FEIN Power Tools GRIT User Manual

METAL

GRIT GX / GI

Belt Grinders

Grinding Modules

Deburring Machines

Accessories

Belt grinding for

professional users in metal working and fabrication trades and industries

GRIT – The brand for belt grinding from FEIN

Solving problems and developing solutions for metal working professionals – a core component of FEIN philosophies. For over 25 years GRIT has set the standard for quality belt grinding machinery. By taking over and investing in the GRIT brand FEIN has set the standards even higher. The comprehensive knowledge of these two leading manufacturers adds profit to your bottom line.

GRIT by FEIN, not a one size fits all product. GRIT by FEIN belt grinders offer the ideal solution for each requirement – with our unique and exclusive modular system; powerful, basic belt grinders and mounted modules are designed and engineered for specific tasks within the entire application range – specialized machines for all applications in metal working trades and industries.

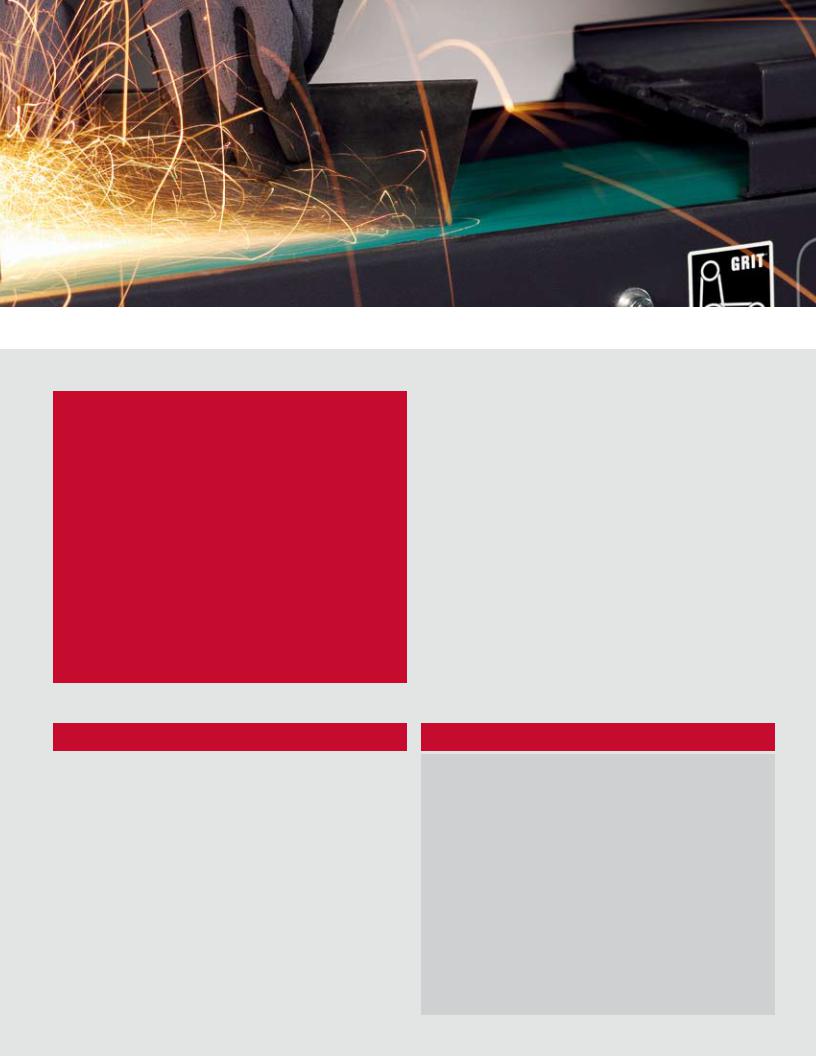

GX

GX – for use in the workshop

Constructed for operation and use in small; job, prototype and fabrication shops. The GRIT GX program stands out due to its high efficiency. Whether for rough grinding or surface polishing with GRIT GX machines you count on the quality you demand. GRIT GX machines can also be quickly converted to a variety of tasks, are reliable in operation and constructed to be tough and durable. The complete GRIT GX program can be found on pages 4 to 15.

All technical data provided by this brochure refer to the models in 220 V / 440 V, 3 ~, 60 Hz (US); 575 V, 3 ~, 60 Hz (CAN). There may be a few deviations of the given voltage and frequency values for the respective country-specific versions.

