Friedrich 2003 User Manual

Service Ma nual

2003

Room Air Conditioners

RACServMn (7-03)

Table of Contents

Unit Identification ............................................... 3

Unit Specifications ............................................. 4

Unit Performance ......................................... 5-11

Refrigeration Sequence of Operation ..............12

Electrical Rating Tables ...................................13

Compressor.....................................................14

Thermal Overload (External) ...........................14

Thermal Overload (Internal).............................15

Fan Motor ........................................................ 15

System Switches/Controls ..........................15-24

Thermostats (Indoor)..................................24-25

Thermostats (Defrost) ................................25-26

Resistor (Heat Anticip ator)............................... 26

Capacitor , Run................................................. 26

Check V alve ....................................................27

Heat Pump Reversing V alve............................ 27

Solenoid Coil (Heat Pump Models)..................28

V alve, Drain Pan.............................................. 29

Heating Element .............................................. 29

Sealed Refrigeration Repairs...................... 29-30

Refrigerant Charging ..................................30-31

Undercharged Refrigerant Systems ...........31-32

Overcharged Refrigerant Systems .................. 32

Restricted Refrigerant System.........................33

Routine Maintenance....................................... 34

Troubleshooting.......................................... 34-45

Wiring Diagrams

"RS", "RM",...................................................46

"SQ" ............................................................. 47

"KQ" ........................................................ 48-49

"XQ" ............................................................. 50

"YQ" ............................................................. 51

"SC" ............................................................. 52

"SS", "SM" .................................................... 53

"SL" ..............................................................54

"KS", "KM", "KL" ...........................................55

"ES", "EM", "EL", "EK" .................................. 56

"YS13", "YM", "YL" ....................................... 57

"YS09"..........................................................58

"EQ" ............................................................. 59

"WS".............................................................60

"WE".............................................................61

"WY"............................................................. 62

Testing XQ and QME Boards .......................... 63

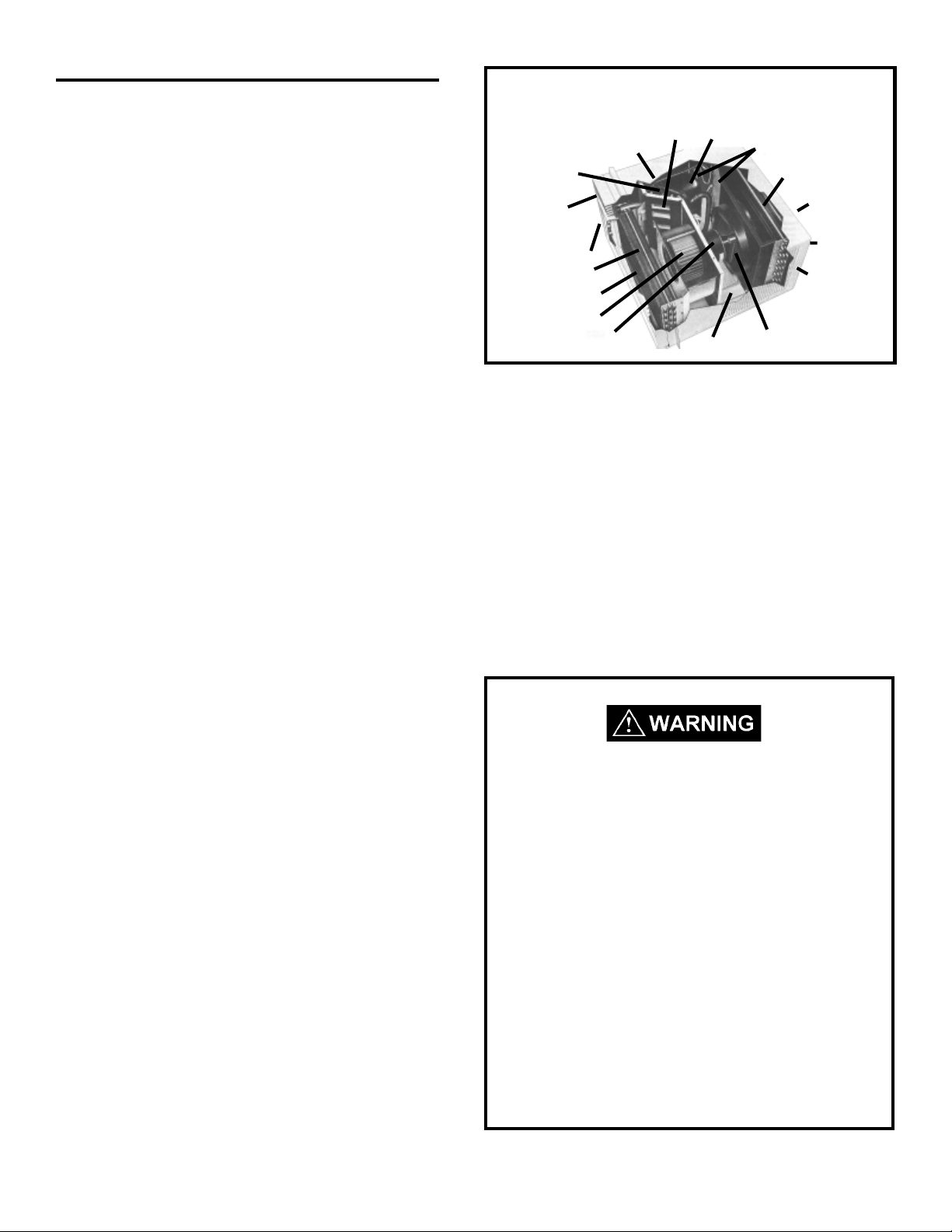

Typical Unit Components

Capillary Tube

Reversing Valve

(some models)

Front Cover

System Switches

Evaporator Coil

Return Air Grille/Filter

Blower Wheel

Blower Motor

Fresh Air

Compressor

Basepan

Liquid Filter Driers

Condenser Coil

Discharge Air

Outdoor Grille

Sleeve

Condenser Fan Blade

Introduction

This service manual is designed to be used in conjunction

with the installation manuals provided with each air

conditioning system component.

This service manual was written to assist the professional

RAC service technician to quickly and accurately diagnose

and repair malfunctions.

This manual will deal with subjects in a general nature.

(i.e. all text will not pertain to all models).

IMPORTANT: It will be necessary for you to accurately

identify the unit you are servicing, so you can be certain of

a proper diagnosis and repair. (See Unit Identification.)

The information contained in this manual is intended

for use by a qualified service technician who is

familiar with the safety procedures required in

installation and repair , and who is equipped with the

proper tools and test instruments.

Installation or repairs made by unqualified persons

can result in hazards subjecting the unqualified

person making such repairs to the risk of injury or

electrical shock which can be serious or even fatal

not only to them, but also to persons being served

by the equipment.

If you install or perform service on equipment, you

must assume responsibility for any bodily injury or

property damage which may result to you or others.

Friedrich Air Conditioning Company will not be

responsible for any injury or property damage arising

from improper installation, service, and/or service

procedures.

2

UNIT IDENTIFICAUNIT IDENTIFICA

UNIT IDENTIFICA

UNIT IDENTIFICAUNIT IDENTIFICA

Model Number Code

SS08J 1 0 R

TIONTION

TION

TIONTION

1st Digit – Function

S = Straight Cool, Value Series

C = Straight Cool, Budget

Series

Y = Heat Pump

E = Electric Heat

K = Straight Cool, Challenger

Series

W = Thru-the Wall,

WallMaster Series

2nd Digit

C = Casement

P = PowerMiser "Portable"

Q = Q-Star

M = Medium Chassis

L = Large Chassis

W = Built -In

H = HazardGard

8th Digit – Engineering

Major change

7th Digit – Options

0 = Straight Cool & Heat Pump Models

1 = 1 KW Heat Strip, Normal

3 = 3 KW Heat Strip, Normal

4 = 4 KW Heat Strip, Normal

5 = 5 KW Heat Strip, Normal

8 = 8 KW Heat Strip, Normal

6th Digit – Voltage

1 = 115 Volts

2 = 230 Volt s

3 = 230-208 Volt s

5th Digit

Alphabetical Modifier

3rd and 4th Digit Approximate BTU/HR

(Cooling)

Heating BTU/Hr capacity listed in

the Specification/Performance

Data Section

RAC Serial Number Identification Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H = 8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H = 8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sep M=Dec

