Frymaster FR2 User Manual

|

FRYERS |

FR 2 |

|

|

|

|

Frymaster |

|

|

Fryer |

|

|

Electric and Gas models using an M2000 Computer |

|

|

|

|

Weekly maintenance task

FR 2 W1 Clean area behind fryers

Bi-weekly maintenance task

FR 2 B1 Calibrate fryer

Monthly maintenance task

FR 2 M1 Calibrate fryer recovery time

Quarterly maintenance tasks

FR 2 Q1 Boil out fry vats (electric fryers only)

FR 2 Q2 Verify high-limit controls

FR 2 Q3 Replace filter o- rings

Semi-annual maintenance task

FR 2 S1 Boil out fry vats (gas fryers only)

Annual maintenance task

FR 2 A1-T Service inspection (Gas fryers only)

FR 2 A2-T Service inspection (Electric fryers only)

FEB 2010

*8196566*

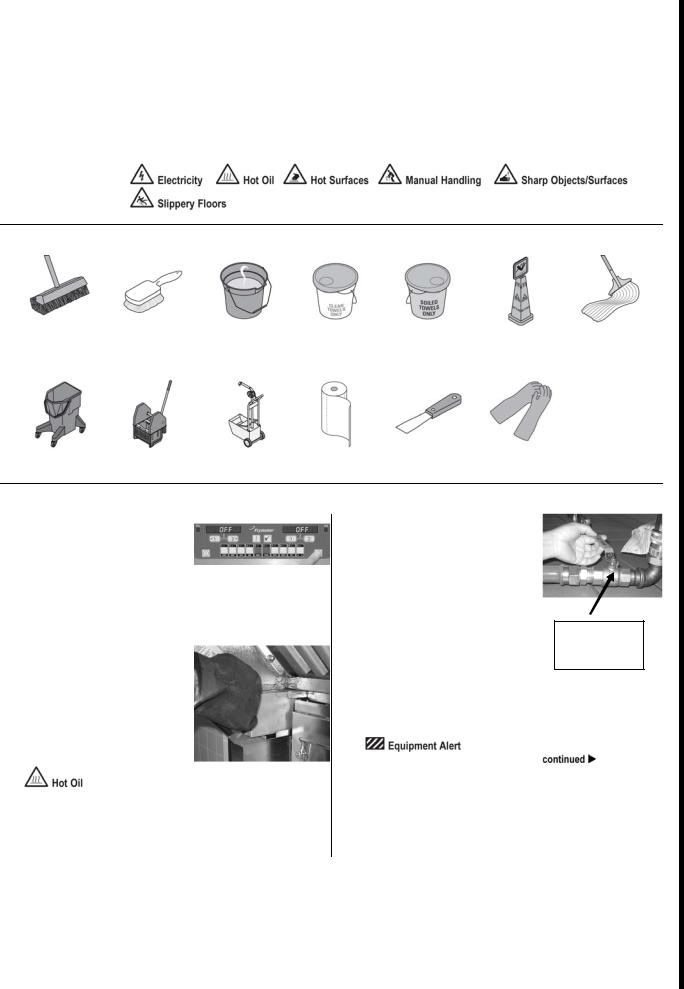

Computer model M2000

A. Cook cycle buttons, B. Temp button, C. Product Buttons, D. ON/OFF, E. Programming button

ELECTRIC

GAS

Hazards

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Equipment alerts

Look for this icon to find information about how to avoid damaging the equipment while doing a procedure.

Tips

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008

Computer M2000 an using models All Fryer Frymaster

2 FR

|

Daily Cleaning of Fryers |

|

|

|

Daily |

|

|

|

FR 2 D1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

Removed caramelized oil from element hub and surrounding housing. |

|

|

|||||||

|

Time required |

5 minutes to prepare |

15 minutes to complete (5 minutes per pot) |

|

|

||||||

|

Time of day |

After close |

For 24-hour restaurants: overnight or during low- |

||||||||

volume periods

Hazard icons

Tools and supplies

No-scratch pad |

EXCEED – Glass and Multi-surface cleanerPaper towel |

Neoprene Filtering Gloves |

|

|

|

Procedure

1Turn fryers off.

