Fujitsu MAP3735NP, MAP3147NC-NP, MAP3735NC-NP, MAP3367NP, MAP3367NC-NP User Manual

...

C141-E166-02EN

MAP3147NC/NP

MAP3735NC/NP

MAP3367NC/NP

DISK DRIVES

PRODUCT/MAINTENANCE MANUAL

FOR SAFE OPERATION

Handling of This manual

This manual contains important information for using this product. Read thoroughly before using the product. Use this product only after thoroughly reading and understanding especially the section “Important Alert Items” in this manual. Keep this manual handy, and keep it carefully.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering damage to their property. Use the product according to this manual.

IMPORTANT NOTE TO USERS

READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THIS PRODUCT. INCORRECT USE OF THE PRODUCT MAY RESULT IN INJURY OR DAMAGE

TO USERS, BYSTANDERS OR PROPERTY.

While FUJITSU has sought to ensure the accuracy of all information in this manual, FUJITSU assumes no liability to any party for any damage caused by any error or omission contained in this manual, its updates or supplements, whether such errors or omissions result from negligence, accident, or any other cause. In addition, FUJITSU assumes no liability with respect to the application or use of any porduct or system in accordance with the descriptions or instructions contained herein; including any liability for incidental or consequential damages arising therefrom.

FUJTSU DISCLAIMS ALL WARRANTIES REGARDING THE INFORMATION CONTAINED HEREIN, WHETHER EXPRESSED, IMPLIED, OR STATUTORY.

FUJITSU reserves the right to make changes to any products described herein without further notice and without obligation.

This product is designed and manufactured for use in standard applications such as office work, personal devices and household appliances. This product is not intended for special uses (atomic controls, aeronautic or space systems, mass transport vehicle operating controls, medical devices for life support, or weapons firing controls) where particularly high reliability requirements exist, where the pertinent levels of safety are not guaranteed, or where a failure or operational error could threaten a life or cause a physical injury (hereafter referred to as "mission-critical" use). Customers considering the use of these products for mission-critical applications must have safety-assurance measures in place beforehand. Moreover, they are requested to consult our sales representative before embarking on such specialized use.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without the express written permission of Fujitsu Limited.

All Right Reserved, Copyright © FUJITSU LIMITED 2002

C141-E166

|

|

REVISION RECORD |

|

|

|

Edition |

Date published |

Revised contents |

|

|

|

01 |

May, 2002 |

|

|

|

|

02 |

July, 2002 |

• Table 2.1 is partly modified. |

|

|

• Specifications of Table 2.2 and 2.3 are partly modified. |

|

|

• Specifications in Figure 3.1 and subsection 3.1.1(1) are partly modified. |

|

|

• Specification of mounting screw in subsection 4.1.1 is added. |

|

|

• Procedures of spindle motor startup in section 4.2(4) is modified. |

|

|

• Section 4.3 is revised. |

|

|

• Section 5.3 is revised. |

|

|

• Length of mounting screw in subsection 5.4.2 is modified. |

|

|

• Troubleshooting in Table 6.2 is added. |

|

|

• APPENDIX A and B are revised. |

|

|

|

|

|

Specification No.: C141-E166-**EN |

|

|

|

C141-E166 |

i |

Related Standards

Product specifications and functions described in this manual comply with the following ANSI (*1) standards.

Document number |

Title |

|

|

T10/1236D Rev.20 |

SCSI Primary Commands-2 (SPC-2) |

[NCITS.351:2001] |

|

|

|

T10/996D Rev.8c |

SCSI-3 Block Commands (SBC) |

[NCITS.306:1998] |

|

|

|

T10/1157D Rev.20 |

SCSI Architecture Model-2 (SAM-2) |

|

|

T10/1365D Rev.7 |

SCSI Parallel Interface-4 (SPI-4) |

|

|

*1 ANSI = American National Standard Institute

In case of conflict between this manual and any referenced document, this manual takes precedence.

ii |

C141-E166 |

PREFACE

This manual describes the MAP3147NC/NP, MAP3735NC/NP and MAP3367NC/NP (hereafter, MAP series), 3.5 type fixed disk drives with an embedded SCSI controller.

This manual details the specifications and functions of the above disk drive, and gives the requirements and procedures for installing it into a host computer system.

This manual is written for users who have a basic understanding of fixed disk drives and their use in computer systems. The MANUAL ORGANIZATION section describes organization and scope of this manual. The need arises, use the other manuals.

OVERVIEW OF MANUAL

This manual consists of the following eight chapters:

CHAPTER 1 GENERAL DESCRIPTION

This chapter introduces the MAP series disk drives and discusses their standard features, hardware, and system configuration.

CHAPTER 2 SPECIFICATIONS

This chapter gives detailed specifications of the MAP series disk drives and their installation environment.

CHAPTER 3 DATA FORMAT

This chapter describes the data structure of the disk, the address method, and what to do about media defects.

CHAPTER 4 INSTALLATION REQUIREMENTS

This chapter describes the basic physical and electrical requirements for installing MAP series disk drives.

CHAPTER 5 INSTALLATION

This chapter explains how to install MAP series disk drives. It includes the notice and procedures for setting device number and operation modes, mounting the disk drive, connecting the cables, and confirming drive operation.

CHAPTER 6 DIAGNOSIS AND MAINTENANCE

This chapter describes the automatic diagnosis, and maintenance of MAP series disk drive. This chapter also describes diagnostic methods for operation check and the basics of troubleshooting the disk drives.

CHAPTER 7 ERROR ANALYSIS

This chapter describes in details how collect the information for error analysis and how analyze collected error information.

APPENDIX A TO B

The appendixes give supplementary information, including a list of setting items and the signal assignments of interface connector.

C141-E166 |

iii |

CONVENTIONS FOR ALERT MESSAGES

This manual uses the following conventions for alerts to prevent physical or property damages to users or by standards.

CAUTION |

This indicates that either minor or moderate |

|

personal injury may occur if the user does not |

|

|

|

perform the procedure correctly. |

|

This indicates that inconvenience to the user |

NOTICE |

|

|

such as damages to the product, equipment, data, |

|

|

|

and/or other property may occur if the user does |

|

not pay attention or perform the procedure |

|

correctly. |

IMPORTANT |

This indicates information that the helps the user |

|

use the product more effectively. |

CONVENTIONS USED IN THIS MANUAL

The MAP3147NC/NP, MAP3735NC/NP and MAP3367NC/NP disk drives are described as "the intelligent disk drive (IDD)", "the drive" or "the device" in this manual.

