your old refrigerator, please follow the instructions below to help prevent accidents.

Before You Throw Away Your Old Refrigerator or Freezer:

■Take off the doors.

■Leave the shelves in place so that children may not easily climb inside.

CFC Disposal

Your old refrigerator has a cooling system that used CFCs (chlorofluorocarbons). CFCs are believed to harm stratospheric ozone.

If you are throwing away your old refrigerator, make sure the CFC refrigerant is removed for proper disposal by a qualified servicer. If you intentionally release this CFC refrigerant you can be subject to fines and imprisonment under provisions of environmental legislation.

USE OF EXTENSION CORDS

Because of potential safety hazards under certain conditions, we strongly recommend against the use of an extension cord.

However, if you must use an extension cord, it is absolutely necessary that it be a UL-listed (in the United

States) or a CSA certified (in Canada), 3-wire grounding type appliance extension cord having a grounding type plug and outlet and that the electrical rating of the cord be 15 amperes (minimum) and 120 volts.

3

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions OperatingInstructions Safety Instructions

CustomerService

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

WARNING!

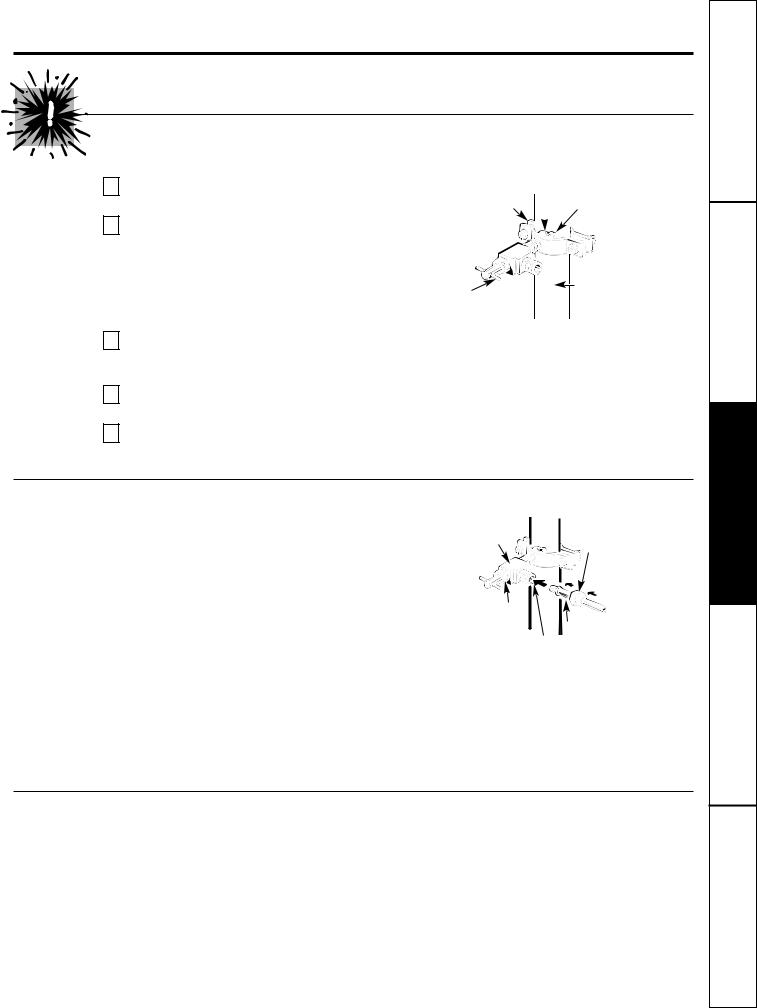

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with a 3-prong (grounding) plug which mates with a standard 3-prong (grounding) wall outlet to minimize the possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it is your personal responsibility and obligation to have it replaced with a properly grounded 3-prong wall outlet.

The refrigerator should always be plugged into its own individual electrical outlet which has a voltage rating that matches the rating plate.

This provides the best performance and also prevents overloading house wiring circuits which could cause a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the power cord. Always grip plug firmly and pull straight out from the outlet.

Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use a cord that shows cracks or abrasion damage along its length or at either end.

When moving the refrigerator away from the wall, be careful not to roll over or damage the power cord.

USE OF ADAPTER PLUGS (Adapter plugs not permitted in Canada)

Because of potential safety hazards under certain conditions, we strongly recommend against the use of an adapter plug.

However, if you must use an adapter, where local codes permit, a temporary connection may be made to a properly grounded 2-prong wall outlet by use of a UL-listed adapter available at most local hardware stores.

The larger slot in the adapter must be aligned with the larger slot in the wall outlet to provide proper polarity in the connection of the power cord.

When disconnecting the power cord from the adapter, always hold the adapter in place with one hand while pulling the power cord plug with the other hand. If this is not done, the adapter ground terminal is very likely to break with repeated use.

If the adapter ground terminal breaks, DO NOT USE the refrigerator until a proper ground has been established.

Attaching the adapter ground terminal to a wall outlet cover screw does not ground the appliance unless the cover screw is metal, and not insulated, and the wall outlet is grounded through the house wiring. You should have the circuit checked by a qualified electrician to make sure the outlet is properly grounded.

Read and follow this Safety Information carefully.

SAVE THESE INSTRUCTIONS

4

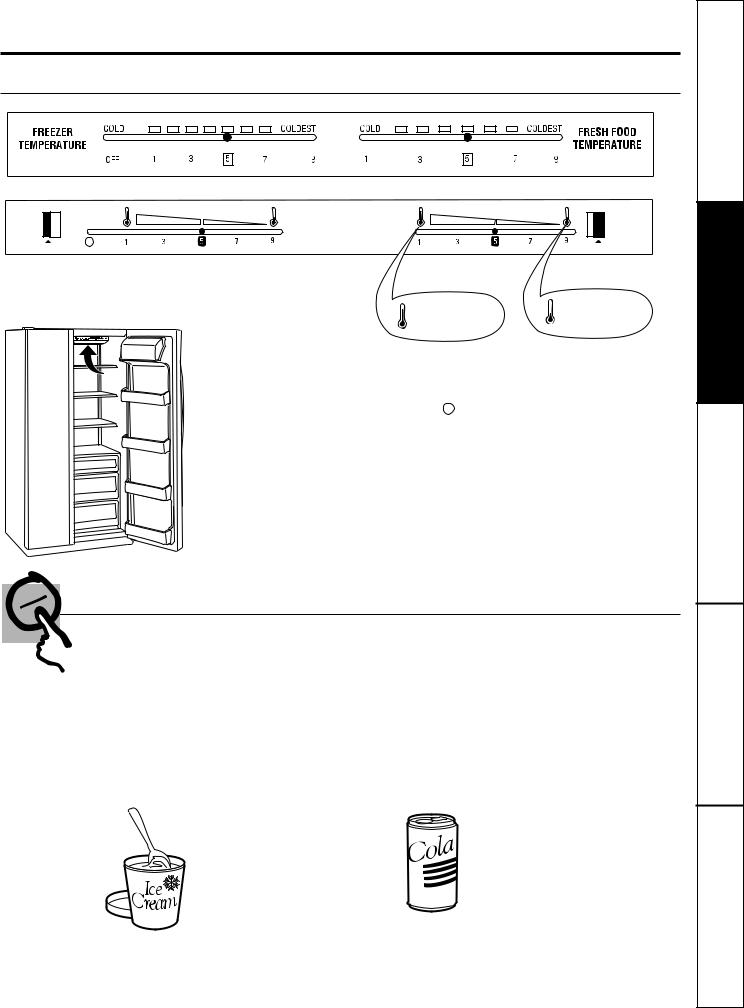

About the controls on the refrigerator.

The controls will look like one of the following.

Freezer Control |

|

Fresh Food |

|

|

|

Control |

|

1. the WARMEST |

9. the COLDEST |

||

setting |

|||

setting |

|

||

|

|

||

Initially, set the fresh food control at 5 and the freezer control at 5 and |

|||

allow 24 hours for the temperature to stabilize. |

|

||

Moving the freezer control to OFF or |

stops cooling in both the |

||

fresh food and freezer compartments but does not shut off electrical |

|||

power to the refrigerator. |

|

|

|

Control settings will vary based on personal preferences, usage, and |

|||

operating conditions and may require more than one adjustment. |

|||

Testing and Adjusting Temperatures

Several adjustments may be required. Each time you adjust controls, allow 24 hours for the refrigerator to reach the temperature you have set.

■The freezer supplies cold air for both compartments.

■The freezer setting determines the compressor and freezer fan run times.

■The fresh food control maintains the temperature in the fresh food compartment by controlling the amount of cold air that flows from the freezer to the fresh food side.

■Both temperature controls may need adjustment to get the desired temperature in the fresh food compartment.

To test the freezer, place ice cream in the center of the freezer.

Check it after 24 hours. If it’s too hard or too soft, adjust the setting.

To test the fresh food compartment, place a beverage on the top shelf. After 24 hours, taste the drink. If the temperature is not satisfactory, adjust the setting.

5

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

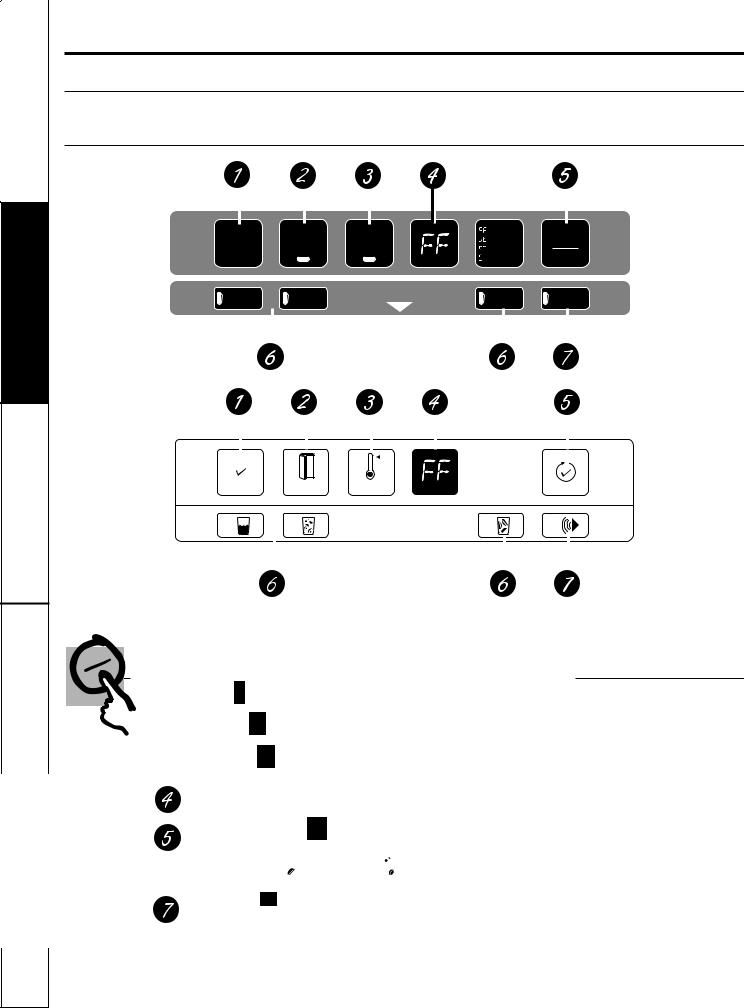

About the controls on the refrigerator.

