Emerson 396P, 396PVP User Manual

396P + 396PVP Sensors Instruction Manual

LIQ_MAN_396P_396PVP

August 2013

TUpH Combination pH/ORP Sensors

396P and 396PVP

This page left blank intentionally

Essential Instructions

Read this page before proceeding

Emerson Process Management designs, manufactures and tests its products to meet many national and international standards. Because these sensors are sophisticated technical products, you MUST properly install, use, and maintain them to ensure they continue to operate within their normal specifications. The following instructions MUST be adhered to and integrated into your safety program when installing, using, and maintaining Rosemount Analytical products. Failure to follow the proper instructions may cause any one of the following situations to occur: Loss of life; personal injury; property damage; damage to this sensor; and warranty invalidation.

•Read all instructions prior to installing, operating, and servicing the product.

•If you do not understand any of the instructions, contact your Emerson Process Management representative for clarification.

•Follow all warnings, cautions, and instructions marked on and supplied with the product.

•Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

•Install your equipment as specified in the Installation Instructions of the appropriate Instruction Manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

•To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

•When replacement parts are required, ensure that qualified people use replacement parts specified by Emerson Process Management. Unauthorized parts and procedures can affect the product's performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

•Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by qualified persons, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without notice.

DANGER: HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in hazardous area locations must be carefully evaluated by qualified on site safety personnel. This sensor is not Intrinsically Safe or Explosion Proof.

To secure and maintain an intrinsically safe installation, the certified safety barrier, transmitter, and sensor combination must be used. The installation system must comply with the governing approval agency (FM, CSA or BASEEFA/CENELEC) hazardous area classification requirements. Consult your analyzer/transmitter instruction manual for details.

Proper installation, operation and servicing of this sensor in a Hazardous Area Installation is entirely the responsibility of the user.

CAUTION: SENSOR/PROCESS APPLICATION COMPATIBILITY

CAUTION: SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is entirely the responsibility of the user.

ATEX DIRECTIVE: Special Conditions for safe use

ATEX DIRECTIVE: Special Conditions for safe use

1.All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid the danger due to a build up of an electrostatic charge.

2.All pH/ORP sensor Models are intended to be in contact with the process fluid and may not meet the 500V r.m.s. a.c. test to earth. This must be taken into consideration at installation.

CAUTION: SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is entirely the responsibility of the user.

CAUTION: SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is entirely the responsibility of the user.

About This Document

This manual contains instructions for installation and operation of the 396P and 396PVP Sensors. The following list provides s concerning all revisions of this document.

Rev. Level |

Date |

Notes |

A |

2/2013 |

Manual updated with SMART sensor information. |

B |

8/2013 |

Wiring diagrams updated. |

396P + 396PVP Sensors Instruction Manual |

Table of Contents |

|

LIQ_MAN_396P_396PVP |

|

August 2013 |

Contents |

|

|

Section 1: Description and Specifications |

|

|

1.1 |

Features and Applications ...................................................................................... |

1 |

1.2 |

Specifications-General ........................................................................................... |

3 |

1.3 |

Ordering Information............................................................................................. |

4 |

Section 2: Installation |

|

|

2.1 |

Unpacking and Inspection...................................................................................... |

7 |

2.2 |

Mounting............................................................................................................... |

7 |

Section 3: 396P-01 Wiring |

|

|

3.1 |

General ............................................................................................................... |

13 |

Section 4: 396P-02 & 396PVP Wiring |

|

|

4.1 |

General ............................................................................................................... |

21 |

Section 5: Start-Up and Calibration |

|

|

5.1 |

396P & 396PVP pH Sensors.................................................................................. |

31 |

5.2 |

396P & 396PVP ORP Sensors................................................................................ |

32 |

Section 6: Maintenance |

|

|

6.1 |

General Information............................................................................................. |

33 |

6.2 |

Automatic Temperature Compensator................................................................. |

33 |

6.3 |

396P & 396PVP pH Sensors.................................................................................. |

33 |

6.4 |

396P & 396PVP ORP Sensors................................................................................ |