Decimal number is represented normally.

Hexadecimal number is represented as X'17B9', 17B9h or 17B9H.

Binary number is represented as "010".

ATTENTION

Please forward any comments you may have regarding this manual.

To make this manual easier for users to understand, opinions from readers are needed. Please write your opinions or requests on the Comment at the back of this manual and forward it to the address described in the sheet.

iv |

C141-E166 |

Important Alert Items

Important Alert Messages

The important alert messages in this manual are as follows:

A hazardous situation could result in minor or moderate personal injury if the user does not perform the procedure correctly. This alert signal also indicates that damages to the product or other property may occur if the user does not perform the procedure correctly.

Task |

Alert message |

Page |

Mounting Installation |

Data loss |

2-5 |

|

For MAP series, Reed Solomon codes are applied for their ECC. |

|

|

The sector-data is divided into 6 interleaving sectors, and ECC is |

|

|

performed in each sector where the maximum number of errors |

|

|

(up to 5 byte) can be corrected. [Total maximum byte: 5 byte × 6 |

|

|

( interleave) = 30 byte] |

|

|

If the error of read sector keeps allowable error byte number, |

|

|

correction is performed. |

|

|

However, if error byte exceeds its allowable number, correction |

|

|

may not be performed properly. |

|

|

Hot temperature |

|

|

To prevent injury, do not handle the drive until after the device has |

5-1 |

|

|

|

|

cooled sufficiently after turning off the power. The DE and LSI |

|

|

become hot during operation and remain hot immediately after |

|

|

turning off the power. |

|

|

Data loss |

5-5 |

|

1. The user must not change the setting of terminals not described |

|

|

in this section. Do not change setting status set at factory |

|

|

shipment. |

|

|

2. Do not change the setting of terminals except following setting |

|

|

pins during the power is turned on. |

|

|

• Write protect: CN2 9-10 (NP model only) |

|

|

3. To short the setting terminal, use the short plug attached when |

|

|

the device is shipped from the factory. |

|

Damage |

5-11 |

1.Make sure that system power is off before connecting or disconnecting cables.

2.Do not connect or disconnect cables when power is on.(except NC model)

C141-E166 |

v |

Task |

|

Alert message |

Page |

Mounting Installation |

Damage |

|

5-11 |

1.Be careful of the insertion orientation of the SCSI connectors. With the system in which terminating resistor power is supplied via the SCSI cable, if the power is turned on, the overcurrent protection fuse of the terminating resistor power supplier may be blown or the cable may be burnt if overcurrent protection is not provided.

When the recommended parts listed in Table 4.2 are used, inserting the cables in the wrong direction can be prevented.

2.To connect SCSI devices, be careful of the connection position of the cable. Check that the SCSI device with the terminating resistor is the last device connected to the cable.

Data loss |

6-4 |

||

When the SEND DIAGNOSTIC command terminates with the |

|

||

CHECK CONDITION status, the INIT must collect the error |

|

||

information using the REQUEST SENSE command. The RECEIVE |

|

||

DIAGNOSTIC RESULTS command cannot read out the error |

|

||

information detected in the self-diagnostics. |

|

||

Caution |

6-5 |

||

1. |

To avoid shocks, turn off the power before connecting or |

||

|

|||

|

disconnecting a cable, connector, or plug. |

|

|

2. |

To avoid injury, do not touch the mechanical assembly during |

|

|

|

disk drive operation. |

|

|

3. |

Do not use solvents to clean the disk drive. |

|

|

Caution |

6-6 |

||

1. |

Always ground yourself with a wrist strap connected to ground |

||

|

|||

|

before handling. ESD (Electrostatics Discharge) may cause |

|

|

|

the damage to the device. |

|

|

2. |

To prevent electrical damage to the disk drive, turn the power |

|

|

|

off before connecting or disconnecting a cable, connector, or |

|

|

|

plug. |

|

|

3. |

Do not remove a PCA. This operation is required to prevent |

|

|

|

unexpected or unpredictable operation. |

|

|

4. |

Do not use a conductive cleaner to clean a disk drive assembly. |

|

|

5. |

Ribbon cables are marked with a colored line. Connect the |

|

|

|

ribbon cable to a cable connector with the colored wire |

|

|

|

connected to pin 1. |

|

|

Damage |

6-6 |

||

Never open the disk enclosure in the field. Opening the disk |

|||

6-15 |

|||

enclosure may cause an irreparable fault. |

|||

|

|||

Data loss |

6-7 |

||

Save data stored on the disk drive before requesting repair. Fujitsu |

|||

does not assume responsibility if data is destroyed during servicing |

|

||

or repair. |

|

||

vi |

C141-E166 |

MANUAL ORGANIZATION |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

PRODUCT/ |

|

1. |

General Description |

|

|

MAINTENANCE |

|

2. |

Specifications |

|

|

MANUAL |

|

3. |

Data Format |

|

|

|

|

4. |

Installation Requirements |

|

|

(This manual) |

|

5. |

Installation |

|

|

|

|

6. |

Diagnostics and Maintenance |

|

|

|

|

7. |

Error Analysis |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCSI Physical |

|

1. |

SCSI Bus |

|

|

Interface |

|

2. |

SCSI Message |

|

|

Specifications |

|

3. |

SCSI Bus Error Recovery Processing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCSI Logical |

|

1. |

Command Processing |

|

|

Interface |

|

2. |

Data Buffer Management |

|

|

Specifications |

|

3. |

Command Specification |

|

|

|

|

4. |

Sense Data and error Recovery Procedure |

|

|

|

|

5. |

Disk Medium Management |

|

|

|

|

|

|

|

C141-E166 |

vii |

This page is intentionally left blank.