On some models. The controls will look like one of the following.

The Electronic Monitor and Diagnostic System controls dispenser functions and monitors the operation of your refrigerator.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DISPLAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER |

SYSTEM |

|

|

||

|

|

N O R M A L |

DOOR |

WARM |

DEFROST |

|

|

||||||

|

|

CHECK |

|

|

|||||||||

|

|

OPEN |

TEMP |

FREEZER |

|

|

|||||||

|

|

|

|

RESET |

|

|

|||||||

|

|

|

|

|

|

|

|

ICEMAKER |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

CHILLED |

CRUSHED |

DISPENSER PUSH BELOW |

CUBED |

DOORALARM |

|

|

|||||

|

|

WATER |

|

ICE |

|

|

ICE |

ON/OFF |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Monitor and Diagnostic System

NORMAL

NORMAL  lights up to indicate that no failure has been detected by the diagnostic system.

lights up to indicate that no failure has been detected by the diagnostic system.

DOOR OPEN flashes when either door is open.

DOOR OPEN flashes when either door is open.

WARM TEMP lights up when freezer food-keeping temperature is above normal.

WARM TEMP lights up when freezer food-keeping temperature is above normal.

Flashing diagnostic codes. What these codes mean—and what to do when they appear—is explained more thoroughly on the following pages.

SYSTEM CHECK-RESET  reviews the diagnosis of four coded functions and allows you to erase codes from the display.

reviews the diagnosis of four coded functions and allows you to erase codes from the display.

Select CUBED ICE

Select CUBED ICE  , CRUSHED ICE

, CRUSHED ICE  or WATER

or WATER  and the signal light confirms your choice.

and the signal light confirms your choice.

DOOR ALARM

lights up when the beeper has been set to sound after either door has been open 30 seconds.

lights up when the beeper has been set to sound after either door has been open 30 seconds.

6

When Your Refrigerator Is First Plugged In

All panel lights come on for five seconds, a beep sounds, and lights go off except as follows:

■PF flashes in the display. Touch SYSTEM CHECK-RESET to erase it.

■NORMAL glows.

■WARM TEMP glows until the refrigerator cools down. It goes off when proper foodkeeping temperature is reached.

■Door alarm beeper is activated and DOOR ALARM glows.

■CRUSHED ICE glows.

■DOOR OPEN flashes if either door is open, goes out when doors are shut.

■Night light in ice and water dispenser is off.

|

|

|

|

|

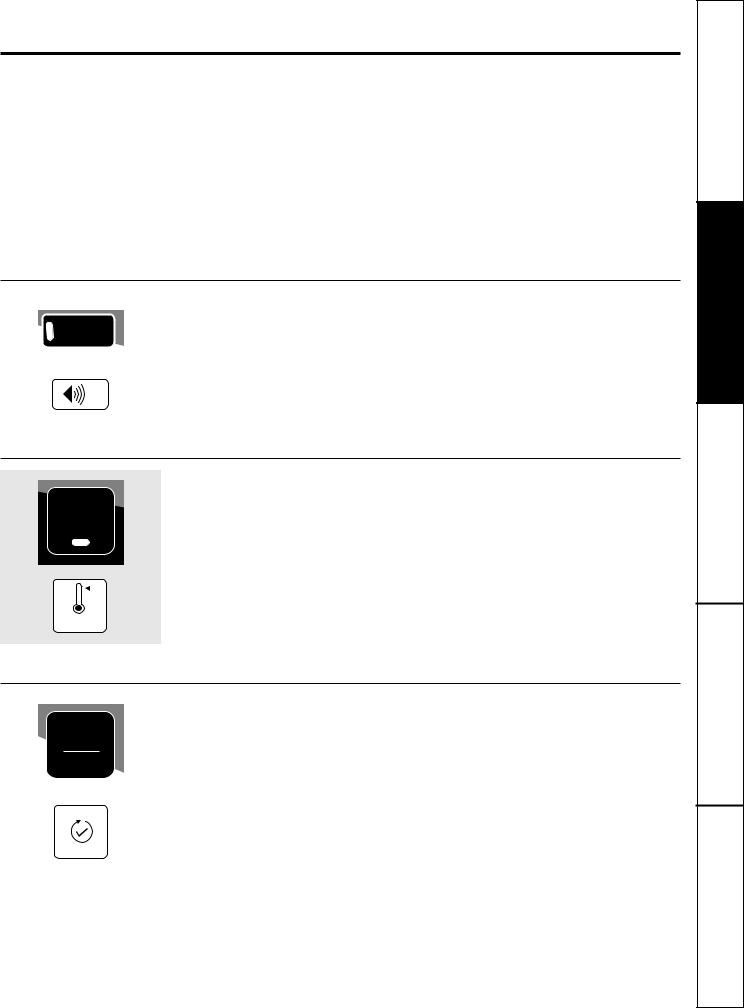

How to Set the Door Alarm |

|

DOORALARM |

|

To set the alarm press DOOR ALARM until it |

||

|

|

||||

|

|

ON/OFF |

|

glows. |

|

|

|

|

|

|

The control beeps if either door is open for |

|

|

|

|

|

|

|

|

|

|

|

more than 30 seconds. |

|

|

|

|

|

The light goes out and the beeping stops |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

when you close the door. |

|

|

|

|

|

|

|

|

|

|

Why the WARM TEMP Light Glows |

|

|

|

|

|

WARM |

At first, it’s probably because your newly- |

|||

installed refrigerator hasn’t completely |

||||

TEMP |

cooled down yet. Wait a few hours for it to |

|||

|

|

|

|

cool, and then the light will go out. |

|

|

|

|

From then on, WARM TEMP will glow |

|

|

|

|

|

|

|

|

|

whenever temperatures inside get too high |

|

|

|

|

for proper food storage. If this happens, |

|

|

|

|

open the doors only when absolutely |

|

|

|

|

necessary, and close them as quickly as |

|

|

|

|

possible. |

As soon as inside temperatures return to normal, the light goes out.

If WARM TEMP reappears and stays on for longer than 4 hours, call for service.

|

|

|

How the Monitor and Diagnostic System Works |

|

|

|

|

||

|

SYSTEM |

|

The diagnostic code flashes and the control |

Pressing SYSTEM CHECK-RESET will erase |

|

|

beeps when something starts to go wrong. |

two codes immediately—PF and CI. The dE |

|

|

CHECK |

|

||

|

|

|

and FF codes can only be erased by pressing |

|

|

RESET |

|

If more than one coded function requires |

|

|

|

|

SYSTEM CHECK-RESET after the condition |

|

|

|

|

attention at the same time, the one with the |

|

|

|

|

that caused the code to flash has been |

|

|

|

|

highest priority will be displayed first. |

corrected. |

|

|

|

|

|

|

|

|

|

SYSTEM CHECK-RESET will also evaluate |

|

|

|

|

all other coded functions. If NORMAL is |

|

|

|

|

lit during the displaying of a code, that |

|

|

|

|

function is operating properly. |

|

|

|

|

|

7

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

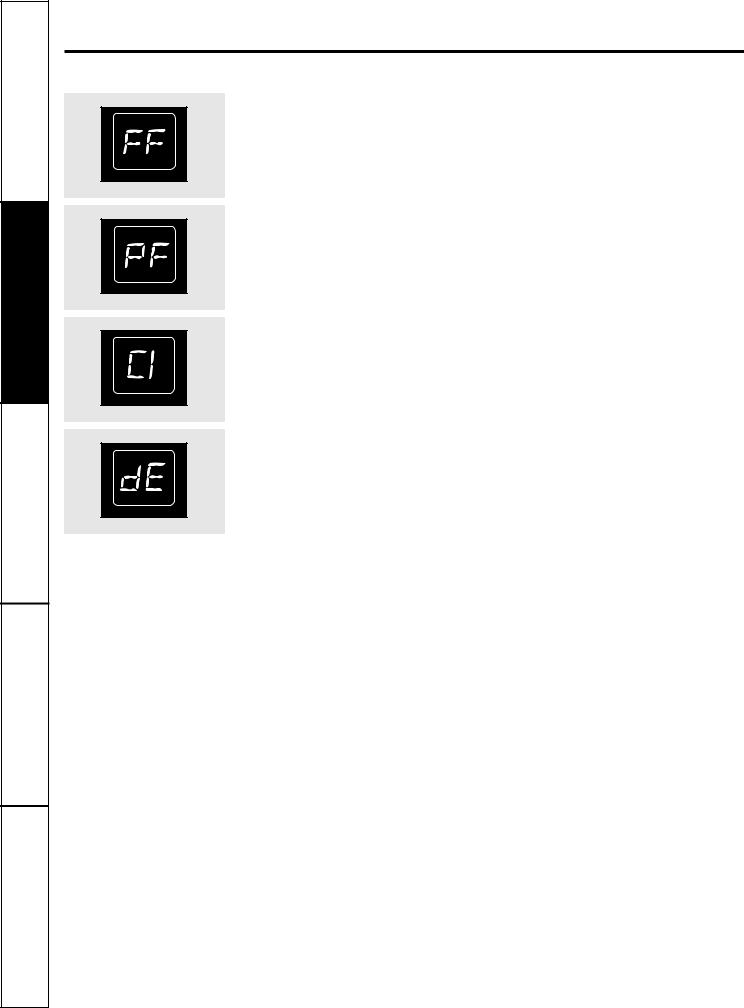

About the controls on the refrigerator.

What the Codes Mean

Check your frozen food. Has any of it started to thaw? A package may be holding the freezer compartment door open. Don’t open the door more often than absolutely necessary while this code is displayed. Touching SYSTEM CHECK-RESET after the freezer compartment temperature has returned to normal will erase the code.

Power to the refrigerator has been interrupted for more than two seconds. Check the condition of food in both the fresh food and freezer compartments. Touch SYSTEM CHECK-RESET to erase the code.

There is no fault with the refrigerator when the PF code flashes.

Check the icemaker. Ice clumps in the storage bin may have stalled the icemaker. Follow corrective measures described in Troubleshooting Tips. If water supply to the icemaker is not connected or not turned on, make sure the icemaker feeler arm is in the STOP (up) position. The code stops flashing when problem is corrected or SYSTEM CHECK-RESET is touched.

Something is wrong with the defrost system—keep doors closed to retain cold and call for service. The code flashes until problem is corrected.

