Emerson Micro Motion 3000 User Manual

Product Data Sheet

PS-00291, Rev. B

May 2007

Micro Motion® Series 3000 Transmitters and Discrete Controllers

Micro Motion® Series 3000 electronics combine transmitter functions and PLC capabilities in one instrument. Series 3000 models feature MVD™ technology, providing high-speed DSP capabilities and a broad range of specialty applications.

Large operator interface for easy setup & control

•128 x 128 pixel display enhances view of process

•Easy to read menus and advanced help system

Transmitter and discrete control from a single instrument

•Functions as an advanced process transmitter or as a discrete batch controller, with 8 I/O channels for maximum adaptability

•HART® and Modbus® support expand communications options

Wide variety of applications

•Concentration & net flow measurement

•Custody transfer with batch control

•Patented meter verification application

2400S Compact integral transmitter

1700 Versatile

2700 field-mount transmitter

1500 Compact

2500 control-room transmitter

3300 |

Frequency-input |

3350 |

discrete controller |

3500 Integrated control

3700 and measurement platform

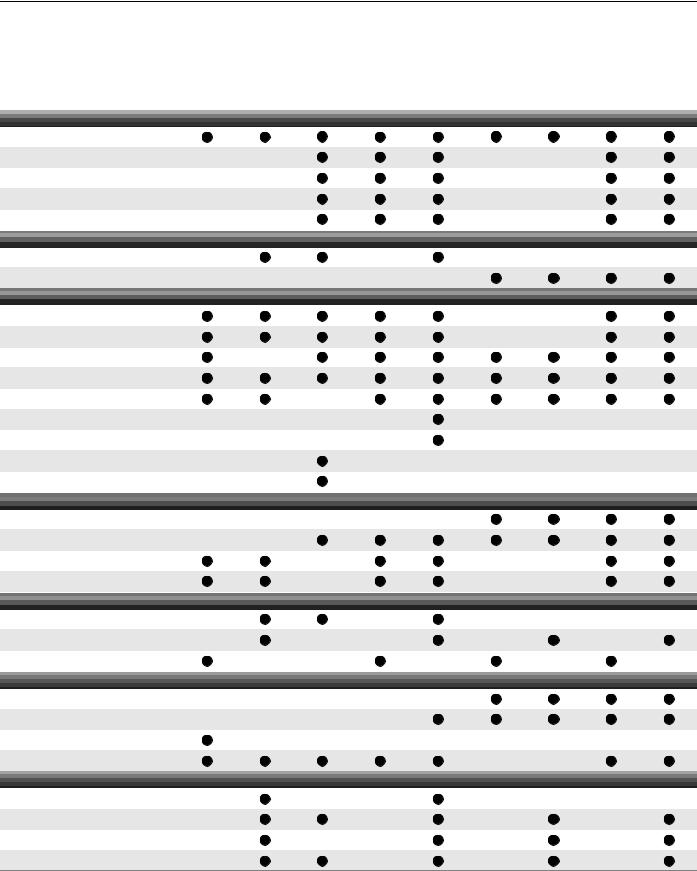

Micro Motion transmitters and controllers

Micro Motion transmitters and controllers fit a wide variety of application needs. The table below can help determine which Micro Motion products are right for your process. For more detailed product information, consult the appropriate Product Data Sheet or contact your local Micro Motion representative.

1500 |

1700 |

2400S |

2500 |

2700 |

3300 |

3350 |

3500 |

3700 |

Output variables

Mass / volume flow

Net mass / volume flow

Temperature

Density

Concentration

Local display

2-line

Multi-line

Outputs

4–20 mA

10 kHz pulse

Discrete

HART®

Modbus®

FOUNDATION fieldbus™

PROFIBUS-PA

PROFIBUS-DP

DeviceNet®

Inputs

10 kHz pulse

Discrete

4-wire Coriolis sensor

9-wire Coriolis sensor

Mounting

Integral – Field

Remote – Field

Remote – Control room

Application type

Batch controller

Custody transfer

Filling & dosing

Meter verification

Hazardous approvals

C1D1

C1D2

Zone 1

Zone 2

2 Micro Motion® Series 3000 Transmitters and Discrete Controllers

Series 3000 transmitters and discrete controllers

MVD technology. MVD technology makes your Micro Motion meter work smarter. Front-end digital processing dramatically reduces signal noise and gives you faster response time compared to analog devices.

Only MVD technology allows you to:

•Measure multiple variables

•Install easily with a standard 4-wire signal cable

•Identify and resolve problems easily with built-in smart diagnostics

•Choose transmitter capabilities based on your application’s needs

•Upgrade transmitter functionality as needed

Series 3000 transmitters and controllers with MVD technology. Model 3500 and 3700 transmitters deliver process measurement and discrete control based on direct input from a Micro Motion Coriolis meter. Model 3300 and 3350 controllers provide discrete control based on a frequency input from a remote transmitter. Series 3000 models are available with specialty applications, such as batch control, enhanced density measurement, petroleum measurement, custody transfer, and meter verification.