L C G S 00001

Production Run Number

PRODUCT LINE

S=RAC

P=PTAC

E=EAC

V=VPAK

H=Split

3

4

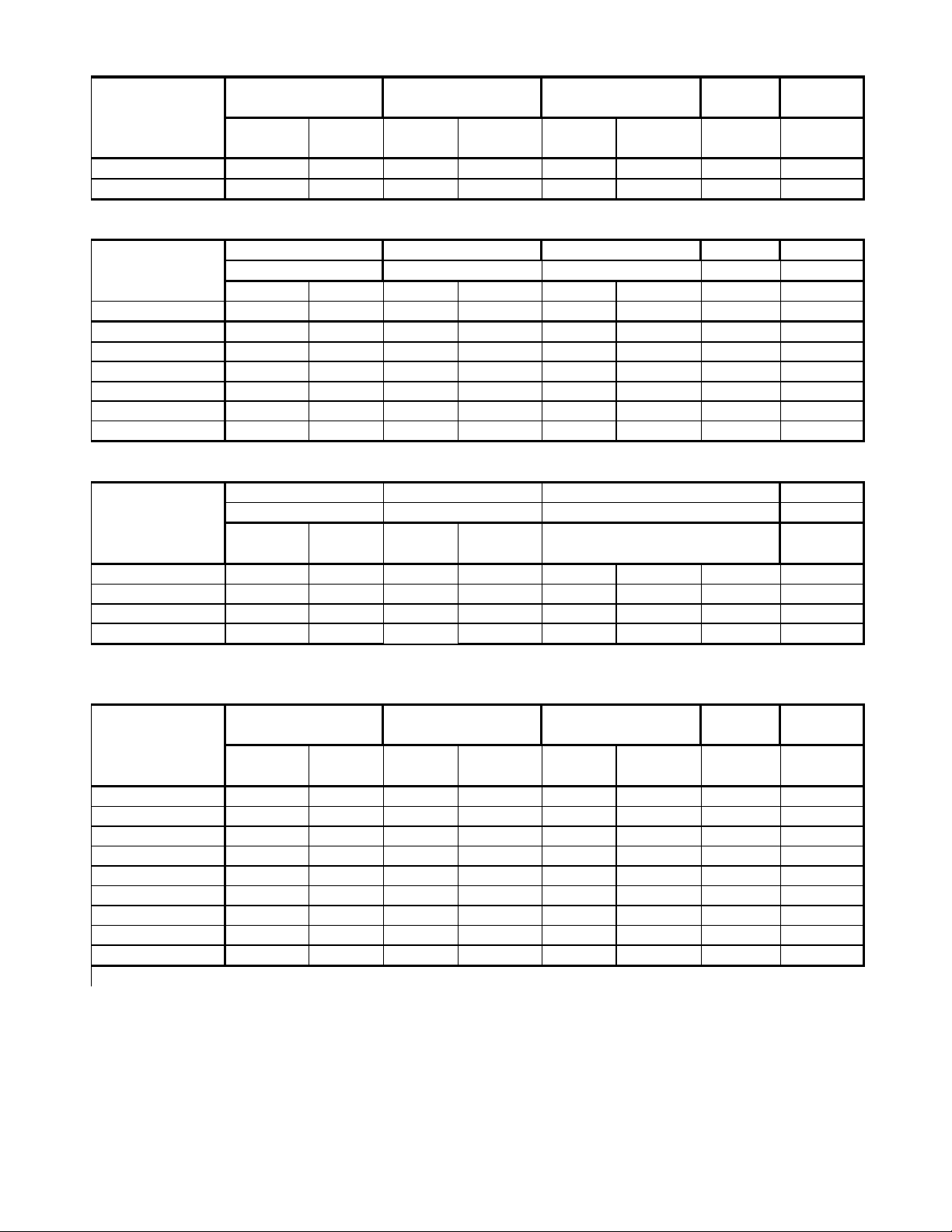

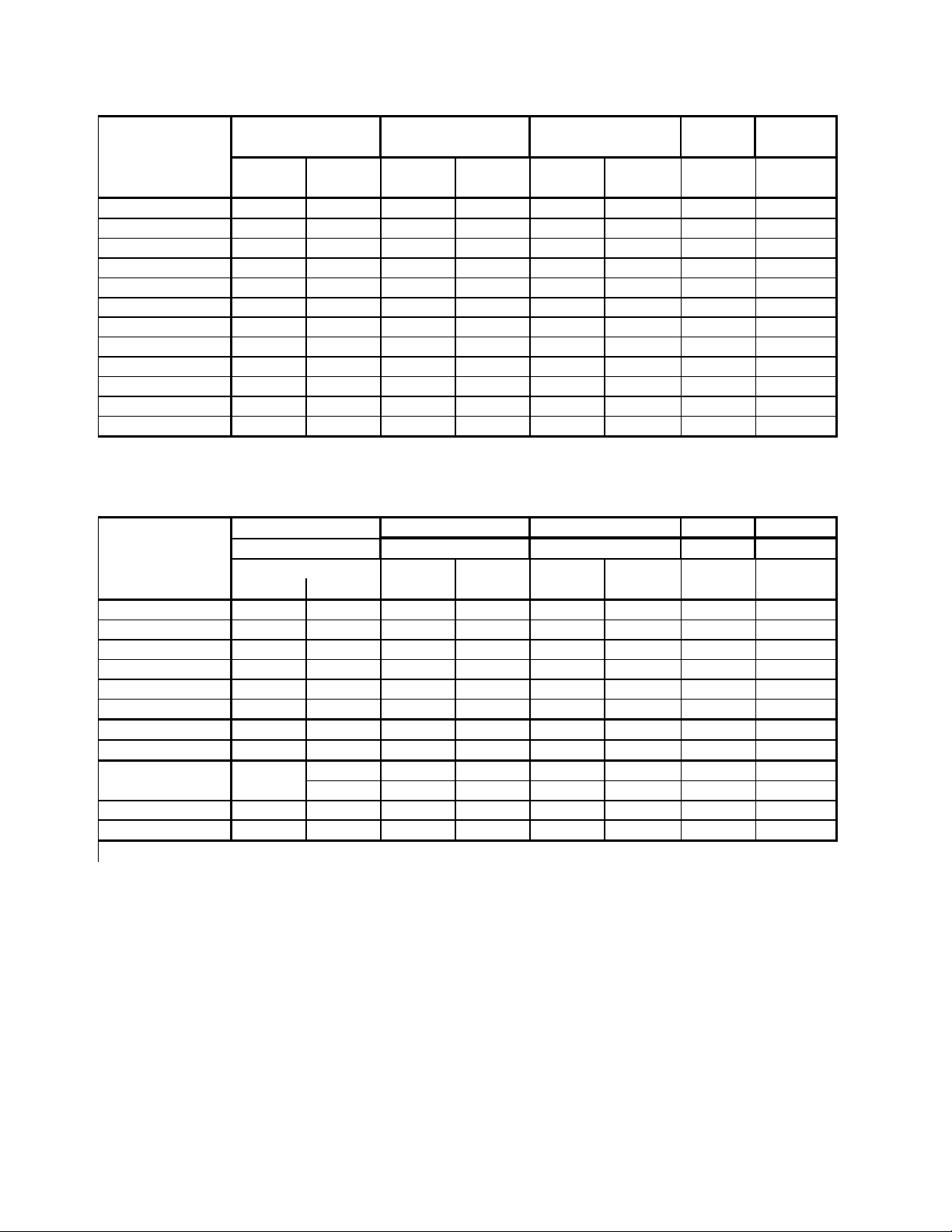

EQ PERF O RMANCE DATA

PERFORMANCE R-22 BREAKER

DATA* REFRIG. FUSE

EVAPORATOR AIR

TEMP. DEG. F.

OPERATING

PRESSURES

ELECTRICAL

RATINGS

Cooli ng Dis charge Temp. Suct i on Dis charge Am p s Loc ked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

EQ08J11-A 50.5 29.5 72 262 7.5 39.2 20 15

EQ08J11-B 50.5 29.5 74 259 7.5 39.2 20 15

XQ PERF O RMANCE DATA

DATA* R-22 BREAKER

Cooling REFRIG. FUSE

EVAPORATOR AIR OPERATING ELECTRICAL

TEMP. DEG. F. PRESSURES RATINGS

Dis charge Temp. Suct i on Dis charge Am p s Loc ked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

XQ05J10B 55.45 24.55 79 245 4.6 34 20 15

XQ06J10-A 51.45 28.55 82 262 5.1 35 21 15

XQ06J10-B 51.45 28.55 79 254 5.1 35 21 15

XQ07J10-1 52.22 27.95 77 250 6.5 37 24 15

XQ08J10-1 50.5 29.5 72 262 4.5 38 20 15

XQ08J10-A 50.5 29.5 72 262 4.5 38 21 15

SQ PERF O RMANCE DATA

PERFORMANCE EVAPORATOR AIR ELECTRICAL R-22 BREAKER

DATA * TEMP. DEG. F. RATINGS REFRIG. F USE

OPERATING

PRESSURES

Cooli ng Dis charge Temp. Suct i on Dis charge Am p s Loc ked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

SQ05J10B-B 55.45 24.55 79 245 4.4 34.'0 16.'0 15

SQ06J10B-A 51.45 28.55 82 262 5.2 35.'0 15.7 15

SQ06J10B-B 51.45 28.55 79 254 5.2 35.'0 15.7 15

SQ08J10C-1 50.5 29.5 72 262 7.5 39.2 19.5 15

KQ-YQ PERFORMANCE DATA

PERFORMANCE R-22 BREAKER

DATA* REFRIG. FUSE

EVAPORATOR AIR OPERATING

TEMP. DEG. F. PRESSURES RATINGS

ELECTRICAL

Cooli ng Dis charge Temp. Suct i on Dis charge Am p s Loc ked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

KQ05J10B-B 56.34 28.66 73 251 5.2 29.'0 15.'0 15

KQ05E10-B 56.34 28.66 79 245 5.2 29.'0 15.'0 15

KQ05E10-C 56.34 28.66 79 245 5.2 29.'0 15.'0 15

KQ06J10B-A 58.02 21.98 82 262 5.8 35.'0 15.'0 15

KQ06J10B-B 58.02 21.98 80 269 5.8 35.'0 19.'0 15

KQ06E10-A 58.02 21.98 82 262 5.8 35.'0 15.'0 15

KQ06E10-B 58.02 21.98 79 254 5.8 35.'0 15.'0 15

YQ06J10B-A 54.1 25.9 81 267 5.7 39.2 19.'0 15

*Rating Condit i ons : 80 degree F. Room Ai r Temperature and 50% Relat ive Humidity with

95 degree F. Outside Ai r Temperature and 40% Relat ive Humitidy

5

R

R

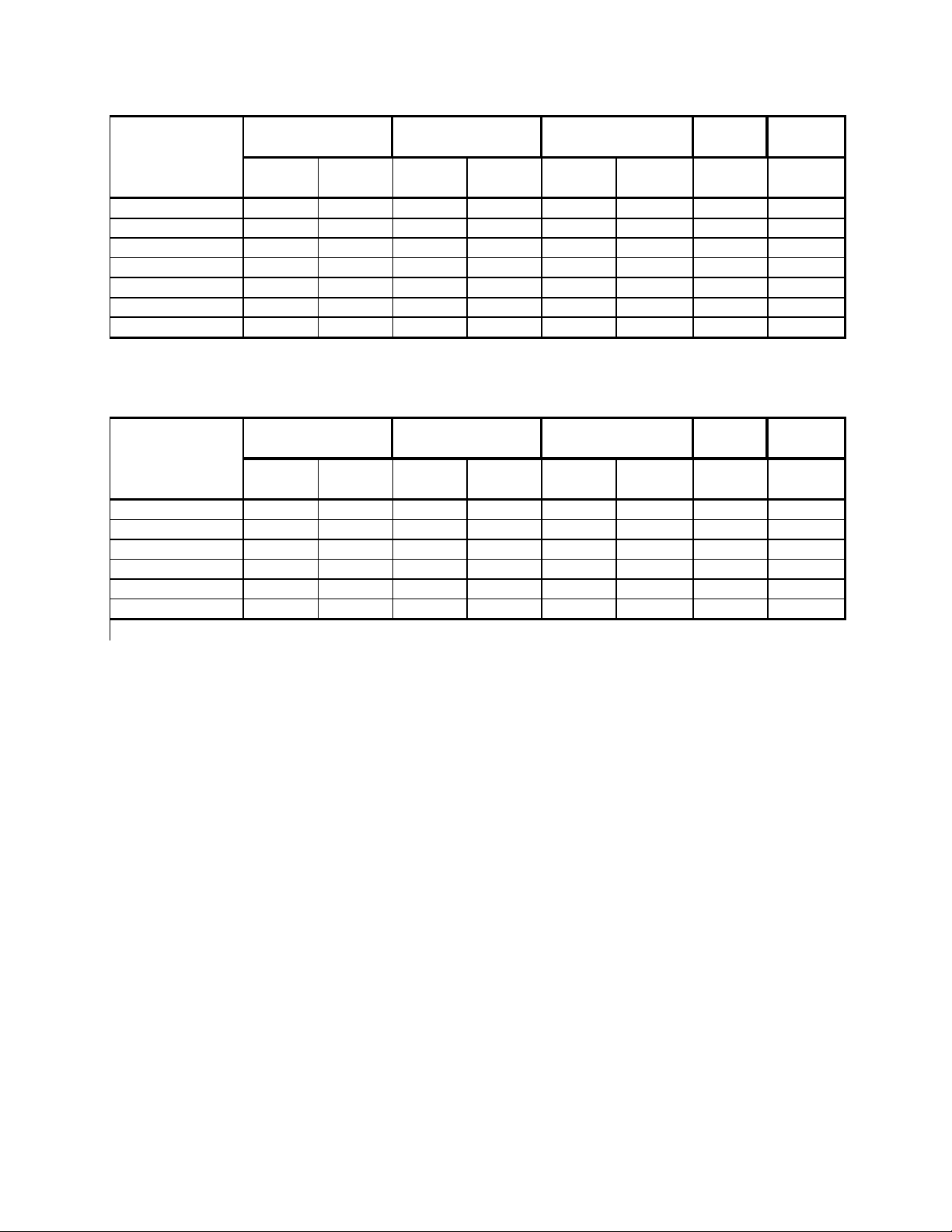

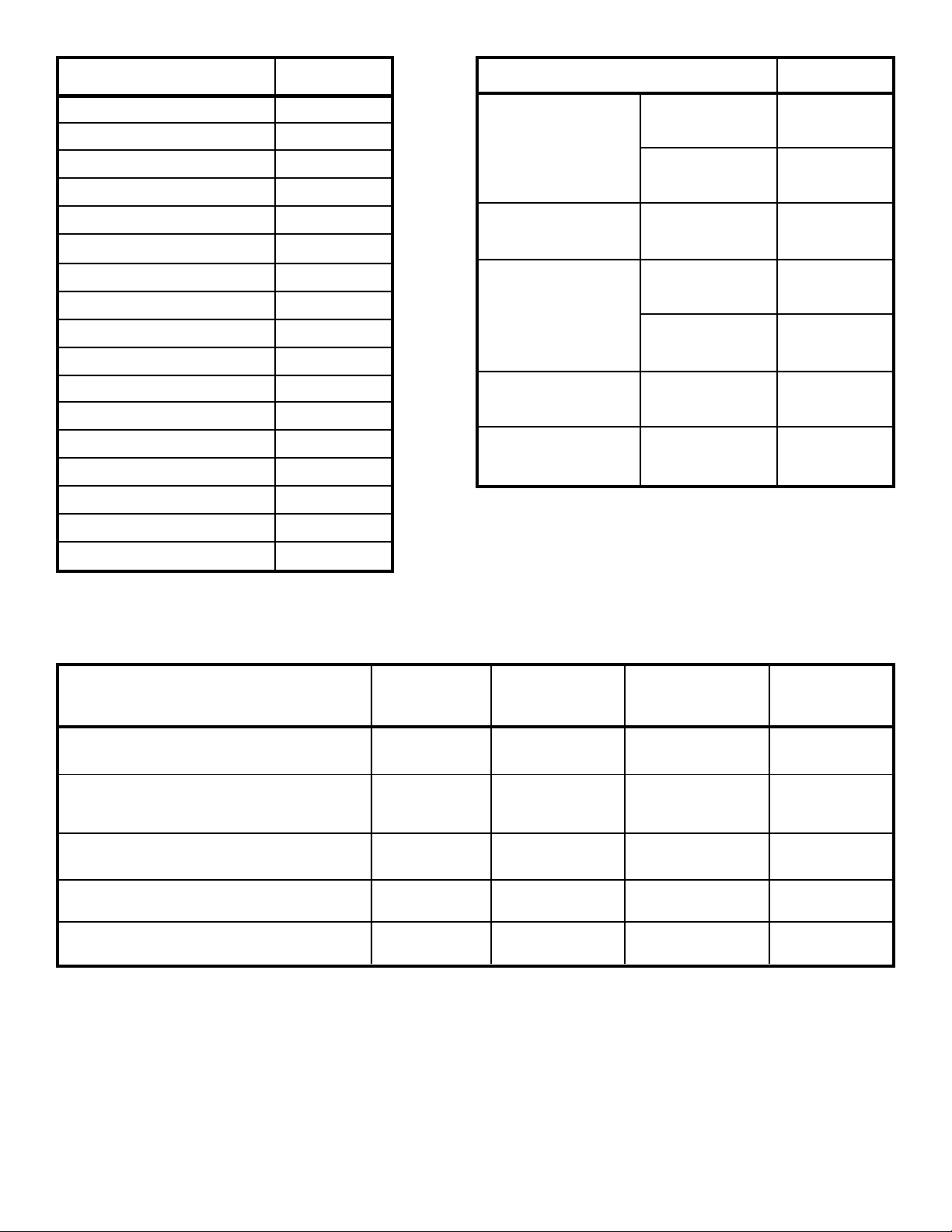

RS-RM PERFORMANCE DA TA

PERFORMANCE R-22 BREAKE

DATA* REFRIG. FUSE

EVAPORATOR AIR

TEMP. DEG. F.