8

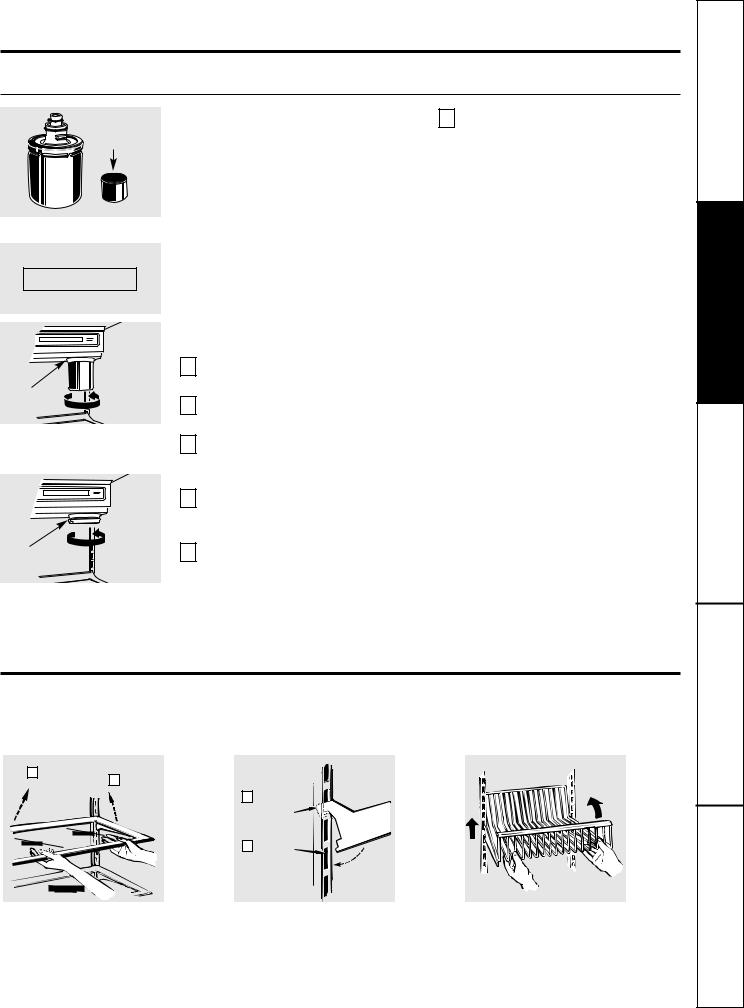

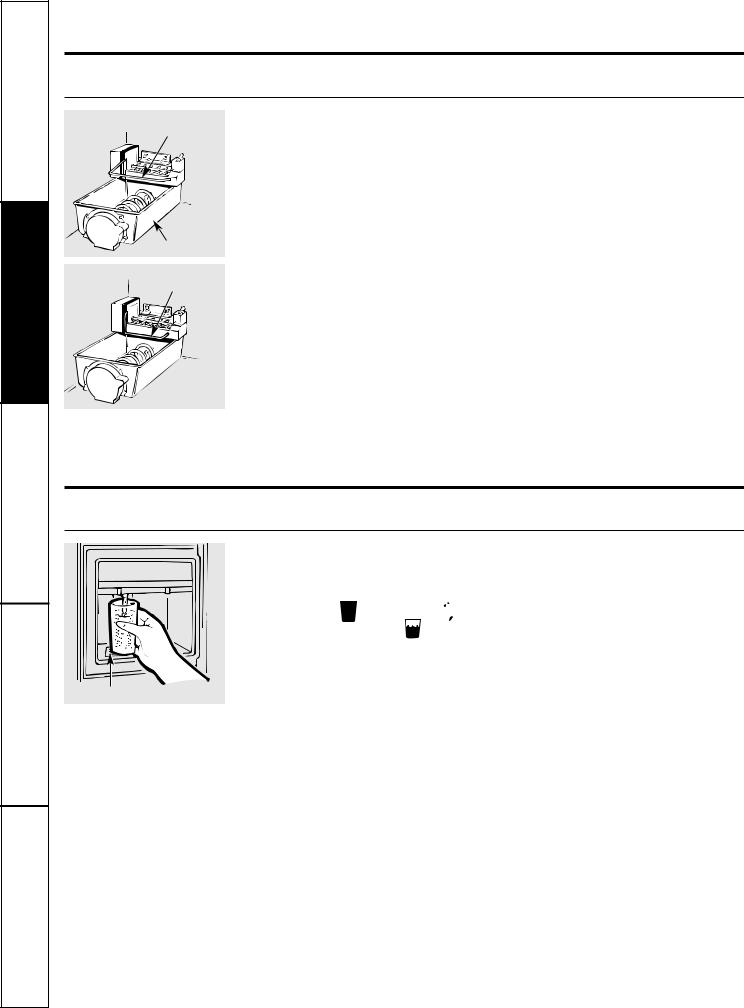

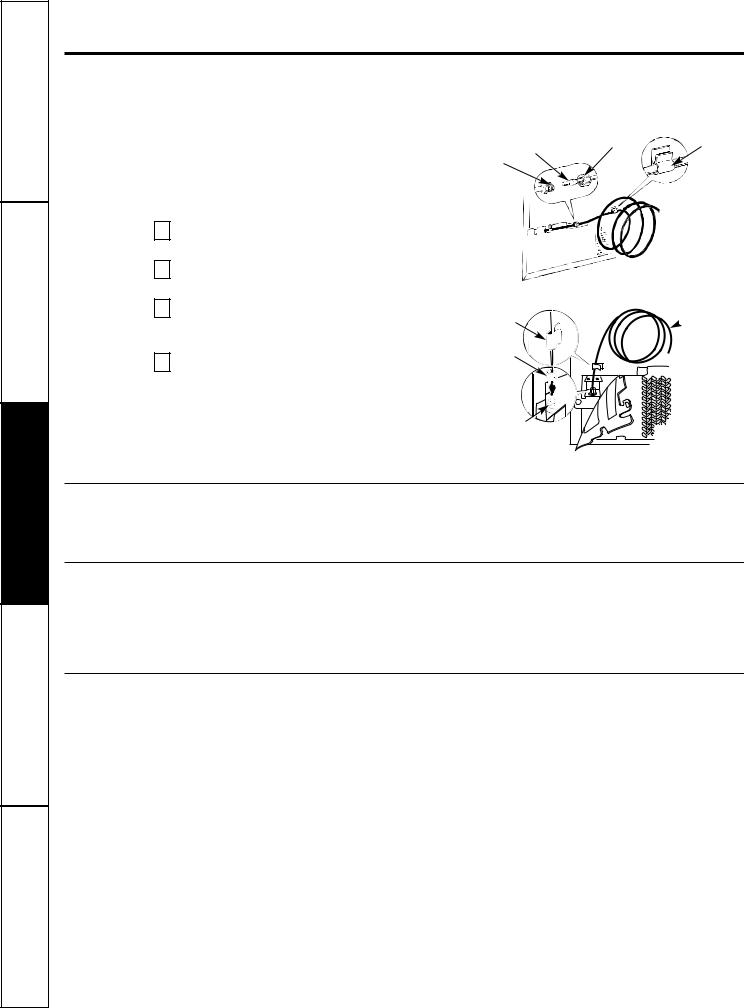

About the water filter cartridge.

On some models

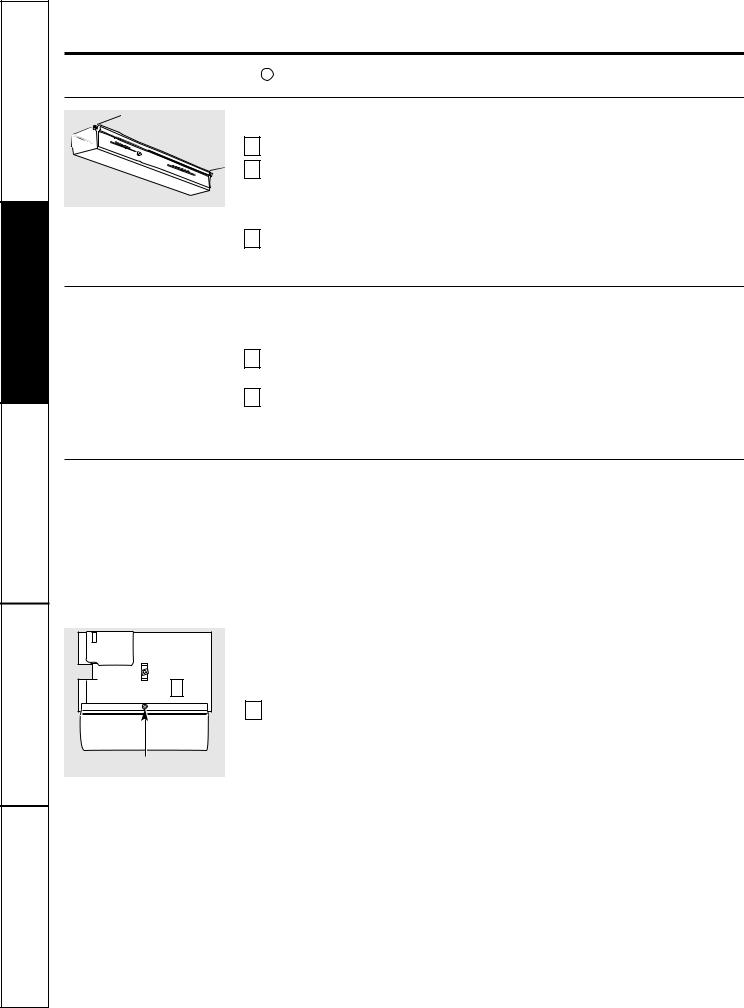

Plastic Cap

Discard the plastic cap.

REPLACE FILTER BY:

(month-year)

replace every 6 months

Cartridge

Holder

Place the top of the cartridge up inside the cartridge holder and slowly turn it to the right.

Filter Bypass Plug

The water filter cartridge is located in the upper right-hand corner of the fresh food compartment, right below the temperature controls.

The filter cartridge should be replaced every six months or earlier if the flow of water to the water dispenser or icemaker decreases.

Installing the Filter Cartridge

1 |

If you are replacing the cartridge, first |

|

remove the old one by slowly turning it |

||

|

||

|

to the left. Do not pull down on the |

|

|

cartridge. A small amount of water may |

|

|

drip down. |

2 Remove and discard the plastic cap from the new cartridge.

3 Fill the replacement cartridge with water from the tap.

4 Apply the month and year sticker to the cartridge to remind you to replace the filter in six months.

5 Place the top of the cartridge up inside the cartridge holder. Do not push it up into the holder.

6 Slowly turn it to the right until the filter cartridge stops. DO NOT OVERTIGHTEN.

As you turn the cartridge, it will automatically raise itself into position.

7 Run water from the dispenser for 1 minute (about a half gallon) to clear the system and prevent sputtering.

NOTE: A newly-installed water filter cartridge may cause water to spurt from the dispenser.

Filter Bypass Plug

You must use the filter bypass plug when a replacement filter cartridge is not

available. The dispenser and the icemaker will not operate without the filter or filter bypass plug.

Questions?…In the United States, call the GE Answer Center® 800.626.2000.

Replacement Filters:

To order additional filter cartridges in the United States, call GE Parts and Accessories, 800-626-2002.

FXRT—Chlorine, Taste and Odor

Suggested Retail $29.95

FXRC—Chlorine, Taste and Odor—

Lead and Cysts

Suggested Retail $34.95

Customers in Canada should consult the yellow pages for the nearest Camco Service Center.