34 |

Section 7: Diagnostics and Troubleshooting |

|

|

7.1 |

56/1056/1057/1066/54e/81/3081/4081/5081/Xmt |

|

|

Diagnostics and Troubleshooting ......................................................................... |

37 |

7.2 |

Troubleshooting without Advanced Diagnostics .................................................. |

38 |

Section 8: Return of Material |

|

|

8.1 |

General ................................................................................................................ |

43 |

8.2 |

Warranty Repair .................................................................................................. |

43 |

8.3 |

Non-Warranty Repair .......................................................................................... |

43 |

Table of Contents |

i |

Table of Contents |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

This page left blank intentionally

ii |

Table of Contents |

396P + 396PVP Sensors Instruction Manual |

Section 1: Description and Specifications |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

Section 1: Description and Specifications

1.1Features and Applications

TUpH™ pH/ORP-sensors are now offered with SMART capabilities. SMART option becomes enabled when used with the 1056, 1057, 1066, and 56 Analyzers and on 6081P wireless transmitter. The pH-loop capabilities include auto-recognition of the SMART sensor, automatic upload of calibration data and associated time stamp, historical recording of pH diagnostics (slope, offset, reference impedance, glass impedance). This trending data allows technicians to predict frequency of maintenance and estimate sensor life for a particular process condition. Additional SMART features include factory calibration, resetting SMART sensor calibration data with user menus, and manufacturing information.

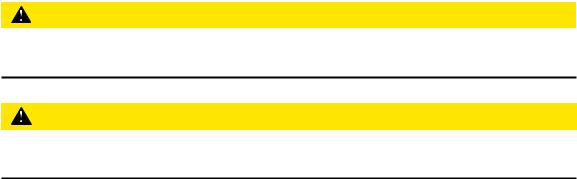

The TUpH large area reference junction for minimum maintenance requirements: The reference junction provides an electrical connection between the reference electrode and the sample, and helps maintain a stable reference potential, regardless of the change in sample pH. The TUpH reference electrode junction, the entire plastic tip surrounding the glass pH electrode, maintains a steady reference signal even in the dirtiest of applications because it resists plugging (a common cause of pH signal drift). This large reference junction area is made of micron sized reference pathways used for ionic exchange so it resists plugging by large particles and will continue to send a steady pH signal, even in the dirtiest of applications. The TUpH reference junction technology has been field-proven for minimum maintenance requirements.

The TUpH helical reference pathway stops reference poisoning. Ions diffuse through the reference pathways and a charge is passed to the reference element. The reference element must be protected from contamination by poisoning ions such as sulfide, mercury, cyanide, and ammonia or else the pH signal will drift. The TupH sensor's long internal helical reference pathway hinders and slows down the rate of contaminants migrating to the reference element therefore providing for a longer sensor life.

The entire line of TUpH model sensors now incorporate the new SILCORE™ technology contaminant barrier. This triple-seal barrier prevents moisture and material impurities from migrating to the pH sensor’s reference electrode’s metal lead wire. By preventing these contaminants from compromising the integrity of the pH measurement, sensor life is increased, especially at higher temperatures where increased migrations occur. In addition, the SILCORE technology provides added protection against sensor failure due to vibrations and shock by transferring damaging energy away from the glass-to-metal seal.

The AccuGLASS™ pH glass formulations exceed industry standards. The AccuGlass pH glass is a result of many years of glass research resulting in a formulation which has been found to increase the life of the sensor. Unlike other pH glasses presently on the market, this glass resists cracking especially at higher temperatures and reduces sodium ion error commonly found in high pH applications. Overall, the AccuGlass formulation enhances the sensor performance to measure pH more accurately and have a longer sensor life than ever before.

