GBC Laminator User Manual

) 2SHUDWLRQ DQG 0DLQWHQDQFH 0DQXDO

© 1998 GBC Pro-Tech

Do not duplicate without written permission

|

NIN |

G |

|

AR |

G |

W |

TUN |

|

ACH |

|

|

|

ING |

W |

ARN |

UNG |

|

ACHT |

|

2

F |

-60™ |

|

|

|

|

-T |

E |

C |

H |

|

R |

O |

|

|

||

P |

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

GBC Pro-Tech |

|

4151 Anderson Road |

|

De Forest, Wisconsin 53532 |

|

Tel: 608-246-8844 |

Part Number 930-016 |

Fax: 608-246-8645 |

F-60 Operation and Maintenance Manual

The information in this publication is provided for reference and is believed to be accurate and complete. GBC Pro-Tech is not liable for errors in this publication or for incidental or consequential damage in connection with the furnishing or use of the information in this publication, including, but not limited to, any implied warranty of fitness or merchantability for any particular use.

GBC Pro-Tech reserves the right to make changes to this publication and to the products described in it without notice. All specifications and information concerning products are subject to change without notice.

Reference in this publication to information or products protected by copyright or patent does not convey any license under the rights of GBC Pro-Tech or others. GBC Pro-Tech assumes no liability arising from infringements of patents or any other rights of third parties.

This manual is copyrighted ©1998 by GBC Pro-Tech. All rights reserved. The information contained in this manual is proprietary and may not be reproduced, stored, transmitted, or transferred, in whole or in part, in any form without the prior and express written permission of GBC Pro-Tech.

ii |

© GBC Pro-Tech 1998 July |

F-60 Operation and Maintenance Manual

7DEOH RI &RQWHQWV

6HFWLRQ 6DIHW\

Caution/Warning Label Locations ................................................................................... |

1-3 |

6HFWLRQ ,QVWDOODWLRQ

Preinstallation Checklist .................................................................................................. |

2-1 |

Unpacking ....................................................................................................................... |

2-3 |

Setup .............................................................................................................................. |

2-5 |

Leveling .......................................................................................................................... |

2-5 |

Startup ............................................................................................................................ |

2-6 |

6HFWLRQ 2SHUDWLRQ

Safety .............................................................................................................................. |

3-1 |

Operator Controls ........................................................................................................... |

3-2 |

Front Control Panel ..................................................................................................... |

3-2 |

Footswitch Operation .................................................................................................. |

3-2 |

Setup .............................................................................................................................. |

3-3 |

Laminator Roll Pressure ............................................................................................. |

3-3 |

Web Up Options .......................................................................................................... |

3-3 |

Loading the Film ............................................................................................................. |

3-3 |

Recommended Films ...................................................................................................... |

3-3 |

Positioning the Film ........................................................................................................ |

3-4 |

Heating ........................................................................................................................... |

3-4 |

Pull Roll Clutch Adjustment ............................................................................................ |

3-4 |

Raising and Lowering the Pull Rolls ............................................................................... |

3-4 |

Paper Tips ....................................................................................................................... |

3-4 |

Process Control Charts ................................................................................................... |

3-5 |

Mounting Only ................................................................................................................. |

3-6 |

Setup ........................................................................................................................... |

3-6 |

Procedure ................................................................................................................... |

3-6 |

Mounting/Laminating ...................................................................................................... |

3-6 |

Setup ........................................................................................................................... |

3-6 |

Procedure ................................................................................................................... |

3-6 |

Encapsulation ................................................................................................................. |

3-6 |

Setup ........................................................................................................................... |

3-6 |

Procedure ................................................................................................................... |

3-6 |

Two-Pass Mount and Laminate (Hot and Cold) .............................................................. |

3-6 |

© GBC Pro-Tech 1998 July |

iii |

|

F-60 Operation and Maintenance Manual |

|

|

Setup .......................................................................................................................... |

3-6 |

Procedure, Pass 1 ...................................................................................................... |

3-6 |

Procedure, Pass 2 ...................................................................................................... |

3-7 |

6HFWLRQ 0DLQWHQDQFH DQG 7URXEOHVKRRWLQJ

Cleaning ......................................................................................................................... |

4-1 |

Adjusting the Nip ............................................................................................................ |

4-3 |

Chain Tensioning ............................................................................................................ |

4-4 |

Lubrication ...................................................................................................................... |