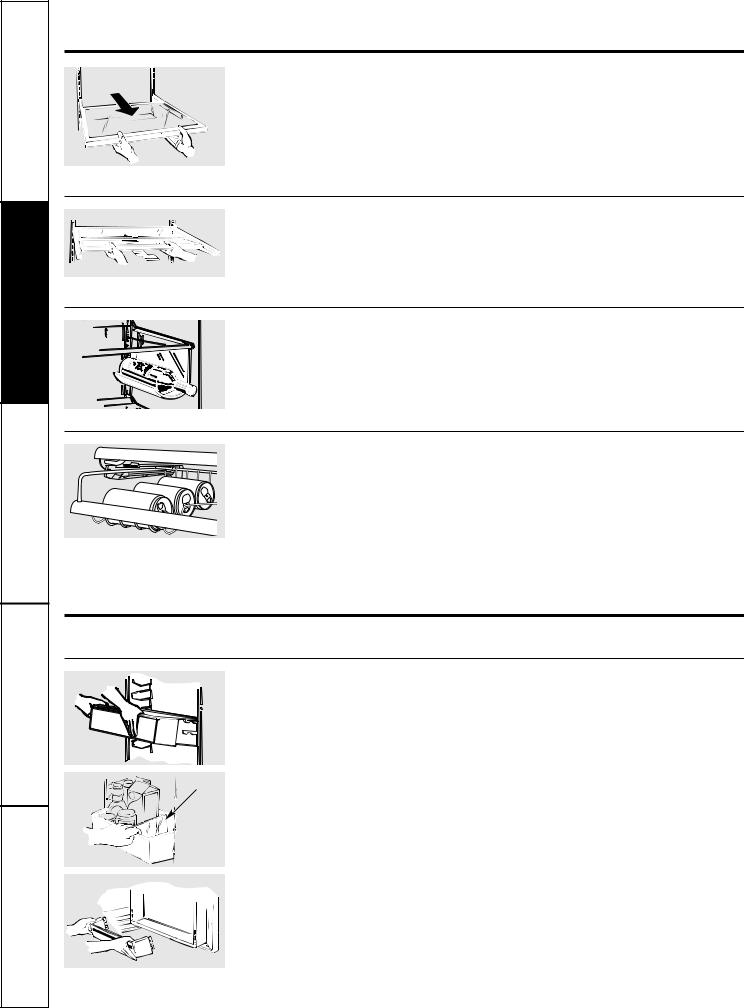

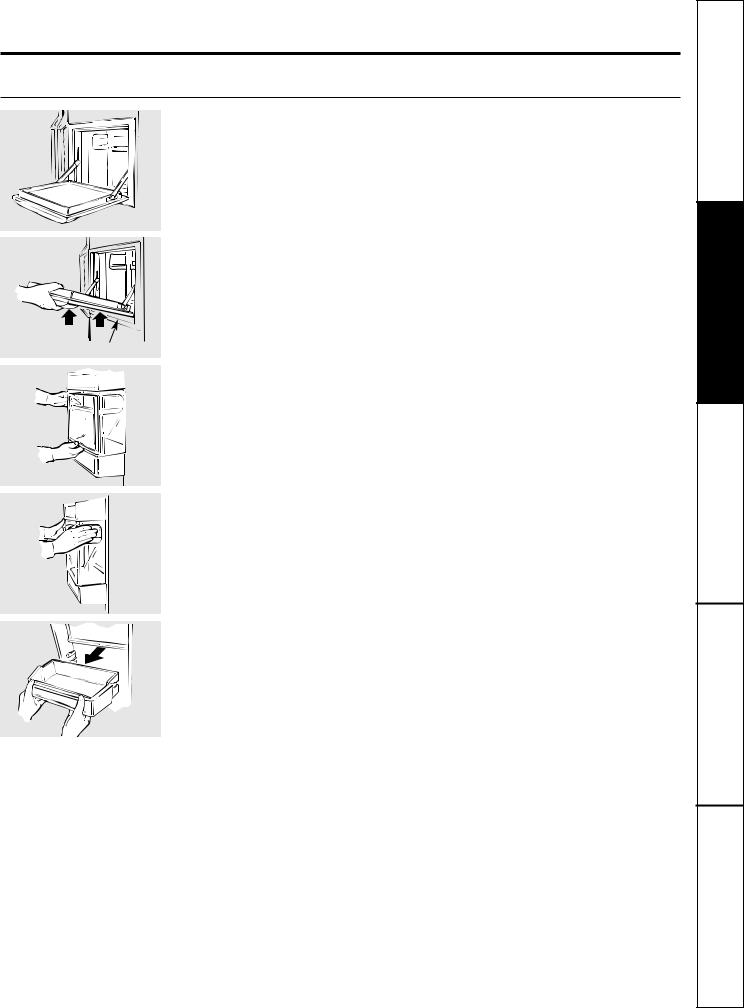

About the shelves and baskets.

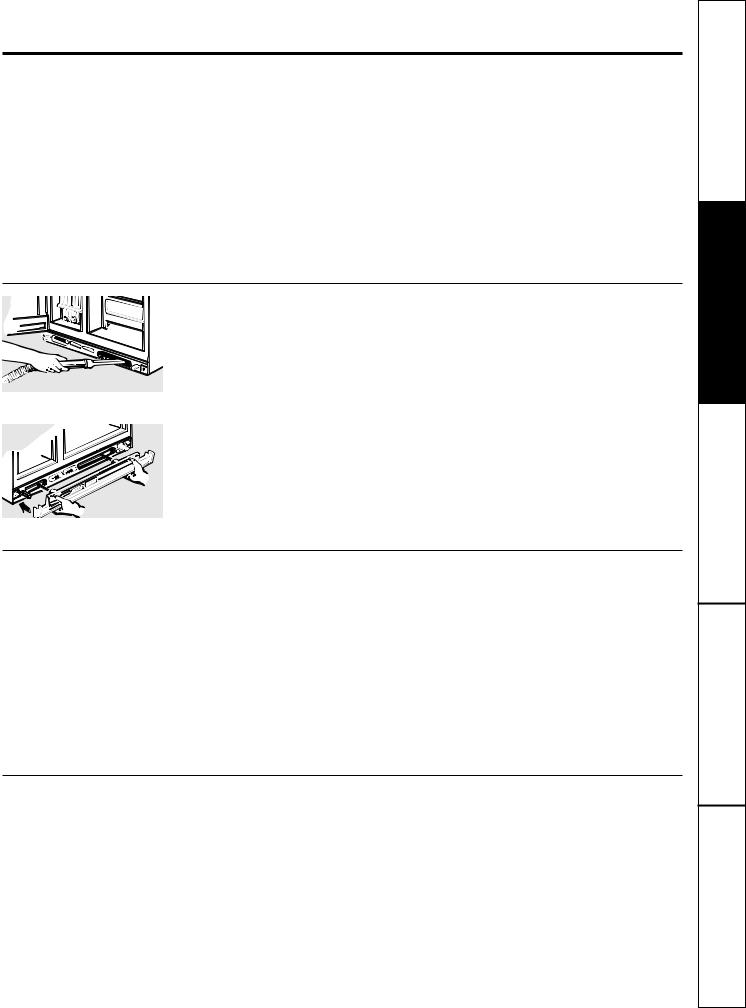

Rearranging the Shelves and Freezer Baskets

Glass and wire shelves are adjustable. |

Wire slide-out freezer baskets can be |

||

|

|

|

relocated in the same way. |

2 Lift up and out |

1 |

Tilt up |

|

|

|

||

|

|

1 |

Insert |

|

|

|

top hook |

|

|

2 |

Lower to |

|

|

|

lock in place |

To Remove |

|

To Replace |

|

9

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

About the shelves and baskets.

Slide-Out Spillproof Shelf (on some models)

The slide-out spillproof shelf allows you to |

Make sure you push the shelves all the way back |

reach items stored behind others. The |

in before you close the door. |

special edges are designed to help prevent |

|

spills from dripping to lower shelves. |

|

Quick Space Shelf

This shelf splits in half and slides under itself for storage of tall items on the shelf below.

Removable Wine Rack

The wine rack is designed to hold a bottle on its side. A good location for the wine rack is the quick space shelf.

SpaceSaver™ Rack

Use this rack to store beverage cans for easy access.

It can also hold a 9″ x 13″ baking dish.

About the refrigerator bins and dishes.

Not all features are on all models.

Bins on the Fresh Food Compartment Door

Adjustable bins can easily be carried from refrigerator to work area.

To remove: Tilt the bin up and pull out on the molded supports until it comes completely out of the door.

Divider

To replace or relocate: Select desired shelf height, engage the bin in the molded supports of the door and slide the bin in. The bin will hook in place.

The divider helps prevent tipping, spilling or sliding of small items stored on the door shelf. Place a finger on either side of the divider near the front and move it back and forth to fit your needs.

To remove fixed bins, first remove the food in the bins. Then, grasping the bin at each end, push in at the bottom as you lift and pull out at the top.

10

Quick Serve™ System

CAUTION: Dishes and lids are not designed for use on the range top, broiler or in the regular oven. Such use can be hazardous.

Quick Serve™ dishes fit into a space-saving rack under the shelf. The rack can be relocated anywhere in the fresh food compartment.

Dishes and lids are safe for use in microwave ovens, refrigerators and freezers.

Do not use when cooking high-fat foods, such as bacon, and high-sugar foods, such as candy and syrup. The high temperatures of the fat and sugar can cause bubbles to form on the inside of the dish.

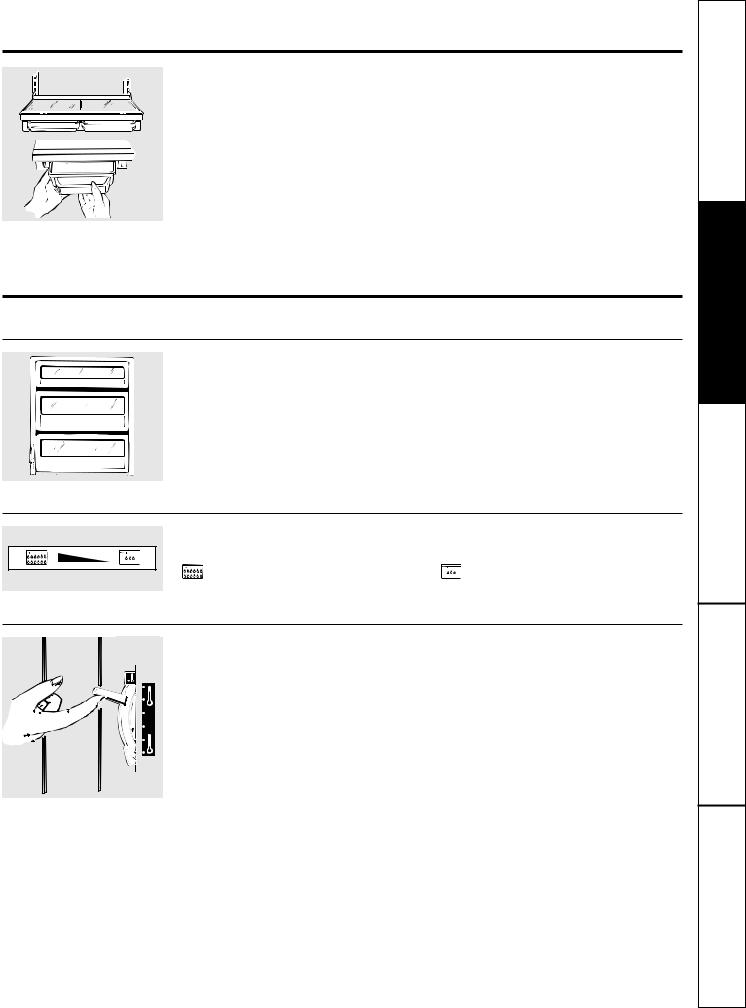

About the storage drawers.

