Enviro Venice, 1200-V Insert, 1700-V Insert User Manual

SHERWOODINDUSTRIESISANENVIRONMENTALLYRESPONSIBLECOMPANY.THISMANUALISPRINTEDONRECYCLEDPAPER.

PLEASE KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

Venice

Wood Stove

BY: SHERWOOD

SHERWOOD  INDUSTRIES LTD

INDUSTRIES LTD

OWNER’S MANUAL

Models: 1200-V & 1700-V Insert

INSTALLER:

Leave this manual with the wood stove.

CONSUMER:

Retain this manual for future reference.

Contact your local building or fire officials, or the authority having jurisdiction about restrictions and installation inspection requirements in your area.

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD BURNING ROOM HEATER. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

Tested & |

O-TL |

Beaverton |

Listed By |

Oregon USA |

|

|

C |

|

|

OMNI-Test Laboratories, Inc, |

|

This heater meets the U. S. Environmental Protection Agencies emission limits for wood heaters sold after July 1st, 1990. Under specific conditions this heater has been shown to deliver heat at rates ranging from 11,479 to 34,196 BTU per hour for the 1200-V and from 9,425 to 31,780 BTU per hour for the 1700.

50-1040

Table of Contents

Safety Precautions.......................................................................................... |

3 |

Operating Instructions..................................................................................... |

4 |

Building Your Fire................................................................................. |

5 |

How It Works...................................................................................... |

9 |

Specifications................................................................................................ |

10 |

Air Control......................................................................................... |

10 |

Specifications..................................................................................... |

10 |

Clearances To Combustibles - 1200-V Insert......................................... |

11 |

Clearances To Combustibles - 1700-V Insert......................................... |

12 |

Dimensions - 1200-V Insert................................................................. |

13 |

Dimensions - 1700-V Insert................................................................. |

14 |

Installation................................................................................................... |

15 |

Removal From Pallet.......................................................................... |

15 |

Modifications For Installation with 191/16” (484mm) High Lintel........... |

15 |

Masonry Fireplace Installation............................................................. |

16 |

Installation Using A Block-Off Plate For USA Only.................................. |

19 |

Model 1200-V Brick Placement & Tube Locations................................. |

21 |

Model 1700-V Brick Placement & Tube Locations.................................. |

22 |

C-Cast Ceramic Baffle Installation........................................................ |

23 |

Fan Wiring Diagrams.......................................................................... |

23 |

Fan Removal...................................................................................... |

24 |

Removal Of Face................................................................................ |

25 |

Installation Of The Surround Panel...................................................... |

25 |

Rating Label................................................................................................. |

26 |

Parts List...................................................................................................... |

27 |

Parts Diagram............................................................................................... |

28 |

Warranty...................................................................................................... |

29 |

Installation Data Sheet.................................................................................. |

32 |

2

Safety Precautions

FOR SAFE INSTALLATION AND OPERATION OF YOUR “ENVIRO” WOOD STOVE, PLEASE CAREFULLY READ THE FOLLOWING INFORMATION:

●Please read this entire manual before you install and use your new woodstove. Failure to follow instructions may result in property damage, bodily injury or even death. Be aware that local Codes and Regulations may override some items in this manual. Check with your local inspector.

●If this appliance is not properly installed, operated and maintained, a serious house fire could result. Do not use any makeshift materials during installation, maintenance, or replacement.

●Never place wood, paper, furniture, drapes or other combustible materials near the stove. Do not let children or pets touch it when it is hot.

●Operate only with the door tightly closed and burn wood directly on the stove hearth. Do not operate if the door glass is broken or a gasket is missing or damaged. Do not alter the combustion air control valves. Dangerous overfiring could occur which could ignite creosote in the chimney or cause a house fire.

●At least 12 square inches (77.4 cm2) of fresh outside air should be admitted into the room or directly to the stove through a 4 inch (10.16 cm) diameter pipe. For the stove to operate combustion-air must be supplied through either the bottom or the back of the pedestal.

●Do not burn coal or charcoal as there is danger of carbon monoxide being produced. Do not use chemical fluids to start or re-fresh the fire. Do not burn garbage or flammable fluids such as gasoline, grease, naphtha or engine oil. Never let the stove become hot enough to get any part red or glowing red.