Turn all fryer power switches to the off position.

2Clean front and topside area of heating element hub.

Wearing heat resistant gloves, place covers on frypots ensuring they are square with the frypot.

Spray EXCEED on a No-scratch pad.

Use No-scratch pad to clean around the element hub and surrounding housing area.

Once area has been

cleaned, wipe off excess with a paper towel.

Remove frypot cover and remove basket rack using a fryer’s friend, set aside. Lift elements using fryer’s friend.

Replace frypot covers and wipe excess oil from the elements with paper towel.

3Clean underside area of heating element hub.

Spray EXCEED on a No-scratch pad.

Use Noscratch pad to clean the underside of the element hub and surrounding housing area.

Once area has been cleaned wipe off excess with paper towel.

Remove frypot cover. Using a fryer’s friend, replace the basket rack and lower the elements.

4Repeat for remaining frypots.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2009 |

Page 1 of 1 |

BIPH14 Model Fryer Frymaster

Daily

D1 FR2

|

Clean area behind fryers |

|

|

|

Weekly |

|

|

|

FR 2 W1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To ensure high-quality fried products and reduce the possibility of a fire near the fryer |

|

|

|||||||

|

Time required |

5 minutes to prepare |

45 minutes to complete |

|

|

||||||

|

Time of day |

After close |

For 24-hour restaurants: overnight or during low- |

||||||||

volume periods

Hazard icons

Tools and supplies

Brush, hi-lo deck |

Brush, pot, nylon |

Bucket with McD All |

Bucket, clean and |

Bucket, soiled towels |

Caution Wet Floor |

Mop |

|

|

Purpose Super |

sanitized towels |

|

Sign |

|

|

|

Concentrate (APSC) |

|

|

|

|

|

|

solution |

|

|

|

|

Mop bucket |

Mop wringer |

Oil removal cart |

Paper towels |

Putty knife |

Neoprene Gloves |

Procedure

1Turn fryers off.

Turn all fryer power switches to the off position.

2Remove and empty grease trough and cup.

Remove the grease trough from the exhaust hood. Remove the grease cup from the hood. The trough and cup are located beneath the hood filters. Pour any oil in the trough and cup into the oil removal cart.

Oil in trough and cup may be hot. Use gloves.

3Shut off and disconnect gas.

If the fryer is not a gas fryer, skip this step.

If the fryer is a gas fryer, use the manual gas shut-off valve to shut off the gas supply. The manual gas shut-off valve is located on the supply line before the quick disconnects. Then disconnect the gas line from the fryer via the quick disconnect.

Use only the manual shut-off valve to shut off the gas. Do not use the quick disconnects.

Manual shut-off

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 1 of 4 |

Computer M2000 Model Using Models Fryer Frymaster

Weekly

W1 2 FR

Clean area behind fryers (continued)

4Prepare fryer for cleaning.

Release the locks on the fryer wheels.

If the fryer has a capping piece, lift the front of the capping piece far enough to let the backsplash clear the filter shelf. Roll the fryer carefully away from the firewall, just until the capping piece clears the filter shelf.

Secure the capping piece, if there is one. Place vat covers on all vats.

Roll the fryer farther away from the firewall, far enough to clean behind the fryer.

Oil in fryer may be very hot. Roll the fryer slowly to avoid splashing the oil. Use gloves

5Disconnect fryer from electricity.

Unplug the fryer’s electrical cord from the outlet by pulling on the electrical plug’s body. You may need to twist the plug to remove from the outlet.

6Clean fryer filters.

Remove the fryer filters from the exhaust hood. Take the filters to the three- compartment-sink and soak them in McD APSC.

McD APSC

7Scrape area behind fryer.

Use a putty knife to scrape off all soft grease and hard carbon from the area behind the fryer. Clean the following areas in this order: the parts of the stack you can reach; the back of the exhaust hood; the sides of the exhaust hood; and the fryer filter recess area.