Your benefits:

Ideal for use in small workshops and for limited production runs

Covers all standard grinding tasks: Belt, radius and cylindrical grinding

Easy to assemble, quickly installed and quickly converted

Great work safety and machine reliability

Quality work results due to professional equipment and accessories

02

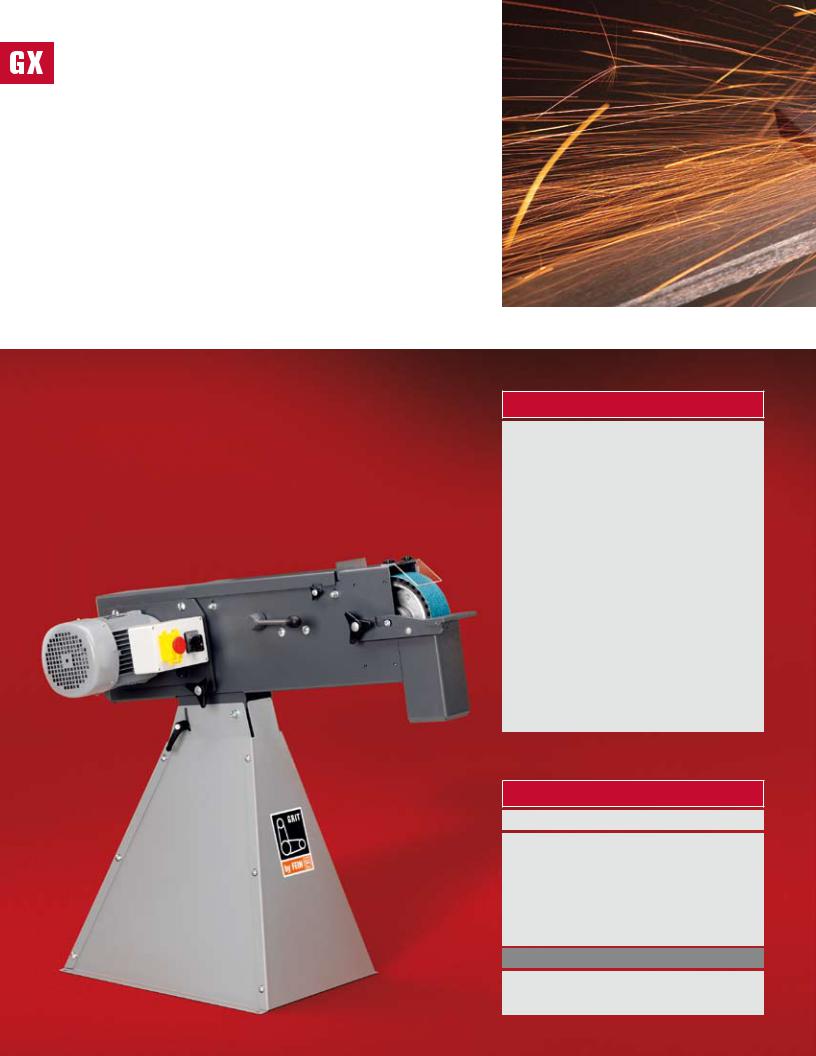

GI

GI – for use in industry

Industrial environments place extremely high demands on belt grinders; from high production, factory settings to harsh applications. The GRIT GI program is designed specifically for intense, industrial duty. All grinders are equipped with extremely powerful motors; even continuous operation times and high loads are no problem for the solidly built GI machines. Simple to operate the entire GI line increases work efficiency as well as machine reliability. The complete GRIT GI program can be found on pages 16 to 33.

All technical data provided by this brochure refer to the models

in 220 V / 440 V, 3 ~, 60 Hz (US); 575 V, 3 ~, 60 Hz (CAN). There may be a few deviations of the given voltage and frequency values for the respective country-specific versions.

Your benefits:

For industrial processing of steel, stainless steel and non-ferrous metals

Suitable for all common materials and grinding applications

Construction and parts are specifically adapted to heavy duty jobs

High abrasive performance leads to economical and professional work results

Great work reliability and simple operation

Special solutions for special applications available

0

Tough, flexible, cost-effective

In short: GRIT GX

If you work on steel or stainless steel every day, then GRIT GX belt grinders are the right choice. Twenty-five years of experience and know-how have evolved into GRIT – evident by the highly flexible design and machine reliability; the GX Grinders have the ability to easily adapt to various materials and applications – from rough grinding to mirror polishing.