●Burning wet, unseasoned wood could cause excessive creosote accumulation in the flue pipe. When ignited, it could cause a chimney fire that could result in a serious house fire.

●Do not use grates, andirons or any other methods to support or raise the fire up off the hearth of the appliance.

●This appliance is tested to ULC-S627 Standard for Space Heaters for Use with Solid Fuel, ULC-S628 Standard for Fireplace Inserts, & UL 1482 Standard for Safety for Solid-Fuel Type Room Heaters.

●Both the 1200-V & 1700-V Fireplace Inserts are approved for installed into a zero-clearance fireplaces in the U.S. In Canada refer to local building or fire officials for restrictions and installation inspection

●In Canada the existing chimney must be lined to the termination for all masonry installs.

IMPORTANT: The following must be done to ensure proper operation. Failure to do so will cause extreme overheating and possible personal injury or property damage:

• If an outside air supply has not been added to this appliance, please ensure that the 4” inch fresh air outlet on the back of the pedestal is removed.

3

Operating Instructions

FIRST START

When first installed, the chimney, firebricks and steel are cold and it usually takes several hours on a fairly high burn for them to become hot and dry enough for the stove to function well. We recommend during the unit’s first burn that a door and window are opened to vent the smoke and fumes created from the unit’s paint curing. The paint will smell a little for the first burn or two as it cures.

DISPOSAL OF ASHES:

If you let the ashes accumulate two or three inches on the floor they tend to burn themselves up.

The fireplace insert models do not have and ash drawer so the ashes will need to be scooped into a metal container with a tightly fitting lid. Place the closed container on a non-combustible floor, well away from combustible materials.

If the ashes are to be buried in soil or otherwise locally dispersed, keep them in a closed container until all cinders have cooled. Small amounts of cold wood ash can be used in the garden or compost.

FAN OPERATION:

All models have been approved for operation with the fans supplied by the manufacturer. On medium or high burns, using a fan will increase the heat transfer slightly. Route the power supply cord along the floor behind the stove where it will remain cool.

1.Plug the fan assembly into a standard three (3) prong grounded electrical receptacle.

2.An auto/off/manual rocker switch allows the fan to be turned on manually, or automatically. When this switch is up, it will be set to manual operation; the center position is off, and when pushed down, it will be set to automatic.

3.In automatic mode set the rotary switch to the desired setting, once operating temperature is reached, the fan temperature sensor will turn the fan on. When the unit cools down, the fan temperature sensor will shut the fan off automatically.

4.In manual mode the fan can be turned on and off any time using the rotary switch.

REPLACING THE GLASS:

Never strike or slam the door, hit the glass or let burning wood rest against it. If the glass cracks when the fire is burning, do not open the door until the fire is out and do not operate the stove again until the glass has been replaced. If the glass is damaged in any way, a factory replacement is required (see “PARTS LIST”). To replace the glass, remove the steel retaining clips and all loose glass. Replace only with Neoceram 5 mm glass 16.61” (422 mm) x 10.63” (270 mm) and wrap the edges with 0.125” (3.2 mm) x 0.5” (13 mm) self-adhesive fiberglass gasket.

Wear gloves when handling damaged glass door assembly to prevent personal injury. When the glass door assembly is being transported, it must be wrapped in newsprint and tape and/or a strong plastic bag.

The glass must be purchased from an ENVIRO dealer. No substitute materials are allowed.

FIRE EXTINGUISHER AND SMOKE DETECTION:

All homes with a solid fuel burning stove should have at least one fire extinguisher in a central location known to all in the household and a smoke detection devise in the room containing the stove. If it sounds the alarm, correct the cause but do not deactivate. You may choose to relocate the smoke detection devise within the room; DO NOT REMOVE THE SMOKE DETECTOR FROM THE ROOM.

4

Operating Instructions

CREOSOTE - ITS FORMATION AND REMOVAL:

When wood is burned slowly, it may produce tar and other vapors that, combined with moisture, form creosote. These vapors condense in the relatively cooler chimney flue of a slow burning fire and, if ignited, make an extremely hot fire. Therefore, the smoke pipe and chimney should be inspected biweekly during the heating season to determine if a build-up has occurred. If creosote has accumulated it should be removed to reduce the risk of a chimney fire.