4-5 |

Contacting Technical Support ......................................................................................... |

4-5 |

Output Troubleshooting Guide ........................................................................................ |

4-6 |

6HFWLRQ :DUUDQW\

Limited Warranty ............................................................................................................. |

5-1 |

Exclusions to the Warranty ......................................................................................... |

5-1 |

6HFWLRQ 6SHFLILFDWLRQV DQG 3DUWV

6HFWLRQ ,QGH[

iv |

© GBC Pro-Tech 1998 July |

F-60 Operation and Maintenance Manual

6HFWLRQ 6DIHW\

DO NOT ATTEMPT TO OPERATE YOUR ORCA-IV VINYL TRANSFER MACHINE UNTIL YOU HAVE READ THIS SECTION CAREFULLY!

Your safety, as well as the safety of others, is important to GBC Pro-Tech. This section contains important safety information.

The following symbols are used throughout this manual to indicate warnings and cautions.

DANGER

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury, or alerts against unsafe practices, or alerts against actions which could damage the product.

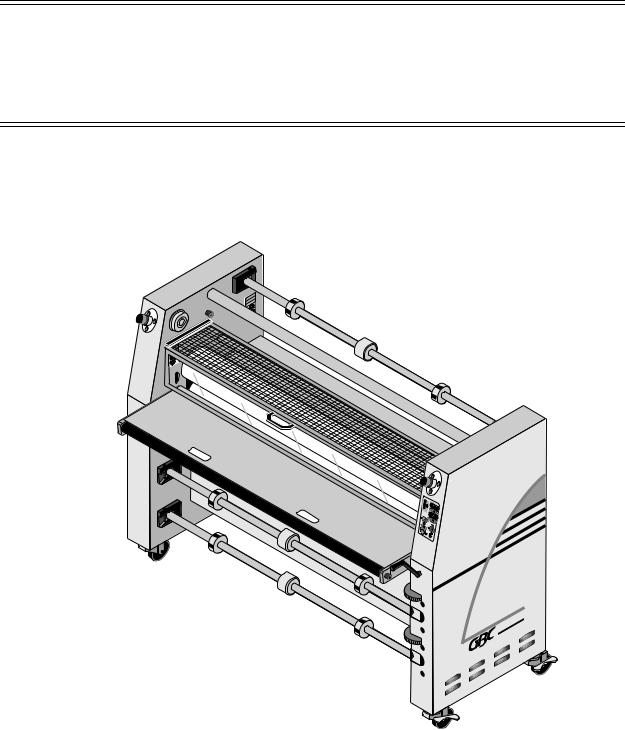

The F-60 Laminator has been designed with safety as a primary consideration. However, you must become thoroughly familiar with the controls, proper operation, proper service procedures, and safety features of the laminator before using or servicing the unit.

GBC Pro-Tech F-60 Laminator is a powerful machine that is designed to mount, laminate and encapsulate. The forces required to accomplish these tasks can vary from negligible to very large.

In addition, the laminating roll of the F-60 can reach temperatures of 270 °F (132 °C). At these temperatures there is a danger of a severe burn if the roll is touched during set-up, operation or servicing.

Safety is an important feature of the F-60 Laminator. It has emergency stop buttons and a mechanical guard system on the infeed. In addition, the pull rolls are contained in an enclosure to prevent injury.