On an electric fryer, next use the putty knife to scrape all soft grease and hard carbon from all sheet metal around the fryer, the standoff piece, and the fryer stand. Skip to step 8 after these areas are cleaned.

On a gas fryer, next use the putty knife to scrape all soft grease and hard carbon from these areas in this order: the flue restrictor, all sheet metal around fryer, the removable gravity blade, the seal angle, the stand-off piece, and the fryer stand.

On a gas fryer, be careful not to drop any soft grease or hard carbon into the fryer flue passage while cleaning.

Do not break the fire protection fusible link in the lower area of the stack. Breaking the link will activate the fire extinguishing system.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 2 of 4 |

Computer M2000 an using models All Fryer Frymaster

Weekly

W1 2 FR

Clean area behind fryers (continued)

8Clean area behind fryer.

Use a nylon pot brush, a hi-lo deck brush, and a bucket of hot McD APSC solution to scrub all of the areas you scraped in step 7. Clean the areas in the same order that you scraped them in step 7. Then use the hi-lo deck brush to scrub the floor around the fryer.

Wipe all areas with paper towels until they are clean and dry.

The floor may be wet where you have scrubbed it.

9Ask manager to inspect.

Ask a manager to inspect your work and approve the cleaning. Repeat any cleaning as your manager directs.

10Wash fryer legs and casters.

Use a nylon pot brush and a bucket of hot McD APSC solution to wash the legs and casters of the fryer. Wipe dry with paper towels.

11Mop floor around fryer.

Use a mop and a bucket of hot McD APSC solution to mop the entire floor around the fryer.

Floor may be wet from mopping.

12Allow surfaces to dry.

Allow all fryer, wall, and floor surfaces to air dry.

13Reconnect fryer to electricity.

Roll the fryer slowly toward the electrical outlet until it is close enough to connect the plug. Plug the fryer into the outlet.

Oil in fryer may be very hot. Roll the fryer slowly to avoid splashing the oil.

14Prepare fryer for use.

Roll the fryer forward carefully until it is close to the filter shelf. Remove the vat covers from all vats. Lift the front of the capping piece until the backsplash clears the filter shelf, and roll the fryer carefully into its normal position.

15Reconnect fryer to gas supply.

If the fryer is an electric fryer, skip this step.

Check both ends of the quick disconnect for grease. Wipe the quick disconnect clean if necessary. Reconnect the gas line coupling.

Be sure the gas quick disconnect is fully engaged and interlocked before turning on the gas supply.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 3 of 4 |

Computer M2000 an using models All Fryer Frymaster

Weekly

W1 2 FR

Clean area behind fryers (continued)

16Reinstall fryer filters and grease trough.

Lock wheels into place. Reinstall the fryer filters and the grease trough in the exhaust hood.

17Turn on gas supply.

If the fryer is an electric fryer, skip this step.

Turn the manual gas shut-off valve to the on position. Turn the computer on to verify burners will re-light. Once the burners have been re-lit you can turn the computer off.

18Clean area behind other fryers.

Repeat steps 1 through 17 for all remaining fryers.

Computer M2000 an using models All Fryer Frymaster

Weekly

W1 2 FR

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 4 of 4 |

|

Calibrate fryer |

|

|

|

|

Bi-weekly |

|

|

|

FR 2 B1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To maintain food safety standards |

|

|

|

|

|

|

|

|

|

|

Time required |

1 minutes to prepare |

5 minutes to complete, once fryer has reached cooking |

||||||||

|

|

|

temperature. Cook temperature should be reached in |

||||||||

|

Time of day |

|

approximately 45 minutes. |

|

|

|

|

||||

|

At open |

For 24-hour restaurants: during low-volume periods |

|||||||||

Hazard icons

Tools and supplies

Pyrometer with fry |

Neoprene Gloves |

vat probe |

|

Procedure

1Calibrate pyrometer.

Fill a hot beverage cup with ice and then add cold water from the drink tower up to the top of the ice. You should have 50 percent ice and 50 percent water.