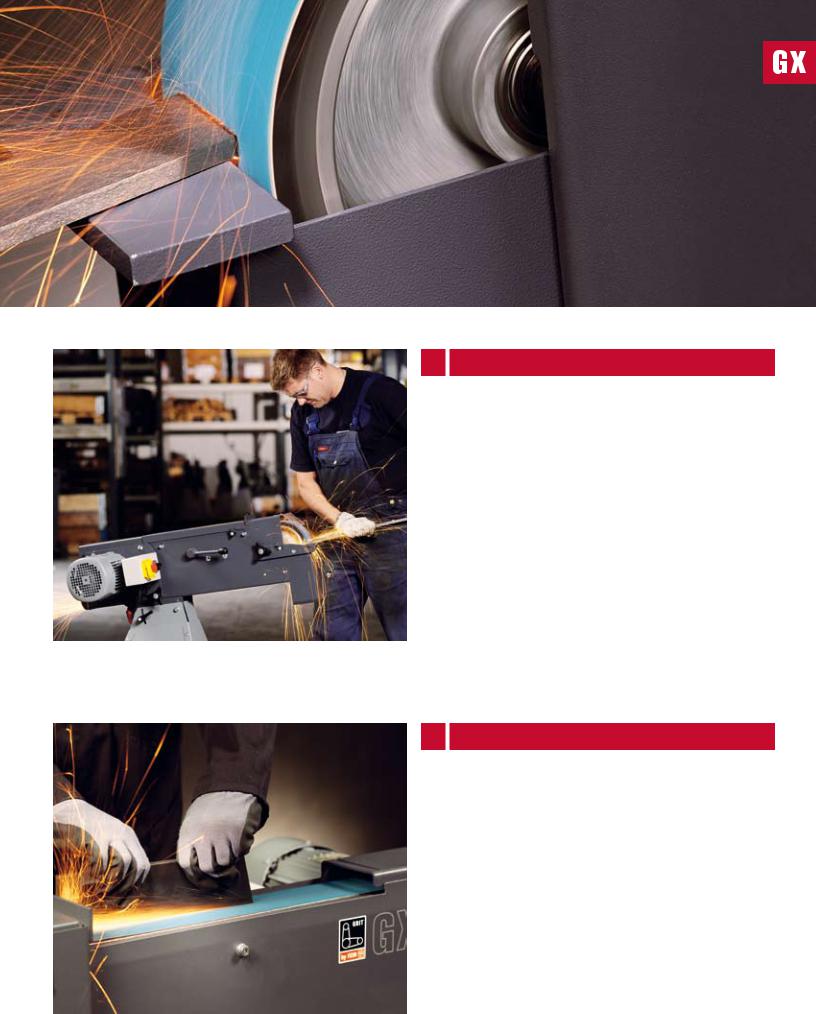

The GRIT GX functions according to the building-block principle. The belt grinder is the foundation of the system. By simply adding modules, the spectrum of perfor-

mance is highly enhanced. i.e. having the ability to notch pipe and tubing. The modular system is highly cost effective, saving both time and money. Grind efficiently and effectively with the GRIT GX system.

1. Belt Grinder GX 75 / GX 75 2H

Powerful belt sander in singleor two-speed models – the heart of the modular GX program. Highly productive and economical as a stand alone grinding center.

2. Radius Grinding Module GXR

Add-on module for quick and efficient radius grinding or notching. Radius grinding applications include: pipe, square/rectangular tubing, bar stock and profiles.

4. Deburring Machine GXE

Independent of the GX program, the GXE machine utilizes durable steel brushes for deburring steel and stainless steel workpieces.

Available with optional pedestal base and steel or stainless steel brushes.

5. Accessories

Accessories for the GX belt grinders range from superior performing grinding belts to a cooling unit module.

3. Cylindrical Grinding Module GXC

Add-on module for finishing and polishing applications on round, ferrous and non-ferrous stock – from rough grinding to mirror polish.

0

GRIT GX:

One system, multiple applications

Grinding, deburring, sanding, cylindrical finishing and notching of steel and stainless steel require a broad range of expensive, single purpose machinery. The GX system allows you to begin with a basic machine and expand capabilities as your requirements demand.