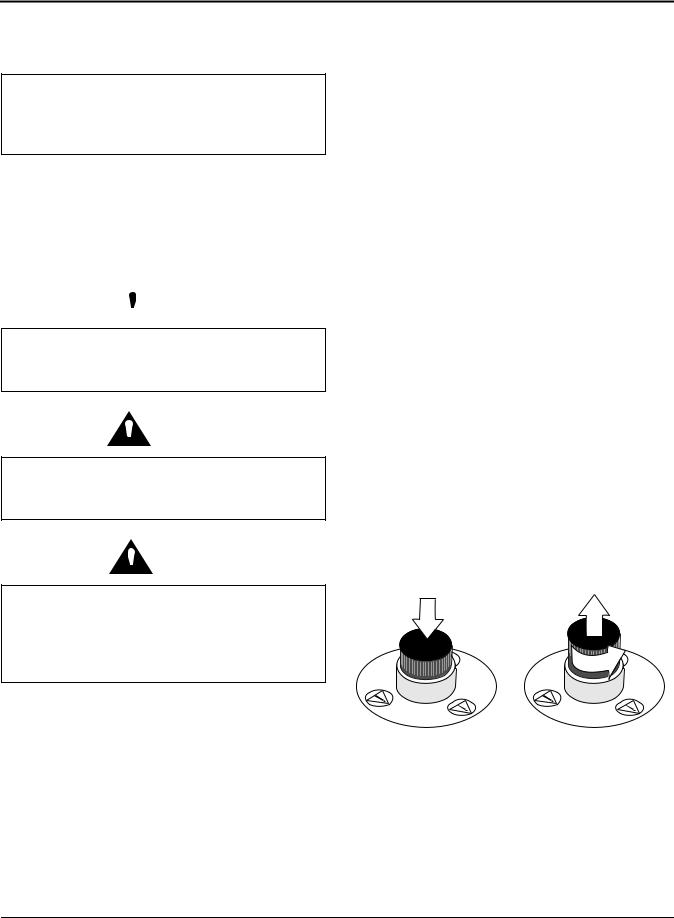

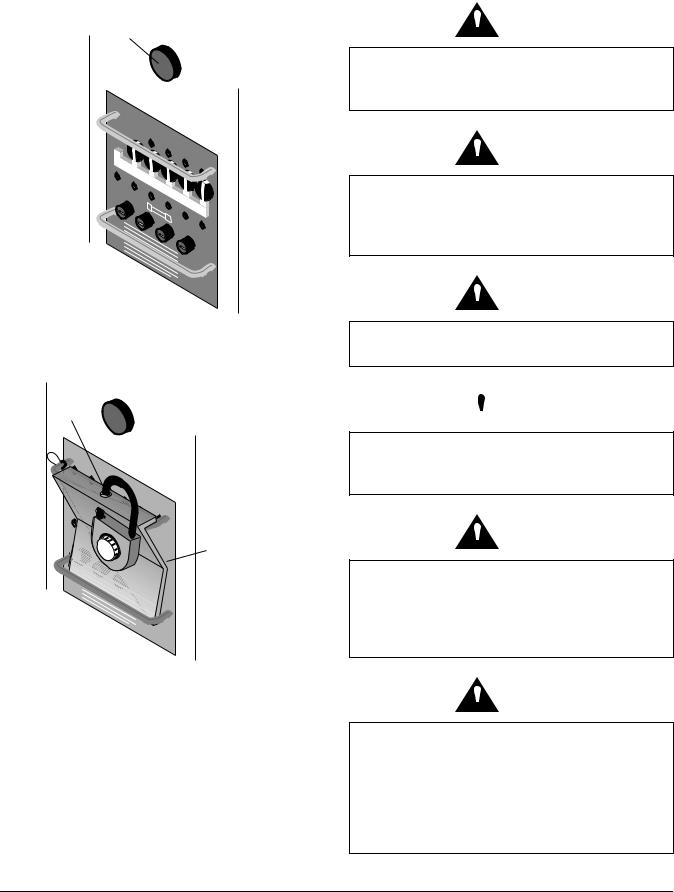

The laminator is equipped with four emergency stop buttons located on the top front and back of either side of the laminator. Any of these, if engaged, stops the laminator. To continue operation all emergency stop buttons must be in the up position and you must press the reset button above the fuse panel on the back of the laminator (see Figure 1-2). The laminator is also equipped with a power lockout (see Figure 1-3) which stops power to the machine.

Push either |

Twist pressed |

button to stop the |

button to resume |

laminator |

operation - the |

|

button pops up |

1 |

|

n |

/ |

||

|

4 tur |

|

Figure 1-1: Using the Emergency Stop Buttons

© GBC Pro-Tech 1998 July |

1-1 |

Safety |

F-60 Operation and Maintenance Manual |

|

|

Reset Button

POWER

POWER

Figure 1-2: Resetting the Laminator

Insert

Lock

Circuit

Breakers

Secured in

"Off" Position

Figure 1-3: Power Lockout

Despite the safety features built into the F-60 Laminator, extreme caution must be used when operating or servicing the unit. READ THE FOLLOWING

WARNINGS AND CAUTIONS BEFORE ATTEMPTING TO OPERATE OR SERVICE THE F-60 LAMINATOR.

WARNING

WARNING

Never place fingers or arms between the rolls when they are turning or when the rolls are in the closed position. You can be crushed or burned.

WARNING

WARNING

Do not wear ties, loose fitting clothing or dangling jewelry while operating or servicing the laminator. These items can get caught in the nip and choke you or you can be crushed or burned.