A choice of flat or hemi glass pH glass electrodes is available to best meet various application needs. Flat glass is advantageous in abrasive or coating applications that etch or build up on glass, respectively. In coating applications, such as slurries, the flat surface allows the process flow to act as a scrubbing agent to reduce coating and maintenance. In abrasive applications pitting from silicates and other similar materials is minimized by the flat glass surface to provide longer sensor life. Flat glass sensors are offered with a flat tip which is flush with the flat glass. The hemi bulb glass is ideal for general purpose use and for those processes requiring greater accuracy over the entire pH range. All hemi bulb sensors are offered with a standard shrouded tip which completely surrounds the glass bulb for protection against solids. An optional slotted tip is also available and

Description and Specifications |

1 |

Section 1: Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

FIGURE 1-1. Cross Section Diagram of the TUpH Reference Technology. All TUpH sensors are designed with a large area reference junction, helical reference pathway, and an AccuGlass pH glass bulb. This sensor technology ensures superior performance while only requiring minimal maintenance.

allows the process to flow by the glass electrode for accurate and reliable pH measurement. Both pH glass bulbs — the standard hemi or optional flat pH glass — are exceptional for increased resistance to high temperature and other effects of aging for longer life.

The TUpH reference junction and helical pathway combined with the AccuGLASS pH glass performs exceptionally well in dirty, high solid applications and requires only minimum maintenance. This is the toughest pH sensor on the market and is still unmatched by all other pH sensors. The constant increase in demand for the TUpH sensor proves it's success as the best process industry pH sensor.

All TUpH sensor models have been specifically designed for improved life in harsh, dirty, and abrasive applications such as lime slurry, waste treatment, paper machine headbox, and pigment/dye applications, where large quantities of suspended solids are present. Various sensor materials, depending on the sensor model, are available for a variety of different application needs.

SMART is the standard option. A preamplifier converts the high impedance pH signal into a stable, noise-free signal and must be used with all pH sensors. An integral SMART preamplifier stores calibration information and can be built into the sensor when ordering the SMART preamplifier option. Otherwise, a standard preamplifier can be used in a junction box or built into the analyzer/transmitter. All integral preamplified SMART TupH Sensors are compatible with all Rosemount Analytical instruments.

The 396VP, 396PVP, and 396RVP are offered with a watertight VP sensor-to-cable connector which eliminates rewiring and cable twisting when replacing sensors. The VP (Variopol) multiple pin connector is an integral part of each sensor model and uses a mating VP cable. Once the cable is installed and wired to the analyzer, sensors are easily replaced without replacing the cable, without rewiring the analyzer (if the replacement sensor is the same as its predecessor). Also the sensor can be disconnected from the cable before removal from the process which eliminates cable twisting. VP8 cable assemblies work with all VP sensors. VP8 wiring is standard across all pH sensor families. VP8 is required when used with SMART preamplified sensors.

2 |

Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

Section 1: Description and Specifications |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

The 396P and 396PVP sensors are available in two configurations: the standard shrouded tip, in which the pH glass is completely recessed within the reference junction for abrasive or rough applications, and the optional slotted tip with a partially exposed pH glass for viscous or low flow applications.

The 396P and 396PVP sensors feature a titanium solution ground, constructed in an annular design around the pH/ORP electrode. The solution ground provides advanced sensor diagnostics for preventative maintenance when used with Rosemount Analytical 54e, 56, 1056, 1057, 5081, 6081, 1066, and XMT instruments. In addition, the Model 396P sensor can be used with most non-diagnostic Rosemount Analytical and other manufacturers’ instruments.

The 396P and 396PVP sensor is housed in a molded polypropylene body with EPDM seals, making it virtually indestructible and chemically resistant. Complete encapsulation eliminates leakage or high humidity problems traditionally found in other pH/ORP designs. The simplified construction, designed with user convenience in mind, does not require electrolyte (KCl) replenishment or any high maintenance troubleshooting procedures.

The 396 and 396VP TUpH Sensors are housed in a stainless steel body with optional 1" threaded connector suitable for insertion, submersion or flow through installation. The sensor includes a general purpose glass pH electrode in the standard bulb or optional flat glass configuration. The TUpH reference has a large area polypropylene junction with a gel filled reference electrolyte. The 396 and 396VP TUpH are available with an optional SMART integral preamplifier when choosing the 396VP-55 option. Automatic temperature compensation is standard 3K Balco or Pt 100 RTD.