MAINTENANCE:

At the end of each heating season clean the chimney and the smoke pipe. If soot has accumulated above the top baffle bricks, remove, clean, and then replace them. If the secondary air tube is badly eroded, replace it. Replace worn door gaskets and broken bricks as needed.

FAILURE TO INSPECT AND CLEAN YOUR CHIMNEY SYSTEM REGULARLY CAN RESULT IN A CHIMNEY FIRE, WHICH COULD DAMAGE THE CHIMNEY OR CAUSE A HOUSE FIRE.

CHIMNEY OR RUN AWAY FIRE:

1.Call local fire department (or dial 911)

2.Close the draft fully

3.Examine the flue pipes, chimney, attic, and roof of the house, to see if any part has become hot enough to catch fire. If necessary, spray with fire extinguisher or water from the garden hose.

4.Do not operate the stove again until you are certain the chimney and its lining have not been damaged.

BUILDING YOUR FIRE:

Proper operation of your stove will help to ensure safe, efficient heating. Please take a few moments to review these simple operating procedures.

IMPORTANT: Please be aware when loading your stove that the air tubes in the rear are lower.

1. Fuel Selection:

This stove is designed to burn natural wood only. Higher efficiencies and lower emissions generally result when burning air-dried seasoned hardwoods, as compared to softwoods or to green or freshly cut hardwoods. DO NOT BURN the following: treated wood, coal, garbage, solvents, colored papers, or trash. Burning these may result in the release of toxic fumes and may poison or render the catalytic ineffective. Burning coal, cardboard, or loose paper can produce soot, or large flakes of char or fly ash that can coat the combustor, causing smoke spillage into the room, and rendering the combustor ineffective.

2. Building/Maintaining a Fire:

a)Open the primary air slide by pulling it all the way to the right.

b)Place a base of crumpled uncolored newspaper in the bottom of the stove. Lay pieces of kindling on top of the newspaper and light it.

CAUTION: “Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids to start or “freshen up” a fire in this heater. Keep all such liquids well away from heater while it is in use.

c)As the kindling begins to burn, add several larger pieces of wood until the fire is burning well. At this point, regular size logs may be added.

NOTE: Until the fire is burning well, leave the air controls fully open.

5

Operating Instructions

d) Regulate the heat output of the stove by adjusting the air controls to allow a larger fire and vice versa. A short period of experimentation with the control settings will allow you to regulate the heat output to keep your home comfortable.

Do not use a grate or elevate the fire. Build wood fire on the stove firebox hearth floor.

3. Refueling the Stove:

Use a long pair of gloves (barbecue gloves) when feeding the fire because these stoves burn at the front. They are clean and efficient but they are also very hot and gloves are useful. Keep a small steel shovel and whisk nearby for moving a log or lifting a fallen ember and for keeping the hearth clean.

a)Before attempting to add fuel to the stove, OPEN the damper control fully by pulling it all the way out. This allows the chimney to carry away the additional smoke, which occurs when the door is open.

b)DO NOT OVERLOAD THE STOVE. Normally, three or four logs will provide heat for several hours. Never operate this stove where portions glow red hot.

c)DO NOT OVERFIRE. If the heater or chimney connector glows, you are overfiring.

d)CAUTION: DO NOT PLACE FUEL WITHIN SPACE HEATER INSTALLATION CLEARANCES OR WITHIN THE SPACE REQUIRED FOR CHARGING AND ASH REMOVAL.

4. For Maximum Efficiency:

When the stove is hot, load it fully to the top of the door opening and burn at medium low settings. When the fuel is mostly consumed, leaving a bed of red coals, repeat the process. Maximum heat for minimum fuel occurs when the stove top temperature is between 250°F (120°C) and 550°F (290°C). The most likely causes of dirty glass are: not enough fuel to get the stove thoroughly hot, burning green or wet wood, closing the draft until there is insufficient air for complete combustion, or a weak chimney draw. Indeed, the cleanness of the glass is a good indicator of the stove operating efficiently.