WARNING

WARNING

Do not operate the laminator near water. You can be severely shocked, electrocuted or cause a fire.

DANGER

DANGER

Remove and lock out power from the laminator before servicing. You can be severely shocked, electrocuted or cause a fire.

WARNING

WARNING

Do not use liquid or aerosol cleaners on the laminator. Do not spill liquid of any kind on the laminator. You can be severely shocked, electrocuted or cause a fire. Use only a damp cloth for cleaning.

WARNING

WARNING

Exercise care when cleaning the rolls with 80% isopropyl alcohol:

•Use only in a well ventilated area.

•Wear rubber gloves.

•Use only on cool rolls.

Cleaning heated rolls can ignite the fumes.

1-2 |

© GBC Pro-Tech 1998 July |

F-60 Operation and Maintenance Manual

CAUTION

CAUTION

Use only 80% isopropyl alcohol or a rubber cement eraser to clean the laminating rolls.

Harsh chemicals like toluene, acetone or MEK destroy the silicone covering of the rolls.

CAUTION

CAUTION

Raise the upper main roll when the laminator is not in operation. Prolonged contact can damage the rolls.

CAUTION

CAUTION

Excess pressure can damage the laminating rolls. Always select the minimum roll pressure necessary to complete the task.

CAUTION

CAUTION

If silicone adhesive contacts the upper or lower roll, remove it IMMEDIATELY using 80% isopropyl alcohol. It can harden within an hour and ruin the roll.

WARNING

WARNING

The operating environment must be free of dust, flammable liquids and vapors. You can be injured by inhaling chemical vapors. Vapor build up or stored flammable liquids can cause a fire. Excessive dust can damage the laminator.

CAUTION

CAUTION

Do not use a knife or other sharp instrument during installation or while servicing the laminator. You can cause irreparable damage to the rolls.

WARNING

WARNING

Do not attempt to move the laminator across anything other than a flat, level surface without trained and qualified riggers. You can be crushed or seriously injured.

The F-60 Laminator is a large and heavy piece of equipment. It is necessary to employ LICENSED RIGGERS ONLY to move the machine. GBC Pro-Tech’s warranty does not cover malfunction of the equipment due to mishandling.

GBC Pro-Tech bears no responsibility for personal injury or damage due to moving the laminator improperly.

WARNING

WARNING

Do not operate the laminator if the power cord is damaged or frayed. You can be severely shocked, electrocuted or cause a fire. Contact a qualified electrician to replace the cord.

WARNING

WARNING

Do not allow anything to rest on the power cord. Do not locate the cord where people can walk on it. You or others can be severely shocked, electrocuted or cause a fire.

Always use good safety practices when operating or servicing the laminator and know how to react quickly in an emergency.

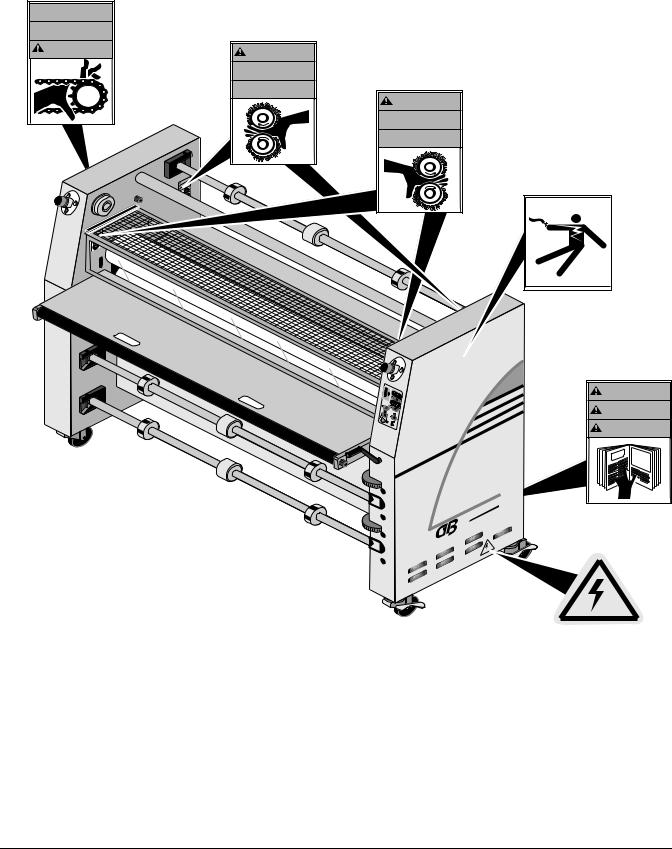

&DXWLRQ :DUQLQJ /DEHO /RFDWLRQV

Posted at various locations on your F-60 Laminator are important safety labels. PAY CAREFUL ATTENTION TO THESE LABELS AT ALL TIMES! Figure 1-4 shows the location of each of these labels.