2 Place probe in water

Place the probe in the ice water and stir continuously until the temperature readout stabilizes.

3 Read temperature

The readout should be 32°F (0°C), plus or minus 2°F (1°C). If not, you need to calibrate, repair, or replace the pyrometer. For calibration, follow the calibration, checking, and adjusting procedures supplied by the manufacturer of your pyrometer.

2Turn on fryer and heat oil.

Press the on/off button to turn the fryer on. Set the fryer for the product to be cooked.

Allow the oil in the fryer to reach cooking temperature and then cycle off.

3Check oil level.

Check the oil level when the oil has reached cooking temperature. If the oil is above the “Oil Level” line, remove oil until the oil is at the line by draining oil into pan or disposal unit. If the oil is below the “Oil Level” line, add oil until the oil reaches the line.

Oil in the fryer is very hot. Use gloves.

4Cycle vat.

Allow the vat to cycle on and off three times. The heat light will come on when the fryer is heating.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 1 of 2 |

Computer M2000 an using models All Fryer Frymaster

weekly-Bi

B1 2 FR

Calibrate fryer (continued)

5Read oil temperature.

Insert the fry vat probe of the pyrometer into the hot oil to within 1 inch (2.5 cm) of the probe’s tip. The tip should be approximately 3 inches (7.6 cm) below the surface of

the oil. Allow the temperature reading to stabilize.

6Display temperature on fryer.

Press the temperature display switch for the vat where you took the pyrometer reading.

The display will show the temperature for the vat.

7Compare temperature readings.

Compare the temperature reading on the pyrometer with the corresponding temperature on the display.

If the two temperatures are less than 5°F (3°C) apart (either plus or minus), you do not need to adjust the temperature setting.

If the two temperatures are more than 5°F (3°C) apart (either plus or minus), call a service technician to report the problem.

8Repeat for other side of splitvat.

If the vat you tested was a full vat, skip this step and go to step 9.

If the vat you tested was one side of a split-vat, repeat steps 5 through 7 on the other side of the split-vat.

9End calibration check.

When you have finished steps 5 through 7 for the vat (including both sides of a splitvat), press the on/off button to end the calibration check for the vat.

10Calibrate remaining fryers.

Repeat steps 1 through 9 for all remaining fryers.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 2 of 2 |

Computer M2000 an using models All Fryer Frymaster

weekly-Bi

B1 2 FR

|

Calibrate fryer recovery time |

|

|

|

Monthly |

|

|

|

FR 2 M1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To maintain food safety standards for fried products |

|

|

|||||||

|

Time required |

1 minute to prepare |

5 minutes to complete, |

|

|

||||||

|

Time of day |

At open |

For 24-hour restaurants: in the morning |

|

|

||||||

|

Hazard icons |

|

|

|

|

|

|

|

|

|

|

Tools and supplies

Paper and pencil

Procedure

1Turn fryer off.

Press the on/off button to turn the fryer off. The display will show “OFF.”

2Check most recent recovery time.

The fryer automatically records the fryer’s recovery time each time the vat temperature rises from 250°F (121°C) to 320°F (160°C).

Press the button marked with a checkmark to enter the fryer’s programming mode. The left display will show “Code.”

Press the buttons marked “1, 6, 5, 2” in that order to enter code 1652. The display will show the most recent recovery time in both displays.

Write down the recovery time.

3Compare most recent recovery time to acceptable recovery time.

The acceptable recovery time for electric fryers is less than 100 seconds. The acceptable recovery time for gas fryers is less than 145 seconds.

If the recovery time you wrote down is less than the fryer’s acceptable recovery time, the fryer’s performance is acceptable. Skip to step 5.

If the time you wrote down is more than the fryer’s acceptable recovery time, the fryer’s performance is not acceptable. Go to the next step.

©McDonald’s Corporation · Planned Maintenance Manual · Revised June 2008 |

Page 1 of 2 |

Computer M2000 an using models All Fryer Frymaster

Monthly

M1 2 FR

Loading...

Loading...