Helpful Hints Worth Repeating

1. Helpful advice on the correct way to start your fire.

a)You will need small pieces of dry wood, called kindling, and paper. Use only newspaper or paper that has not been coated or had other materials glued or applied to it. Never use coated (typically advertising flyers) or coloured paper.

b)Always open the door of the wood stove slowly to prevent suction and drawing smoke into the room.

c)Crumple several pieces of paper and place them in the center of the firebox and directly onto the firebricks of the wood stove. Never use a grate to elevate the fire.

d)Place small pieces of dry wood (kindling) over the paper in a “teepee” manner. This allows for good air circulation, which is critical for good combustion.

e)Light the crumpled paper in 2 or 3 locations. Note: It is important to heat the air in the stovepipe for draft to start.

f)Fully open the air controls of the wood stove and close the door until it is slightly open, allowing for much needed air to be introduced into the firebox. Never leave the door fully open, as sparks from the kindling may fly out of the stove, causing damage or injury. As the fire begins to burn the kindling, some additional kindling may be needed to sustain the fire. DO NOT add more paper after the fire has started.

6

Operating Instructions

g)Once the kindling has started to burn, add some smaller pieces of seasoned, dry firewood. Note: Adding large pieces at the early stages will only serve to smother the fire. Continue adding small pieces of seasoned dry firewood, keeping the door slightly open until each piece starts to ignite. Remember to always open the door slowly between placing wood into the fire.

h)Once the wood has started to ignite and the smoke has reduced, close the wood stove door fully. The reduction of smoke is a good indication that the draft in the chimney has started and good combustion is now possible. Larger pieces of seasoned, dry firewood can now be added when there is sufficient space in the firebox. Adjust the air control setting to desired setting. Note: The lower the air control setting, the longer the burn time of your firewood.

2. What type of wood is best to use as firewood?

Both hardwood and softwood burn well in this stove. Both woods contain about 8,000 BTU/lb (18,570 KJ/Kg), but hardwood is generally more dense, will weigh more per cord, and burns a little slower and longer. Cutting firewood so that it will fit horizontally, front to back, makes it easier loading and less likely for the fuel to roll on the glass. Except for a cold start, there is no need to crisis-cross the logs. Ideal length for the logs used in the 1200-V would be about 16“ (381 mm) but it can burn pieces up to 18” long. Ideal length for the logs used in the 1700-V would be about 18“ (381 mm) but it can burn pieces up to 20” long logs. Burn only dry, seasoned wood. It produces more heat and less soot or creosote. Freshly cut wood has about 50% moisture. A 10 pound (4.5 Kg) log contains 5 pounds (2.3 Kg) of water. To season firewood, split and stack it so that air can get to all parts of the wood. Burn beach wood only if its salt content has been washed away in a season of rain and then the wood dried. To prevent smoke spillage when refueling, open the door slowly.

3. What does dry, seasoned wood mean?

Wood that has been dried for a period of one year in a well-ventilated and sheltered area would be considered dry, seasoned wood. Wood from slow-growing trees is generally considered better than wood from fast-growing trees. To season firewood, split and stack it so that air can get to all parts of the wood.

4. Will following the above-listed steps for starting a fire mean perfect results every time?

The quick answer is ‘most of the time’. There are many variables that may affect your success when starting a fire. Most of those variables and how to deal with them will be learned through experience. Your ability to start a good fire will significantly increase with time and patience. Some of the reasons for poor stove performance will be covered in the next section of these instructions.

5. Why can’t I get the fire lit?

Damp or wet wood and poor drafts are the main reasons for poor results in starting a fire. Always use dry, seasoned wood for your fire. Even wood dried for two years will be difficult to ignite if it has become wet.

6. Is it normal for soot to cover the glass at the beginning of a fire?

Your stove has been built with an air-wash system that will help keep the glass clear when the firebox has reached a good operating temperature and has a good draft. Normally a hot stove will keep the glass clean, but if you must clean the glass, use a soft cloth with no abrasive and clean only when cold. Cold firebox temperature and poor draft cause sooting of the glass. Once the firebox temperature and the draft increase, the soot will burn off.

7

Operating Instructions

7. What is draft?

Draft is the ability of the chimney to exhaust or draw smoke produced during the normal combustion process. Too much draft may cause excessive temperatures in the appliance and may damage the appliance. Inadequate draft may cause backpuffing or “plugging” of the chimney. There is a certain amount of draft that is required to allow for your stove to function at its’ highest efficiency. A water column gauge can be used to reference this amount.