© GBC Pro-Tech 1998 July |

1-3 |

Safety |

F-60 Operation and Maintenance Manual |

|

|

(Inside cabinet)

WARNING

WARNING

ACHTUNG

ACHTUNG

MISE EN GARDE |

WARNING |

|

ACHTUNG

ACHTUNG

MISE EN GARDE

MISE EN GARDE

WARNING

ACHTUNG

ACHTUNG

MISE EN GARDE

MISE EN GARDE

|

G |

|

NIN |

AR |

|

W |

TUNG |

ACH |

|

NING

WAR UNG

ACHT

ACHT

(Inside cabinet)

©1994 Hazard Communication Systems, Inc. 800-748-0241 |

2

F |

-60™ |

|

WARNING |

ACHTUNG |

MISE EN GARDE |

-TECH  PRO

PRO

Figure 1-4: Locations of Safety Labels

1-4 |

© GBC Pro-Tech 1998 July |

F-60 Operation and Maintenance Manual

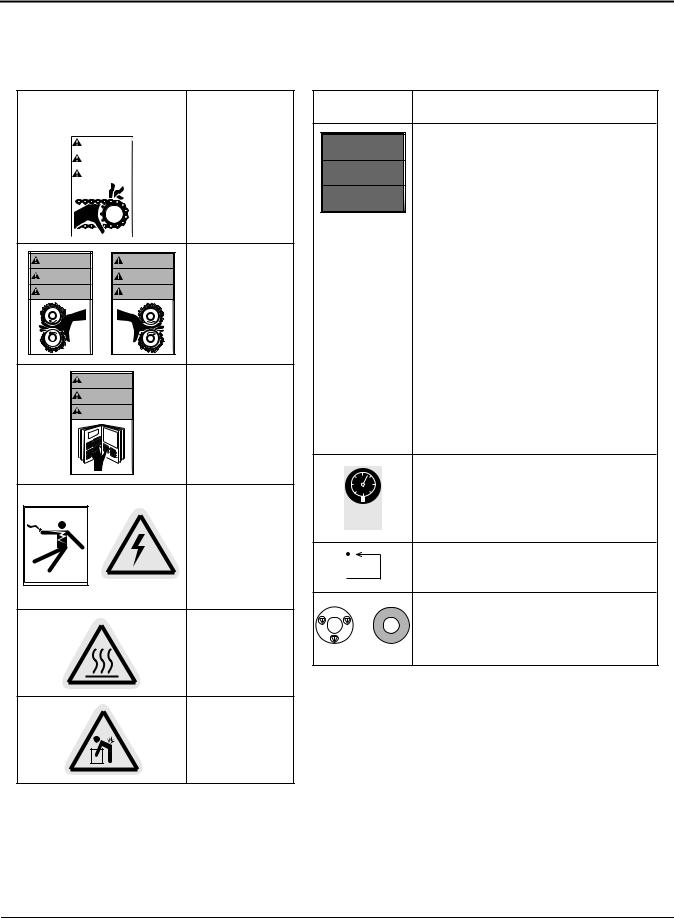

The following are typical safety hazard decals used on GBC Pro-Tech machines, with a brief description (“Meaning” column) of each decal.