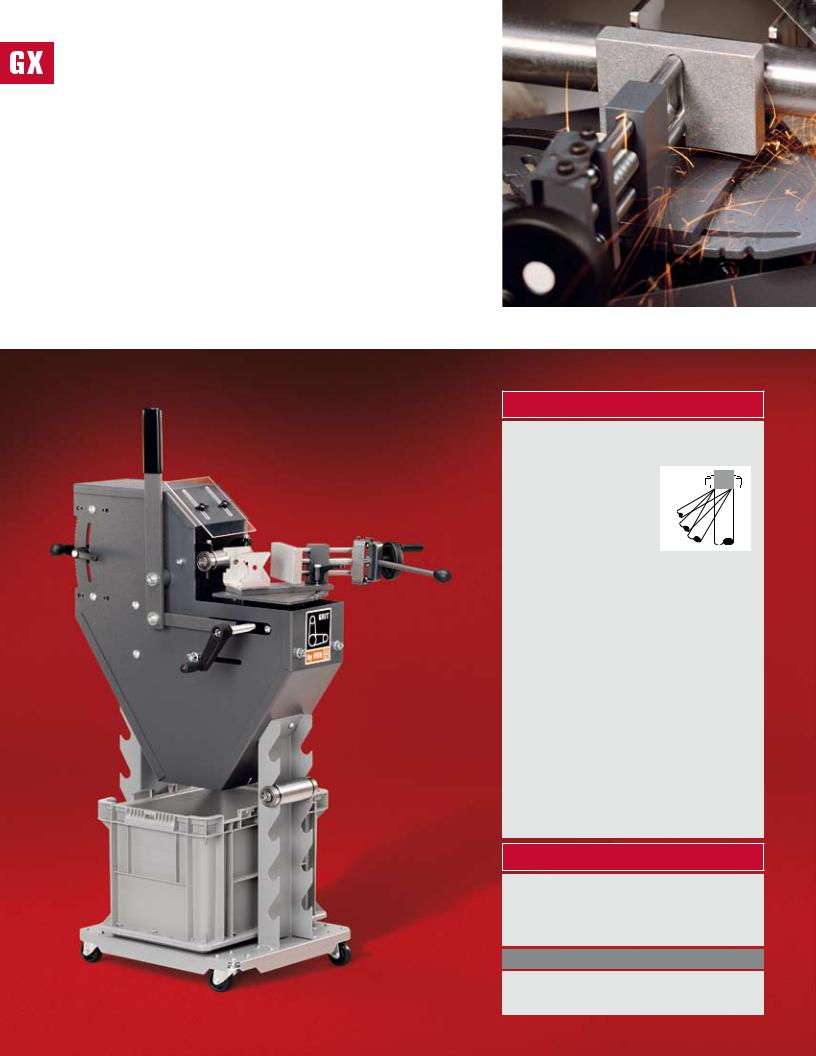

The system that grows with the requirements

The GRIT GX program is modularly designed. By attaching the appropriate modules you can quickly transform a basic belt grinder into a cylindrical or radius grinding machine. The easy and flexible GX program saves extensive time, money and space.