8. What can cause a poor draft?

The most common factors for poor draft are:

a)Air supply

b)Environmental conditions

c)Cold chimney temperature

d)Poor chimney installation and maintenance

e)Atmospheric pressure

a)Air supply – Inside the home, normal household appliances such as clothes dryers and forced-air furnaces compete for air, resulting in air starvation to the fire. This creates a condition in the house known as negative pressure. When a house experiences negative pressure, the combustion gases can be drawn from the chimney and into the house. This condition is commonly referred to as downdrafting. Increased amounts of insulation, vinyl windows, extra caulking in various places and door seals can all keep heat in but may also make a home too airtight. An easy way to stop negative pressure in a home is to crack a window in the room containing the stove.

b)Environmental Conditions - High trees, low-lying house location such as in a valley, tall buildings or structures surrounding your house and windy conditions can cause poor draft or down-drafting.

c)Cold Chimney Temperature - Avoid cold chimney temperatures by burning a hot fire for the first fifteen to forty minutes, being careful not to over-fire the stove. If any part of the chimney or parts of the stove start to glow, you are over-firing the stove. Where possible, install a temperature gauge on the chimney so temperature drops can be seen.

d)Chimney Installation and Maintenance - Avoid using too many elbows or long horizontal runs. Too short a chimney can cause difficult start-up, dirty glass, back smoking when door is open, and even reduced heat output. Too tall a chimney may prompt excessive draft, which can result in very short burn times and excessive heat output. If in doubt, contact a chimney expert and/or chimney manufacturer for help. Clean chimney, rain caps and especially the spark arrestor regularly, to prevent creosote buildup, which will significantly reduce chimney draw and possibly a chimney fire.

Note: These instructions are intended as an aid and do not supercede any local, provincial or state requirements. Check with officials or authorities having jurisdiction in your area.

8

Operating Instructions

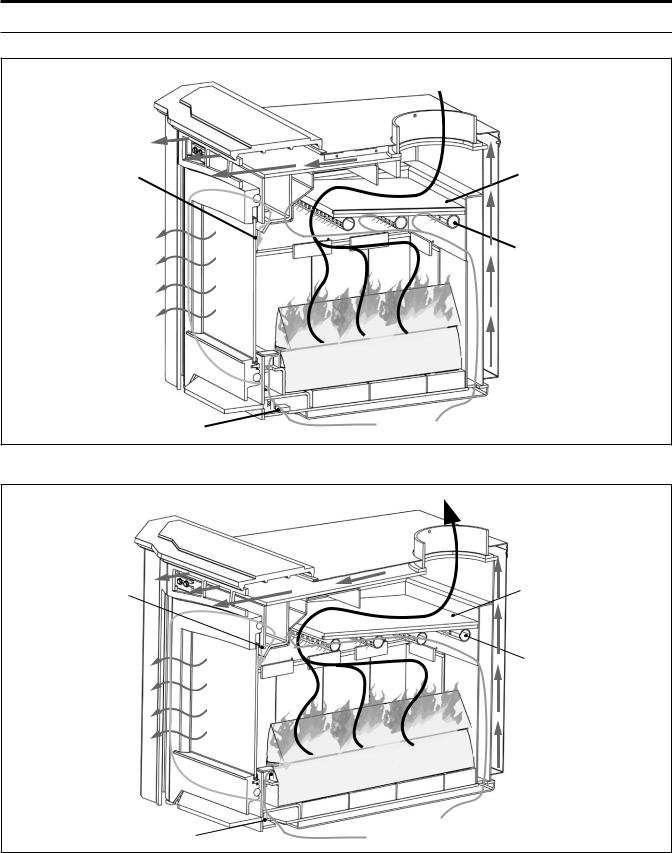

HOW IT WORKS:

Exhaust Smoke

Convection Heat

Primary air; window air wash (cooler air to keep the glass clean).

Radiant Heat

Pilot air through

Twin pilot injection ports.

Twin pilot injection ports.

1/2" Ceramic baffle; reflects heat down to burn the particles in the smoke.

Secondary air tubes; creates a second burn on the particles in the smoke for a more efficient & cleaner burn.