CONTENTS

|

|

|

page |

CHAPTER 1 |

GENERAL DESCRIPTION ............................................................................ |

1-1 |

|

1.1 |

Standard Features .............................................................................................................. |

1-2 |

|

1.2 |

Hardware Structure............................................................................................................ |

1-6 |

|

1.3 |

System Configuration ........................................................................................................ |

1-9 |

|

CHAPTER 2 |

SPECIFICATIONS........................................................................................... |

2-1 |

|

2.1 |

Hardware Specifications.................................................................................................... |

2-1 |

|

2.1.1 |

Model name and order number.......................................................................................... |

2-1 |

|

2.1.2 |

Function specifications...................................................................................................... |

2-2 |

|

2.1.3 |

Environmental specifications ............................................................................................ |

2-4 |

|

2.1.4 |

Error rate ........................................................................................................................... |

2-5 |

|

2.1.5 |

Reliability.......................................................................................................................... |

2-5 |

|

2.2 |

SCSI Function Specifications............................................................................................ |

2-7 |

|

CHAPTER 3 |

DATA FORMAT............................................................................................... |

3-1 |

|

3.1 |

Data Space......................................................................................................................... |

3-1 |

|

3.1.1 |

Cylinder configuration....................................................................................................... |

3-1 |

|

3.1.2 |

Alternate spare area ........................................................................................................... |

3-4 |

|

3.1.3 |

Track format...................................................................................................................... |

3-5 |

|

3.1.4 |

Sector format ..................................................................................................................... |

3-7 |

|

3.1.5 |

Format capacity ................................................................................................................. |

3-9 |

|

3.2 |

Logical Data Block Addressing......................................................................................... |

3-9 |

|

3.3 |

Defect Management........................................................................................................... |

3-11 |

|

3.3.1 |

Defect list .......................................................................................................................... |

3-11 |

|

3.3.2 |

Alternate block allocation ................................................................................................. |

3-11 |

|

CHAPTER 4 |

INSTALLATION REQUIREMENTS ............................................................. |

4-1 |

|

4.1 |

Mounting Requirements .................................................................................................... |

4-1 |

|

4.1.1 |

External dimensions .......................................................................................................... |

4-1 |

|

4.1.2 |

Mounting ........................................................................................................................... |

4-4 |

|

4.1.3 |

Notes on mounting ............................................................................................................ |

4-4 |

|

4.2 |

Power Supply Requirements ............................................................................................. |

4-8 |

|

4.3 |

Connection Requirements.................................................................................................. |

4-11 |

|

4.3.1 |

SCA2 connector type 16-bit SCSI model (NC model) ...................................................... |

4-11 |

|

C141-E166 |

ix |

4.3.2 |

68 pin connector type 16-bit SCSI model (NP model)...................................................... |

4-13 |

4.3.3 |

Cable connector requirements ........................................................................................... |

4-20 |

4.3.4 |

External operator panel (on NP model drives only) .......................................................... |

4-21 |

CHAPTER 5 INSTALLATION............................................................................................... |

5-1 |

|

5.1 |

Notes on Handling Drives ................................................................................................. |

5-1 |

5.2 |

Connections....................................................................................................................... |

5-3 |

5.3 |

Setting Terminals .............................................................................................................. |

5-5 |

5.3.1 |

SCSI ID setting.................................................................................................................. |

5-6 |

5.3.2 |

Each mode setting ............................................................................................................. |

5-8 |

5.3.3 |

Mode settings .................................................................................................................... |

5-10 |

5.4 |

Mounting Drives................................................................................................................ |

5-11 |

5.4.1 |

Check before mounting ..................................................................................................... |

5-11 |

5.4.2 |

Mounting procedures......................................................................................................... |

5-11 |

5.5 |

Connecting Cables............................................................................................................. |

5-12 |

5.6 |

Confirming Operations after Installation and Preparation for use ..................................... |

5-13 |

5.6.1 |

Confirming initial operations............................................................................................. |

5-13 |

5.6.2 |

Checking SCSI connection................................................................................................ |

5-14 |

5.6.3 |

Formatting ......................................................................................................................... |

5-17 |

5.6.4 |

Setting parameters ............................................................................................................. |

5-19 |

5.7 |

Dismounting Drives........................................................................................................... |

5-23 |

5.8 |

Spare Disk Drive ............................................................................................................... |

5-23 |

CHAPTER 6 DIAGNOSTICS AND MAINTENANCE ........................................................ |

6-1 |

|

6.1 |

Diagnostics ........................................................................................................................ |

6-1 |

6.1.1 |

Self-diagnostics ................................................................................................................. |

6-1 |

6.1.2 |

Test programs.................................................................................................................... |

6-4 |

6.2 |

Maintenance Information .................................................................................................. |

6-5 |

6.2.1 |

Precautions ........................................................................................................................ |

6-5 |

6.2.2 |

Maintenance requirements................................................................................................. |

6-6 |

6.2.3 |

Maintenance levels ............................................................................................................ |

6-8 |

6.2.4 |

Revision numbers .............................................................................................................. |

6-9 |

6.2.5 |

Tools and test equipment................................................................................................... |

6-10 |

6.2.6 |

Tests .................................................................................................................................. |

6-10 |

6.3 |

Operation Check................................................................................................................ |

6-12 |

6.3.1 |

Initial seek operation check ............................................................................................... |

6-12 |

6.3.2 |

Operation test .................................................................................................................... |

6-12 |

x |

C141-E166 |

6.3.3 |

Diagnostic test ................................................................................................................... |

6-12 |

6.4 |

Troubleshooting Procedures.............................................................................................. |

6-13 |

6.4.1 |

Outline of troubleshooting procedures .............................................................................. |

6-13 |

6.4.2 |

Troubleshooting with disk drive replacement in the field ................................................. |

6-13 |

6.4.3 |

Troubleshooting at the repair site ...................................................................................... |

6-15 |

6.4.4 |

Troubleshooting with parts replacement in the factory ..................................................... |

6-16 |

6.4.5 |

Finding possibly faulty parts ............................................................................................. |

6-16 |

CHAPTER 7 ERROR ANALYSIS ......................................................................................... |

7-1 |

|

7.1 |

Error Analysis Information Collection .............................................................................. |

7-1 |

7.1.1 |

Sense data.......................................................................................................................... |

7-1 |

7.1.2 |

Sense key, sense code, and subsense code ........................................................................ |

7-1 |

7.2 |

Sense Data Analysis .......................................................................................................... |