OPERATING

PRESSURES

ELECTRICAL

RATINGS

Cooling Dis c harge Temp. Suct i on Discharge Amps Lock ed Charge in 60 Hert z

Ai r Drop F. Rotar Amp OZ. Am p s

RS10J10-C 61 19 82 248 7.5 44 26 15

RS12J10A-B 57 23 83 271 9.8 54 30 15

RS15J10-A 57 23 77 279 11.1 42 29.5 15

RS16J30A-A 56.5 24 77 296 7.2 42 30 15

RS18J30-A 56 24 72 293 8.7 42 48 15

RM24J30-A 57 23.65 68 301 12.2 44 54 15

YS-YM-YL PERFORMANCE DATA

PERFORMANCE R-22 BREAKE

DATA* REFRIG. FUSE

EVAPORATOR AIR OPERATING ELECTRICAL

TEMP. DEG. F. PRESSURES RATINGS

Cooling Dis c harge Temp. Suct i on Di scharge Amps Locked Charge in 60 Hert z

Ai r Drop F. Rotar Amp OZ. Am p s

YS09J10 B-A 59 21 90 243 7.7 39.2 25 15

YS12J33 - A 56 24 80 264 5.2/5.6 30 28 20

YM18J34B-A 53 27 74 284 8.7/9.2 42 54 30

YL24J35C-A 55 25 72 260 10.0/12.0 61 74 30

* Rating Condit i ons : 80 degree F. Room Ai r Temperature and 50% Relati ve Hum i dity wit h

95 degree F. Outside Ai r Temperature at 40% Relat i ve Hum idi t y.

6

PERFORMANCE R-22 BREAKE

R

DATA* REFRIG. FUSE

EVAPORATOR AIR

TEMP. DEG. F.

OPERATING

PRESSURES

ELECTRICAL

RATINGS

Cooling Dis c harge Temp. S ucti on Discharge A m ps Locked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

ES12J33B-A 58 22 82 265 5.76.6 26.3 28 20

ES16J33 A-A 53 27 77 269 7.5/8.0 42.'0 30 20

EM18J34B-A 55 25 71 267 8.6/9.2 42.'0 40.5 30

EL25J35-A 55 25 75 284 11.5/12.6 61.'0 48.5 30

EL35J35-A 52 28 72 317 18/20 94.'0 60 30

EL35J35-B 52 28 72 317 18/20 94.'0 60 30

PERFORMANCE H ea t Ris e

DATA heating

ES12J33 B-A 30.5 16/14.7

ES16J33 A-A 30.5 16/14.7

EM18J34B-A 28.3 19.5/17

EL25J35-A 28.6 24/22/4

EL35J35-A 22.9 24/22.4

EL35J35-B 22.9 24/22.4

KS-KM PERFORMANCE DATA

DATA* R-22 BREAKER

Cooling REFRIG. FUSE

EVAPORATOR AIR OPERATING ELECTRICAL

TEMP. DEG. F. PRESSURES RATINGS

Discharge Temp Amps Lock ed Charge in 60 Herts

Air Drop F. Rotar Amp OZ. Amps

KS10E10-A 61 19 82 248 9.1 48.3 2 6.08 15

KS10J10 - B 61 19 80 263 9.1 48.3 2 6.88 15

KS12E10-A 57 23 83 271 10.8 54.'0 28 15

KS12J10 B-A 57 23 84 268 10.8 54.'0 28 15

KS15J10 - A 55.78 23.52 77 279 12.'0 67.'0 29.5 15

KS12J30 B-A 57 23 76 285 6.2 26.'0 30.08 15

KS18J30 - A 56 24 72 293 8.7 48 4 8 15

KM20J30-A 55 24 70 279 9.9 48 48 15

KM24J30-A 55 25 68 301 15.'0 71.'0 54.08 15

* Rating Condit i ons : 80 degree F. Room Air Temperature and 50% Relative Humidity with

95 degree F. Out s i de A i r Temperature at 40% Relat i ve Hum i dit y.

7

R

R

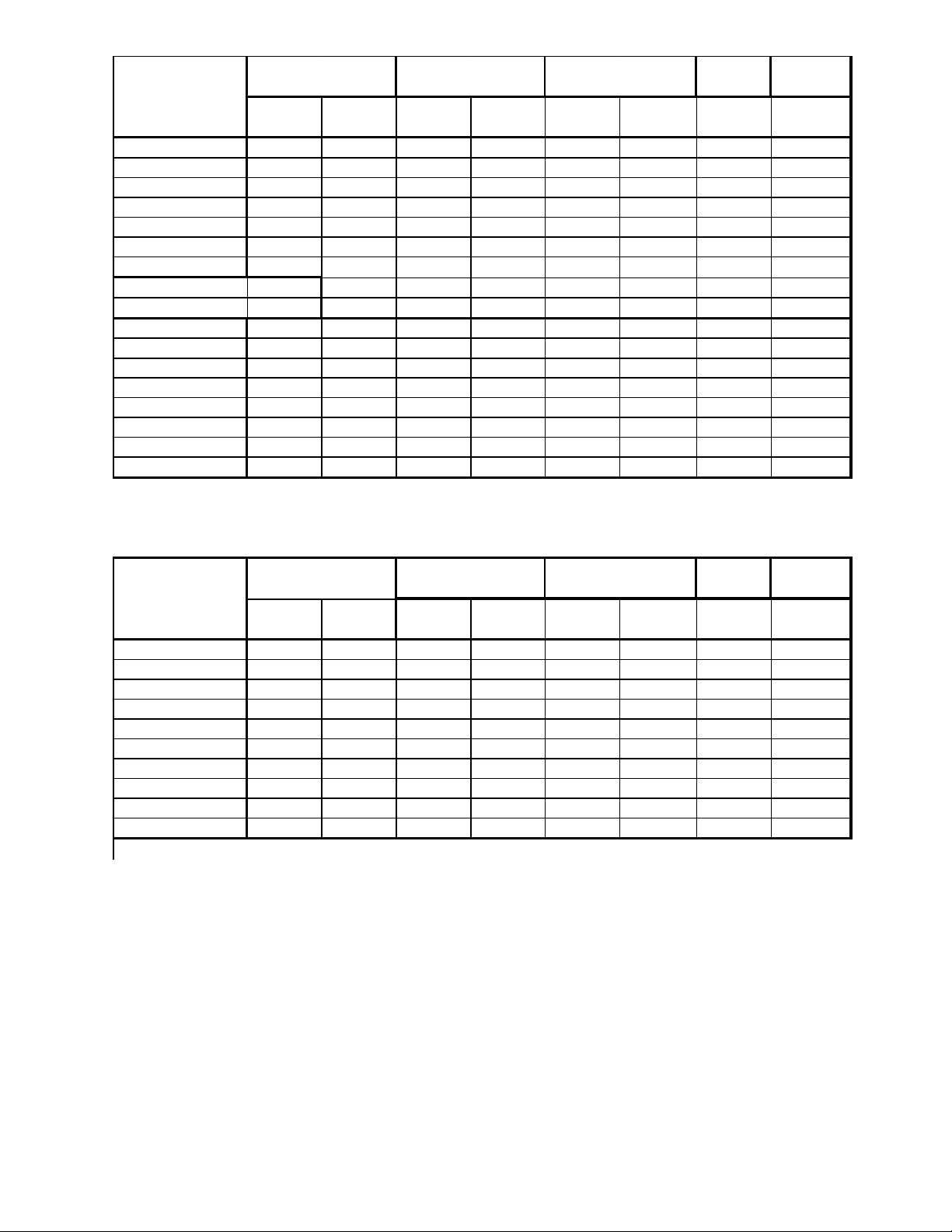

SS PERFORMANCE DATA

PERFORMANCE R-22 BREAKE

DATA* REFRIG. FUSE

EVAPORATOR AIR

TEMP. DEG. F.

OPERATING

PRESSURES

ELECTRICAL

RATINGS

Cooling Dis c harge Temp. S uction Dis charge A mps Lock ed Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

SS08J1 0R-B 61.4 1 8.6 87 251 6.7 29 39.'0 15

SS08J1 0R-A 61.4 1 8.6 84 248 6.7 36.2 24.'0 15

SS09J1 0C-A 57.8 2 2.2 82 254 7.4 44 22.6 15

SS10J10AR-A 57.22 22.78 84 245 7.5 42 26.'0 15

SS12J1 0AR-B 57.2 22.8 83 271 9.8 44 30.'0 15

SS14J10R-A 57.22 22.9 77 279 12 61 29.5 15

SS12J3 0D-A 57.2 22.8 82 265 5.0/5.2 21 27.5 20

SS16J3 0A-A 56.9 23 77 296 7.5/8.0 2 8 30.'0 20

SS18J3 0R-A 56.9 23 77 293 8.1/8.7 45 48 20

SM-SL PE RF ORMANCE DA TA

PERFORMANCE R-22 BREAKE

DATA* REFRIG. FUSE

EVAPORATOR AIR OPERATING ELECTRICAL

TEMP. DEG. F PRE SS URES RATINGS

Cooling Dis c harge Temp Suction Dis charge A mps Lock ed Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

SM20J30-A 52.58 27.42 70 279 9.9 43 47 20

SM24J30-A 54.86 25.14 68 301 12.2 68 54 20

SL25J30-A 52.32 27.68 75 284 11.5/12.6 68 48.5 20

SL28J30B-A 52.1 26.9 74 278 13.0/14.2 88 50 20

SL35J30-A 52.93 27.07 72 317 18.0/20.0 92 60 30

SL35J30-B 52.93 27.07 72 317 18.0/20.0 92 60 30

* Rating Condit ions: 80 degree F. Room A i r Temperature and 50% Relati ve Humi di t y with

95 degree F. Out s i de A i r Temperature at 40% Rel at i ve Humi dity.

8

WS PERFORMANCE DATA

PERFORMANCE R-22 BREAKER

DATA* REFRIG. FUSE

EVAPORATOR AIR

TEMP. DEG. F.

OPERATING

PRESSURES

ELECTRICAL

RATINGS

Cooling Dis c harge Temp. S ucti on Di scharge Amps Locked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

WS07A10E-B 59.5 19.5 84 300 7.'0 32 19 15

WS07A10E-C 59.5 19.5 85 299 7.'0 32 28 15

WS07A10E-D 59.5 19.5 85 299 7.'0 32 20 15

WS10A10-A 58 22 83 307 9.8 48 25 15

WS10A10-B 58 22 83 307 9.8 48 26 15

WS12A10E-B 55 25 81 290 11.9 54 28.5 15

WS13A10-A 55 25 79 281 12 55 36 15

WS09A30E-B 58 22 86 302 4.7 44 22 15

WS12A30E-A 47.1 32.9 80 308 11.9 54 27.5 15

WS12A30E-B 46 33 80 305 11.9 54 42 15

WS15A30-A 47 33 72 310 8.5 42 43.5 15

W E-WY PERF O RM ANCE DATA

DATA* R-22 BREAKER

Cooling REFRIG. FUSE

EVAPORATOR OPERATION ELECTRICAL

TEMP. DEG. F. P RESSURES RATINGS

Discharge Temp. Suct i on Discharge A m ps Locked Charge in 60 Hertz

Air Drop F. Rotar Amp OZ. Amps

WE09A33E-C 58 22 86 302 4.7 44 23 20

WE12A33E-B 55 25 80 308 6.5 54 27.5 20

WE15A33-A 47.1 32.9 71 310 8.5 42 43.5 20

WY09A33F-A 58 22 83 288 4.3 44 24 20

WY12A33G-A 55 25 81 295 6.2 54 37 20

PERFORMANCE H ea t Rise

DATA heating

WE15A33-A 40 16.2

WE09A33E-C 39 14.7

WE12A33E-B 36 14.7

* Rating Condit ions: 80 degree F. Room A i r Temperature and 50% Relat ive Hum i dity

95 degree F. Out s i de A i r Temperature at 40% Relat i ve Hum idi t y

9

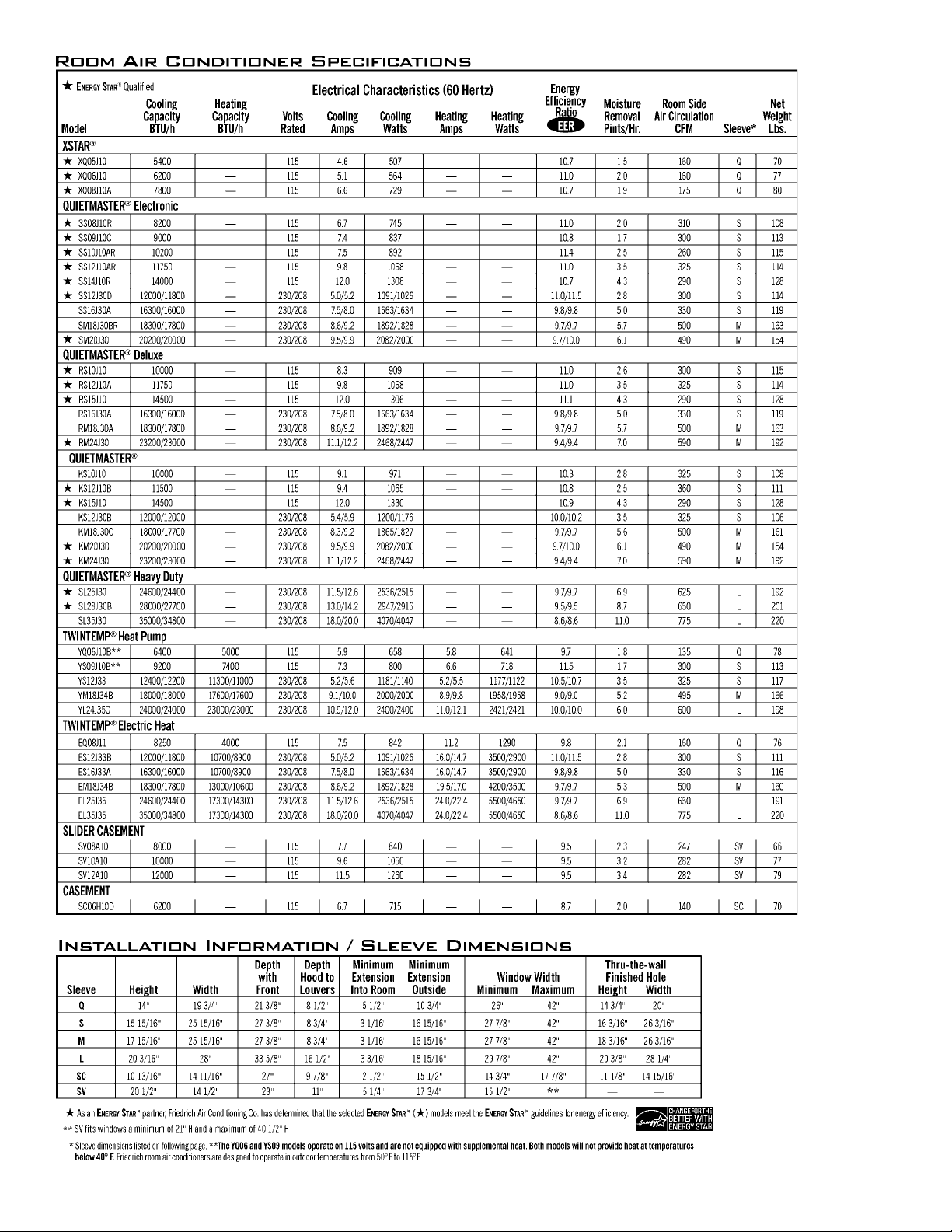

SPECIFICATIONS SC06H10E

BTUH (Cooling) 5950

E.E.R. (Cooling) 8.0

Volts 115

Amperes (Cooling) 6.8

Total Watts (Cooling) 760

Hertz 60

Fuse/Breaker Size 15

Fan RPM 1595

Evaporator Air CFM 125

Dehumidification Pts/Hr 2.0

Width 141 1/16"