The 396R and 396RVP Sensors are designed for use with a 1-1/4 in. or 1-1/2 in. ball valve for hot tap installation. The 396R and 396RVP are constructed of molded polypropylene housed in a titanium tube with EPDM seals to provide maximum chemical resistance. The sensors feature a titanium solution ground used for advanced sensor diagnostics when used with Rosemount Analytical 54e, 56, 1056, 1057, 5081, 6081, 1066, and XMT instruments. These advanced sensor diagnostics provide preventative maintenance by notifying the operator of the need for replacement and cleaning of an aged or fouled sensor, thus allowing continuous optimum performance.

The Rosemount Analytical 54e, 56, 1056, 1057, 1066, 5081, 6081, and XMT instruments offer advanced sensor diagnostics to provide preventative maintenance by notifying the operator of the need for replacement and cleaning of an aged or fouled sensor, thus allowing continuous optimum performance. The 396R and 396RVP sensors also feature a slotted tip for protection from breakage while allowing the process to flow by the glass electrode for accurate and reliable pH measurement.

1.2Specifications - General

Measurements and Ranges: pH*: 0-14 / ORP: -1500 to 1500 mv

Available pH ACCUGLASS Types: GPLR hemi or flat glass

Wetted Materials: Titanium, Polypropylene, EPDM, glass; platinum (ORP only)

Process Connection: 1 in. MNPT front and rear facing threads

Temperature Range: 0-100°C (32-212°F)

Pressure Range-Hemi bulb: 100-1135 kPa [abs] (0-150 psig)

Pressure Range-Flat bulb: 100-790 kPa [abs] (0-100 psig)

Minimum Conductivity: 100 μS/cm

Description and Specifications |

3 |

Section 1: Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

Integral Cable 396P: Code 01 - 25 ft; Code 02 - 15 ft coaxial / 396PVP: none - must use mating VP cable

Preamplifier Options: Remote or Integral SMART preamplifier

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/2 lb)

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/

*Percent Linearity

pH Range |

396 / 396VP |

396P / 396PVP |

396R / 396RVP |

|||

|

|

|

|

|

|

|

|

GPHT Hemi |

GPHT Flat |

GPHT Hemi |

GPLR Flat |

GPHT Hemi |

GPHT Flat |

|

|

|

|

|

|

|

0-2 pH |

94% |

95% |

94% |

– |

94% |

93% |

|

|

|

|

|

|

|

2-12 pH |

99% |

99% |

97% |

98% |

97% |

98% |

|

|

|

|

|

|

|

12-13 pH |

97% |

96% |

98% |

95% |

98% |

95% |

|

|

|

|

|

|

|

13-14 pH |

92% |

– |

98% |

– |

98% |

– |

|

|

|

|

|

|

|

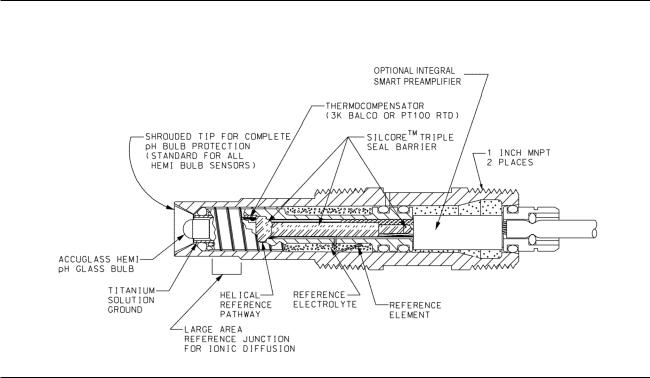

1.3Ordering Information

The 396P Sensor is housed in a molded reinforced polypropylene body with 1 in. MNPT threads suitable for insertion, submersion or flow through installation. The sensor includes a general purpose pH electrode or a platinum ORP electrode, a reference junction and a solution ground. The 396P comes standard with a recessed electrode; an optional slotted tip is also available. In addition, the 396P features an optional integral hermetically sealed preamplifier and 15 ft or 25 ft cable lengths. Automatic temperature compensation, Pt 100 or 3K Balco, is standard with the 396P.