|

Decal |

Meaning |

|

|

|

|

|

WARNING! |

|

WARNING |

Moving parts can |

|

ACHTUNG |

|

|

crush and cut. |

|

|

MISE EN GARDE |

|

|

Do not operate with |

|

|

|

|

|

|

guard or door open. |

|

|

|

WARNING |

WARNING |

WARNING! |

|

||

ACHTUNG |

ACHTUNG |

Crush and burn |

|

|

hazard. Stay clear of |

MISE EN GARDE |

MISE EN GARDE |

moving rollers. Stop |

|

or |

machine and raise roll |

|

|

before cleaning. |

WARNING |

WARNING! |

|

|

||

ACHTUNG |

Carefully read |

|

|

|

Operator's Manual |

MISE EN GARDE |

before handling this |

|

|

|

machine. Observe |

|

|

instructions and safety |

|

|

rules when operating. |

|

|

WARNING! |

|

|

HAZARDOUS |

|

|

VOLTAGE. |

|

or |

To be serviced only by |

|

|

|

|

|

trained and authorized |

|

|

personnel. |

©1994 Hazard Communication Systems, Inc. 800-748-0241 |

|

Lockout power before |

|

|

servicing. |

|

|

CAUTION! |

|

|

Surface is hot. |

|

|

A burn hazard exists. |

|

|

CAUTION! |

|

|

Rolls are heavy. |

|

|

Use proper lifting |

|

|

techniques to prevent |

|

|

injury. |

Decal

SAFETY INSTRUCTIONS

SICHERHEITSRICHTLINIEN

CONSIGNES DE SÉCURITÉ

≤ 100 PSI

≥ 700 KPa

©1997 HCS, Inc. 800-748-0241 No. 6101-52BVPK

|

|

|

Y STO |

P |

|

|

|

|

|

|

|

NC |

|

|

|

|

|

|

|

G |

E |

|

A |

|

|

|

|

|

|

|

R |

||||

or |

E |

R |

|

|

|

R |

||

|

|

|

|

|

E |

|||

S |

|

|

|

|

|

U'D |

||

|

M |

|

|

|

|

|

|

T |

|

E |

|

|

|

|

|

|

|

|

U |

|

|

G |

R |

|

||

|

|

A |

|

NE |

|

|

||

|

|

|

T |

|

|

|

|

|

|

|

|

ON |

EC |

|

|

|

|

Meaning

WARNING!

1.Read and understand the Operation Manual and all safety labels before operating this machine.

2.Only a trained person is to be permitted to operate this machine. Training should include instruction in operation under normal conditions and emergency situations.

3.This machine is to be serviced only by trained and authorized personnel. Follow lockout procedures before servicing.

4.Never reach into the machine for any reason unless the machine is at a COMPLETE STOP.

5.Never leave the machine stopped in such a manner that another worker can start the machine while you are working on or within the machine.

6.Never change or defeat the function of electrical interlocks or other machine "shutdown" switches.

7.Before starting this machine, check that:

-All persons are clear of the machine.

-No maintenance work is being performed on the machine.

-All guards are in place.

-All parent rolls are well chucked in the unwind stands.

-The machine is free of paper scraps, wraps and jams.

8.There is a potential hazard of entanglement in this machine caused by items such as long hair, loose clothing, and jewelry. Make sure your clothing and hair fit closely to your body and that all jewelry, rings and watches are removed.

CAUTION!

Air pressure must be less than 100 PSI (700 kPa) to avoid damaging the machine.

Reset.

WARNING!

EMERGENCY STOP BUTTON

Press this button to stop the machine cycle, remove electric power, and separate (open) rolls to eliminate a pinch point (on some machines).

© GBC Pro-Tech 1998 July |

1-5 |

Safety |

F-60 Operation and Maintenance Manual |

|

|

Blank page.

1-6 |

© GBC Pro-Tech 1998 July |

F-60 Operation and Maintenance Manual |

Installation |

|

|

6HFWLRQ ,QVWDOODWLRQ

GBC Pro-Tech is committed to a program of ongoing product improvement. As a result, we are providing these instructions so that you can insure that your new F-60 Laminator is properly and securely unpacked, moved and installed.

Before a F-60 Laminator can be installed, there are a few requirements that must be met. Make certain that each of the requirements listed in the following preinstallation checklist are met before beginning installation.

CAUTION

CAUTION

Failure to follow the preinstallation checklist can result in damage to the laminator.

3UHLQVWDOODWLRQ &KHFNOLVW

Are doorways and hallways wide enough for the laminator to be moved to the installation site?

Is there ample room for the laminator?