7-3 |

7.2.1 |

Error information indicated with sense data ...................................................................... |

7-3 |

7.2.2 |

Sense data (3-0C-03), (4-40-xx), (4-44-xx), and (4-C4-xx) .............................................. |

7-4 |

7.2.3 |

Sense data (1-1x-xx), (3-1x-xx) and (E-1D-00): Disk read error .................................... |

7-4 |

7.2.4Sense data (5-2x-xx), (5-3D-00), (5-90-00), (B-47-xx), (B-49-00),

|

(B-4D-xx) and (B-4E-00): SCSI interface error............................................................... |

7-4 |

APPENDIX A SETTING TERMINALS .................................................................................. |

A-1 |

|

A.1 |

Setting Terminals (on NP model only) .............................................................................. |

A-2 |

APPENDIX B CONNECTOR SIGNAL ALLOCATION ....................................................... |

B-1 |

|

B.1 |

SCSI Connector Signal Allocation: SCA2 type LVD 16-bit SCSI................................... |

B-2 |

B.2 |

SCSI Connector Signal Allocation: 68 pin type LVD 16-bit SCSI .................................. |

B-3 |

INDEX |

........................................................................................................................................ |

IN-1 |

C141-E166 |

xi |

|

FIGURES |

|

|

|

page |

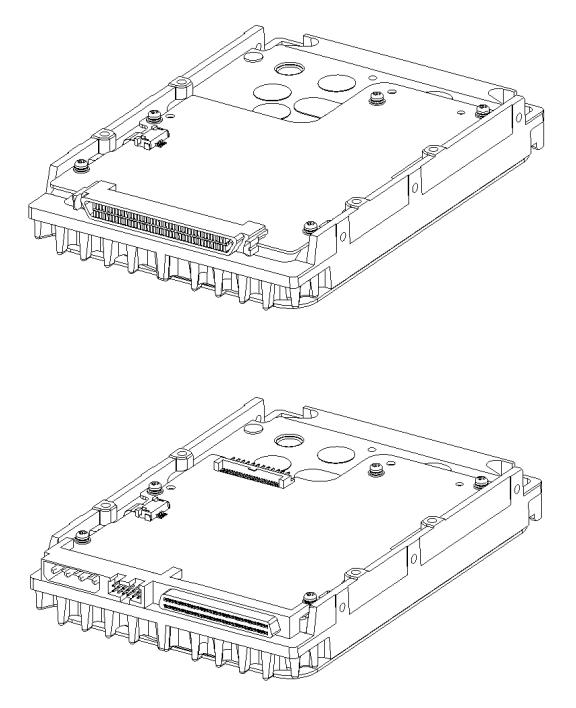

Figure 1.1 |

NC model drives outer view ................................................................................................. |

1-6 |

Figure 1.2 |

NP model drives outer view ................................................................................................. |

1-6 |

Figure 1.3 |

Disk/head configuration........................................................................................................ |

1-7 |

Figure 1.4 |

System configuration ............................................................................................................ |

1-9 |

Figure 3.1 |

Cylinder configuration.......................................................................................................... |

3-2 |

Figure 3.2 |

Spare area in cell .................................................................................................................. |

3-5 |

Figure 3.3 |

Alternate cylinder ................................................................................................................. |

3-5 |

Figure 3.4 |

Track format ......................................................................................................................... |

3-6 |

Figure 3.5 |

Track skew/head skew.......................................................................................................... |

3-7 |

Figure 3.6 |

Sector format ........................................................................................................................ |

3-7 |

Figure 3.7 |

Alternate block allocation by FORMAT UNIT command ................................................. |

3-13 |

Figure 3.8 |

Alternate block allocation by REASSIGN BLOCKS command ........................................ |

3-14 |

Figure 4.1 |

NC external dimensions........................................................................................................ |

4-2 |

Figure 4.2 |

NP external dimensions ........................................................................................................ |

4-3 |

Figure 4.3 |

IDD orientations ................................................................................................................... |

4-4 |

Figure 4.4 |

Mounting frame structure ..................................................................................................... |

4-5 |

Figure 4.5 |

Limitation of side-mounting ................................................................................................. |

4-5 |

Figure 4.6 |

Surface temperature measurement points ............................................................................. |

4-6 |

Figure 4.7 |

Service clearance area .......................................................................................................... |

4-7 |

Figure 4.8 |

Spin-up current waveform (+12 VDC) ................................................................................. |

4-8 |

Figure 4.9 |

Power on/off sequence (1) .................................................................................................... |

4-8 |

Figure 4.10 |

Power on/off sequence (2) .................................................................................................... |

4-9 |

Figure 4.11 |

Power on/off sequence (3) .................................................................................................... |

4-9 |

Figure 4.12 |

AC noise filter (recommended) .......................................................................................... |

4-11 |

Figure 4.13 |

NC connectors location ...................................................................................................... |

4-11 |

Figure 4.14 |

SCA2 type 16-bit SCSI connector ...................................................................................... |

4-12 |

Figure 4.15 |

NP connectors and terminals location ................................................................................ |

4-13 |

Figure 4.16 |

68 pin type 16-bit SCSI interface connector....................................................................... |

4-14 |

Figure 4.17 |

Power supply connector (68 pin type 16-bit SCSI) ............................................................ |

4-14 |

Figure 4.18 |

External operator panel connector (CN1)........................................................................... |

4-15 |

Figure 4.19 |

External operator panel connector (CN2)........................................................................... |

4-15 |

xii |

C141-E166 |

Figure 4.20 |

16-bit SCSI ID external input ............................................................................................. |

4-16 |

Figure 4.21 |

Output signal for external LED .......................................................................................... |

4-18 |

Figure 4.22 |

SCSI cables connection ...................................................................................................... |

4-19 |

Figure 4.23 |

External operator panel circuit example ............................................................................. |

4-21 |

Figure 5.1 |

SCSI bus connections .......................................................................................................... |

5-4 |

Figure 5.2 |

Setting terminals location (on NP models only) ................................................................... |

5-5 |

Figure 5.3 |

CN2 setting terminal (on NP models only)........................................................................... |

5-6 |

Figure 5.4 |

Checking the SCSI connection (A)..................................................................................... |

5-15 |

Figure 5.5 |

Checking the SCSI connection (B) ..................................................................................... |