GX 75 / GX 75 2H |

GXR |

Belt grinder (basic units) |

Radius grinding module |

|

|

7 901 01 / 7 901 02 |

|

||

9 90 01 001 00 0 |

Radius grinding machine |

||

|

GX 75 / GX 75 2H |

GXC |

GXW |

|

Cylindrical |

Cooling lubricant |

|

Belt grinder (basic units) |

grinding module |

module |

|

7 901 01 / 7 901 02 |

7 901 03 |

7 901 04 |

Cylindrical grinding machine “Centerless” |

0

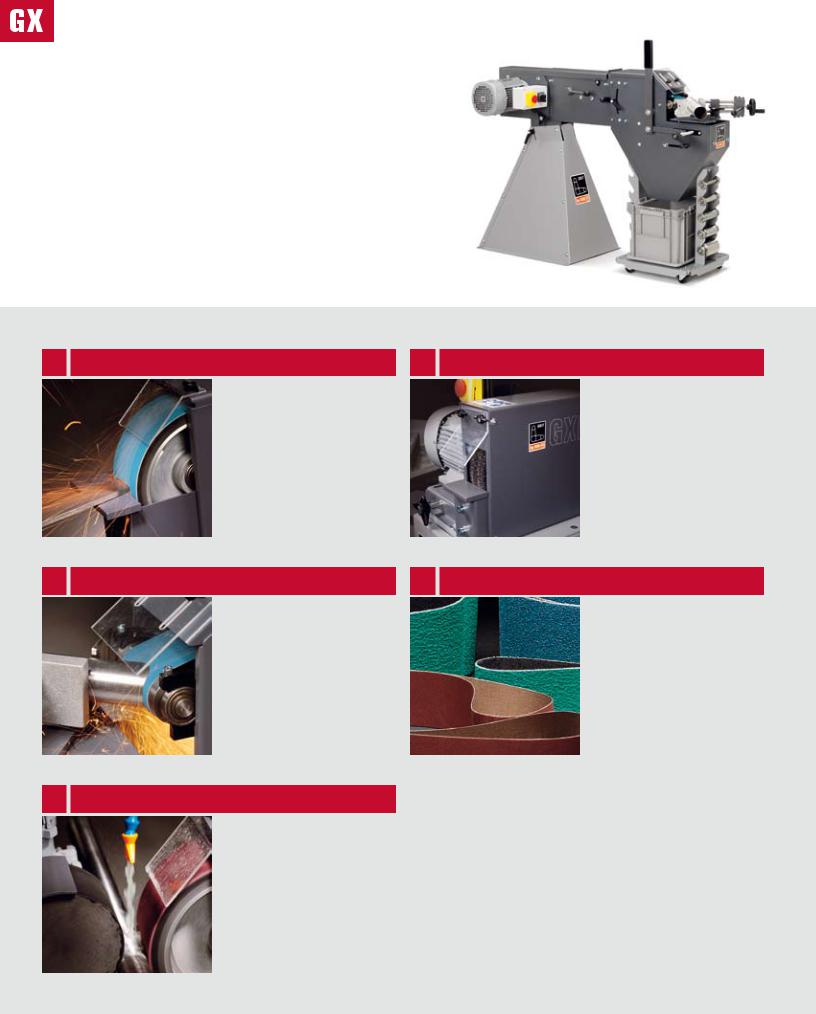

The perfect base:

GX 75* / GX 75 2H* Belt Grinder

The GX 75 or GX 75 2H is the heart of the system. A reliable, powerful belt grinder for professional applications – based on a foundation of 25 years experience in mechanical engineering and belt grinding: built solid, easy to assemble, and equipped with everything that eases the work and the operation.

GX 75* / GX 75 2H*

Tough AC motor provides grinding with constant speed

Ideal speeds for metal working: GX 75* at 3,600 rpm; GX 75 2H*, dual speed, 1,800 or 3,600 rpm

One step, self adjusting belt tension

Comfortable operation through an adjustable work level, height-adjustable support for flat grinding, and easy belt adjustment

Safe and reliable production results from

a stable machine base and solid grinding table

Integrated dust extractor connection (3 ⁄ " / 90 mm dia.)

Detachable grinding particle collector

* US version order #:

GX 75 2V; single speed; 220 V GX 75; single speed; 440 V GX 75 2H 2V; two speed; 220 V GX 75 2H; two speed; 440 V

Technical data

|

GX 75* |

GX 75 2H* |

Power |

3 kW (4 HP) |

1.5 / 2 kW (2/2.5 HP) |

Voltage US |

220 or 440 V (3~) |

220 or 440 V (3~) |

Amps US |

13.6 or 6.8 |

6.8 / 9.1 or 3.4 / 4.6 |

Voltage CAN |

575 V (3~) |

575 V (3~) |

Amps CAN |

5.2 |

2.6 / 3.5 |

Speed |

3,600 rpm |

1,800 / 3,600 rpm |

Belt size |

3" × 79" |

3" × 79" |

|

(75 × 2,000 mm) |

(75 × 2,000 mm) |

Connecting cable |

6.5 ft |

6.5 ft |

Weight |

145 lbs |

145 lbs |

PartBes ellnrNumber:. |

7 901790101 |

779010202 |

Included in delivery: |

|

|

1 grinding belt 3" × 79", K 36 Z

0

1.Versatility for every job

GX 75 belt grinders feature high power motors providing outstanding capacities to assure maximum grinding production. The GX 75 and GX 75 2H also exhibit minimal vibration characteristics during operation, due in part to a patented belt tensioning system. Operator production and comfort is a standard feature with GRIT GX belt grinders.