The 396P insertion/submersion sensor shown with the fully recessed bulb (standard option).

396P TUpH INSERTION/SUBMERSION POLYPROPYLENE pH/ORP SENSOR

CODE |

PREAMPLIFIER/CABLE (Required Selection) |

01 |

With integral SMART preamplifier, 25 ft (7.6m) cable |

|

|

02 |

Without integral preamplifier, 15 ft (4.6m) cable |

|

|

CODE |

MEASURING ELECTRODE TYPE (Required Selection) |

10 |

GPLR hemi bulb, General Purpose Low Resistivity (0-14 pH) |

12ORP

13GPLR flat bulb, General Purpose Low Resistivity (2 - 13 pH)

CODE |

ANALYZER/TC COMPATIBILITY (Required Selection) |

50 |

For 1181 (3K TC) |

54For 1054A/B, 2054, 2081 (Pt 100 RTD)

55For 54e, 3081, 81, 4081, 1055, 5081, Xmt (PT-100 RTD)

CODE |

OPTIONAL SELECTION |

|

41 |

Slotted Tip (not available on flat bulb sensors) |

|

396P - |

01 - 10 - 55 |

EXAMPLE |

|

|

|

NOTE: The 396P is also compatible with Model SCL-P/Q (option 02-54 only).

4 |

Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

Section 1: Description and Specifications |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

The 396PVP Sensor has similar features to the 396P. However, the 396PVP is offered with the Variopol (VP) connector and uses a mating VP cable (purchased separately).

A Variopol cable is required for all new installations. See below for cable selection.

Variopol connector shown with |

The 396PVP insertion/ submersion sensor |

mating variopol cable receptacle |

with the VP (Variopol) connector |

396PVP TUpH INSERTION/SUBMERSION POLYPROPYLENE pH/ORP SENSOR

CODE |

MEASURING ELECTRODE |

10 |

pH GPLR Glass, General Purpose Low Resistivity (0 - 14 pH) |

12ORP

13GPLR Flat Bulb, General Purpose Low Resistivity (2 - 13 pH)

CODE |

MEASURING ELECTRODE |

50 |

For use with Model 1181pH/ORP (3K TC) |

54For use with Models: 1054, 2054; Series 2081 (Pt-100)

55For use with Models: 54, 56, 1055, 1056, 1057, 81,3081, 4081, 5081, 6081 XMT (Pt-100)

CODE OPTIONAL

–No Selection

41 |

Slotted Tip |

|

|

CODE |

PREAMPLIFIER OPTION |

–No Preamplifier

70 |

With Integral Smart Preamplifier for 396PVP; available with 396PVP-10-55 and 396PVP-13-55 only |

Examples of all sensing tip offerings

Shrouded Tip is |

Optional Slotted Tip |

Flat Tip is available |

standard on all |

is available on all hemi |

with flat glass bulb |

hemi bulb sensors |

bulb sensors, ordered |

sensors |

|

as option -41 |

|

Description and Specifications |

5 |

Section 1: Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

Accessories

Connector cable, VP8 (required for all first time installations of VP sensors)

24281-00 |

15 ft. (4.6m) VP8 cable |

|

|

24281-01 |

25 ft. (7.6m) VP8 cable |

|

|

24281-03 |

50ft (15.2m) VP8 Cable |

|

|

24281-04 |

100ft (30.5m) VP8 Cable |

|

|

24281-06 |

10ft (3.0m) VP8 Cable |

|

|

24281-07 |

20ft (6.1m) VP8 Cable |

|

|

24281-08 |

30ft (9.1m) VP8 Cable |

|

|

Remote Junction Boxes and Mounting Brackets; for use when standard cable lengths need to be extended |

|

|

|

23555-00 |

Junction Box; contains preamplifier for 54e, 56, 1055, 1056, 1057, 1066, 3081, 4081, 5081, 6081, XMT |

|

|

23550-00 |

Junction Box with board for point-to-point cable extension; use with sensors containing integral preamplifiers |

|

|

2002565 |

Mounting Bracket Kit with mounting plate and U-bolts; use with PN 23555-00 or 23550-00 junction boxes |

|

|

Extension Cables (required when using a remote junction box)