Height 1013/16"

Depth 27"

Minimum Ext. Into Room 2½"

PERFORMANCE DA T A* SC06H10E

DISCHARGE 56.1

EVAPORA TOR AIR AIR

TEMP. °F TEMP 23.9

DROP °F

OPERATING SUCTION 72

PRESSURES DISCHARGE 293

AMPS 6.8

ELECTRICAL

RA TINGS LOCKED 35.0

ROTOR AMPS

R-22 CHARGE IN 14

REFRIG. OUNCES

COMP. CHARGE IN 9.8

OIL FLUID OZ.

Minimum Ext. To Outside 15½"

Net Weight 70

* Rating Conditions:

80°F Room Air Temperature and 50% Relative Humidity with

95°F Outside Air Temperature at 40% Relative Humidity .

Shipping Weight 80

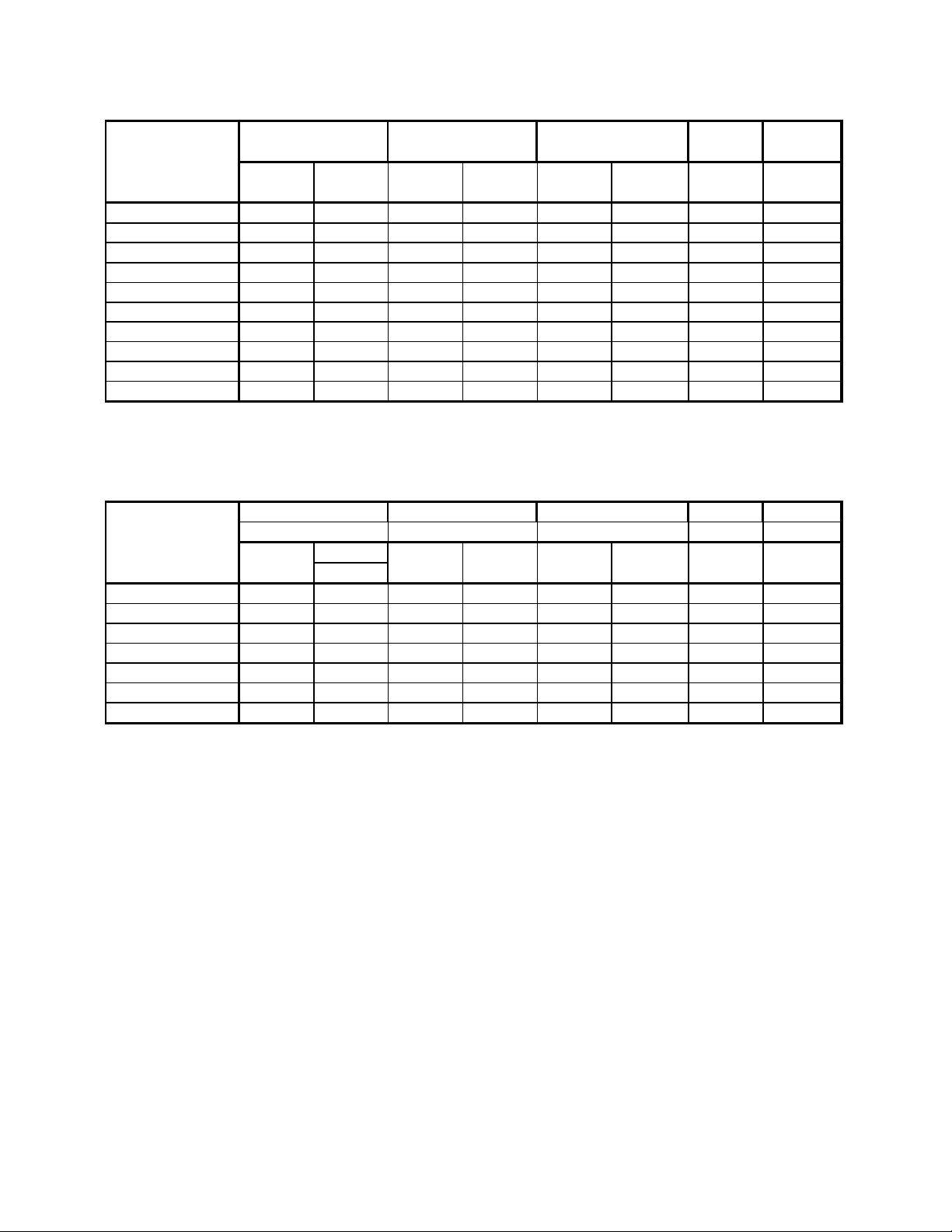

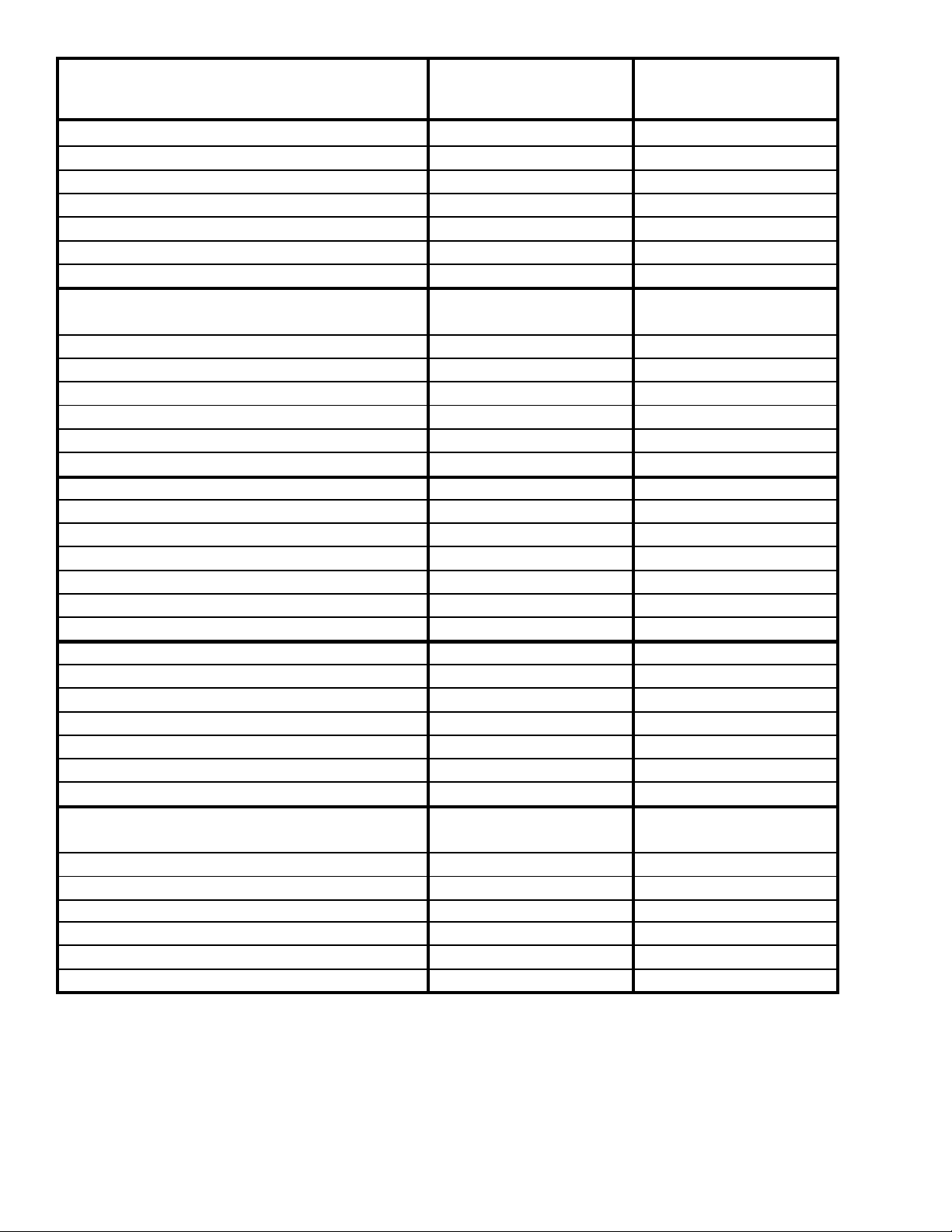

PERFORMANCE DA T A *YS09J10B-A **YS12J33-A **YM18J34A-A **YL24J35C-A

(Heating)

AHAM @ 70°F Inside 47°F Outside 8300 12400/12300 17200/17200 23000/22800

@ 70°F Inside 35°F Outside 10700/8900 13000/10600 17300/14300

Evaporator Air Temperature Rise

@ 70°F Inside 47°F Outside 19.62 31.38 24.74 31.71

@ 70°F Inside 35°F Outside 28.69/23.87 24.46/20.22 24.38/20.16

AMPS @ 70°F Inside 47°F Outside 6.7 6.0/6.5 8.5/9.0 10.4/11.5

@ 70°F Inside 35°F Outside 16.0/14.7 19.5/17.0 24.0/22.4

Watts @ 70°F Inside 47°F Outside 760 1340/1300 1880/1820 2350/2340

@ 70°F Inside 35°F Outside 3500/2900 5500/4650 5500/4650

Suction/Head PSIG

@ 70°F Inside 47°F Outside 53.5/222 52.5/251 53/225 54/236.5

* Do not operate below 37° ambient.

** Heating element comes on at 35°F outside ambient and compressor shuts off.

10

PERFORMANCE DA T A *WY09A33F-A *WY12A33F-A

(Heating)

BTUH @70°F Inside 62°F Outside 9700 12400

@70°F Inside 57°F Outside 9300 12000

@70°F Inside 52°F Outside 8800 11400

** @70°F Inside 47°F Outside 8200/8100 10800/10400

@70°F Inside 42°F Outside 7600 10000

@70°F Inside 37°F Outside 6800 9000

@70°F Inside 35°F Outside 1 1000/9100 11000/9100

Evaporator Air Temperature Rise

@70°F Inside 62°F Outside 32.00 37.60

@70°F Inside 57°F Outside 30.75 36.40

@70°F Inside 52°F Outside 29.10 34.50

** @70°F Inside 47°F Outside 27.10/26.80 32.70/31.50

@70°F Inside 42°F Outside 25.10 30.30

@70°F Inside 37°F Outside 22.50 27.30

@70°F Inside 35°F Outside 36.40/30.10 33.30/27.60

AMPS @70°F Inside 62°F Outside 4.0 5.6

@70°F Inside 57°F Outside 3.9 5.5

@70°F Inside 52°F Outside 3.85 5.4

** @70°F Inside 47°F Outside 3.8/4.1 5.3/5.6

@70°F Inside 42°F Outside 3.6 5.1

@70°F Inside 37°F Outside 3.4 4.8

@70°F Inside 35°F Outside 16.0/14.7 16.0/14.7

Watt s @70°F Inside 62°F Outside 880 1280

@70°F Inside 57°F Outside 870 1260

@70°F Inside 52°F Outside 860 1220

** @70°F Inside 47°F Outside 835/810 1175/1155

@70°F Inside 42°F Outside 800 1 1 30

@70°F Inside 37°F Outside 760 1070

@70°F Inside 35°F Outside 3550/2950 3550/2950

Suction/Head PSIG

@70°F Inside 62°F Outside 66/315 61/325

@70°F Inside 57°F Outside 62/285 59/290

@70°F Inside 52°F Outside 57/285 53/275

** @70°F Inside 47°F Outside 53/265 49/255

@70°F Inside 42°F Outside 49/215 45/240

@70°F Inside 37°F Outside 45/203 41/220

@70°F Inside 35°F Outside 44/200 40/215

* Heating Element comes on at 35°F outside ambient and compressor shuts off.