Not all features are on all models.

Storage Drawers

Excess water that may accumulate in the bottom of the drawers should be emptied and the drawers wiped dry.

Adjustable Humidity Drawers

Slide the control all the way to the |

Slide the control all the way to the |

setting to provide high humidity |

setting to provide lower humidity |

recommended for most vegetables. |

levels recommended for most fruits. |

Normal

Coldest

Convertible Meat Drawer

The convertible meat drawer has its own cold air duct to allow a stream of cold air from the freezer compartment to flow around the drawer.

The variable temperature control regulates the air flow from the freezer compartment.

Set control lever down to the coldest setting to store fresh meats. If lever is left in meat position for a long period of time, some frost may form on the inside of the drawer.

Set control lever up to convert the drawer to normal refrigerator temperature and provide extra vegetable storage space. Cold air duct is turned off. Variable settings between these extremes can be selected.

11

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

About storage drawer removal.

Not all features are on all models.

Drawer

Guides

When replacing the drawers, make sure you slide them through both drawer guides on the right side.

Drawer Removal

Drawers can easily be removed by tilting up slightly and pulling past the stop location.

Remove the door bins from the fresh food door before removing the drawer.

To remove the shelf above the top drawer, first remove the top drawer and any food on the shelf. Then tilt the shelf up at the front and lift it up and out of the tracks.

To replace the shelf, raise the shelf front slightly and place the top hooks in the lowest large track slots. Then lower the front of the shelf until it is level.

To remove the drawers when the fresh food compartment door cannot be opened fully you need to roll the refrigerator forward until the door can be fully opened. In some cases this will require moving the refrigerator to the left as you roll it out.

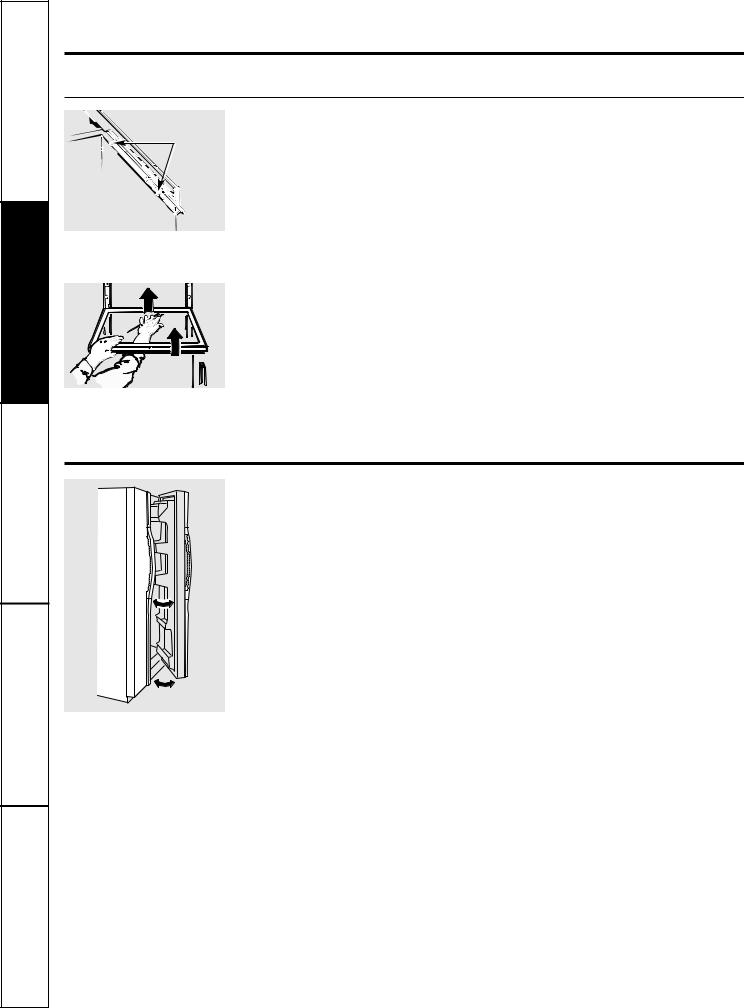

About the refrigerator doors

Refrigerator Doors

The refrigerator doors may feel different than the ones you are used to. The special door opening/closing feature makes sure the doors close all the way and are securely sealed.

When opening and closing the door you will notice a stop position. If the door is opened past this stop point, the door will remain open to allow you to load and unload food more easily. When the door is only partially open it will automatically close.

When the door is only partially open it will automatically close.

Beyond this stop the door will stay open.

The resistance you feel at the stop position will be reduced as the door is loaded with food.

12

About the refreshment center.

On some models

The Refreshment Center Compartment stores frequently used items.

When open, the Refreshment Center door provides a convenient work surface. Although durable, the work surface should not be used as a cutting board. Close the door when finished. The upper fresh food compartment light will come on when the Refreshment Center door is opened.

The special design of the door allows you to tilt and lift up the door in order to clean the bottom of the frame.

NOTE: Use caution in closing or using the clean-out feature in the presence of small children.

Bottom of Frame

Cold air entering from the freezer compartment keeps the temperature in the

Refreshment Center Compartment at proper food-keeping levels.

The bin panel limits the amount of cold air that escapes when the Refreshment Center door is opened. To reach food from the inside, lift the panel up.

To remove the Refreshment Center bin, first remove the panel using the hand holds.

Then remove the bin by lifting it up and out.

13

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

About the automatic icemaker.

A newly-installed refrigerator may take 8 to 12 hours to begin making ice.

Feeler arm in the STOP (up) position

Ice Storage Bin

Feeler arm in the ON (down) position

Automatic Icemaker

The icemaker will produce eight cubes per cycle—approximately 120 cubes in a 24-hour period, depending on freezer compartment temperature, room temperature, number of door openings and other use conditions.

If the refrigerator is operated before the water connection is made to the icemaker, keep the feeler arm in the STOP (up) position.

When the refrigerator has been connected to the water supply, move the feeler arm to the ON (down) position.

The icemaker will fill with water when it cools to freezing. A newly-installed refrigerator may take 8 to 12 hours to begin making ice cubes.

Throw away the first few batches of ice to allow the water line to clear.

Be sure nothing interferes with the swing of the feeler arm.

It is normal for several cubes to be joined together.

If ice is not used frequently, old ice cubes will become cloudy and taste stale.

About the ice and water dispenser.

On some models

To Use the Dispenser

Press the rim of the glass gently against the dispenser pad.

Select CUBED ICE  , CRUSHED ICE

, CRUSHED ICE

(on some models) or WATER .

The spill shelf is not self-draining. To reduce water spotting, the shelf and its grille

should be cleaned regularly.

Spill Shelf

If no water is dispensed when the refrigerator is first installed, there may be air in the water line system. Press the dispenser pad for at least two minutes to remove trapped air from the water line and to fill the water system. To flush out impurities in the water line, throw away the first six glassfuls of water.

A light switch (on some models) turns the night light in the dispenser on or off. The light also comes on when the dispenser pad is pressed. The light in the dispenser should be replaced with a 7 watt maximum bulb when it burns out.

CAUTION: Never put fingers or any other objects into the ice crusher discharge opening.

14

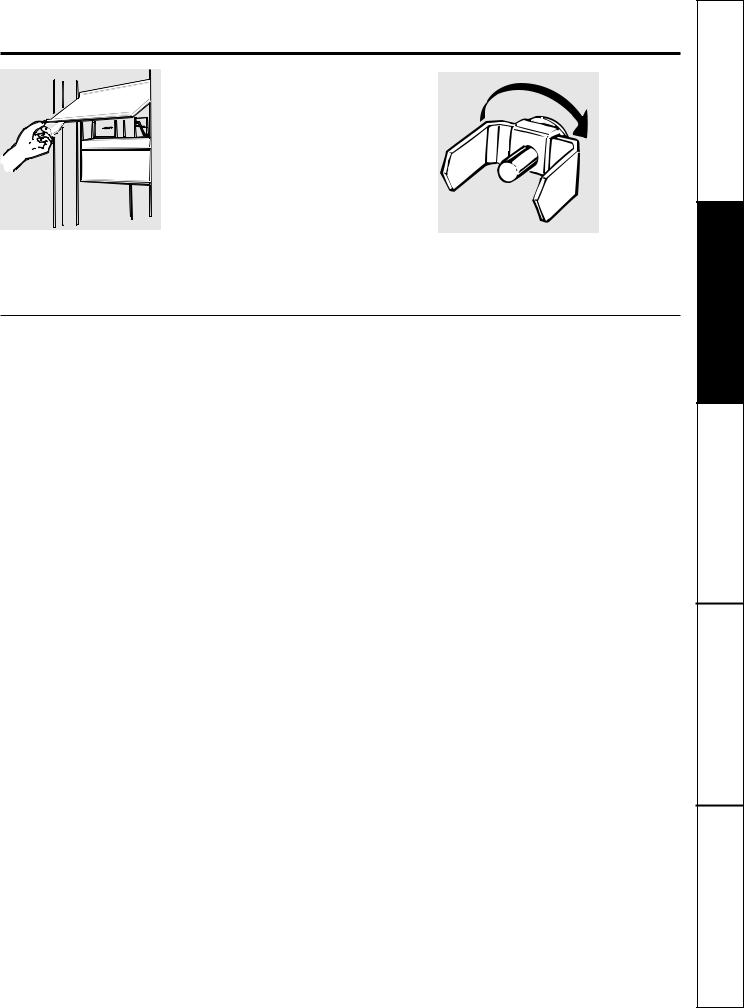

Ice Storage Bin

To remove: |

Rotate |

Lift the left corner to free the bin from the shelf and pull the bin straight out while supporting it at front and rear.

To replace:

Drive

Slide the bin back until the tab on the bin Mechanism locks into the slot on the shelf. If the bin

does not go all the way back, remove it and rotate the drive mechanism 1/4 turn. Then push the bin back again until the tab on the bin locks into the slot on the shelf.

Important Facts About Your Dispenser

■Add ice before filling the glass with a beverage.

■Do not add ice from trays or bags to the storage bin. It may not crush or dispense well.

■Avoid overfilling glass with ice and use of narrow or extra-tall glasses. Backed-up ice can jam the chute or cause the door in the chute to freeze shut. If ice is blocking the chute, poke it through with a wooden spoon.

■Beverages and foods should not be quick-chilled in the ice storage bin. Cans, bottles or food packages in the storage bin may cause the icemaker or auger to jam.

■Some crushed ice may be dispensed even though you selected CUBED ICE. This happens occasionally when a few cubes accidentally get directed to the crusher.

■After crushed ice is dispensed, some water may drip from the chute.

■Sometimes a mound of snow will form on the door in the ice chute. This condition is normal and usually occurs when you have dispensed crushed ice repeatedly. The snow will eventually evaporate.

■Dispensed water is not ice cold. For colder water, add crushed ice or cubes before dispensing water.