Configuration, operation, and maintenance are all accomplished using the innovative Series 3000 user interface. The interface features a large, easy-to- use backlit display with big, tactile-feedback push buttons. Other user interfaces (such as hand-held communication devices) are not required, but can be used. Modbus and HART communication allow configuration devices such as ProLink II, AMS, and HART Communicators to be used with the

Series 3000, and the Series 3000 can be integrated into a PlantWeb network.

Contents

Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Interface/display. . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . 5 Input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Environmental specifications . . . . . . . . . . . . . . . . . 8 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Hazardous area classifications . . . . . . . . . . . . . . . 9

Model 3100 accessory . . . . . . . . . . . . . . . . . . . . 10

Model 3500/3700 liquid flow performance . . . . . 10

Model 3500/3700 density

performance (liquid only). . . . . . . . . . . . . . . . . . . 11

Model 3500/3700 gas flow performance . . . . . . . 11

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ordering information . . . . . . . . . . . . . . . . . . . . . . 16

Micro Motion® Series 3000 Transmitters and Discrete Controllers |

3 |

Housings

Rack-mount |

19-inch (486.2 mm) rack-mount housing meets DIN standard 41494 and IEC 297-3 |

|

Front panel is rated IP40 |

Panel-mount |

Front panel with bezel is rated NEMA 4X (IP65) |

Field-mount |

Compartment with threaded cover contains electronics |

Terminal compartment contains:

•Non-intrinsically safe compartment with input/output and power supply terminals

•Intrinsically safe compartment with interface/display, sensor terminals (Model 3700 only), and optional input and output terminals

Mounting bracket and interface/display rotate to allow mounting in four different orientations

Rated NEMA 4X (IP67)

Applications

Process monitor/totalizer |

Process monitoring and totalizing for multiple variables, including mass flow, volume flow, density, |

|

and temperature. |

Discrete batch control |

• Configuration of up to six preset batch recipes |

|

• One-stage or two-stage batch control |

|

• End-of-batch warning and batch-overrun alarms |

|

• Configuration by quantity or by percent of target for primary valve closure, secondary valve |

|

opening and closure, end warning, and batch overrun |

|

• Configuration for target lockout, or for target adjustment during batch operation |

|

• Automatic overshoot compensation |

Meter verification |

Provides in-situ assessment of a Micro Motion Coriolis meter, determining whether the meter has |

|

been affected by erosion, corrosion, or other influences affecting meter calibration. No secondary |

|

references are required to perform this operation. |

Enhanced density |

Enhanced density measurement for a number of applications, including: |

|

• %HFCS, °Brix, °Plato, °Balling, |

|

• °Baumé at SG60/60 |

|

• Density at reference temperature |

|

• Specific gravity |

|

• Concentration derived from reference density |

|

• Concentration derived from specific gravity |

Custody transfer |

• Physical and software security |

|

• Security-alarm posting |

|

• Mass or volume totalizer that can be configured by the user |

|

• Custom formatting of receipt tickets |

|

• Audit trail of configuration changes |

|

• Multidrop printing capability |

Petroleum measurement (API) Provides API process variables, such as API volume flow and API average density.

4 Micro Motion® Series 3000 Transmitters and Discrete Controllers

Interface/display

Display

Models 3300 and 3500 Backlit LCD, 128 × 128 pixel, bit map

Adjustable contrast

Non-glare, chemical-resistant acrylic lens

Models 3350 and 3700 Backlit LCD, 128 × 128 pixel, bit map

Adjustable contrast

Non-glare tempered glass lens

Suitable for hazardous area installation

Keypad membrane switch Large push buttons with tactile feedback

Software-defined function keys

Chemical-resistant polyester

Electrical connections

Input and output connections |

|

Rack-mount |

Type D connectors per DIN standard 41612 (IEC 603-2) |

|

Available as solder tails (standard) or screw terminals (optional) |

|

Screw terminals accept 24 AWG (0.25 mm2) to 16 AWG (1.5 mm2) wires |

Panel-mount |

Screw terminals (standard) or I/O cable with remote DIN rail-mount screw |

|

terminals (optional) |

|

Remote terminals attach to any of four rail types. I/O cable is available in lengths of 2, 5, and 10 |

|

feet (0.6, 1.5, and 3 meters) |

|

Screw terminals accept 24 AWG (0.25 mm2) to 16 AWG (1.5 mm2) wires |

Field-mount |

Two color-coded wiring compartments: |

|

• Compartment with intrinsically safe terminals has two 3/4-inch NPT or M20 × 1.5 conduit |