** AHAM Rating Conditions.

11

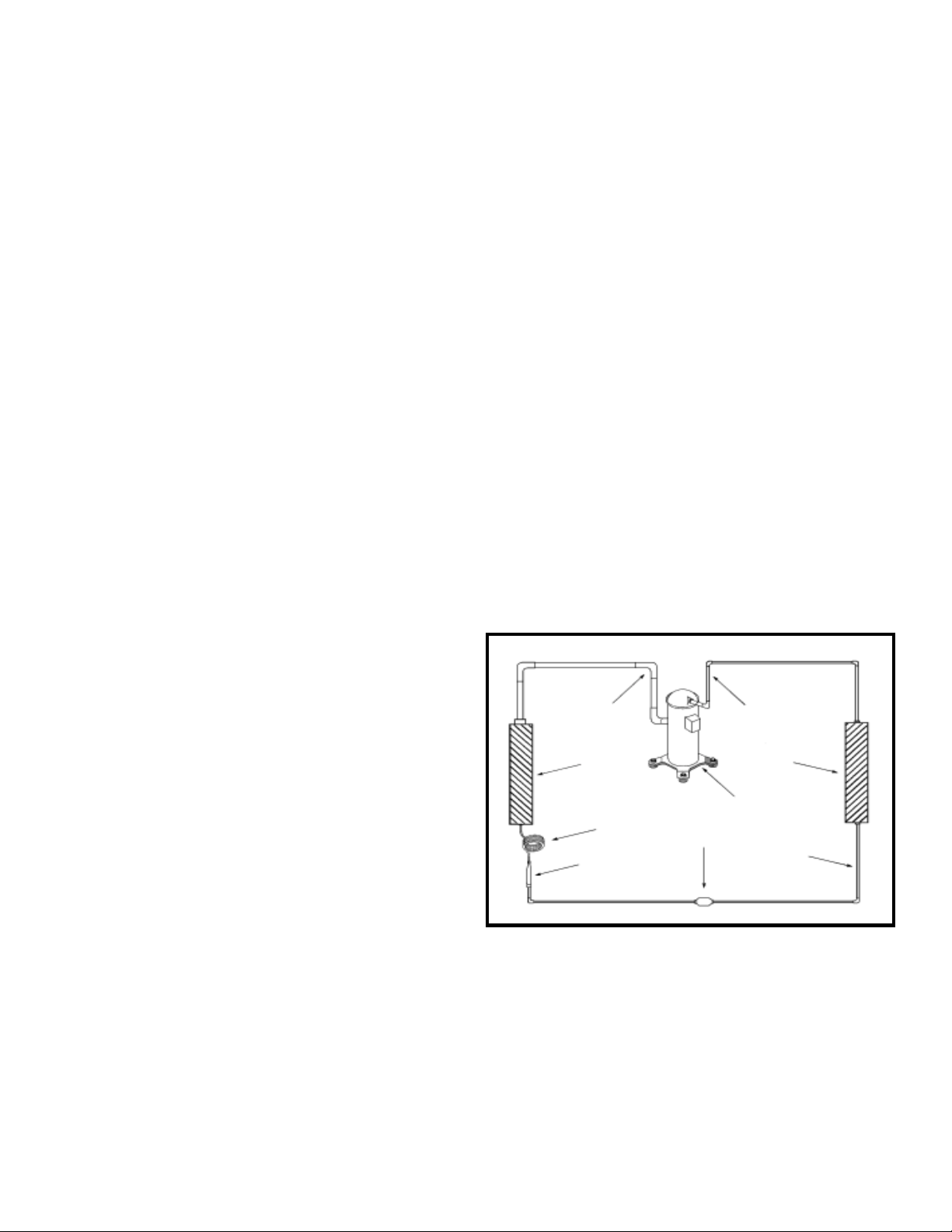

Refrigeration SystemRefrigeration System

Refrigeration System

Refrigeration SystemRefrigeration System

Sequence of OperationSequence of Operation

Sequence of Operation

Sequence of OperationSequence of Operation

A good understanding of the basic operation of the refrigeration

system is essential for the service technician. Without this

understanding, accurate troubleshooting of refrigeration

system problems will be more difficult and time consuming, if

not (in some cases) entirely impossible. The refrigeration

system uses four basic principles (laws) in its operation they

are as follows:

1. "Heat always flows from a warmer body to a cooler body."

2. "Heat must be added to or removed from a substance

before a change in state can occur"

3. "Flow is always from a higher pressure area to a lower

pressure area."

4. "The temperature at which a liquid or gas changes state

is dependent upon the pressure."

The refrigeration cycle begins at the compressor. Starting

the compressor creates a low pressure in the suction line which

draws refrigerant gas (vapor) into the compressor. The

compressor then "compresses" this refrigerant, raising its

pressure and its (heat intensity) Temperature.

The refrigerant leaves the compressor through the discharge

line as a hot high pressure gas (vapor). The refrigerant enters

the condenser coil where it gives up some of its heat. The

condenser fan moving air across the coil's finned surface

facilitates the transfer of heat from the refrigerant to the

relatively cooler outdoor air.

In the case of the capillary tube this is accomplished (by design)

through size (and length) of device, and the pressure difference

present across the device.

Since the evaporator coil is under a lower pressure (due to the

suction created by the compressor) than the liquid line, the liquid

refrigerant leaves the metering device entering the evaporator coil.

As it enters the evaporator coil, the larger area and lower pressure

allows the refrigerant to expand and lower its temperature (heat

intensity). This expansion is often referred to as "boiling". Since

the unit's blower is moving Indoor air across the finned surface of

the evaporator coil, the expanding refrigerant absorbs some of

that heat. This results in a lowering of the indoor air temperature,

hence the "cooling" effect.

The expansion and absorbing of heat cause the liquid refrigerant

to evaporate (i.e. change to a g as). Once the refrigerant has

been evaporated (changed to a gas), it is heated even further by

the air that continues to flow across the evaporator coil.

The particular system design determines at exactly what point (in

the evaporator) the change of state (i.e. liquid to a gas) takes

place. In all cases, however, the refrigerant must be totally

evaporated (changed) to a gas before leaving the evaporator coil.

The low pressure (suction) created by the compressor causes the

refrigerant to leave the evaporator through the suction line as a

cool low pressure vapor. The refrigerant then returns to the

compressor, where the cycle is repeated.

When a sufficient quantity of heat has been removed from

the refrigerant gas (vapor), the refrigerant will "condense" (i.e.

change to a liquid). Once the refrigerant has been condensed

(changed) to a liquid it is cooled even further by the air that

continues to flow across the condenser coil.

The RAC design determines at exactly what point (in the

condenser) the change of state (i.e. gas to a liquid) takes place.

In all cases, however, the refrigerant must be tot ally condensed

(changed) to a liquid before leaving the condenser coil.

The refrigerant leaves the condenser coil through the liquid line

as a warm high pressure l iquid. It next will pass through the

refrigerant drier (if so equipped). It is the function of the drier to

trap any moisture present in the system, contaminants, and large

particulate matter.

The liquid refrigerant next enters the metering device. The metering

device is a capillary tube. The purpose of the metering device is to

"meter" (i.e. control or measure) the quantity of refrigerant entering

the evaporator coil.

Suction

Line

Evaporator

Coil

Metering

Device

Refrigerant

Dryer

Discharge

Line

Condenser

Coil

Compressor

Refrigerant

Drier

Liquid

Line

12

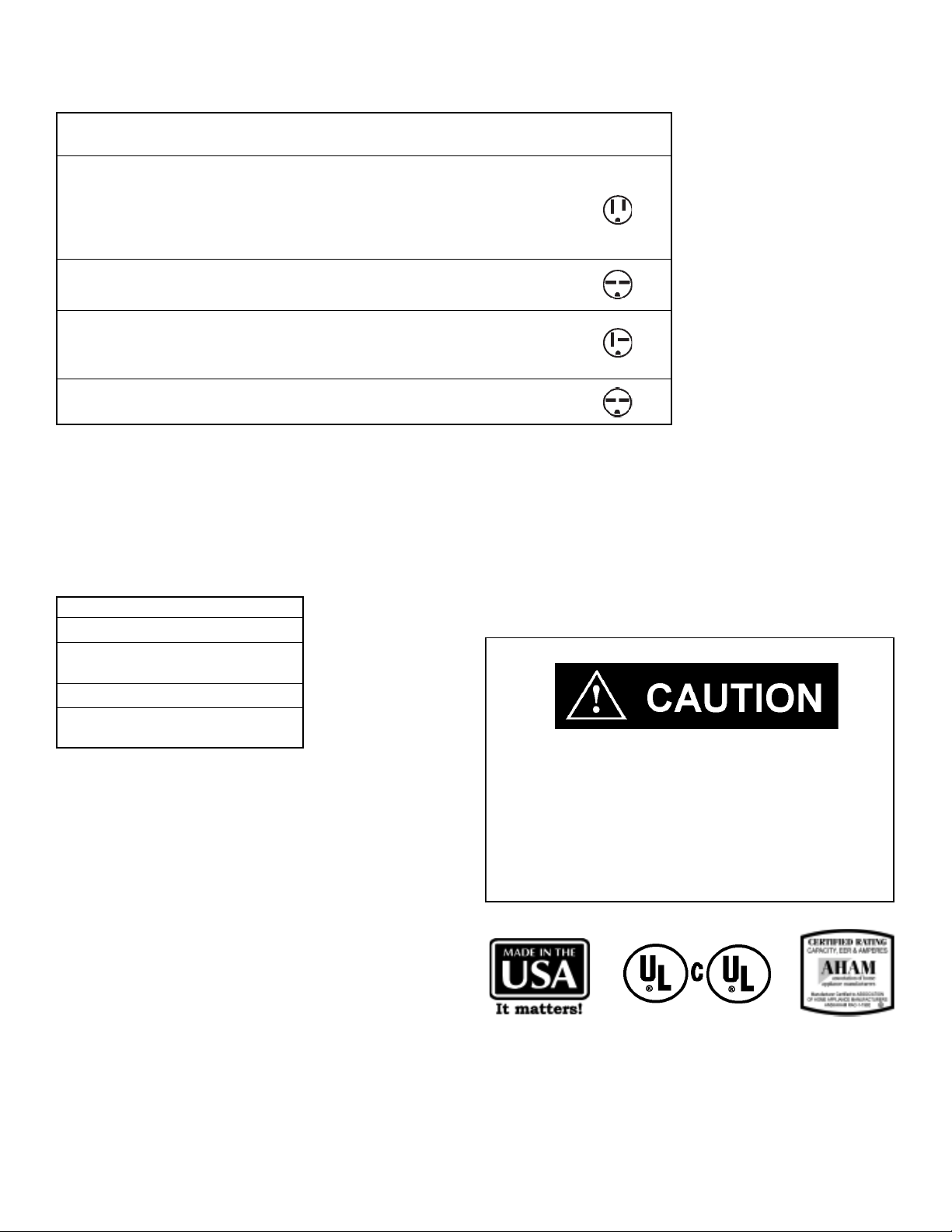

Electrical Rating TElectrical Rating T

Electrical Rating T

Electrical Rating TElectrical Rating T

Circuit Rating Plug Face Appearance

Model Breaker or T-D Fuse (NEMA#) (Facing Blades)

ALL SV and XQ MODELS,

KS10J10, KS12J10B, KS15J10, RS10J10, RS12J10A,

RS15J10, SS08J10R, SS09J10C, SS10J10AR,

SS12J10AR, SS14J10R, SC06H10D,

EQ08J11, YQ06J10B, YS09J10B

125V - 15A 5 - 15P

ablesables

ables

ablesables

KS12J30B, KM18J30C, RS16J30A,

RM18J30A, SS12J30D, SS16J30A, SM18J30BR

KM20J30, KM24J30, SM20J30,

SL25J30, SL28J30B*, ES12J33B, 250V - 20A

ES16J33A, YS12J33

SL35J30, EM18J34B, EL25J35, EL35J35,

YM18J34B, YL24J35C

*

Optional 30 Amp Kit (618-869-00) is recommended in 208 Volt power supply areas that fall below 208 Volts.

For more information, call the Friedrich Service Department.

Due to a program of continuing improvement, specifications are subject to change without notice.

250V - 15A

250V - 30A 6 - 30P

6 - 15P

6 - 20P

Installation Notes:

Supply Cord - All with right angle plug 6' on 115V; 5' on 230/208V.

Room air conditioners include accessories for window or thru-the-wall installation.

TWINTEMP

Window mounting requires use of optional accessory kit as listed below:

MODEL KIT NO.

EQ08J11, YQ06J10B WIKQ

ES12J33B, ES16J33A, WIKS

YS09J10B, YS12J33

EM18J34B, YM18J34B WIKM

EL25J35, EL35J35, WIKL

YL24J35C

®

models include accessories for thru-the-wall installation only.

Turn off electric power before service or installation.

Electric shock hazard.

Wire Size Use ONLY wiring size recommended for

single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR

Breaker circuit breaker indicated on unit's rating

plate. Proper current protection to the unit

is the responsibility of the owner.

Grounding Unit MUST be grounded from branch circuit

through service cord to unit, or through

separate ground wire provided on permanently

connected units. Be sure that branch circuit

or general purpose outlet is grounded.

Receptacle The field supplied outlet must match plug on

service cord and be within reach of service

cord.

Do NOT alter the service cord or plug. Do

NOT use an extension cord. Refer to the table

above for proper receptacle and fuse type.

All electrical connections and wiring MUST be installed by a qualified

electrician and conform to the National Electrical Code and all local

codes which have jurisdiction.

Failure to do so can result in property damage, personal injury and/

or death.

The consumer - through the AHAM Room Air Conditioner

Certification Program - can be certain that the AHAM

Certification Seal accurately states the unit's cooling and

heating capacity rating, the amperes and the energy efficiency

ratio.

