Frigidaire FAM157S1A11, FAM157S1A12, FAM157S1A13, FAM157S1A14, FAM157S1A15 Installation Guide

...

installation instructions

For Heavy Duty (FAS Models) and

Median (FAM Models) Air Conditioners

Please read ALL instructions before installing. Two people are

recommended to install this product. If a new electrical outlet

is required, have the outlet installed by a qualified electrician

before installing unit, See#5 in Preliminary Instructions

following.

Prelimi nary instru ctions

Do the following before starting to install unit. See illustrations

below.

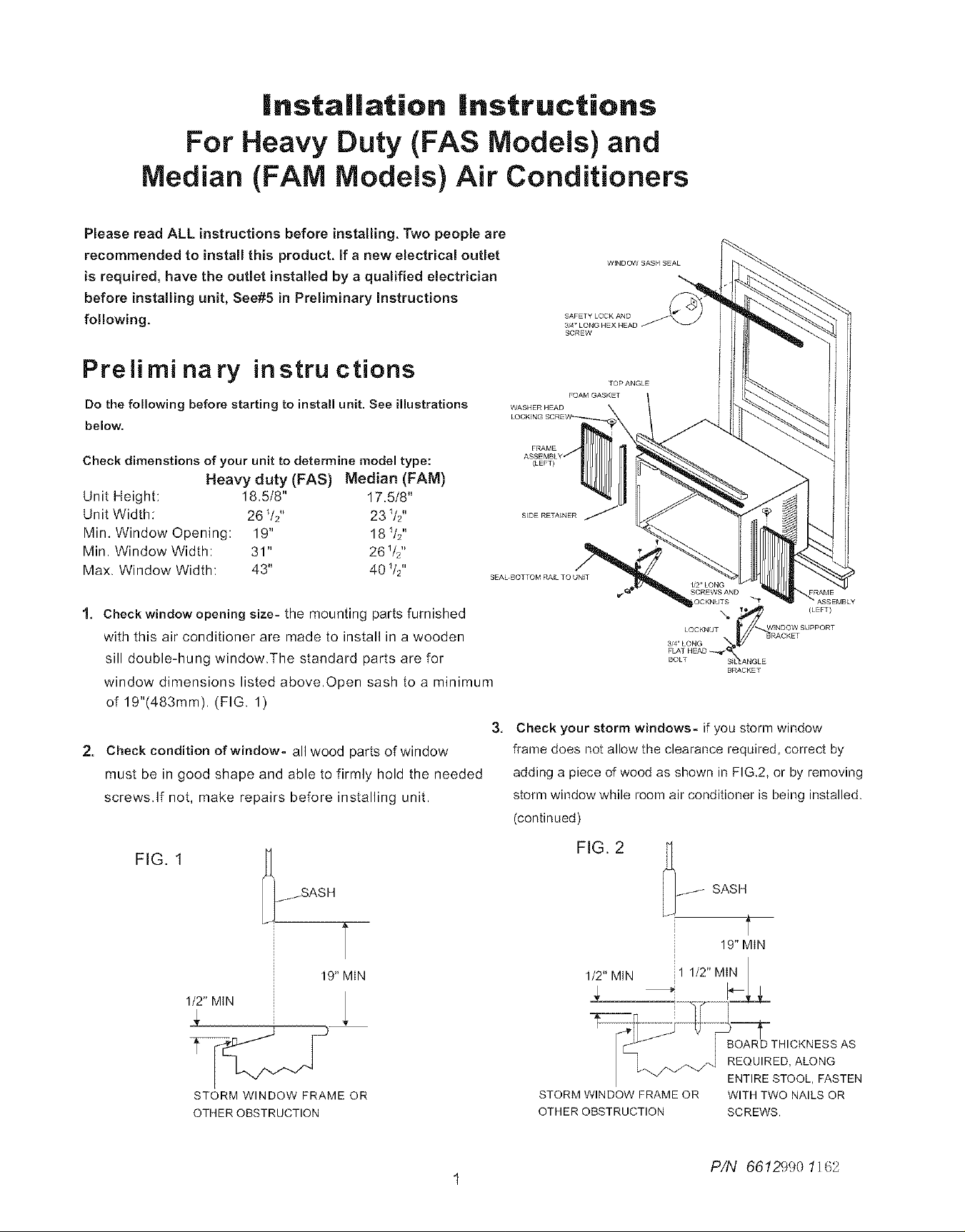

Check dimenstions of your unit to determine model type:

