Frigidaire FFN15M5HW, FGCH25M8LW, GLFC1526FW, PN 297079200, FGCH20M7LW User Manual

Use & Care Manual

Freezer

Product Registration |

2 |

Energy Saving Ideas |

2 |

Important Safety Instructions |

2-3 |

First Steps |

3 - 4 |

Setting |

4 |

the Temperature Control |

|

Freezer Optional Features |

4 - 6 |

Care and Cleaning |

7 - 8 |

Power Failure/Freezer Failure |

8 |

Avoid Service Checklist |

9 - 10 |

Warranty |

11 |

READ AND SAVE THESE INSTRUCTIONS |

P/N 297079200 (Feb 2006) |

Product Registration

The information contained in this Use and Care Guide will instruct you on how to properly operate and care for your product. Please read through the information contained in your literature pack to learn more about your new freezer.

Record your Model and Serial Numbers

Record the model number and serial number of this freezer in the space provided below.

Model No.

Serial No.

Register Your Product

The self-addressed PRODUCT REGISTRATION CARD (shown above) should be filled in completely, signed and returned to Electrolux Home Products.

This Use and Care Guide provides operating instructions for your model. Use your freezer only as instructed in this Use and Care Guide.

Energy Saving Ideas

•The freezer should be located in the coolest area of the room, away from heat producing appliances or heating ducts, and out of direct sunlight.

2

S

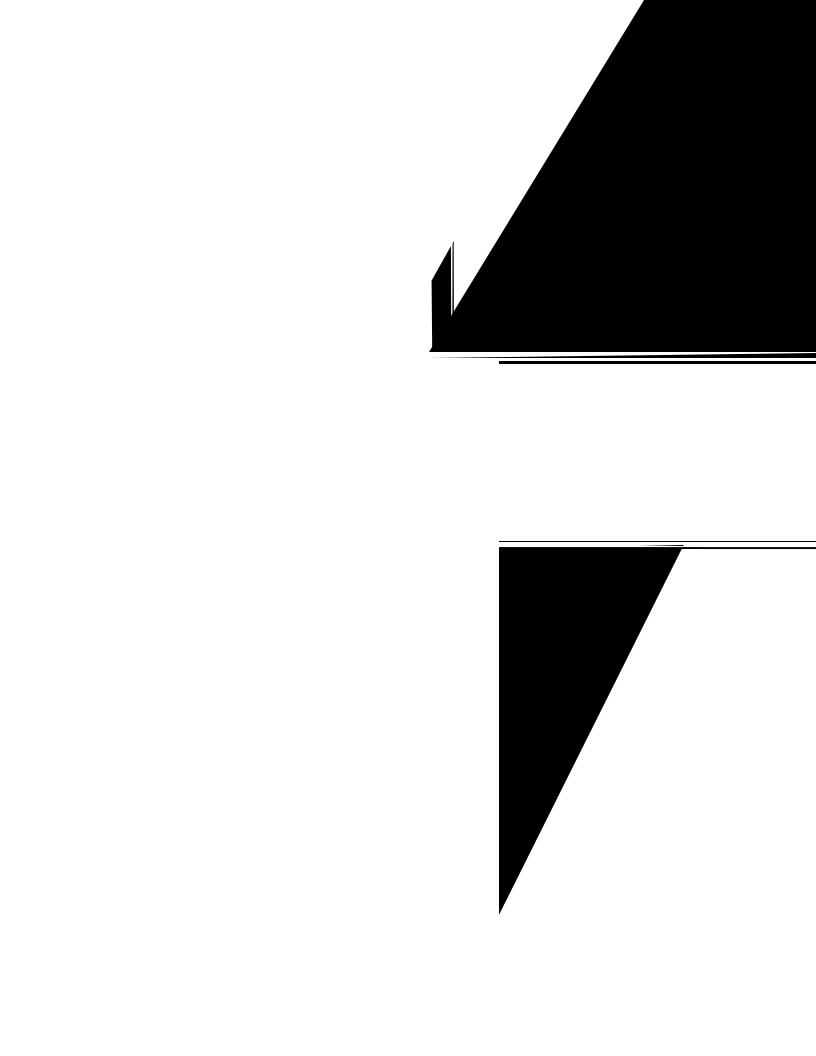

Electrical Information

Electrical Information

These guidelines must be followed to ensure that safety mechanisms in the design of this freezer will operate properly.

Avoid fire hazard or electric shock. Do not use an extension cord or an adapter plug. Do not remove any prong from power cord.

•Refer to the serial plate for correct electrical rating. The power cord of the freezer is equipped with a three-prong grounding plug for protection against shock hazards. It must be plugged directly into its own properly grounded three-prong receptacle, protected with a 15 amp time delay fuse or circuit breaker. The receptacle must be installed in accordance with the local codes and ordinances. Consult a qualified electrician. Receptacles with Ground Fault Circuit Interrupters (GFCI) are NOTRECOMMENDED.DONOTUSEANEXTENSIONCORDOR

ANADAPTERPLUG.

•If the voltage varies by 10 percent or more, freezer performance may be affected. Operating the freezer with insufficient power can damage the motor. Such damage is not covered under the warranty. If you suspect your voltage is high or low, consult your power company for testing.

•To prevent the freezer from being turned off accidentally, do not plug the unit into an outlet controlled by a wall switch or pull cord.

•Do not pinch, knot, or bend the power cord in any manner.

Other Precautions

•To defrost, always unplug unit first.

•Never unplug the freezer by pulling on the power cord. Always grip the plug firmly and pull straight out from the receptacle.

•Turning the control to “OFF” turns off the compressor but does not disconnect power to other electrical components.