5-16 |

Figure 6.1 |

Revision label ....................................................................................................................... |

6-9 |

Figure 6.2 |

Indicating revision numbers................................................................................................ |

6-10 |

Figure 6.3 |

Test flowchart ..................................................................................................................... |

6-11 |

Figure 7.1 |

Format of extended sense data.............................................................................................. |

7-2 |

C141-E166 |

xiii |

TABLES

|

|

page |

Table 2.1 |

Model names and order numbers.............................................................................................. |

2-1 |

Table 2.2 |

Function specifications ............................................................................................................. |

2-2 |

Table 2.3 |

Environmental/power requirements.......................................................................................... |

2-4 |

Table 2.4 |

SCSI function specifications..................................................................................................... |

2-7 |

Table 3.1 |

Zone layout and track capacity ................................................................................................. |

3-3 |

Table 3.4 |

Format capacity ........................................................................................................................ |

3-9 |

Table 4.1 |

Surface temperature check point............................................................................................... |

4-6 |

Table 4.2 |

Recommended components for connection ............................................................................ |

4-20 |

Table 5.1 |

SCSI ID setting......................................................................................................................... |

5-7 |

Table 5.2 |

Setting SCSI terminator power supply (NP model) .................................................................. |

5-8 |

Table 5.3 |

Motor start mode setting........................................................................................................... |

5-8 |

Table 5.4 |

Write protect setting (NP model).............................................................................................. |

5-9 |

Table 5.5 |

Setting of the SCSI interface operation mode (NP model) ....................................................... |

5-9 |

Table 5.6 |

Setting the bus width of the SCSI interface (NP model).......................................................... |

5-9 |

Table 5.7 |

Default mode settings (by CHANGE DEFINITION command) ............................................ |

5-10 |

Table 5.8 |

Setting check list (NP model only) ......................................................................................... |

5-11 |

Table 6.1 |

Self-diagnostic functions .......................................................................................................... |

6-1 |

Table 6.2 |

System-level field troubleshooting ......................................................................................... |

6-14 |

Table 6.3 |

Disk drive troubleshooting ..................................................................................................... |

6-15 |

Table 7.1 |

Definition of sense data ............................................................................................................ |

7-3 |

Table A.1 |

CN2 setting terminal (on NP model drives only)................................................................. |

A-2 |

Table B.1 |

SCSI connector (SCA2 type LVD 16-bit SCSI): CN1 ........................................................... |

B-2 |

Table B.2 |

SCSI connector (68 pin type LVD 16-bit SCSI): CN1........................................................... |

B-3 |

xiv |

C141-E166 |

CHAPTER 1 GENERAL DESCRIPTION

1.1Standard Features

1.2Hardware Structure

1.3System Configuration

This chapter describes the feature and configuration of the MAP series intelligent disk drives (IDD).

IDDs are high performance large capacity 3.5 type fixed disk drives with an embedded SCSI controller.

The MAP series disk drives support the Small Computer System Interface (SCSI) as described in the ANSI SCSI SPI-4 [T10/1365D Rev.7] to the extent described in this manual.

The flexibility and expandability of the SCSI, as well as the powerful command set of the IDD, allow the user to construct a high-performance reliable disk subsystem with large storage capacity.

The data format can be changed from the format at factory shipment by reinitializing with the user's system. Refer to SCSI Logical Interface Specifications for details.

C141-E166 |

1-1 |

1.1Standard Features

(1)Compactness

Since the SCSI controller circuit is embedded in the standard 3.5 type fixed disk drive form factor, the IDD is extremely compact. The IDD can be connected directly to the SCSI bus of the host system.

(2)SCSI standard

The IDD provides not only SCSI basic functions but also the following features:

•Arbitration

•Disconnection/Reconnection

•Data bus parity

The SCSI commands can manipulate data through logical block addressing regardless of the physical characteristics of the disk drive. This allows software to accommodate future expansion of system functions.

(3)8-bit SCSI/16-bit SCSI

The IDD has 16-bit data bus width (16-bit SCSI), which have the wide transfer function suitable for SCSI-2. 8-bit data bus is available only with NP model.

See subsection 5.3.2 for details of the bus width setting.

For the ultra SCSI model, number of connectable SCSI devices on the same SCSI bus is varied as follows.

• |

8-bit SCSI: |

8 drives max. (option for NP model) |

• |

16-bit SCSI: |

16 drives max. |

(4)High speed data transfer

Such a high data transfer rate on the SCSI bus can be useful with the large capacity buffer in the IDD.

• |

8-bit SCSI: |

The data transfer rate on the SCSI bus is 40 MB/s maximum at the |

|

|

synchronous mode. |

• |

16-bit SCSI: |

The data transfer rate on the SCSI bus is 320 MB/s maximum at the paced |

|

|

transfer synchronous mode. |

1-2 |

C141-E166 |

Note:

The maximum data transfer rate in asynchronous mode may be limited by the response time of initiator and the length of SCSI bus length. The maximum data transfer rate in synchronous mode may be limited by the cable length, transmission characteristics of the SCSI bus and the connected SCSI device number.

(5)Continuous block processing

The addressing method of data blocks is logical block address. The initiator can access data by specifying block number in a logically continuous data space without concerning the physical structure of the track or cylinder boundaries.

The continuous processing up to [64K-1] blocks in a command can be achieved, and IDD can perform continuous read/write operation when processing data blocks on several tracks or cylinder.

(6)Programmable multi-segment data buffer

The data buffer is 8M bytes. Data is transferred between SCSI bus and disk media through this data buffer. This feature provides the suitable usage environment for users.

Since the initiator can control the disconnect/reconnect timing on the SCSI bus by specifying the condition of stored data to the data buffer or empty condition of the data buffer, the initiator can perform the effective input/output operations with utilizing high data transfer capability of the SCSI bus regardless of actual data transfer rate of the disk drive.

(7)Cache feature

After executing the READ command, the IDD reads automatically and stores (prefetches) the subsequent data blocks into the data buffer (Read-ahead caching).

The high speed sequential data access can be achieved by transferring the data from the data buffer without reaccessing the disk in case the subsequent command requests the prefetched data blocks.

IMPORTANT

You should ensure that the cashed data is surely flushed to the disc media before you turn off the drive's power.