Heavy duty (FAS) Median (FAM)

Unit Height: 18,5/8" 17.5/8"

Unit Width: 261/2" 231/2"

Min. Window Opening: 19" 181/2"

Min. Window Width: 31" 26 Vj'

Max. Window Width: 43" 40 V2"

WASHERHEAD

LOCKENG SCREW_._._ X

ASSEMBLY

SIDE RETAENER J

FOAM GASKET

(LEFT)

1. Check window opening size- the mounting parts furnished

with this air conditioner are made to install in a wooden

sill double-hung window.The standard parts are for

window dimensions listed above.Open sash to a minimum

of 1g"(483mm). (FIG. 1)

2. Check condition of window- all wood parts of window

must be in good shape and able to firmly hold the needed

screws.if not, make repairs before installing unit.

FIG. 1

_1SASH

19" MIN

1/2" MIN

BRACKET

3. Check your storm windows= if you storm window

frame does not allow the clearance required, correct by

adding a piece of wood as shown in FIG.2, or by removing

storm window while room air conditioner is being installed.

(continued)

FIG. 2

// SASH

f

19"MIN

1112

STORM WINDOW FRAME OR

OTHER OBSTRUCTION

STORM WINDOW FRAME OR WITH TWO NAILS OR

OTHER OBSTRUCTION SCREWS.