23646-01 |

Extension Cable, 11-conduit with shields, wires prepared for easy installation, per foot (or meter); best choice for easiest |

|

installation |

||

|

||

|

|

|

9200273 |

Extension Cable, 11-conduit with shield, raw cable (user must cut and prepare cable ends), per foot (or meter) |

|

|

|

|

Calibration Accessories |

||

|

|

|

9210012 |

Buffer Solution, pH 4.01, 16 oz (473 ml) |

|

|

|

|

9210013 |

Buffer Solution, pH 6.86, 16 oz (473 ml) |

|

|

|

|

9210014 |

Buffer Solution, pH 9.18, 16 oz (473 ml) |

|

|

|

|

R508-8OZ |

ORP Standard, 475mV, 8oz (236 ml) |

|

|

|

|

Mounting Assemblies |

||

|

|

|

11275-01 |

Handrail Mounting Assembly; includes a 6 ft straight pipe, pipe coupling, 6 ft long sweep pipe, unistrut, pipe clamps, and |

|

mounting channels |

||

|

||

|

|

|

2002011 |

CPVC flow through Tee, 1-1/2" NPT process connections |

|

|

|

|

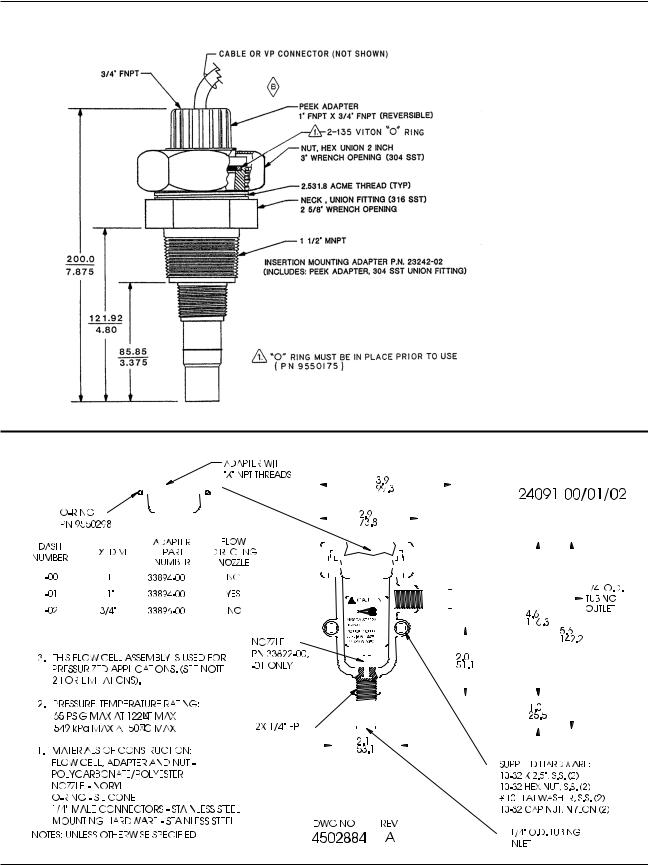

24091-00 |

Low Flow Cell with 1/4 inch inlet and outlet |

|

|

|

|

915240-03 |

Tee, Flow-through, 2" PVC tee with " NPT process connections and mounting adapter to eliminate cable twisting |

|

|

|

|

915240-04 |

Tee, Flow-through, 2" PVC tee with 1" NPT process conections and mounting adapter to eliminate cable twisting |

|

|

|

|

915240-05 |

Tee, Flow-through, 2" PVC tee with 1 " NPT process connections and mounting adapter to eliminate cable twisting |

|

|

|

|

12707-00 |

Jet Spray Cleaner; for use with water or air cleaning using interval timer from instrument |

|

|

|

|

6 |

Description and Specifications |

396P + 396PVP Sensors Instruction Manual |

Section 2: Installation |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

Section 2: Installation

2.1Unpacking and Inspection

Inspect the outside of the carton for any damage. If damage is detected, contact the carrier immediately. Inspect the hardware. Make sure all the items in the packing list are present and in good condition. Notify the factory if any part is missing. If the sensor appears to be in satisfactory condition, proceed to Section 2.2, Mounting.