|

openings |

|

• Compartment with non-intrinsically safe terminals has three 3/4-inch NPT or M20 × 1.5 |

|

conduit openings |

|

Screw terminals accept 22 AWG (0.34 mm2) to 16 AWG (1.5 mm2) wires |

Power connection |

|

Rack-mount |

Screw terminals are fixed to rack chassis |

|

Ground makes first and breaks last |

|

Screw terminals accept 18 AWG (0.75 mm2) to 14 AWG (2.5 mm2) wires |

Panel-mount |

Screw terminals accept 18 AWG (0.75 mm2) to 14 AWG (2.5 mm2) wires |

Field-mount |

Screw terminals accept 18 AWG (0.75 mm2) to 12 AWG (4.0 mm2) wires |

|

|

Micro Motion® Series 3000 Transmitters and Discrete Controllers |

5 |

Input signals

Non-intrinsically safe input signals |

|

|

One 2-wire |

Frequency range |

0–20,000 Hz |

frequency/pulse input |

Minimum pulse width |

25 μ-sec |

|

Power |

Sourcing or sinking |

|

Voltage |

0–0.8 VDC low state |

|

|

3–30 VDC high state |

|

Current |

Nominal 5 mA pull-up |

Two discrete |

Pulse width |

0.15 sec minimum |

momentary inputs |

Voltage |

0–0.8 VDC low state |

|

|

3–30 VDC high state |

|

|

Dry contacts |

Intrinsically safe input signals

One 4-wire Coriolis sensor signal input with ground

Output signals

Non-intrinsically safe output signals

Two active

4–20 mA outputs

Three discrete outputs

One 2-wire frequency/pulse output

Isolated to ±50 VDC from all other outputs and earth ground

Maximum load limit of 1000 Ohms

Output is linear with process from 3.8 to 20.5 mA per NAMUR NE43 (June 1994)

Configurable for the application |

|

Polarity |

Active high or active low, software selectable |

Power |

Internal pull-up to 24 V |

Voltage |

24 VDC nominal |

Current |

Sourcing at 5.6 mA when Vout = 3 VDC |

|

Sinking up to 500 mA at 30 VDC maximum |

Scalable to 10,000 Hz

Output is linear with flow rate to 12,500 Hz

Pulse width |

50% duty cycle above the crossover frequency(1) |

|

|

Configurable between 0.543 ms and 277 ms |

|

Polarity |

Active high or active low, software selectable |

|

Power |

Active or passive, software selectable |

|

Voltage |

24 |

VDC nominal, active |

|

30 |

VDC applied maximum, passive |

Current |

Sourcing at 10 mA at 3 VDC, active |

|

|

Sinking at 500 mA, active or passive |

|

(1)The crossover frequency depends on the configured value of the pulse width. At the minimum pulse width value of 0.543 ms, the crossover frequency is 922 Hz. At the maximum pulse width value of 277 ms, the crossover frequency is 1.8 Hz.

6 Micro Motion® Series 3000 Transmitters and Discrete Controllers

Output signals continued

Fault indication

When a fault is detected, outputs go to configured states. User can select upscale, downscale, internal zero, or none. Milliamp outputs conform to NAMUR NE43 (June 1994).

Upscale |

Milliamp |

21 to 24 mA, user configurable |

|

Frequency |

15,000 Hz |

Downscale |

Milliamp |

1 to 3.6 mA, user configurable |

|

Frequency |

0 Hz |

Internal zero |

Drives the mA and frequency outputs for process variables to zero values |

|

None |

Ignores fault conditions |

|

Digital communications |

|

|

RS-485 port |

One pair of terminals supports SP (service port) mode or RS-485 mode. On device power-up, the |

|

|

user has 10 seconds to connect in SP mode. After 10 seconds, the terminals switch to RS-485 |

|

|

mode. The communication parameters in SP mode are: |

|

|

Data rate |

38,400 baud |

|

Parity |

No parity |

|

Stop bit |

One stop bit |

|

Address |

111 |

|

In RS-485 mode, the Series 3000 can communicate via Modbus RTU, Modbus ASCII, or HART(1) |

|

|

protocols. The communication parameters are configurable with ProLink II software, Modbus, or |

|

|

the display. The shipped default parameters are: |

|

|

Data rate |

9600 baud |

|

Parity |

Odd |

|

Stop bit |

One stop bit |

|

The RS-485 port can also be configured as a printer port (see below). |

|

HART Bell 202(1) |

The HART Bell 202 signal is superimposed on the primary mA output, and is available for host |

|

|

system interface. The HART Bell 202 communication parameters are: |

|

|

Frequency |

1.2 and 2.2 KHz |

|

Amplitude |

0.8 mA peak-to-peak |

|

Data rate |

1200 baud |

|

Resistance |

Loop requires 250 to 600 Ohms resistance |

Printer port |

The RS-485 port can be configured as a printer port. When the RS-485 port is |

|

|

configured as a printer port, it cannot be used for any other function. |

|

|

Requires external RS-232 adapter (not included) |

|

Bidirectional with Epson printer; send only with all other printers and when using a multidrop configuration

(1)Using HART, it is possible to configure basic transmitter functionality, and read/write batch setpoints and totals. Series 3000 batch applications or enhanced density applications cannot be configured using HART. Using Modbus, all transmitter functionality, batch commands, and batch applications can be controlled.