P/N 6612990 1162

1

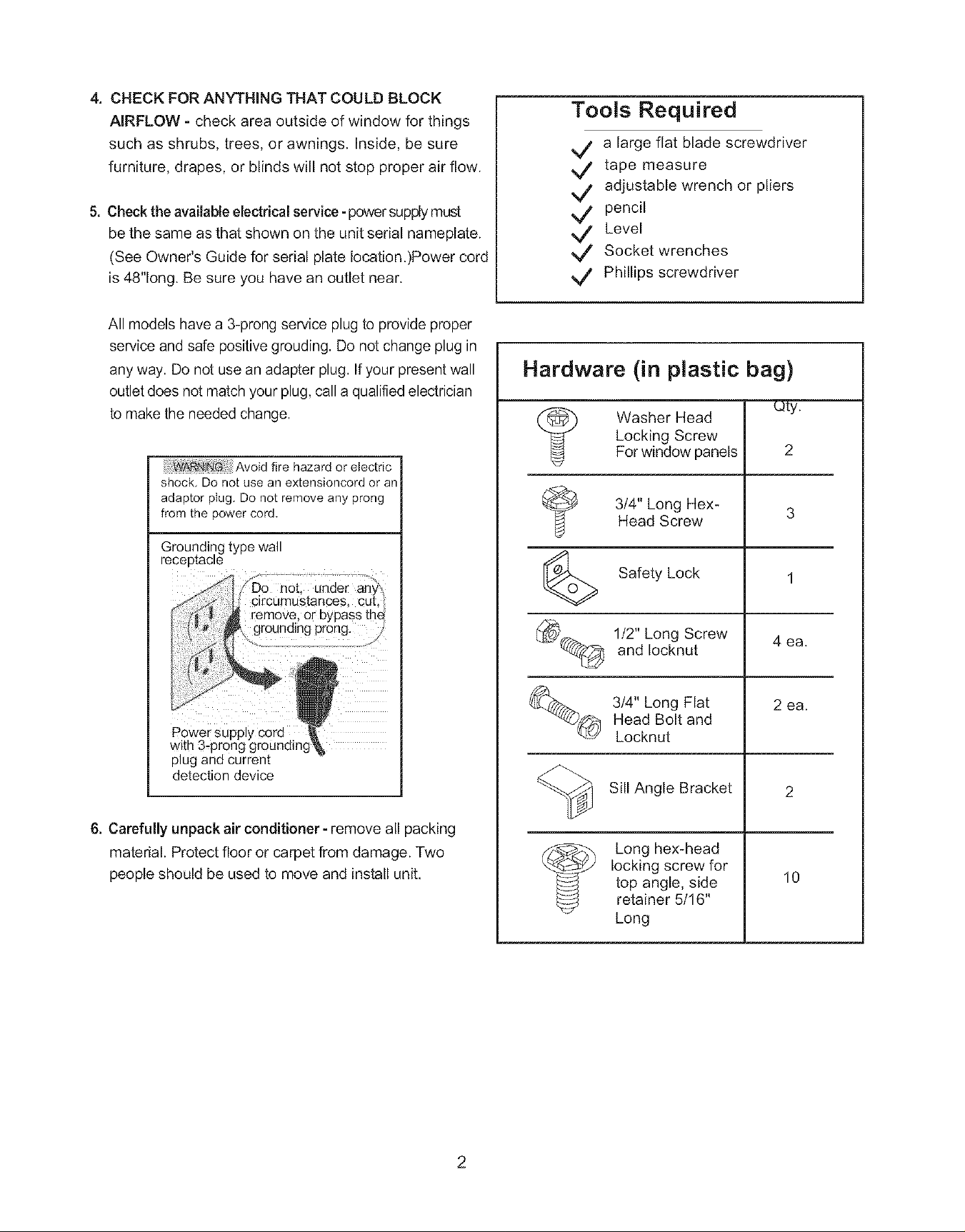

4. CHECK FOR ANYTHING THAT COULD BLOCK

AIRFLOW - check area outside of window for things

such as shrubs, trees, or awnings. Inside, be sure

furniture, drapes, or blinds will not stop proper air flow.

5. Check the available electrical service - power supply must

be the same as that shown on the unit serial nameplate.

(See Owner's Guide for serial plate Iocation.)Power cord

is 48"long. Be sure you have an outlet near.

All models have a 3-prong service plug to provide proper

service and safe positive grouding. Do not change plug in

any way. Do not use an adapter plug. If your present wall

outlet does not match your plug, call a qualified electrician

to make the needed change.

::_i Avoid fire hazard or electric

shock, Do not use an extensioncord or an

adaptor plug. Do not remove any prong

from the power cord.

Tools Required

a large flat blade screwdriver

tape measure

adjustable wrench or pliers

pencil

_/ Level

_/ Socket wrenches

_/ Phillips screwdriver

Hardware (in plastic bag)

LJty.

Locking Screw

Washer Head

For window panels

Head Screw

3/4" Long Hex-

2

Grounding type wall

receptacle

Power supply core

NIth3-prong groundi

plug and current

detection device

6. Carefully unpack air conditioner - remove a!l packing

material. Protect floor or carpet from damage. Two

people should be used to move and install unit.

[_ Safety Lock

_ 1/2" Long Screw

and Iocknut

3/4" Long Flat

Head Bolt and

Locknut

Sill Angle Bracket

locking screw for

top angle, side

Long hex-head

retainer 5116"

Long

4 ea.

2 ea.