NOTE: Save the original packing cartons and materials as most carriers require proof of damage due to mishandling, etc. Also, if it is necessary to return the sensor to the factory, you must pack the sensor in the same manner as it was received. Refer to Section 6.0 for return instructions. If the sensor is to be stored, the vinyl boot should be filled with pH buffer solution and replaced on sensor tip until ready to use.

CAUTION

Buffer solution, in the vinyl boot, may cause skin or eye irritation.

WARNING

WARNING

Glass electrode must be wetted at all times (in storage and in line) to maximize sensor life.

2.2Mounting

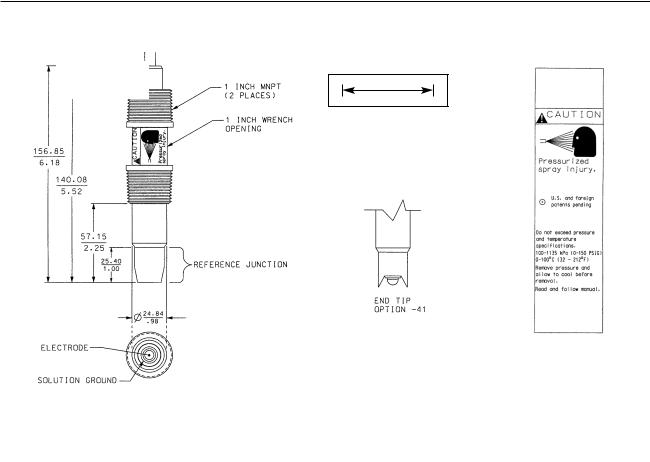

The sensor has been designed to be located in industrial process environments. Temperature and pressure limitations must not be exceeded at any time. A caution label regarding this matter is attached to the sensor. Please do not remove the label. See Figure 2-1.

CAUTION

CAUTION

Internal electrolyte fill solution may cause skin or eye irritation.

Mounting Guidelines:

1.Shake the sensor in a downward motion to remove any air bubbles that may be present inside the tip of the pH glass.

2.Do not install the sensor on the horizontal. The sensor must be 10° off the horizontal to ensure accuracy.

3.Do not install the sensor upside down.

4.Air bubbles may become trapped in the sensor end between the glass bulb and the sensor body. This problem is most commonly encountered in areas of low flow or during calibration. Shake the probe while immersed in solution to remove bubbles. This problem can be avoided by ordering the sensor with the slotted tip (option -41).

In most cases, the pH sensor can simply be installed as shipped and readings with an accuracy of

± 0.6 pH may be obtained. To obtain greater accuracy or to verify proper operation, the sensor must be calibrated as a loop with its compatible analyzer or transmitter.