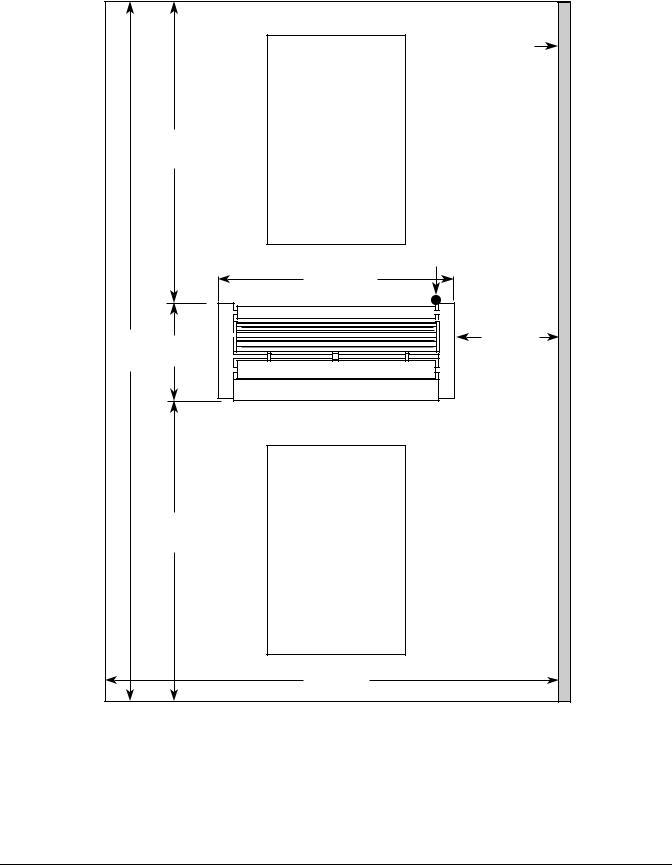

A work area must be established that allows for operation in both the front and the rear of the machine and provides space for efficient material flow. Figure 2-1 shows a typical machine area layout.

Is the environment appropriate for the laminator? The laminator requires a clean, dust and vapor free environment to operate properly, such as an air conditioned office area with forced 10% make up air. However, the laminator must not be located where there is air blowing directly on it. Major fluctuation in temperature and humidity are to be avoided.

WARNING

WARNING

The operating environment must be free of dust, flammable liquids and vapors. You can be injured by inhaling chemical vapors. Vapor build up or stored flammable liquids can cause a fire. Excessive dust can damage the laminator.

CAUTION

CAUTION

Do not locate the laminator where air is blowing directly on the machine. The air flow can cool the rolls unevenly and result in poor quality output.

Is there an appropriate power outlet available or has a certified electrician been contacted to wire the laminator directly?

The laminator requires 55A single phase, 220/230/ 240 VAC service or, in Europe,

3 Phase, 240/400 VAC with 25 Amps per phase.

WARNING

WARNING

Do not attempt to defeat the grounding feature of the ground plug on the laminator. You can be severely shocked, electrocuted or cause a fire. The three prong plug fits only into a groundingtype power outlet. If you are unable to insert the plug into the existing outlet, contact a qualified electrician to replace the obsolete outlet.

WARNING

WARNING

Do not use an extension cord on this laminator. You can be severely shocked, electrocuted or cause a fire. If you need a longer cable contact a qualified electrician.

WARNING

WARNING

Do not operate the laminator if the power cord is damaged or frayed. You can be severely shocked, electrocuted or cause a fire. Contact a qualified electrician to replace the cord.

WARNING

WARNING

Do not allow anything to rest on the power cord. Do not locate the cord where people can walk on it. You or others can be severely shocked, electrocuted or cause a fire.

© GBC Pro-Tech 1998 July |

2-1 |

Installation |

F-60 Operation and Maintenance Manual |

|

|

|

|

4' x 6' (~1.22 m x 2 m) |

Wall |

|

|

|

|

|

|

Work Table |

|

|

|

on Wheels |

|

|

|

Table Height |

|

|

|

35-3/4" |

|

|

8'6-1/2" |

(~.94 - .95 m) |

|

|

(~2.6 m) |

|

|

|

|

|

Electrical |

|

|

|

Supply |

|

|

78" (~2 m) |

|

|

|

Rear |

|

20' |

30" |

|

3' (~1 m) |

|

|

||

(~.6 m) (~.76 m) |

|

|

|

|

|

Front |

|

|

|

4' x 6' (~1.22 m x 2 m) |

|

|

|

Work Table |

|

|

|

on Wheels |

|

|

8'6-1/2" |

Table Height |

|

|

(~2.6 m) |

35-3/4" |

|

|

|

(~.94 - .95 m) |

|

|

|

13' (~4 m) |

|

Figure 2-1: Laminator Space Requirements

2-2 |

© GBC Pro-Tech 1998 July |

Loading...

Loading...