2

10

2

"ndow Mounting

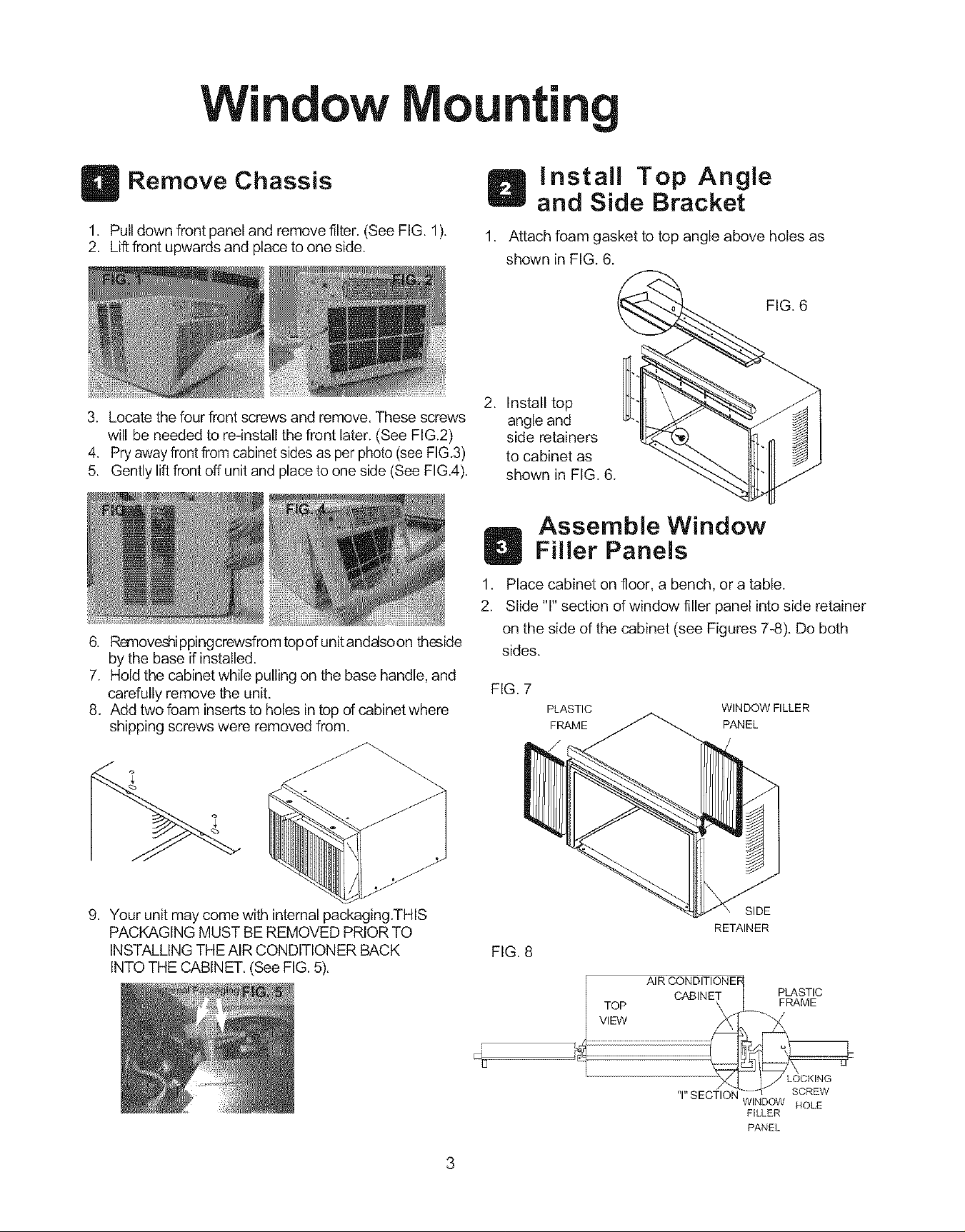

g Remove Chassis

1. Pull down front panel and remove filter. (See FIG. 1).

2. Lil_front upwards and place to one side.

3. Locate the four front screws and remove. These screws

will be needed to re-install the front later. (See FIG.2)

4. Pry away front from cabinet sides as per photo (see FIG .3)

5. Gently lift front off unit and place to one side (See FIG.4).

6. Removeshi ppingcrewsfrom top d unit and_tso on theside

by the base if installed.

7. Hold the cabinet while pulling on the base handle, and

carefully remove the unit.

8. Add two foam inserts to holes in top of cabinet where

shipping screws were removed from.

D Install Top Angle

1. Attach foam gasket to top angle above holes as

2. Install top

and Side Bracket

shown in FIG. 6.

FIG. 6

angle and

side retainers

to cabinet as

shown in FIG. 6.

Assemble Window

a Filler Panels

1. Place cabinet on floor, a bench, or a table.

2. Slide 'T' section of window filler panel into side retainer

on the side of the cabinet (see Figures 7-8). Do both

sides.

FIG. 7

PLASTIC WINDOW FILLER

FRAME PANEL

9. Your unit may come with internal packaging.THIS

PACKAGING MUST BE REMOVED PRIOR TO

INSTALLING THE AIR CONDITIONER BACK

INTO THE CABINET. (See FIG. 5).

SIDE

RETAINER

FIG. 8

PLASTIC

FILLER

PANEL

FRAME

LOCKING

HOLE

TOP

VIEW

'T'SECTION WINDOW SCREW

3

Loading...

Loading...