Micro Motion® Series 3000 Transmitters and Discrete Controllers |

7 |

Environmental specifications

EMI effects |

All Series 3000 devices Meet EMC directive 89/336/EEC per EN 61326 Industrial, and all Series |

||

|

3000 devices conform to NAMUR NE21 (June 1997). |

|

|

Ambient temperature effect |

On analog outputs |

±0.005% of span per °C |

|

Ambient temperature limits(1) |

Operating |

–4 to +140 °F |

–20 to +60 °C |

|

Storage |

–40 to +158 °F |

–40 to +70 °C |

Temperature accuracy |

Models 3500 and 3700 |

±1.0 °C ±0.5% of reading in °C |

|

Temperature repeatability |

Models 3500 and 3700 |

±0.2 °C |

|

Humidity limits |

5 to 95% relative humidity, non-condensing at 140 °F (60 °C) |

|

|

Vibration limits |

Per IEC 68-2-6, endurance sweep, 5 to 2000 Hz, 50 sweep cycles at 1.0 g |

||

(1) If exposed to direct sunlight, the ambient temperature can be expected to rise by an additional 50 °F (10 °C).

Power supply

AC power supply

Model 3300

Models 3350, 3500, and 3700

DC power supply

Model 3300

Models 3350, 3500, and 3700

85 to 265 VAC 50/60 Hz, 15 VA

0.25 A maximum at 85 VAC, 0.12 A maximum at 265 VAC IEC 127-3/4 fuse, 0.63 A time-delay

Complies with European low-voltage directive 2006/95/EC per IEC 61010-1 Installation (Overvoltage) Category II, Pollution Degree 2

85 to 265 VAC 50/60 Hz, 30 VA

0.33 A maximum at 85 VAC, 0.15 A maximum at 265 VAC IEC 127-3/4 fuse, 0.63 A time-delay

Complies with European low-voltage directive 2006/95/EC per IEC 61010-1 Installation (Overvoltage) Category II, Pollution Degree 2

18 to 30 VDC

7 watts typical, 14 watts maximum IEC 127-3/4 fuse, 1.6 A time-delay

18 to 30 VDC

18 watts typical, 25 watts maximum IEC 127-3/4 fuse, 1.6 A time-delay

8 Micro Motion® Series 3000 Transmitters and Discrete Controllers

Hazardous area classifications

UL is a U.S.A. approvals agency. CSA is a Canadian approvals agency that provides approvals accepted in both the U.S.A. (C-US) and Canada. ATEX is a European directive.

UL and CSA |

Model 3300 |

Class I, Div. 2, Groups A, B, C, and D when installed in a suitable |

|

|

|

enclosure |

|

|

Model 3350 |

Class I, Div. 2, Groups A, B, C, and D |

|

|

Model 3500 |

Class I, Div. 2, Groups A, B, C, and D when installed in a suitable |

|

|

|

enclosure |

|

|

|

Provides non-incendive sensor outputs for use in Class I, Div. 2, |

|

|

|

Groups A, B, C, and D, or intrinsically safe sensor outputs for use |

|

|

|

in Class I, Div. 1, Groups C and D; Class II, Div. 1, Groups E, F, |

|

|

|

and G |

|

|

Model 3700 |

Class I, Div. 2, Groups A, B, C, and D |

|

|

|

Provides non-incendive sensor outputs for use in Class I, Div. 2, |

|

|

|

Groups A, B, C, and D, or intrinsically safe sensor outputs for use |

|

|

|

in Class I, Div. 1, Groups C and D; Class II, Div. 1, Groups E, F, |

|

|

|

and G |

|

ATEX |

Model 3350 |

ATEX Zone 1 |

|

|

|

CE 0575 |

II 2G EEx de [ib] IIB/IIC T4 |

|

Model 3500 |

Safe area only. Can be connected to a sensor in ATEX Zone 1 |

|

|

|

area. |

|

|

|

CE 0575 |

II (2)G [EEx ib] IIB/IIC |

|

Model 3700 |

ATEX Zone 1 |

|

|

|

CE 0575 |

II 2G EEx de [ib] IIB/IIC T4 |

|

|

|

|

Micro Motion® Series 3000 Transmitters and Discrete Controllers |

9 |

Loading...

Loading...