15

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

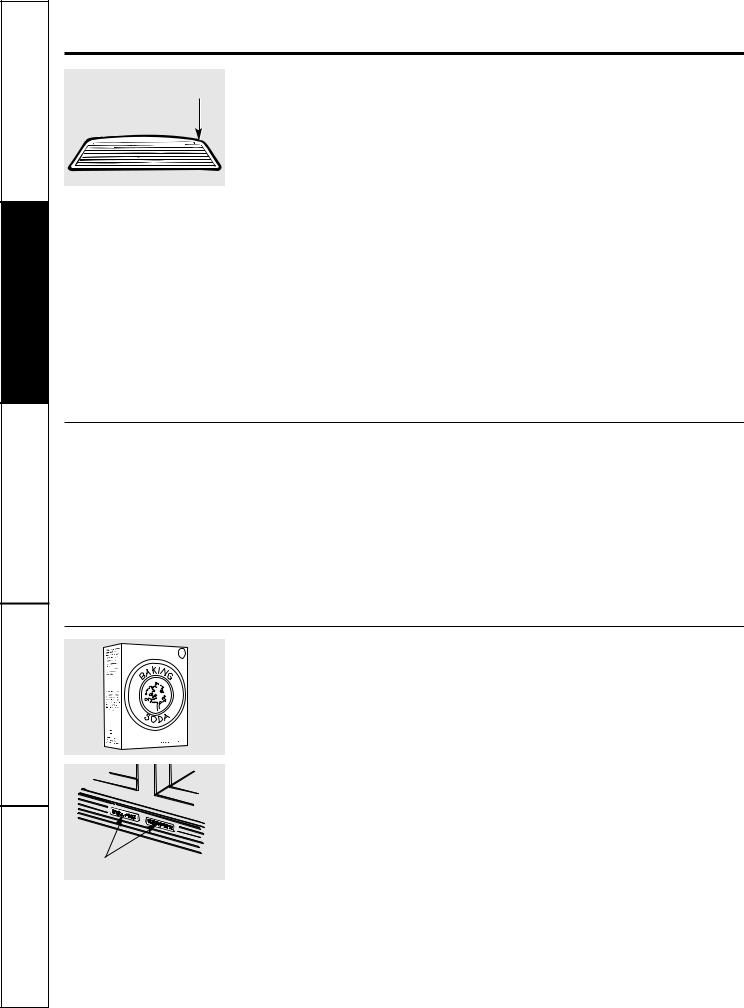

Care and cleaning of the refrigerator.

Press here to remove grille.

Cleaning the Outside

Refreshment Center Compartment door— outside. It’simportantthatyouuseonly windowcleanerwithoutammoniaoradamp clothtocleantheglassandtrim.Avoidusing waxontheRefreshmentCenterdoor.

The dispenser well, beneaththegrille,should bewipeddry.Waterleft in the well may leave deposits. Remove the deposits by adding undiluted vinegar to the well. Soak until the deposits disappear or become loose enough to rinse away.

The dispenser pad. Clean with warm water and baking soda solution—about a tablespoon (15 ml) of baking soda to a

quart (1 l) of water. Rinse thoroughly and wipe dry.

HINT: Open the freezer door part way to prevent dispensing of ice or water when cleaning.

The door handles and trim. Clean with a cloth dampened with soapy water. Dry with a soft cloth.

The stainless steel panels and door handles

(on some models) can be cleaned with a commercially available stainless steel cleaner using a clean, soft cloth.

Keep the outside clean. Wipe with a clean cloth lightly dampened with kitchen appliance wax or mild liquid dish detergent. Dry and polish with a clean, soft cloth.

Do not wipe the refrigerator with a soiled dish cloth or wet towel. These may leave a residue that can erode the paint. Do not use scouring pads, powdered cleaners, bleach or cleaners containing bleach because these products can scratch and weaken the paint finish.

Cleaning the Decorator Door Panels

Clean these panels using an anti-static cleaner or a mild detergent and water. (Look for anti-static cleaner in electronic or computer departments.) Rinse thoroughly and blot dry with a clean, damp cloth or chamois. Do not use paper towels to wash or dry the panels. Do not use cleaners that contain solvents, such as ammonia, because they can damage the panels.

Shallow scratches and abrasions can be corrected with a good grade of hard automobile paste wax. The wax will fill in any minor surface scratches and will help to maintain the luster of the panels. Apply the wax sparingly and buff lightly with a clean, soft cloth using a circular motion. Do not use a cleaner/wax combination.

|

Cleaning the Inside |

|

To help prevent odors, leave an open box of |

|

baking soda in the fresh food and freezer |

|

compartments. |

|

Unplug the refrigerator before cleaning. If this |

|

is not practical, wring excess moisture out of |

|

sponge or cloth when cleaning around |

|

switches, lights or controls. |

|

Use warm water and baking soda solution— |

|

about a tablespoon (15 ml) of baking soda |

|

to a quart (1 l) of water. This both cleans |

|

and neutralizes odors. Rinse and wipe dry. |

Door Magnets |

Door magnets can be cleaned the same way. |

Refreshment Center Compartment door—inside.

Wipe up spills right away. Use one tablespoon (15 ml) of baking soda in one quart (1 l) of water to clean the inside door surface, Refreshment Center bin and inside access door. Rinse, wipe dry.

Avoid cleaning cold glass shelves (on some models) with hot water because the extreme temperature difference may cause them to break. Handle glass shelves carefully. Bumping tempered glass can cause it to shatter.

Do not wash any plastic refrigerator parts in the dishwasher except Quick Serve dishes and lids.

16

Behind the Refrigerator

Be careful when moving the refrigerator away from the wall. All types of floor coverings can be damaged, particularly cushioned coverings and those with embossed surfaces.

Pull the refrigerator straight out and return it to position by pushing it straight in. Moving the refrigerator in a side direction may result in damage to the floor covering or refrigerator.

When pushing the refrigerator back, make sure you don’t roll over the power cord or icemaker supply line.

Clean the condenser coils at least once a year.

Under the Refrigerator

For most efficient operation, keep the area under the refrigerator clean. Remove the base grille and sweep away or vacuum up dust.

For best results, use a brush specially designed for this purpose. It is available at most appliance parts stores.

To remove the base grille, open both doors, grasp the bottom of the grille and pull it out.

To replace the base grille, line up the clips on the back of the grille with the openings in the baseplate and push the grille forward until it snaps into place.

Preparing for Vacation

For long vacations or absences, remove food and unplug the refrigerator. Move the freezer control to the OFF or position, and clean the interior with a baking soda solution of one tablespoon (15 ml) of baking soda to one quart (1 L) of water. Leave the doors open.

position, and clean the interior with a baking soda solution of one tablespoon (15 ml) of baking soda to one quart (1 L) of water. Leave the doors open.

Move the icemaker feeler arm to the STOP (up) position and shut off the water supply to the refrigerator.

When you return from vacation, select WATER on the dispenser and press the dispenser pad for at least two minutes to remove stale water from the water system.

If the temperature can drop below freezing, have a qualified servicer drain the water supply system to prevent serious property damage due to flooding.

Preparing to Move

Secure all loose items such as grille, shelves and drawers by taping them securely in place to prevent damage.

Be sure the refrigerator stays in an upright position during moving.

17

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips InstallationInstructions Operating Instructions SafetyInstructions

CustomerService

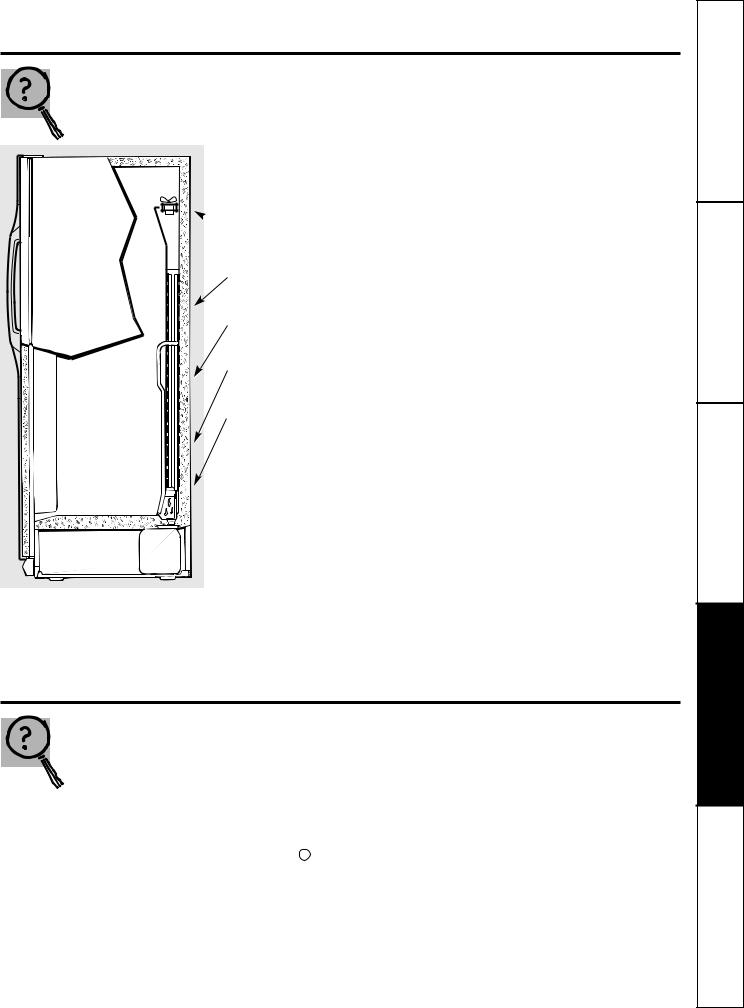

Replacing the light bulbs.

Turning the control to the OFF or |

position does not remove power to the light circuit. |

TEMFPREEREZER ATURE

COLD |

|

OFF |

|

1 |

COLDEST |

5 |

|

3 |

|

* |

7 |

9

ProfileALL *INITIAL

OW 24 HRTSE.MFOPRERTAETMUPR.ETOSESTTTAINBIGLSIZE

COLD 1

3 |

COLDEST |

5 |

|

* |

7 |

|

9 |

FRESH |

FOOD |

|

TEM |

|

|

|

PERATURE |

|

Fresh Food Compartment—Upper Light

1 Unplug the refrigerator.

2 To align the control knobs properly, note position of each knob for proper reassembly, move both knobs all the way to the left, then pull them off.

3 To remove the light shield, pull it straight out.

After replacing with an appliance bulb of the same or lower wattage, reinstall the light shield. Replace the control knobs, move them to their previous settings and plug the refrigerator back in.

Fresh Food Compartment—Two Lower Lights (on some models)

These lights are located behind the top drawer.

1 Unplug the refrigerator and remove the top drawer and cover.

2 Grasp the bottom of the light shield and pull it forward and up to free its bottom edge.

After replacing with an appliance bulb of the same or lower wattage, reinstall the light shield, drawer and cover and plug the refrigerator

back in.

Freezer Compartment—Non-Dispenser Models

|

|

|

|

|

|

|

|

Unplug the refrigerator. |

After replacing with an appliance bulb of the |

|

|

|

|

|

|

|

1 |

||

|

|

|

|

Remove the shelf just below light shield. |

same or lower wattage, reinstall the shield and |

||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

2 |

shelf, and plug the refrigerator back in. |

|

|

|

|

|

|

|

|

|

Pull the plastic light shield, which is |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

underneath the ice compartment, |

|

||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

toward you. |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Freezer Compartment—Dispenser Models |

|||

|

|

|

|

|

|

|

|

Unplug the refrigerator. |

After replacing with an appliance bulb of the |

|

|

|

|

|

|

|

1 |

||

|

|

|

|

|

|

Remove the ice storage bin. |

same or lower wattage, reinstall the shield and |

||

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

2 |

ice storage bin, and plug the refrigerator back in. |

|

|

|

|

|

||||||

|

|

|

|

|

|

||||

3 Remove screw at top of light shield.

Screw

18

Preparing to install the refrigerator.