To ensure it, you should issue either the SYNCHRONIZE CASHE command or the STOP UNIT command and then confirm that the command is surely terminated with the GOOD STATUS.

(8)Command queuing feature

The IDD can queue maximum 128 commands, and optimizes the issuing order of queued commands by the reordering function. This feature realizes the high speed processing.

C141-E166 |

1-3 |

(9)Reserve and release functions

The IDD can be accessed exclusively in the multi-host or multi-initiator environment by using the reserve and release functions.

(10)Error recovery

The IDD can try to recover from errors in SCSI bus or the disk drive using its powerful retry processing. If a recoverable data check occurs, error-free data can be transferred to the initiator after being corrected in the data buffer. The initiator software is released from the complicated error recover processing by these error recovery functions of the IDD.

(11)Automatic alternate block reassignment

If a defective data block is detected during read or write the IDD can automatically reassign its alternate data block.

(12)Programmable data block length

Data can be accessed in fixed-block length units. The data block length is programmable, and can be specified at initializing with a multiple of four within the range of 512 to 528 bytes.

IMPORTANT

Error rate increase

1.The drive format at factory shipment is generally 512 byte.

2.The Recoverable Error of the drive might increase when the format would be modified from 512 bytes to the following values: 516 bytes, 520 bytes, 524 bytes, 528 bytes.

3.The Recoverable Error referred to here is sense data (1-13-xx).

(13)Defective block slipping

A logical data block can be reallocated in a physical sequence by slipping the defective data block at formatting. This results in high speed contiguous data block processing without a revolution delay due to defective data block.

(14)High speed positioning

A rotary voice coil motor achieves fast positioning.

1-4 |

C141-E166 |

(15)Large capacity

A large capacity can be obtained from 3.5 inch disk drives by dividing all cylinders into several partitions and changing the recording density on each partition (constant density recording). The disk subsystem with large capacity can be constructed in the good space efficiency.

(16)Start/Stop of spindle motor

Using the SCSI command, the host system can start and stop the spindle motor.

(17)Diagnosis

The IDD has a diagnostic capability which checks internal controller functions and drive operations to facilitate testing and repair.

(18)Low power consumption

By using highly integrated LSI components, the power consumption of the IDD is very low, and this enables the unit to be used in wide range of environmental conditions.

(19)Low noise and low vibration

The noise level is low; approx. 3.4 Bels Ready for MAP series. This makes it ideal for office use.

(20)Microcode downloading

The IDD implements the microcode download feature. This feature achieves easy maintainability of the IDD and function enhancing.

C141-E166 |

1-5 |

1.2Hardware Structure

An outer view of the IDD is given in Figures 1.1 and 1.2. The IDD is composed of the disk, head, spindle motor, mounted disk enclosure (DE) with actuator and air circulation filter, as well as read/write pre-amp with the printed circuit assembly (PCA) of the controller.

Figure 1.1 NC model drives outer view

Figure 1.2 NP model drives outer view

1-6 |

C141-E166 |

(1)Disks

The disks have an outer diameter of 84 mm (3.3 inch) and an inner diameter of 25 mm (0.98 inch) for MAP series. The disks are good for at least 20,000 contact starts and stops. Each model contains following number of disks.

MAP3147NC/NP: 4

MAP3735NC/NP: 2

MAP3367NC/NP: 1

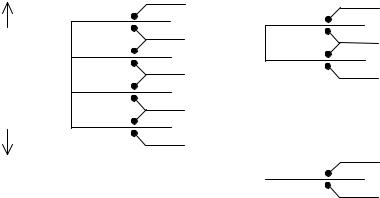

(2)Heads

The MR (Magnet - Resistive) of the CSS (contact start/stop) type heads are in contact with the disks when the disks are not rotating, and automatically float when the rotation is started. Figure 1.3 shows the configuration of disks and heads

MAP3147NC/NP |

MAP3735NC/NP |

|

Base |

|

|

0 |

0 |

|

1 |

1 |

|

2 |

2 |

|

3 |

3 |

|

4 |

|

|

5 |

|

|

6 |

MAP3367NC/NP |

|

7 |

||

|

||

Cover |

0 |

|

|

1 |

Figure 1.3 Disk/head configuration

(3)Spindle motor

The disks are rotated by a direct-drive hall-less DC motor. The motor speed is controlled by a feedback circuit using the counter electromotive current to precisely maintain of the specified speed.

(4)Actuator

The actuator, which uses a rotary voice coil motor (VCM), consumes little power and generates little heat. The heads at the end of the actuator arm is controlled and positioned via feedback of servo information in the data.

The heads are positioned on the CCS zone over the disks when the power is off or the spindle motor is stopped.

C141-E166 |

1-7 |

(5)Air circulation (recirculation filter, breather filter)

The disk enclosure (DE) configures a clean room to keep out particle and other contaminants. The DE has a closed-loop air recirculation system. Using the movement of the rotating disks, air is continuously cycled through a filter. This filter will trap any particle floating inside the enclosure and keep the air inside the DE contaminant free. To prevent negative pressure in the vicinity of the spindle when the disks begin rotating, a breather filter is attached. The breather filter also equalizes the internal air pressure with the atmospheric pressure due to surrounding temperature changes.

(6)Read/write circuit

The read/write circuit utilizes a read channel mounted with a head IC that supports high-speed transmission and an MEEPR4ML (Modified Enhanced Extended Partial Response Class 4 Maximum Likelihood) modulation/demodulation circuit in order to prevent errors being triggered by external noise and to improve data reliability.

(7)Controller circuit

The controller circuit uses LSIs to increase the reliability and uses a high speed microprocessing unit (MPU) to increase the performance of the SCSI controller.

1-8 |

C141-E166 |

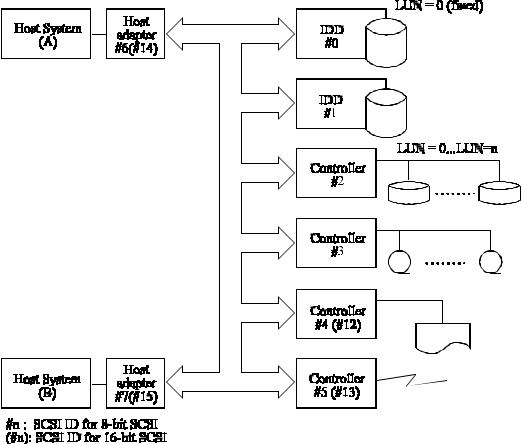

1.3System Configuration

Figure 1.4 shows the system configuration. The IDDs are connected to the SCSI bus of host systems and are always operated as target. The IDDs perform input/output operation as specified by SCSI devices which operate as initiator.