13

COMPONENTS:

OPERATION & TESTING

WARNING

DISCONNECT ELECTRICAL POWER TO

UNIT BEFORE SERVICING OR TESTING

COMPRESSORS

Compressors are single phase, 115 or 230/208 volt,

depending on the model unit. All compressor motors are

permanent split capacitor type using only a running capacitor

across the start and run terminal.

All compressors are internally spring mounted and externally

mounted on rubber isolators.

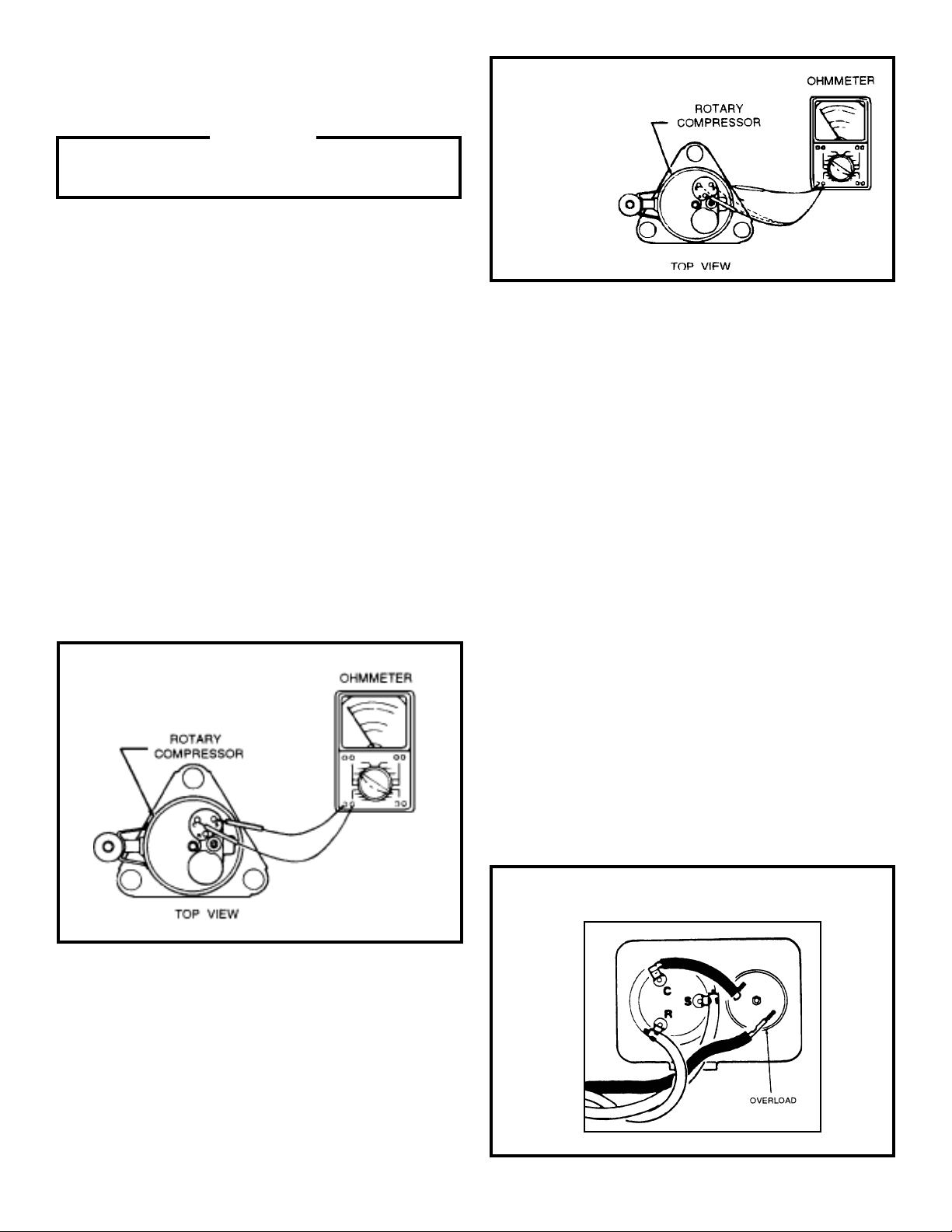

WINDING TEST

Remove compressor terminal box cover and disconnect wires

from terminals. Using an ohmmeter, check continuity across

the following: (See Figure 1)

1. Terminal "C" and "S" - no continuity - open winding replace compressor.

2. Terminal "C" and "R" - no continuity - open winding replace compressor.

3. Terminal "R" and "S" - no continuity - open winding replace compressor.

Figure 2

Typical Ground Test

CHECKING COMPRESSOR EFFICIENCY

The reason for compressor inefficiency is normally due to broken

or damaged suction and/or discharge valves, reducing the ability

of the compressor to pump refrigerant gas.

This condition can be checked as follows:

1. Install a piercing valve on the suction and discharge or

liquid process tube.

2. Attach gauges to the high and low sides of the system.

3. Start the system and run a “cooling or heating

performance test.”

If test shows:

A. Below normal high side pressure

B. Above normal low side pressure

C. Low temperature difference across coil

The compressor valves are faulty - replace the

compressor.

Figure 1

GROUND TEST

Use an ohmmeter set on its highest scale. Touch one lead to

the compressor body (clean point of contact as a good connection is a must) and the other probe in turn to each compressor terminal (see Figure 2.) If a reading is obtained, the

compressor is grounded and must be replaced.

THERMAL OVERLOAD (External)

Some compressors are equipped with an external overload

which is located in the compressor terminal box adjacent to

the compressor body (See Figure 3.)

The overload is wired in series with the common motor

terminal. The overload senses both major amperage and

compressor temperature. High motor temperature or

amperage heats the disc causing it to open and break the

circuit to the common motor terminal.

Figure 3- External Overload

14

Heat generated within the compressor shell is usually due to:

1. High amperage

2. Low refrigerant charge

3. Frequent recycling

4. Dirty condenser

FAN MOTOR - TEST

1. Determine that capacitor is serviceable.

2. Disconnect fan motor wires from fan speed switch or

system switch.

3. Apply "live" test cord probes on black wire and common

terminal of capacitor . Motor should run at high speed.

TERMINAL OVERLOAD - TEST

(Compressor - External T ype)

1. Remove overload.

2. Allow time for overload to reset before attempting to

test.

3. Apply ohmmeter probes to terminals on overload wires.

There should be continuity through the overload.

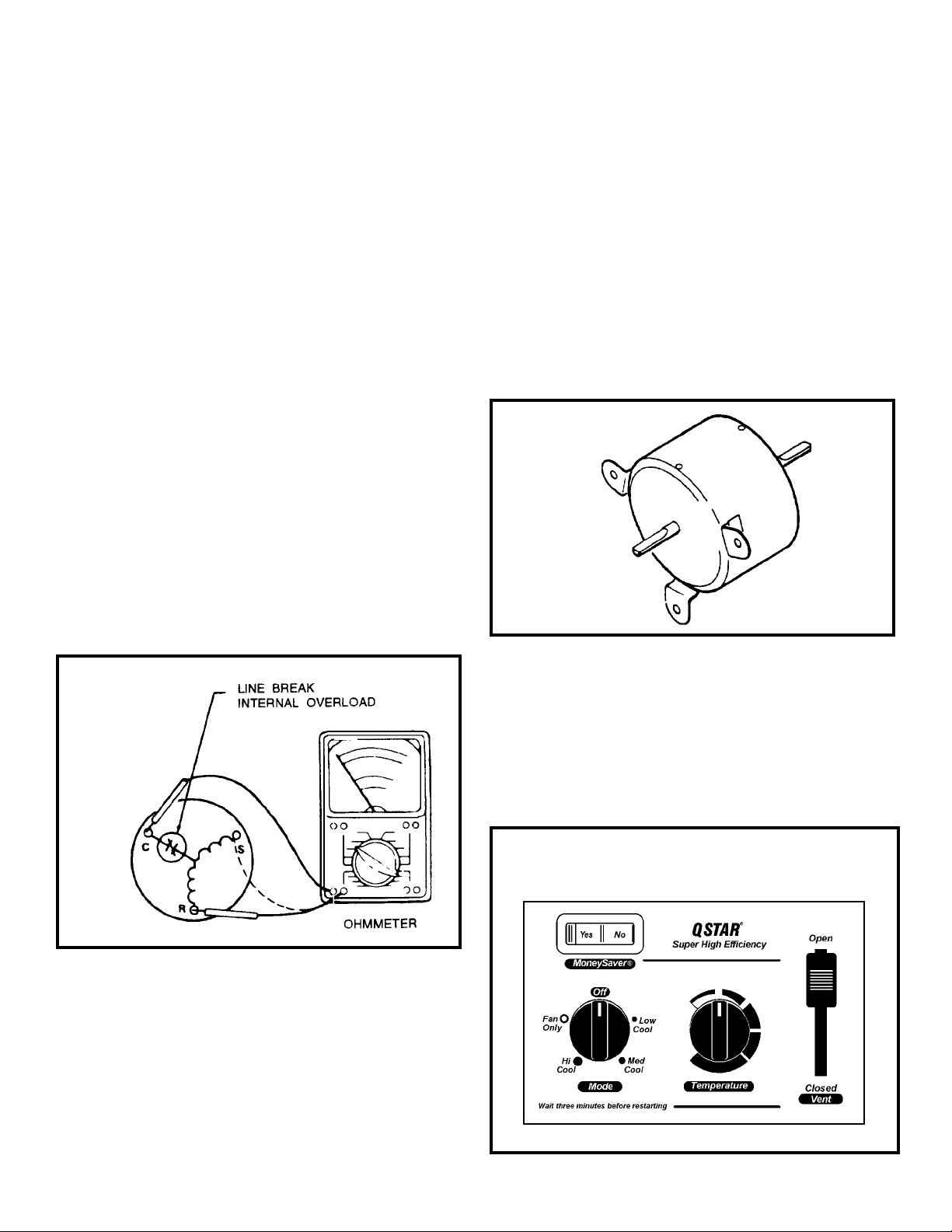

TERMINAL OVERLOAD (Internal)

Some model compressors are equipped with an internal

overload. The overload is embedded in the motor windings

to sense the winding temperature and/or current draw. The

overload is connected in series with the common motor

terminal.

Should the internal temperature and/or current draw become

excessive, the contacts in the overload will open, turning off

the compressor. The overload will automatically reset, but

may require several hours before the heat is dissipated.

CHECKING THE INTERNAL OVERLOAD

(See Figure 4)

4. Apply "live" test cord probes on red wire and common

terminal of capacitor . Motor should run at low speed.

5. Apply "live" test cord probes on each of the remaining

wires from the speed switch or system switch to test

intermediate speeds. If the control is in the

"MoneySaver" mode and the thermostat calls for

cooling, the fan will start - then stop after approximately

2 minutes; then the fan and compressor will start

together approximately 2 minutes later.

Figure 5

Fan Motor

Figure 4

Internal Overload

1. With no power to unit, remove the leads from the compressor terminals.

2. Using an ohmmeter, test continuity between terminals

C-S and C-R. If no continuity , the compressor overload

is open and the compressor must be replaced.

FAN MOTOR

A single phase permanent split capacitor motor is used to drive

the evaporator blower and condenser fan. A self-resetting overload is located inside the motor to protect against high temperature and high amperage conditions. (See Figure 5)

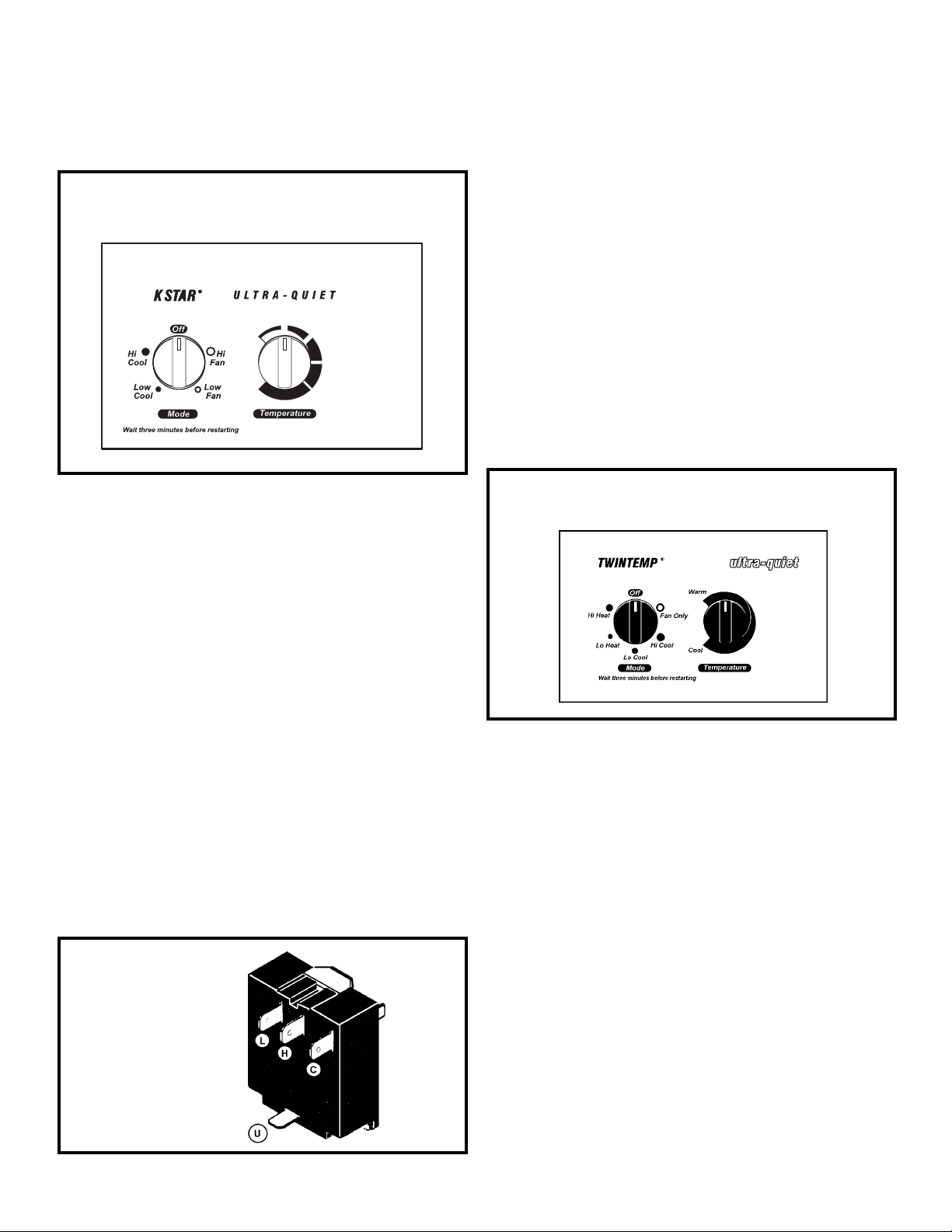

SYSTEM CONTROL PANEL- SQ Models (See Figure 6)

A five-position control switch is used to regulate the operation

of the fan motor and compressor. The compressor can be

operated with the fan operating at low, medium or high speed.