First Steps

Before starting the freezer, follow these important first steps.

Installation / Freezer Placement

•Choose a place that is near a grounded electrical outlet.

•The freezer should be located where surrounding temperature will not exceed 110ºF (43ºC). Temperatures of 32ºF (0ºC) and below will NOT affect freezer operation. Additional compressor heaters are not recommended.

•Allow space around the unit for good air circulation. Leave a 3 inch (75mm) space on all sides of the freezer for adequate circulation.

3" AIR SPACE |

3" |

3" |

3" |

1" |

Installation |

Leveling

The freezer must have all bottom corners resting firmly on a solid floor. The floor must be strong enough to support a fully loaded freezer. It is VERY IMPORTANT for your freezer to be level in order to function properly. If the freezer is not leveled during installation, the door/lid may be misaligned and not close or seal properly, causing cooling, frost or moisture problems.

To level Upright Units:

After discarding crating screws and wood base, use a carpenter’s level to level the freezer from front to back. Adjust the plastic leveling feet in front, ½ bubble higher, so that the door closes easily when left halfway open.

To level Chest Units:

If needed, add metal or wood shims between feet pads and floor.

Unpacking and Leveling - Upright Freezers |

3

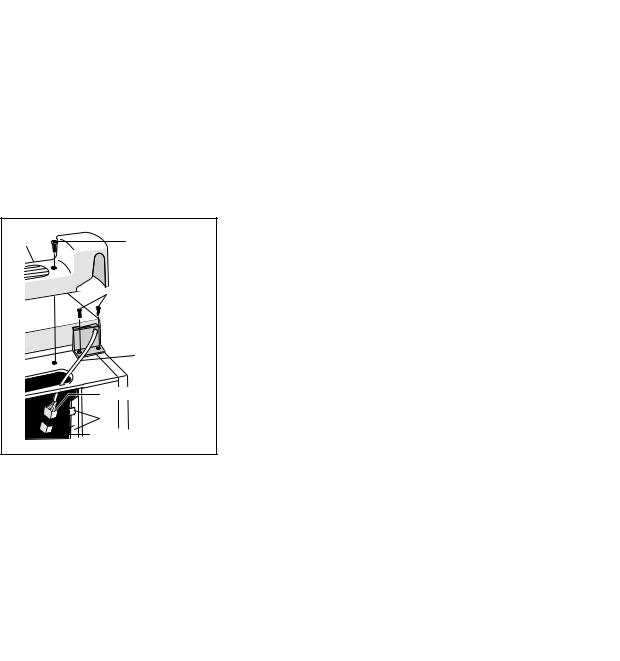

Door Removal (Upright Models)

•Unplug the unit

•Gently lay freezer on its back, on a rug or blanket.

•Remove two base screws and base panel. Remove wire from clips on bottom of cabinet, if required.

•Unplug connector, if required, by holding the cabinet connector in place and pulling the door connector out.

•Remove the bottom hinge screws.

•Remove the plastic top hinge cover.

•Remove the screws from the top hinge.

•Remove the top hinge from the cabinet.

•Remove the door and bottom hinge from the cabinet.

•To replace door, reverse the above procedures and securely tighten all screws to prevent hinge slippage.

Base |

|

Panel |

Base Panel Screws |

|

Hinge Screws |

Wire

Door Connector

Clips

Cabinet Connector

Cabinet Connector

Electromechanical Control

Figure 1

Standard Electronic Temperature Control (Some Upright Frost Free Models)

The standard electronic temperature control is located inside the freezer on upright models (see Figure 2). Temperature is factory preset to provide satisfactory food storage temperatures. To adjust the temperature setting, move the UP ( ) button for warmer temperature and DOWN ( ) button for colder temperature on the control panel. Allow several hours for the temperature to stabilize between adjustments.

Standard Electronic Temperature Control

Lid Removal (Chest Models)

• See lid removal instructions on the back of the cabinet.

Setting the Temperature Control

Cool Down Period

•For safe food storage, allow four (4) hours for freezer to cool down completely. The freezer will run continuously for the first several hours. Foods that are already frozen may be placed in the freezer after the first few hours of operation. Unfrozen foods should NOT be loaded into the freezer until freezer has operated for four (4) hours.

•When loading freezer, freeze only three (3) pounds of fresh food per cubic foot of freezer space at one time. Distribute packages to be frozen evenly throughout the freezer. It is not necessary to turn the control knob to a colder setting while freezing food.

Electromechanical Temperature Control (Chest and Some Upright Models)

The electromechanical temperature control is located inside the freezer on upright models, and on the left exterior wall on chest models (see figure 1). The temperature is factory preset to provide satisfactory food storage temperatures. However, the temperature control is adjustable to provide a range of temperatures for your personal satisfaction. To adjust the temperature setting, turn the temperature control knob clockwise or counter clockwise. Allow several hours for the temperature to stabilize between adjustments.

4

Figure 2

Deluxe Electronic Temperature Control (Some Upright Frost Free Models)

Refer to the Electronics Control Guide supplied when you purchase a deluxe electronic upright model. See Figure 3 for deluxe electronics control panel.

|

Freezer Temp |

|

Extreme Freeze |

Temp Alarm |

|

On/ |

Reset |

|

Off |

||

|

Deluxe Electronic Temperature Control

Figure 3

Freezer Optional Features

Your freezer may have some or all of the features listed below. Become familiar with these features and their use and care.

Power On Light

The power on light indicates that the freezer is properly connected to an electrical power. The light glows even when the temperature control is turned to “OFF”. If the light goes out, refer to “Freezer does not run” in the Avoid Service Checklist section.

Loading...

Loading...