SCSI bus

Figure 1.4 System configuration

C141-E166 |

1-9 |

(1)SCSI bus configuration

Up to eight SCSI devices operating as an initiator or a target can be connected to the SCSI bus for the 8-bit SCSI and up to 16 SCSI devices operating as an initiator or a target can be connected to the SCSI bus for the 16-bit SCSI in any combination.

For example, the system can be configured as multi-host system on which multiple host computers that operate as initiator or connected through the SCSI bus.

Using disconnect/reconnect function, concurrent input/output processing is possible on multi-SCSI devices.

(2)Addressing of peripheral device

Each SCSI device on the bus has its own unique address (SCSI ID:#n in Figure 1.4). For input/output operation, a peripheral device attached to the SCSI bus that operates as target is addressed in unit called as logical unit. A unique address (LUN: logical unit number) is assigned for each logical unit.

The initiator selects one SCSI device by specifying that SCSI ID, then specifies the LUN to select the peripheral device for input/output operation.

The IDD is constructed so that the whole volume of disk drive is a single logical unit, the selectable number of SCSI ID and LUN are as follows:

• |

SCSI ID: |

8-bit SCSI:Selectable from 0 to 7 (option for NP model, switch selectable) |

|

|

16-bit SCSI:Selectable from 0 to 15 (switch selectable) |

• |

LUN: |

0 (fixed) |

1-10 |

C141-E166 |

CHAPTER 2 SPECIFICATIONS

2.1Hardware Specifications

2.2SCSI Function Specifications

This chapter describes specifications of the IDD and the functional specifications of the SCSI.

2.1Hardware Specifications

2.1.1Model name and order number

Each model has a different recording capacities and interface connector type when shipped. Table 2.1 lists the model name and order number.

The data format can be changed by reinitializing with the user's system.

Table 2.1 Model names and order numbers

Model name |

Order number |

SCSI type |

Capacity |

Number of |

Number |

|

|

|

|

(user area) |

disks |

of heads |

|

|

|

|

|

|

|

|

MAP3147NC |

CA06200-B400 |

SCA2, LVD |

147.01 GB |

4 |

8 |

|

|

|

|

||||

MAP3147NP |

CA06200-B460 |

68-pin, LVD |

||||

|

|

|

||||

|

|

|

|

|

|

|

MAP3735NC |

CA06200-B200 |

SCA2, LVD |

73.50 GB |

2 |

4 |

|

|

|

|

||||

MAP3735NP |

CA06200-B260 |

68-pin, LVD |

||||

|

|

|

||||

|

|

|

|

|

|

|

MAP3367NC |

CA06200-B100 |

SCA2, LVD |

36.74 GB |

1 |

2 |

|

|

|

|

||||

MAP3367NP |

CA06200-B160 |

68-pin, LVD |

||||

|

|

|

||||

|

|

|

|

|

|

C141-E166 |

2-1 |

2.1.2Function specifications

Table 2.2 shows the function specifications of the IDD.

|

|

|

|

|

|

|

Table 2.2 |

Function specifications |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Specification |

|

|||||

|

|

|

MAP3147NC/NP |

|

MAP3735NC/NP |

|

MAP3367NC/NP |

||||||

|

|

|

|

|

|

|

|

|

|||||

Formatted capacity/device (*1) |

147.01 GB |

|

73.50 GB |

|

36.74 GB |

||||||||

Number of disks |

4 |

|

|

2 |

|

1 |

|||||||

Number of heads |

8 |

|

|

4 |

|

2 |

|||||||

Number of cylinders (*2) |

47,926 |

|

|

47,996 |

|

48,122 |

|||||||

Formatted capacity/track (B) |

|

|

|

272,896 to 479,232 |

|

||||||||

Number of rotations min-1 (rpm) |

|

|

10,025±0.2% |

|

|

||||||||

Average latency time |

|

|

|

2.99 msec |

|

||||||||

|

|

|

|

|

Track to Track |

|

|

|

0.3 ms/0.5 ms |

|

|||

Seek time (*3) |

|

|

Average |

|

|

|

4.5 ms/5.0 ms |

|

|||||

(Read/Write) |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Full stroke |

|

|

|

10.0 ms/11.0 ms |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

Start/stop time |

|

Start time |

|

|

|

30 s typ. (60 s max.) |

|

||||||

(*4) |

|

|

|

|

Stop time |

|

|

|

30 s typ. |

|

|||

Recording mode |

|

|

|

32/34 MEEPRML |

|

||||||||

External |

|

|

Height: |

|

|

|

25.4 mm |

|

|||||

|

|

Width: |

|

|

|

101.6 mm |

|

||||||

dimensions |

|

|

|

|

|

|

|||||||

|

|

Depth: |

|

|

|

146.0 mm |

|

||||||

|

|

|

|

|

|

|

|

|

|||||

Weight (max) |

|

|

|

|

|

|

|

0.75 kg |

|

||||

Power consumption (*5) |

9.5 W |

|

|

6.6 W |

|

5.8 W |

|||||||

|

|

|

|

|

Fast 5 SCSI |

|

|

|

Cable length: 6 m max |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Single- |

|

|

Fast 10 SCSI |

|

|

|

Cable length: 3 m max |

|

||||

Inter- |

Ended |

|

|

|

|

|

|

|

|

|

|

||

|

|

Fast 20 SCSI |

|

|

Cable length: 3 m max (*6) |

|

|||||||

face |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

Cable length: 1.5 m max (*7) |

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

LVD |

|

|

U160 |

|

|

Cable length: 25 m max (*8) |

|

|||||

|

|

|

|

|

Cable length: 12 m max (*9) |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