The fan motor can also be operated independently on medium

speed. See switch section as indicated on the decorative

control panel.

Figure 6

System Control Panel (SQ Models Only)

15

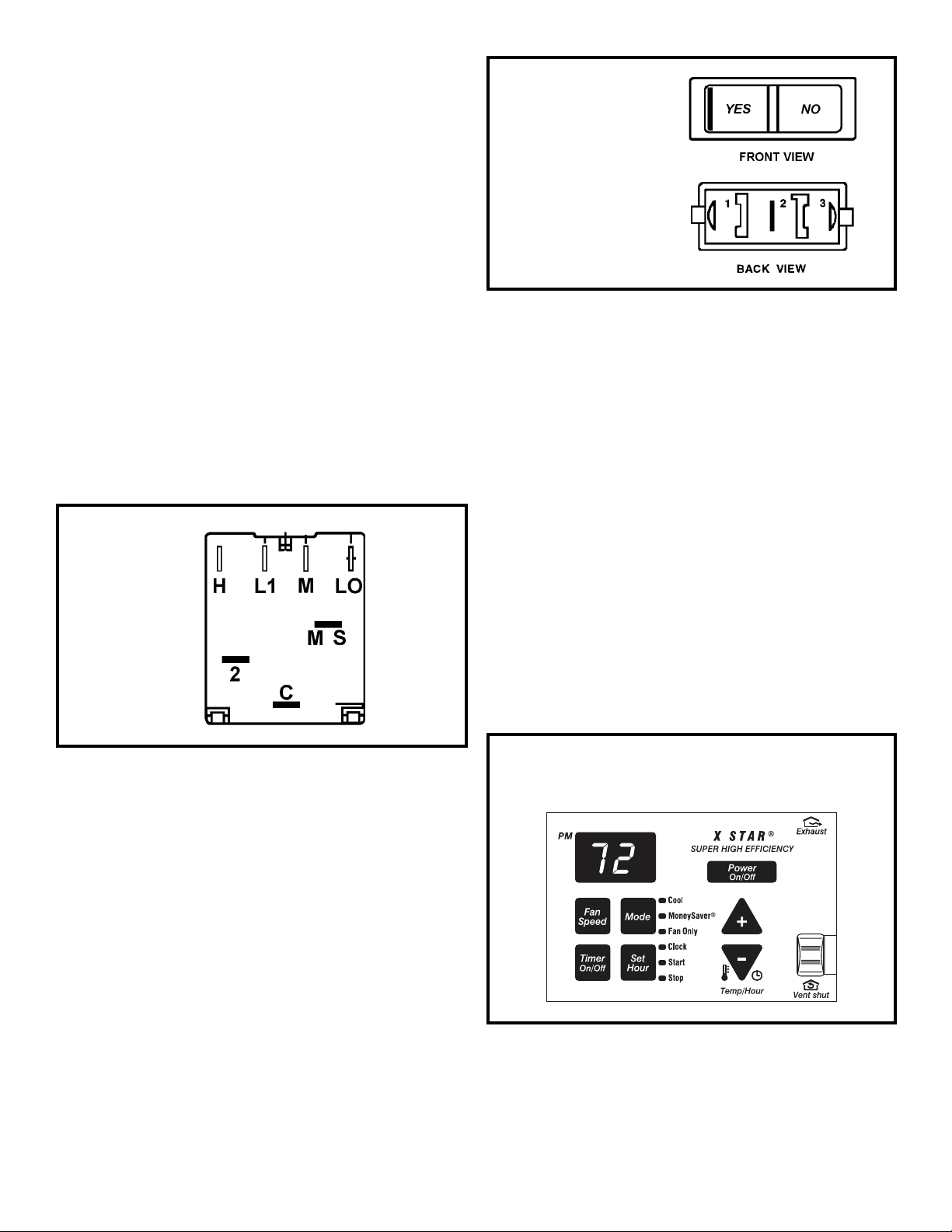

SYSTEM CONTROL SWITCH - TEST (See Figure 7)

Disconnect the leads from the control switch. There must be

continuity as follows:

1. "Off" Position - no continuity between terminals.

2. "Lo Cool" Position - between terminals "L1" and "C", "Lo"

and MS".

3. "Med Cool" Position - between terminals "L1" and "C", "M"

and "MS".

4. "Hi Cool" Position - between terminals L1" and "C", "H"

and "MS".

5. "Fan Only" Position - between terminals "L1" and "2".

Rocker Switch

Figure 8

SYSTEM CONTROL PANEL (XQ MODELS ONLY)

(See Figure 9)

RESISTOR

(Heat Anticip ator) (SQ Only)

Failure of the resistor will cause prolonged "off" and "on" cycles

of the unit. When replacing a resistor, be sure and use the

exact replacement. Resistor rating 1 15 V olts 12500 ohm, 1.05

watts.

Figure 7

System Switch

(SQ Only)

MONEYSAVER® SWITCH (Rocker Switch- See Figure 8)

This rocker switch can be depressed to either YES or NO. In

the YES position you will get the most economical operation.

Both the fan and the compressor will cycle on and off together ,

maintaining the selected temperature at a more constant level

and reducing the humidity more efficiently. This control will

only operate when the unit is in a cooling mode. In the NO

position, the fan will run constantly as long as the unit is in the

cooling mode. Disconnect leads from switch. Depress switch

to function being tested.

1. Power button turns the unit on and off.

2. Fan Speed button allows selection between three cooling speeds and fan only .

3. The mode button allows the unit to switch between modes

(i.e., fan only, cooling, etc.).

4. Timer on/off button allows for programmed on and off

times (one hour increments).

5. The plus and minus buttons allows adjustments for room

air temperature.

6. Set hour button enables the unit’s timer on/off feature to

operate for times selected.

7. Exhaust/vent shut feature (if applicable) allows for room

air to continuously recalculate or if enabled, to exhaust

stale air.

Note: Please refer the troubleshooting guides on page if the

control is malfunctioning.

Figure 9

System Control Panel (XQ Models Only)

1. When YES is depressed, there should be continuity

between terminals "1" and "2."

2. When NO is depressed, there should be continuity

between terminals "2" and "3."

16

SYSTEM CONTROL PANEL

("KQ" Models Only- See Figure 10)

The KQ Model unit uses a five position control switch to regulate the operation of the unit. Function of each position (clockwise rotation) is as follows:

SYSTEM CONTROL PANEL

EQ Model Only (See Figure 12 )

The EQ Model unit uses a six-position control switch to regulate

the operation of the unit. Function of each position (clockwise

rotation) is as follows:

1. “Off” Turns everything off.

Figure 10

System Control Panel (KQ Models Only)

1. "Off" - Turns everything off.

2. "Hi Fan" - Maximum circulation of filtered room air (no

cooling.)

3. "Low Fan" - Fan runs slower for less circulation of filtered room air.

4. "Low Cool" - Fan runs slowly for quiet operation when

maximum cooling is not needed.

5. "Hi Cool" - Highest fan speed for maximum cooling.

2. “Fan Only” To circulate filtered room air, but no cooling

or heating

3. “Hi Cool” Fan runs continuously, compressor goes on

and off to maintain the selected room temperature

4. “Lo Cool” fan runs continuously, compressor goes on and

off to maintain the selected room temperature.

5. “Lo Heat” Fan runs continuously, heating turns on and

off to maintain the selected room temperature.

6. Hi Heat” Fan runs continuously, heating turns on and of f

to maintain the selected room temperature.

Figure 12

System Control Panel (EQ Models only)

SYSTEM CONTROL SWITCH - TEST (See Figure 1 1) Turn knob

to phase of switch to be tested. There must be continuity as follows:

1. "Hi Fan" Position - between terminals "L1" and "H".

2. "Low Fan" Position - between terminals "L1" and "L".

3. "Low Cool" Position - between terminals "L1" and "L" and

"C".

4. "Hi Cool" Position - between terminals "L1" and "H" and "C".

Figure 11

System Control Switch

(KQ Models Only)

SYSTEM CONTROL SWITCH – TEST (See Figure 13)

Turn knob to phase of switch to be tested. There must be

continuity as follows:

1. “Fan Only” Position – between terminals “MS” and “H”

2. “Hi Cool” Position – between terminals “L1” and “C” and

“MS” and “H”

3. “Low Cool” Position – between terminals “L1” and “C”

and “MS” and “LO”

4. “Low Heat” Position – between terminals “L2” and “2”

and “MS” and “LO”

5. “Hi Heat” Position – between terminals “L2” and “2” and

“MS” and “H”

17

Figure 13

System Control Switch

(EQ Models)

MS

LO

L1

B1

L2

C

H

2

SYSTEM CONTROL PANEL ("YQ" Model Only)

(See Figure 14)

The YQ Model unit uses a six position control switch to regulate

the operation of the unit. Function of each position (Clockwise

rotation) is as follows:

1. "Off" - Turns everything off.

2. "Fan Only" - To circulate filtered room air, but no cooling

or heating.

3. "Hi Cool" - Fan runs continuously, compressor goes on

and off to maintain the selected room temperature.

4. "Lo Cool" - Fan runs continuously, compressor goes on

and off to maintain the selected room temperature.

5. "Lo Heat" - Fan Runs continuously, heating turns on and

off to maintain the selected room temperature.

4. "Lo Heat" Position - between terminals "C" and "2", and

"C" and "4".

5. "Hi Heat" Position - between terminals "C" and "1", and

"C" and "4".