Whether grinding, weld seam polishing, chamfering, debur ring, or flat sanding – with Grit work is: efficient, productive and especially, cost effective!

2.Optimal flat grinding

Flat grinding is another standard feature with GRIT machines. A 3" x 16 ⁄ " (75 x 420 mm) height adjustable grinding table for flat work is standard on both GX 75 and GX 75 2H.

0

Everything simply fits together:

GXR radius grinding module

The perfect solution for pipe and tube fabrication. By attaching the GXR module, the GX 75 2H belt grinder converts to the ideal platform for precise radius profiles on pipe and round or square stock. Standard features include: a quick clamp system, traverse carriage, indexed degree table and depth stop. User friendly with professional results; quickly and effortlessly.

GXR

For precise grinding of profiles and pipes from ⅝"–3" (16–75 mm) dia.

For angles of 30° to 90°

30° / max. 1 ½" (37.5 mm) dia. |

30° |

|

45° / max. 2 ¹⁄ " (53.0 mm) dia. |

45° |

|

60° / max. 2 ⁄ " (64.5 mm) dia. |

60° |

90° |

90° / max. 3" (75.0 mm) dia. |

|

|

|

|

User-friendly, with integrated depth stop and vise with quick–clamping for round and square pipes as well as solid material

Contact rolls are available in all common sizes

Vise with stainless steel clamping jaws

Low speed (1,800 rpm) optimal for processing stainless steel. Less burrs and heat tarnish.

Moves easily on 4 casters

Can also be combined with the GI program (GI 75 / GI 75 2H).

Requires adapter # 6 99 02 186 00 0

Technical data

Pipe diameter |

⅝"–3" (16–75 mm) dia. |

Profile dimensions/ |

|

Square material max. |

3" × 3" (75 × 75 mm) |

Belt size |

3" × 88 ⁄ " (75 × 2,250 mm) |

Weight |

119 lbs |

PartBes ellnummerNumber |

9 90 01 0019 9001 001 00 0 |

Included in delivery: 1 contact roll 1 ¹¹⁄ " (42.4 mm) dia.; 1 contact roll 1 ⅞" (48.3 mm) dia.;

1 grinding belt 3" × 88 ⁄ ", K 36 Z, 1 water container

0

GX 75 / GX 75 2H |

GXR |

|

|

||

|

9 90 01 001 00 0 |

|

Belt grinder |

|

|

(basic units) |

Radius grinding module |

Radius grinding machine |

1. Perfect fit at any angle

It makes no difference whether pipes, profiles, or solid material is being ground – the GXR radius grinding module is ideally suited. Precise, efficient and economical processing is achieved through a quickly indexed angle gauge and unique, quick clamp vise* for round and square stock – comes standard with stainless steel jaws.

(* patent pending)

2. Custom fit contact rollers

Pipes sized ⅝"– 3" (16–75 mm) dia. and an attack angle

of 30° to 90° can be ground to a perfect fit with the radius grinding module. The extensive GRIT contact roller selection covers all standard pipe and tube diameters.

3. With length stop for production in series

The retrofitable length stop for the GXR radius grinding module ensures consistent, precise results in repetitive production. The length stop is adjustable through 39 ⅜" (1 m) and can be added at any time.