Data |

|

Disk drive |

|

|

|

64.1 to 107.86 MB/s |

|

||||||

transfer |

|

|

|

|

|

|

|

|

|

|

|

||

|

SCSI |

Synchronous |

|

|

|

320 MB/s max. |

|

||||||

rate (*10) |

|

|

|

|

|

||||||||

|

|

|

|

|

|

mode |

|

|

|

|

|

|

|

Logical data block length (*11) |

|

|

512 to 528 byte (Fixed length) |

|

|||||||||

SCSI command specification |

SPI-4 (T10/1365D Rev.7), SAM-2 (T10/1157D Rev.20), |

||||||||||||

SPC-2 (T10/1236D Rev.20), SBC (T10/996D Rev.8c) |

|||||||||||||

|

|

|

|

|

|

|

|||||||

Data buffer |

|

|

|

|

|

|

|

8 MB FIFO ring buffer |

|

||||

Acostic noise (Ready) |

|

|

|

3.4 Bels |

|

||||||||

2-2 |

C141-E166 |

(*1) The formatted capacity can be changed by changing the logical block length and using spare sector space. See Chapter 3 for the further information. The formatted capacity listed in the table is an estimate for 512 bytes per sector.

(*2) The number of user cylinders indicates the max., and includes the alternate cylinder. The number of user cylinders and alternate cylinders can be specified at format of the IDD.

(*3) The positioning time is as follows:

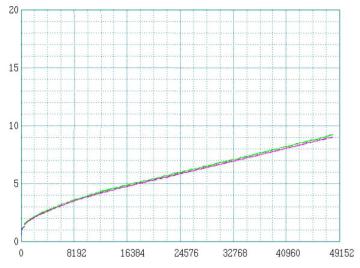

Seek time [ms]

Seek Difference [2048 Cyl/div]

(*4) The start time is the time from power on or start command to when the IDD is ready, and the stop time is the time for disks to completely stop from power off or stop command.

(*5) This value indicates at ready mode.

(*6) Up to 4 SCSI devices having capacitance of 25pF or less can use cable length of up to 3.0 m.

(*7) 5 to 8 SCSI devices having capacitance of 25pF or less can use cable length of up to 1.5 m.

(*8) 1 on 1 connection case.

(*9) 1 host, 15 devices case.

(*10) The maximum data transfer rate may be restricted to the response speed of initiator and by transmission characteristics.

(*11) The terminator power pin (SCSI connector) which supplies power to other terminators is not used.

C141-E166 |

2-3 |

2.1.3Environmental specifications

Table 2.3 lists environmental and power requirements.

|

|

Table 2.3 |

Environmental/power requirements |

|

||||

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Specification |

|

||

|

|

MAP3147NC/NP |

|

MAP3735NC/NP |

|

MAP3367NC/NP |

||

|

|

|

|

|

||||

|

Operating |

|

|

|

5 to 55°C |

|

||

|

Non-operating |

|

|

–40 to 70°C |

|

|||

Temperature |

Transport |

|

|

|

–40 to 70°C |

|

||

(within a week) |

|

|

|

|||||

(*1) |

|

|

|

|

|

|||

DE surface temperature |

|

|

5 to 60°C |

|

||||

|

|

|

|

|||||

|

at operating |

|

|

|

||||

|

|

|

|

|

|

|||

|

Gradient |

|

|

|

15°C/h or less |

|

||

|

Operating |

|

|

|

5 to 95%RH |

|

||

|

Non operating |

|

|

5 to 95%RH |

|

|||

Relative |

Transport |

|

|

|

5 to 95%RH |

|

||

humidity |

(within a week) |

|

|

|

||||

|

|

|

|

|

||||

|

Maximum wet bulb |

|

29°C (no condensation) |

|

||||

|

temperature |

|

|

|||||

|

|

|

|

|

|

|||

Vibration |

Operating (*3) |

0.3 mm (5 to 20Hz)/9.8 m/s2 (1G) (20 to 300 Hz) or less |

||||||

Non-operating (*4) |

3.1 mm (5 to 20Hz)/49m/s2 (5G) (20 to 300Hz) or less |

|||||||

(*2) |

|

|

|

|

|

|

|

|

Transport (packaged) |

3.1 mm (5 to 20Hz)/49m/s2 (5G) (20 to 300Hz) or less |

|||||||

|

||||||||

|

Operating |

|

|

637.4m/s2 (65G) (2 ms) |

|

|||

Shock (*2) |

Non-operating |

|

1961.3m/s2 (200G) (2 ms) |

|

||||

|

Transport (packaged) |

|

1961.3m/s2 (200G) (2 ms) |

|

||||

Altitute |

Operating |

|

|

|

–300 m to 3,000 m |

|

||

(above sea |

Non-operating |

|

|

–300 m to 12,000 m |

|

|||

level) |

|

|

|

|||||

|

|

|

|

|

|

|

||

|

|

Ready |

0.65 A |

|

0.42 A |

|

0.33 A |

|

|

|

(Average) |

|

|

||||

|

|

|

|

|

|

|

||

|

|

Peak within |

|

|

|

|

|

|

|

+12 VDC |

100 s at |

|

|

3.0 A |

|

||

|

±5% |

spin-up |

|

|

|

|

|

|

Power |

Random |

|

|

|

|

|

||

|

|

|

|

|

|

|||

|

W/R |

|

|

|

|

|

||

requirements |

|

0.90 A |

|

0.65 A |

|

0.55 A |

||

|

(about 80 |

|

|

|||||

Input power |

|

|

|

|

|

|

||

|

IOPS) |

|

|

|

|

|

||

(*5) |

|

|

|

|

|

|

||

|

Ready |

|

|

0.38 A |

|

|||

|

|

|

|

|

||||

|

+5 VDC |

Random |

|

|

|

|

|

|

|

W/R |

|

|

|

|

|

||

|

±5% (*6) |

|

|

0.70 A |

|

|||

|

|

(about 80 |

|

|

|

|

|

|

|

|

IOPS) |

|

|

|

|

|

|

|

Ripple (*7) |

|

+5 V/+12 V 250 mVp-p |

|

||||

(*1) For detail condition, see Section 4.1.

(*2) Vibration applied to the drive is measured at near the mounting screw hole on the frame as much as possible.

(*3) At random seek write/read and default on retry setting with log sweep vibration.

2-4 |

C141-E166 |

Loading...

Loading...