Read these instructions completely and carefully.

Water Supply to the Icemaker

You will need to connect the icemaker to a cold |

A water supply kit (containing copper tubing, |

water line. |

shutoff valve, fittings and instructions) is available |

|

at extra cost from your dealer or from Parts and |

|

Accessories, 800-626-2002. |

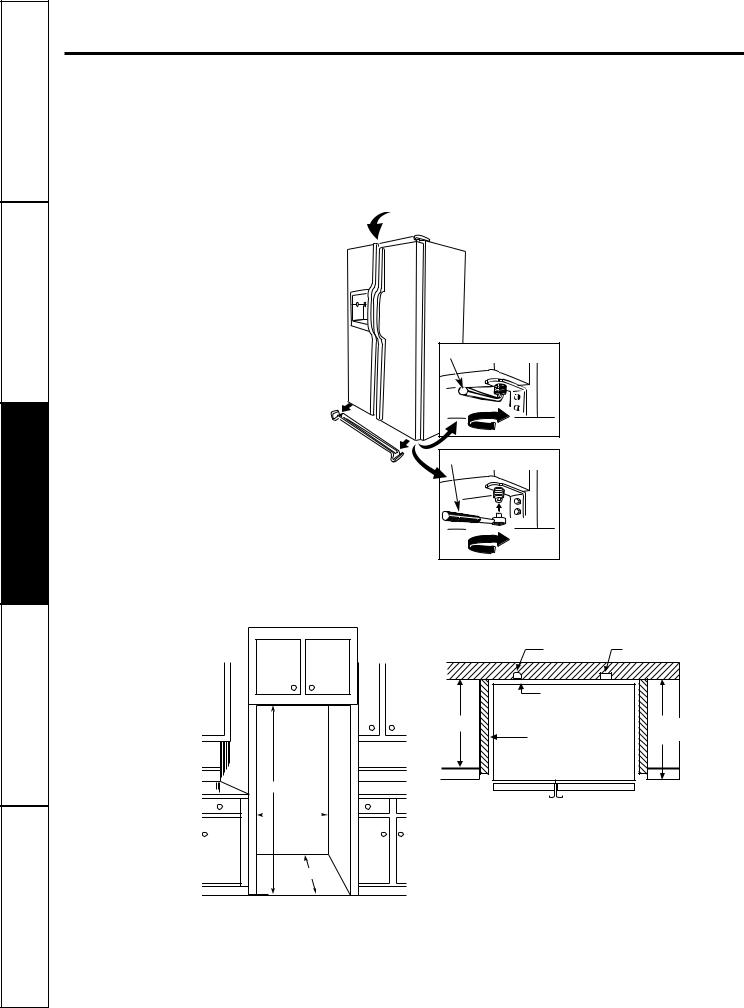

Refrigerator Location

Install it on a floor strong enough to support it fully loaded.

Clearances

Allow the following clearances for ease of installation, proper air circulation and plumbing and electrical connections.

|

24′ Model |

28′ Model |

30′ Model |

Sides |

1/8″ (3 mm) |

1/8″ (3 mm) |

1/8″ (3 mm) |

Top |

1″ (25 mm) |

1/8″ (3 mm) |

1/8″ (3 mm) |

Back |

1/2″ (13 mm) |

1/2″ (13 mm) |

1/2″ (13 mm) |

If built-in, allow 7/8″ (22 mm) for hinge covers.

If the refrigerator is against a wall on either side, allow 3/4″ (19 mm) on each side for a 90° door opening.

90°

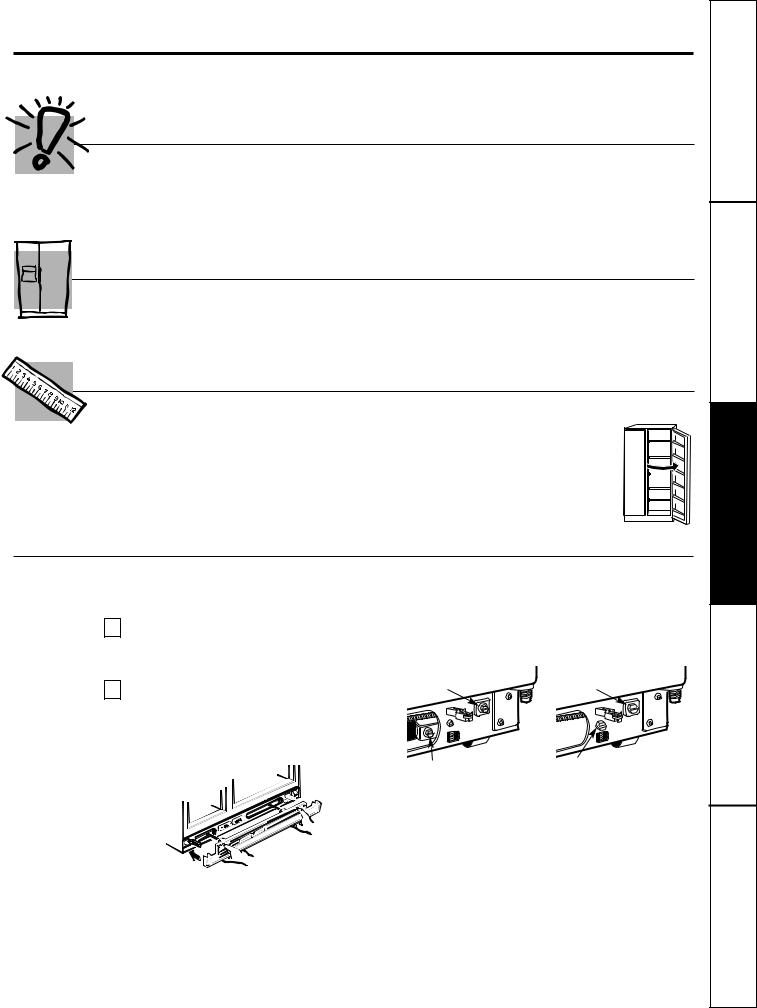

Leveling Rollers

The rollers have 2 purposes:

1 |

The rollers can be adjusted so the refrigerator is |

firmly positioned on the floor and does not rock |

back and forth.

2 Rollers allow you to move the refrigerator away from the wall for cleaning.

To adjust the rollers, remove the base grille by pulling it out at the bottom.

Turn the two front roller adjusting screws clockwise to raise the refrigerator, counterclockwise to lower it. Use a 3/8″ socket wrench, adjustable wrench or pliers.

Front Roller |

Front Roller |

Adjusting Screw |

Adjusting Screw |

Rear Roller Adjusting Screw |

Rear Roller Adjusting Screw |

(on Built-In Style models only). |

(on Built-In Style models only). |

Use this screw if the refrigerator |

Use this screw if the refrigerator |

has one. |

does not have the screw pictured |

|

to the left. |

Built-In Style models also have rear adjustable rollers so you can align the refrigerator with your kitchen cabinets. Use a 5/16″ socket wrench to turn the screws for the rear rollers—clockwise to raise it, counterclockwise to lower it.

19

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips Installation Instructions OperatingInstructions SafetyInstructions

CustomerService

Preparing to install the refrigerator.

Door Alignment

After leveling, make sure that doors are even at the top.

To make the doors even, adjust the fresh food door. Using a 3/16″ Allen wrench or a 5/16″ socket wrench (depending on model), turn the door adjusting screw to the right to raise the door, to the left to lower it. (A nylon plug, imbedded in the threads of the pin, prevents the pin from turning unless a wrench is used.) After one or two turns of the wrench, open and close the fresh food door and check the alignment at the top of the doors.

Remove base grille by opening the doors and pulling the grille straight out.

3/16″ Allen Wrench |

Raise |

or |

5/16″ Socket Wrench |

Raise |

Dimensions and Specifications (for CustomStyle models)