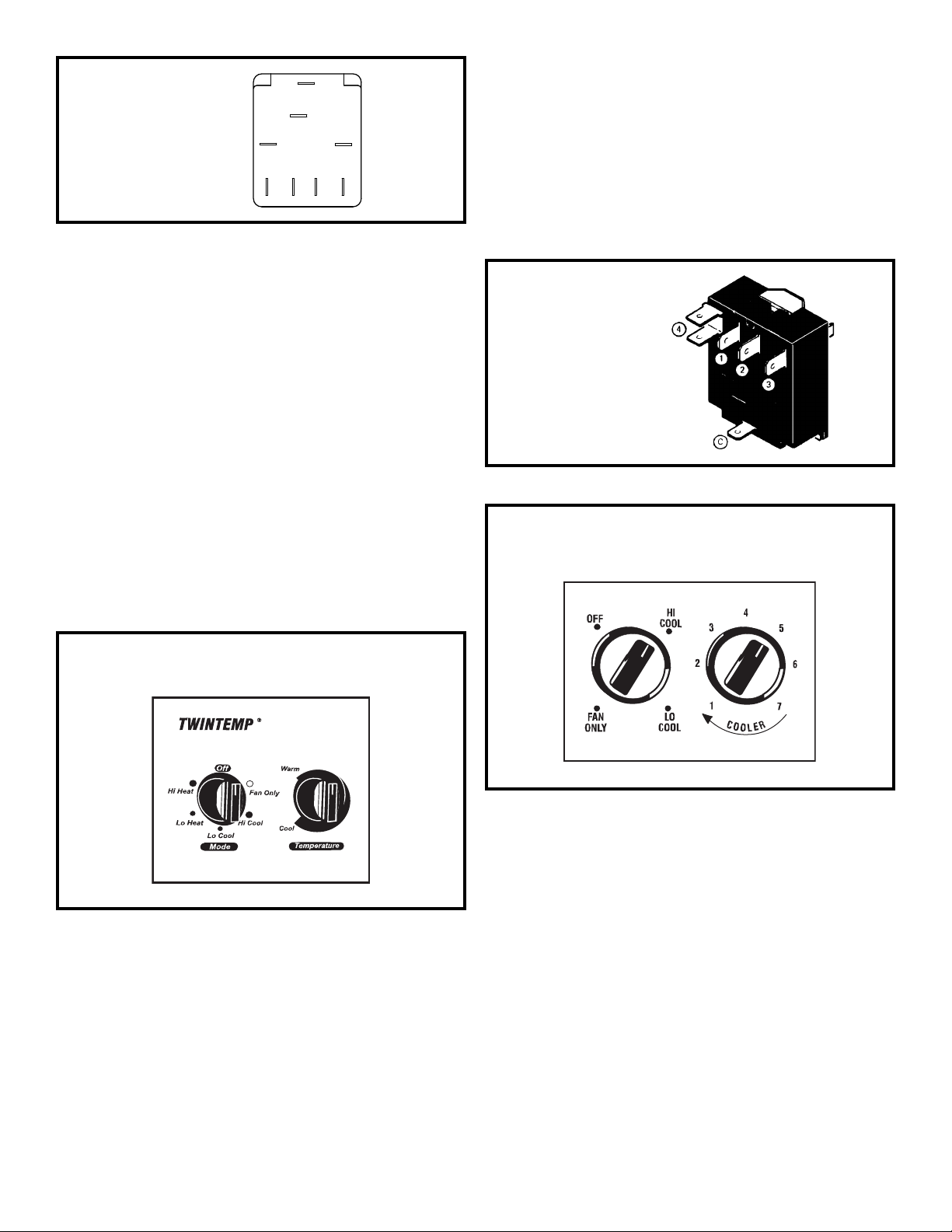

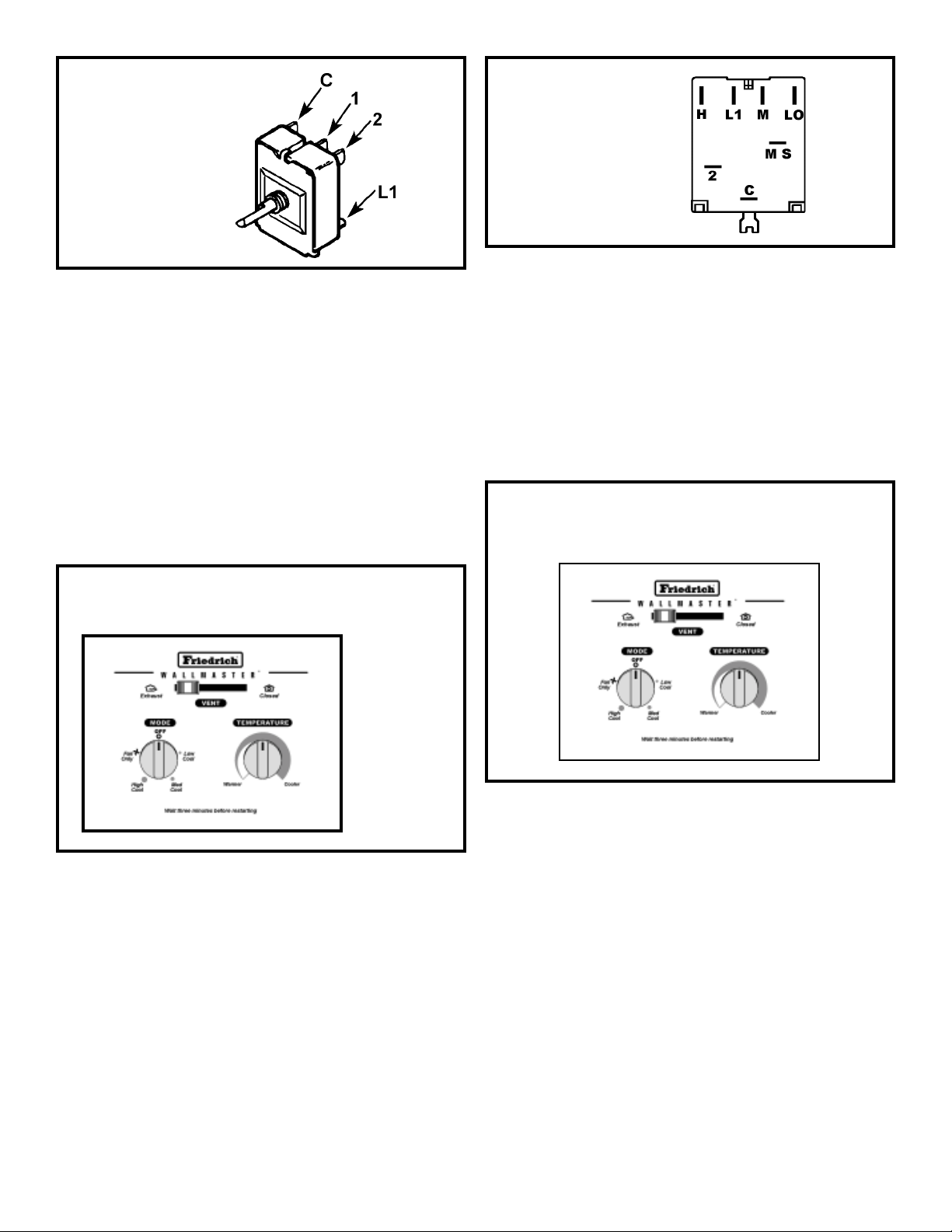

ROT ARY (SYSTEM) SWITCH: "SC" Model (See Figure 16)

A rotary four position switch is used to turn on the unit and

select the operation desired. Switch selection is as follows:

Figure 15

System Control Switch

(YQ Model Only)

Figure 16

System Control Panel (SC Model Only)

6. "Hi Heat" - Fan Runs continuously, heating turns on and

off to maintain the selected room temperature.

Figure 14

System Control Panel (YQ Model Only)

SYSTEM CONTROL SWITCH - TEST (See Figure 15)

Turn knob to phase of switch to be tested. There must be

continuity as follows:

1. "Fan Only" Position - between terminals "C" and "1".

2. "Hi Cool" Position - between terminals "C" and "1", "C"

and "3".

3. "Lo Cool" Position - between terminals "C" and "2", and

"C" and "3".

1. "Hi Cool" T urns on the compressor and fan at high speed

2. "Lo Cool" Turns on the compressor and fan at low speed.

3. "Fan Only" Turns on the fan at high speed.

4. "Off" Turns everything off.

The switching arrangement of the control is as follows:

(See Figure 17)

1. "Off" All contacts open.

2. "Hi Fan

Contacts closed between terminals "L1" and

"1".

3. "Hi Cool" Contacts closed between terminals "L1" to "1"

and "L1" and "C".

4. "Lo-Cool" Contacts are closed between terminals "L1"

to "2" and "L1 to "C".

18

Figure 16

System Control Switch

(SC Model Only)

1. Disconnect leads from control switch.

2. Check continuity between all switch positions shown in

Figure 17.

SYSTEM CONTROL PANEL

"WS" Models (See Figure 18)

A five position control switch is used to regulate the operation

of the fan motor and compressor. The compressor can be

operated with the fan operating at low , medium or high speed.

The fan motor can also be operated independently on medium

speed. See switch section as indicated on decorative control

panel

Figure 19

System Control Switch

(WS Models)

SYSTEM CONTROL SWITCH "WE" & "WY" Models

(See Figure 20)

An eight position switch is used to regulate the operation of

the fan motor, compressor and electric heater. The unit can

be operated in cooling or heating mode with the compressor

or electric heater on and the fan motor operating on low,

medium or high speed.

The fan motor can also be operated independently on medium

speed. See switch section as indicated on decorative control panel.

Figure 20

System Control Panel

(WE & WY Models)

Figure 18

System Control Panel (WS Models)

SYSTEM CONTROL SWITCH - TEST

Disconnect leads from control switch (See Figure 19)

There must be continuity as follows:

1. "Off" Position - no continuity between terminals.

2. "Lo Cool" Position - between terminals "L1" and "C", "LO"

and "MS."

3. "Med Cool" Position - between terminals "L1" and "C", "M"

and "MS".

4. "Hi Cool" Position - between terminals "L1" and C", "H"

and "MS."

5. "Fan Only" Position - between terminals "L1" and "2."

SYSTEM CONTROL SWITCH - TEST (See Figure 21)

Disconnect leads from control switch. Turn control to position

being tested. There must be continuity as follows:

1. "Off" Position-no continuity between terminals.

2. "Lo Cool" Position-between terminals "C" and "3", "C2"

and "2", "LO" and "M/S", "AR" and "5".

3. "Med Cool" Position-between terminals "C" and "3",

"C2" and "2", "M" and "M/S", "AR" and "5".

4. "Hi Cool" Position-between terminals "C" and "3", "C2"

and "2", "H" and "M/S", "AR" and "5".

5. "Hi Heat" Position-between terminals "C" and "1", "C2"

and "4", "H" and "M/S", "AR" and "5".

19

6. "Med Heat" Position-between terminals "C" and "1",

"C2" and "4", "M" and "M/S", "AR" and "5".

7. "Lo Cool" Position-between terminals "C" and "1", "C2"

and "4", "LO" and "M/S", "AR" and "5".

8. "Fan Only" Position-between terminals "L1" and "M".

Figure 21

System Control Switch

Heat Pump / Electric Heat

(WE & WY Models)

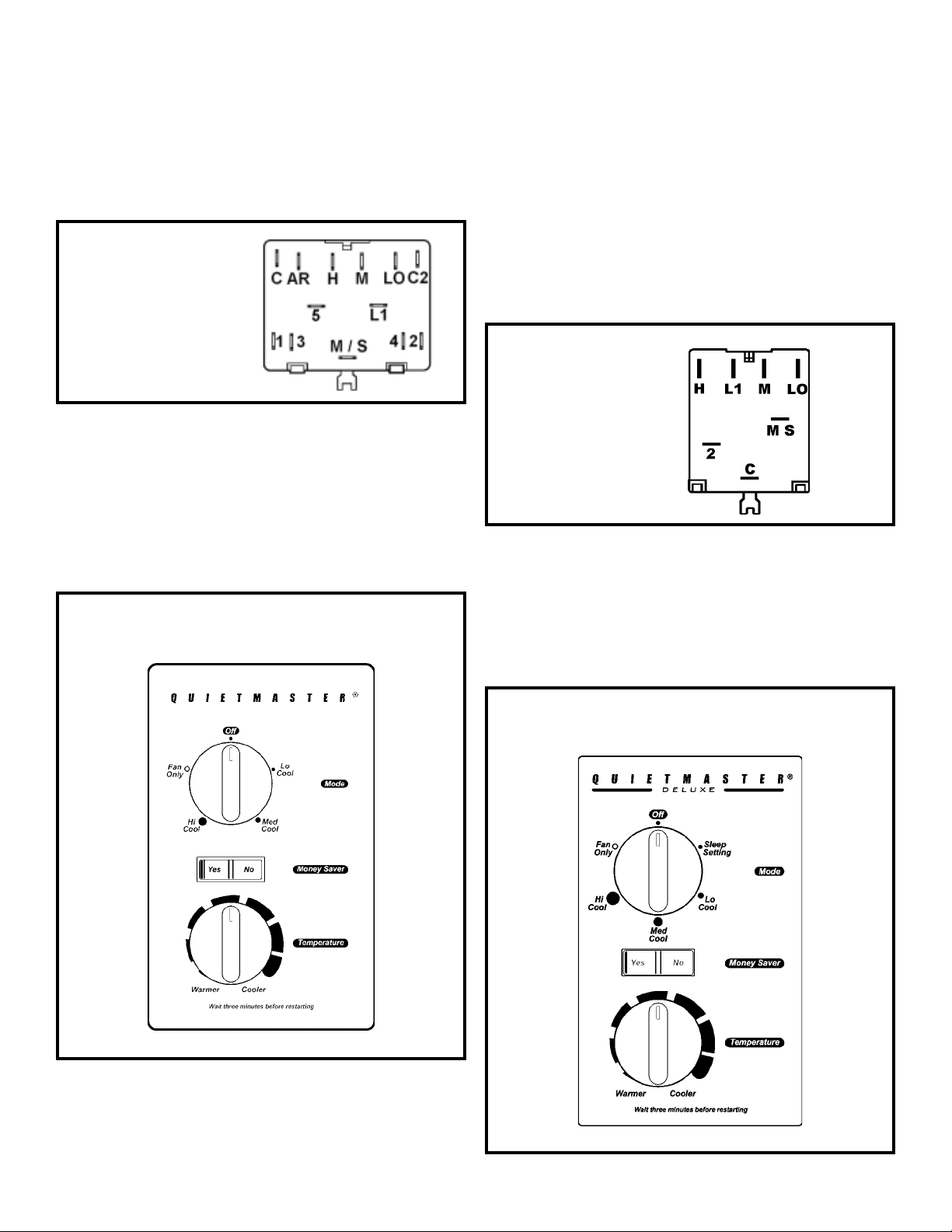

SYSTEM CONTROL SWITCH KS, SS, KM, SM, SL Models

(See Figure 22)

A five position control switch is used to regulate the operation of

the fan motor and compressor. The compressor can be operated

with the fan operating at low, medium or high speed. The fan

motor can also be operated independently on medium speed.

See switch section as indicated on decorative control panel.

Figure 22

System Control Panel (KS, SS, KM, SM, SL)

SYSTEM CONTROL SWITCH - TEST (See Figure 23)

Disconnect leads from control switch. There must be continuity

as follows:

1. "Off" Position - no continuity between terminals.

2. "Lo Cool" Position - between terminals "L1" and "C," "LO"

and "MS."

3. "Med Cool" Position - between terminals "L1" and "C,"

"M" and "MS."

4. "Hi Cool" Position - between terminals "L1" and "C,"

"H"and "MS."

5. "Fan Only" Position - between terminals "L1" and "2."

Figure 23

System Control Switch

SYSTEM CONTROL PANEL (See Figure 24)

A six-position control switch is used to regulate the operation of

the fan motor and compressor. The compressor can be operated

with the fan operating at low, medium or high speed. The fan

motor can also be operated independently on medium speed.

See switch section as indicated on decorative control panel.

Figure 24

System Control Panel - Deluxe Series (RS & RM)

20

Loading...

Loading...