Slider plate; used |

Intake air. |

for air flow control. |

|

|

Figure 1: 1200-V Air Flow Path. |

|

Exhaust Smoke |

Convection Heat |

1/2" Ceramic baffle; |

|

reflects heat down |

Primary air; window |

to burn the particles |

air wash (cooler air to |

in the smoke. |

keep the glass clean). |

Secondary air tubes; |

|

|

|

creates a second burn |

|

on the particles in the |

|

smoke for a more efficient |

Radiant Heat |

& cleaner burn. |

|

Pilot air through

Twin pilot Seasoned Firewood injection ports.

Slider plate; used |

|

for air flow control. |

Intake air. |

Figure 2: 1700-V Air Flow Path.

9

Specifications

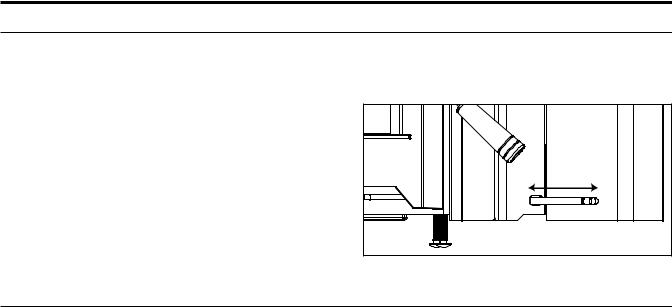

AIR CONTROL:

The air wash and pilot air (control the amount of air to the fire) are controlled by the rod located on the right side of the unit. To increase your air, pull the rod out and to decrease, push the rod in. All the units have a secondary air that flows through the tubes at the top of the firebox, just below the baffles.

Pull this control all the way out when first starting the stove. Once the fire has been established you may adjust this control to set the burn rate of the fire. If this damper is closed at first start-up, the fire will burn very slowly and could soot the appliance.

When shutting down the stove, fully open the air control. This allows the chimney temperatures to remain as high as possible for as long as possible. Cold chimney temperatures create creosote.

Increase air - pull rod out |

Decrease air - push rod in |

Figure 3: Air Control Rod.

SPECIFICATIONS:

Table 1: 1200-V & 1700-V General Information.

Model |

1200 Insert |

1700 Insert |

|

|

|

|

|

Width x Depth |

273⁄4” x 211⁄2” |

273⁄4” x 26” |

|

(705 mm x 546 mm) |

(705 mm x 660 mm) |

||

|

|||

|

|

|

|

Height of body |

191/16” (484 mm) or 199/16” (497 mm) |

||

Fire box size |

16.1” x 18.25” x 11.15” |

20.65” x 18.25” x 11.95” |

|

(depth x width x height) |

(409 mm x 464 mm x 283 mm) |

(525 mm x 464 mm x 304 mm) |

|

|

|

|

|

Capacity |

1.85 feet3 |

2.5 feet3 (0.0708 meter3) |

|

(0.0526 meter3) |

|||

* Approximate heating area |

800 - 1,500 feet2 |

1,000 - 2,200 feet2 |

|

(74.3 - 139.4 meter2) |

(92.9 - 205.4 meter2) |

||

**E.P.A. output rating |

11,479 to 34,196 BTU/hour |

9,425 to 31,780 BTU/hour |

|

(3,361 to 10,013 watt) |

(2,760 to 9,306 watt) |

||

|

|||

|

|

|

|

*Duration on low burn |

6 -10 hours |

8 - 12 hours |

|

|

|

|

|

Weight with packaging |

335 lb (151.95 Kg) |

390 lb (176.90 Kg) |

|

|

|

|

|

E.P.A. Emissions |

3.3 grams/hour |

4.48 grams/hour |

|

(0.116 oz/hour) |

(0.158 oz/hour) |

||

|

|||

|

|

|

|

Surround Panels |

|

|

|

|

|

||

Standard (width x height) |

461⁄8” x 28” (1171 mm x 711 mm) |

||

|

|

||

Oversized (width x height) |

461⁄8” x 331⁄8” (1171 mm x 843 mm) |

||

|

|

||

|

|

||

Rating Label Location |

Side of Unit; Behind Right Shroud |

||

|

|

|

|

10

Loading...

Loading...