|

Water |

Electrical |

|

3/4″ Airspace |

|

|

(1/2″ Gap + 1/4″ |

|

24″ Cabinet |

Wall Plates) |

25″ |

|

24″ Side Panels |

Counter Top |

|

|

701/4″

36″

24″

20

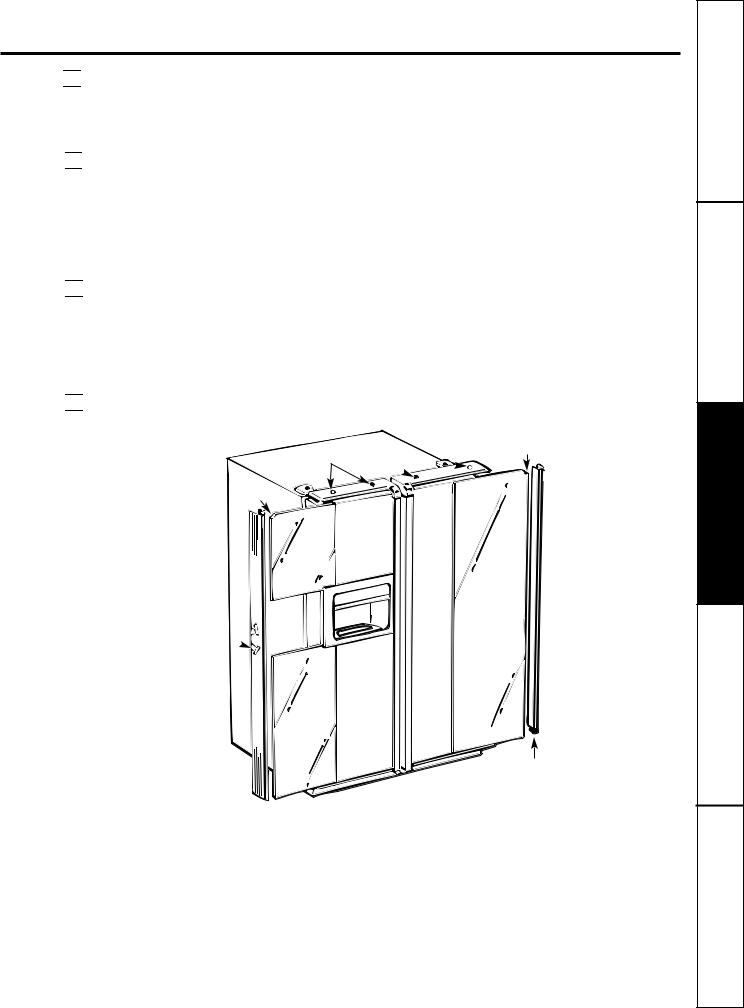

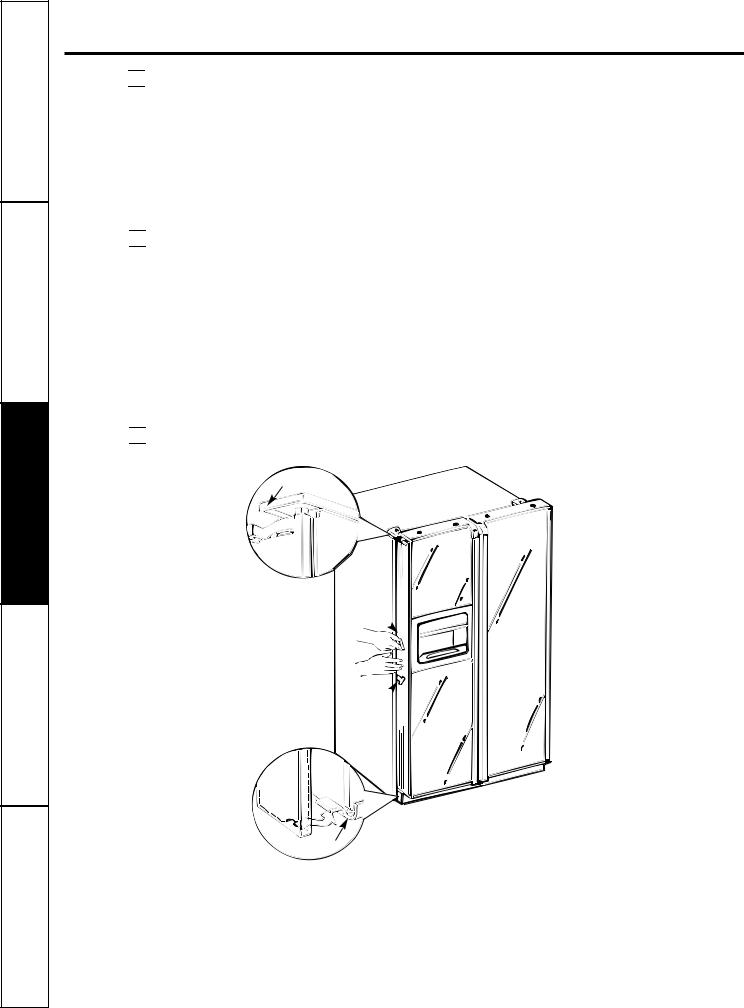

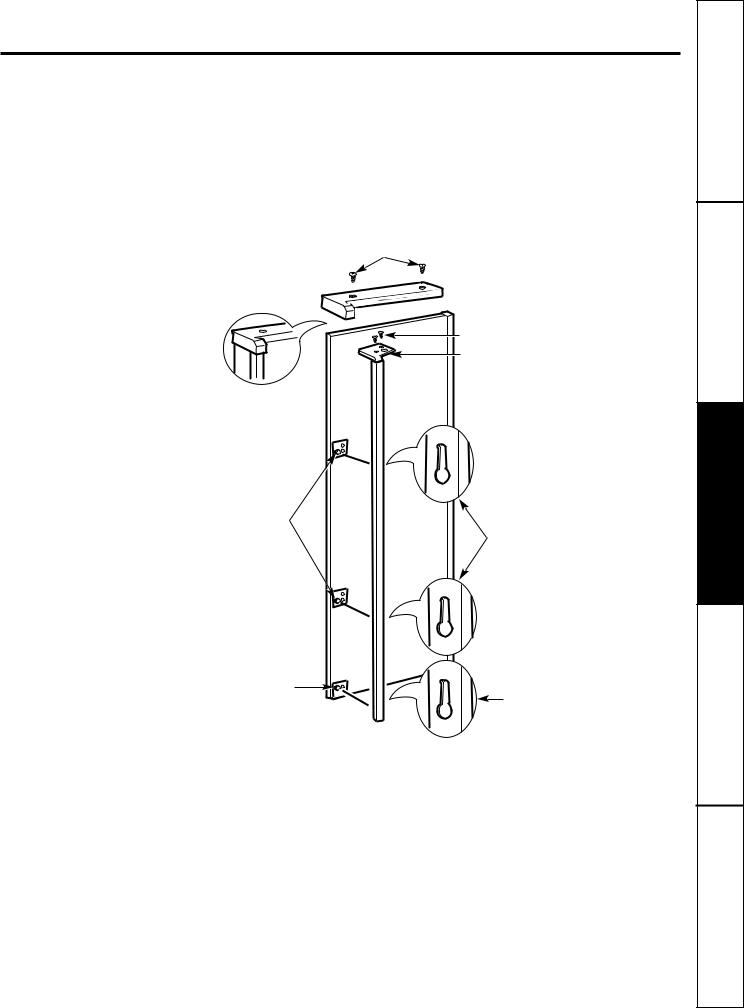

Trim kits and decorator panels.

For CustomStyle models

Read these instructions completely and carefully.

Before You Begin

Some models are equipped with trim kits that allow you to install door panels. You can order pre-cut black or white decorator panels from GE Parts and Accessories, 800-626-2002, or you can add wood panels to match your kitchen cabinets.

Panels less than 1/4″ (6 mm) thick

When installing wood panels less than 1/4″ (6 mm) thick, you need to create a filler panel, such as 1/8″ cardboard, that will fit between the face of the door and the wood panel. If you are installing the pre-cut decorator panels, pre-cut filler panels are included in the kit. The combined thickness of the decorator or wood panel and the filler panel should be 1/4″ (6 mm).

3/4″ (19 mm) or Raised Panel

A raised panel design screwed or glued to a 1/4″ (6 mm) thick backing, or a 3/4″ (19 mm) routed board can be used. The raised portion of the panel must be fabricated to permit clearances of at least 2″ (51 mm) from the handle side for fingertip clearance.

Weight limitations for custom panels:

Fresh Food 35 lb. (16 kg) max.

Freezer Door 25 lb. (11 kg) max.

1/4″ (6 mm) Thick Backing

2″ (51 mm) Clearance

Handle Side

3/4″ (19 mm)

Appearance

Panel Refrigerator Door

21

Tips Troubleshooting Instructions Installation Instructions Operating Instructions Safety

Service Customer

TroubleshootingTips Installation Instructions OperatingInstructions SafetyInstructions

CustomerService

Trim kits.

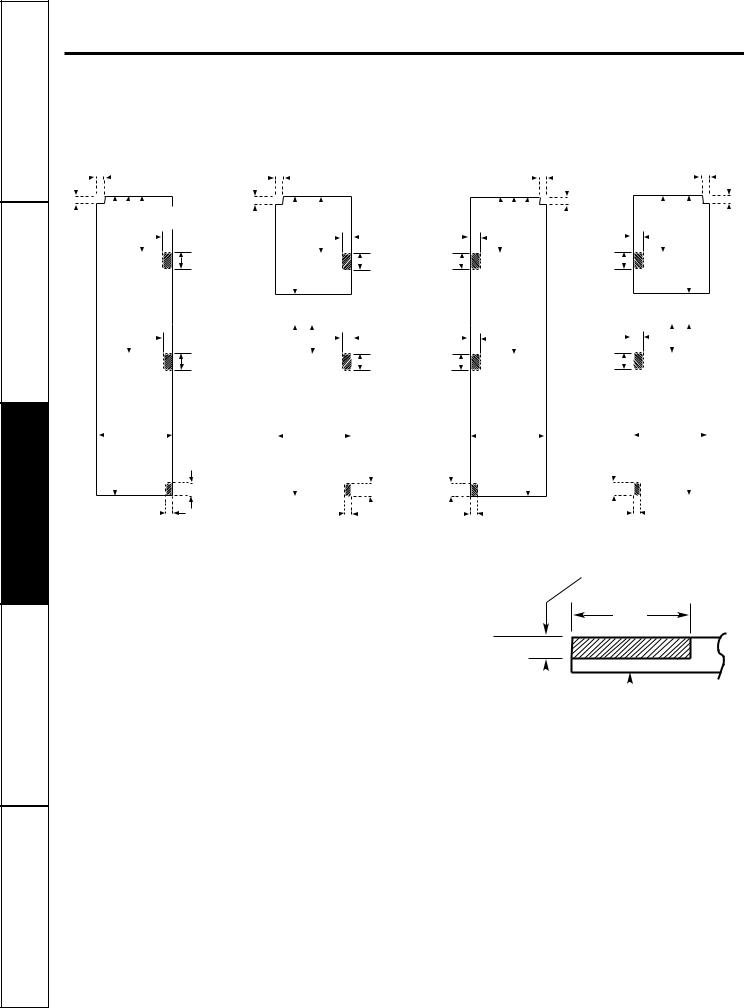

Dimensions for Custom Wood Panels

Freezer Panel |

Freezer Panel |

|

Fresh Food Panel |

Without Dispenser |

With Dispenser |

Fresh Food Panel |

With Refreshment Center |

Cut |

|

|

|

|

|

1/8″ |

|

|||||||||||||||

out |

|

|

|

|

|

|

|

(3 mm) |

|

|||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

111 |

/4″ |

|

|||||||||

5/16″ |

|

|

|

|

|

|

|

|

(286 mm) |

|

||||||||||||

(8 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

375 |

/8″ |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

(956 mm) |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

671 |

/8″ |

|

|

|||||||||||||||

|

|

|

|

|

|

(1705 mm) |

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

FRONT |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

141/2″ |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

(368 mm) |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11/8″

(29 mm)

(29 mm)

23/8″

(60 mm)

11/8″

(29 mm)

(29 mm)

23/8″

(60 mm)

2″

(50 mm)

1″

(25 mm)

Cut |

|

|

|

|

|

1/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

out |

|

|

|

|

|

|

|

(3 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

111/4″ |

|

|

|

|

|

|

|

1 |

/ ″ |

|||||||||||||

5/16″ |

|

|

|

|

|

|

|

(286 mm) |

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

1 |

8 |

||||||||||||||||||||||||

(8 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(29 mm) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

1813/16″ |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(60 mm) |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

(478 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11/8″ |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(29 mm) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23/8″ |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

413/16″ |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

(122 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

(60 mm) |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

FRONT |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

141/2″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

(368 mm) |

|

|

|

|

|

|

|

|

2″ |

|

|||||||||||||

|

|

|

|

|

345/16″ |

|

|

|

|

|

(50 mm) |

||||||||||||||||||||||

|

|

|

|

|

(872 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1″ |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(25 mm) |

|

||||||||||||||||

The areas at the top of the panels need to be cut out of the panels. The shaded areas indicate areas that must be routed out about 5/32″ (4 mm) on the back side of panels 1/4″ (6 mm) thick or more. For panels less than 1/4″ (6 mm) thick, these areas can be cut out of the filler panels.

|

|

|

|

|

|

|

|

|

|

|

|

|

1/8″ |

|

|

Cut |

|

|

|

|

|

|

|

|

1/8″ |

|

|

Cut |

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

(3 mm) |

|

|

|

|

|

out |

|

|

|

|

|

|

|

(3 mm) |

|

|

|

|

|

out |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5/16″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

1 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(8 mm) |

|

|

|

|

|

|

|

111/4″ |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

11 |

/ ″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

1 / ″ |

|

|

|

|

(286 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 / ″ |

|

|

|

|

(286 mm) |

|

|

|

|

|

|

|

|

|

|

5/16″ |

||||||||||||||||||||||||||||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

(29 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(29 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(8 mm) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

23/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

13/16″ |

|

|

|

|

||||||||||||||||||||||||||||||||

(60 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(60 mm) |

|

|

|

|

|

|

|

|

|

|

(478 mm) |

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

375 |

/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

(956 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

11/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

(29 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(29 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

23/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23/8″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

413/16″ |

|

|