0

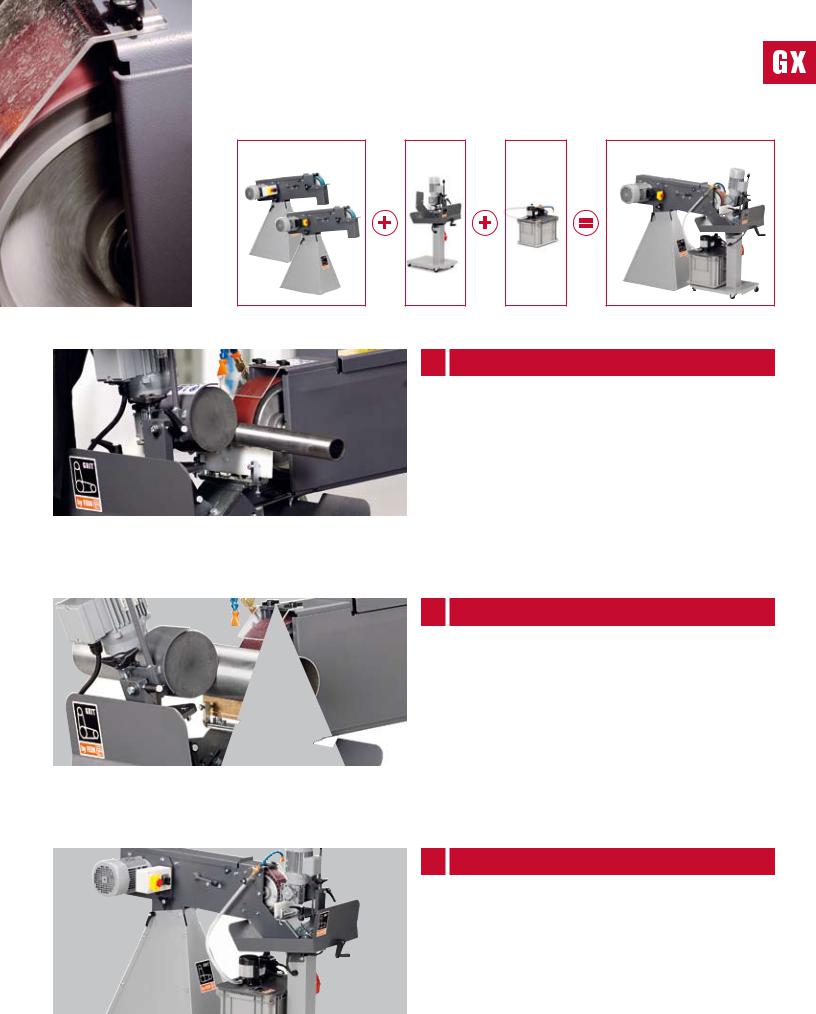

Quality and efficient finishing:

GXC cylindrical grinding module

The GXC cylindrical grinding module allows for perfect surfaces in the simplest manner. The conversion to a “Centerless” cylindrical grinding machine is done in just a few steps. Efficiency and flexibility are apparent in the design and construction.

GXC

For grinding of pipes and shafts from ⅜"–4" (10–100 mm) dia.

High process speed for highest surface quality.

Suitable for wet-grinding when used with the GXW cooling lubricant module

Moves easily on 4 casters

Can also be combined with the GI program (GI 75 / GI 75 2H).

Requires adapter # 6 99 02 187 00 0

Technical data

Pipes |

⅜"–4" (10–100 mm) dia. |

Belt size |

3" × 79" (75 × 2,000 mm) |

Voltage US |

220 / 440 V (3~) |

Voltage CAN |

575 V (3~) |

Weight |

106 lbs |

PartBes ellnummerNumber |

7 901703901 03 |

Included in delivery: 2 guide rail, nylon; 1 guide rail, brass, 1 connecting cable with CEE plug 16 A

GXW Cooling lubricant module

Voltage US |

220 / 440 V (3~) |

Voltage CAN |

575 V (3~) |

Weight |

19 lbs |

PartBes ellnummerNumber |

7 901790104 04 |

Included in delivery:

¼ gal (1 liter) cooling lubricant emulsion (1:30)

10

Belt grinder (basic units)

GX 75 / GX 75 2H

Cylindrical |

Cooling |

Cylindrical grinding machine |

grinding |

lubricant |

“Centerless” |

module |

module |

|

GXC |

GXW |

7 901 03 |

7 901 04 |

1. Quick brilliant results all around

Perfect surface quality and high process speeds on pipes and shafts are no problem for the GXC cylindrical grinding module. Even commercially available fleece belts can be used in connection with the GX 2H basic unit. The feed rate

can be adjusted for various materials through an infinite range up to 6.6 ft/min (2 m/min).

2. Always on the right track

Quality surface finishes are always assured with the GXC. Included are two nylon and one brass guide rail for all your finishing needs. The brass rail is used for wet or dry finishing on rough surfaces such as corrosion, scale, etc. The nylon rail is used for wet finishing on sensitive materials when a highly polished surface is required.

3. GXW for wet grinding

There are several arguments for wet grinding using the GXW cooling lubricant module: A liquid coolant captures the metal dust, which increases the service life of the sanding belts; the finishing results are noticeably improved; and thanks to the reduction of heat generated during grinding the corrosion risk for stainless steel pipes is reduced. A self contained, closed circulation system minimizes coolant consumption.

11

Loading...

Loading...