Installation |

7 |

Section 2: Installation |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

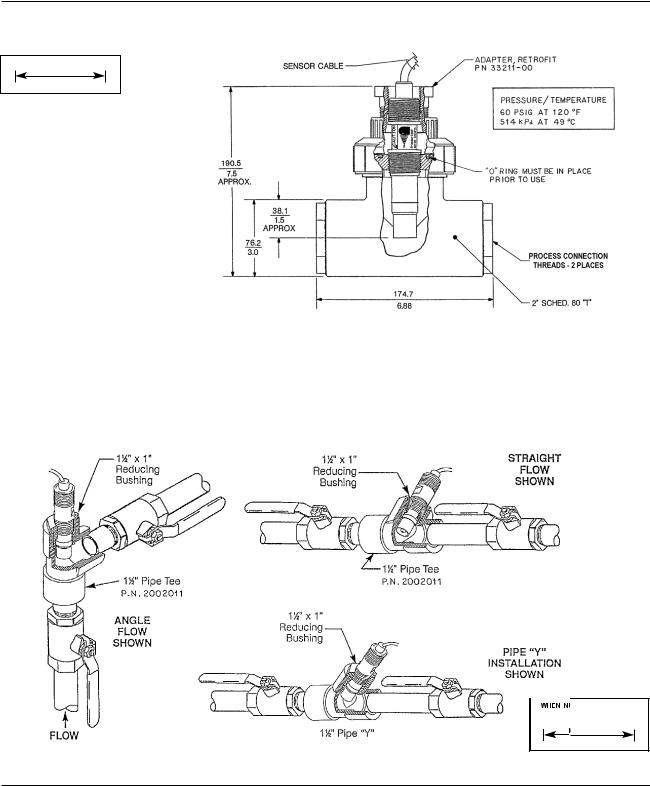

2.2.1Flow Through and Insertion Mounting

396P and 396PVP Sensors have a 1-inch MNPT process connection at the front of the sensor for mounting into a 1-1/2 inch tee or the process pipes. See Figure 2-2 through Figure 2-7 for installation configurations.

NOTE: LARGE PIPE WRENCHES MUST NOT BE USED TO TIGHTEN THE SENSOR INTO A FLANGE OR OTHER TYPE OF MOUNTING.

2.2.2Submersion Mounting

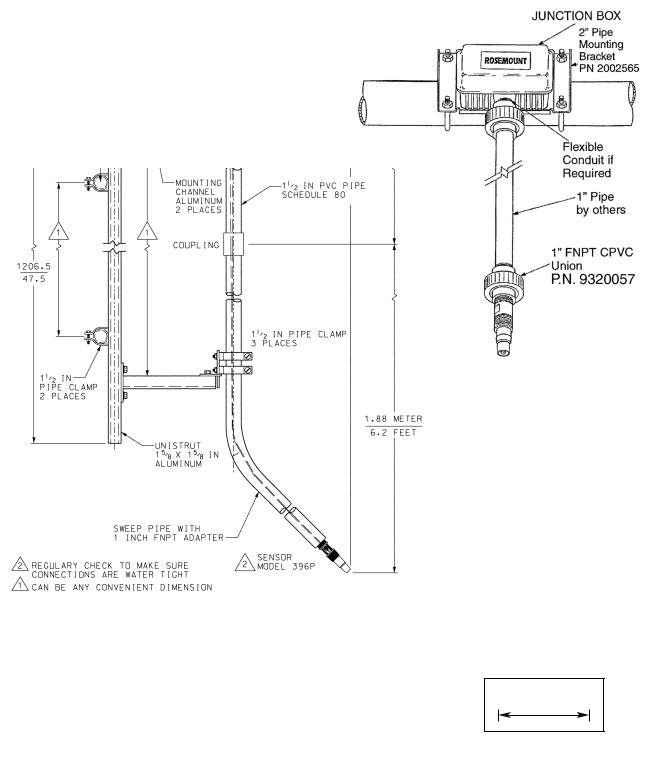

396P and 396PVP Sensors also have a 1 inch MNPT process connection at the back of the sensor. Utilizing a standard 1 inch union, the sensor may be mounted to a 1 inch SCH 80 CPVC or PVDF standpipe. Tapered pipe threads in plastic tend to loosen after installation. It is therefore recommended that Teflon1 tape be used on the threads and that the tightness of the connection be checked frequently to assure that no loosening has occurred. To prevent rain water or condensation from running into the sensor, a weatherproof junction box is recommended. The sensor cable must be run through a protective conduit for isolation from electrical interference or physical abuse from the process. The sensor should be installed within 80° of vertical, with the electrode facing down. The sensor’s cable should not be run with power or control wiring.

Figure 2-1. Dimensional Drawing

SENSOR CABLE (OR VP CONNECTOR - NOT SHOWN)

MILLIMETER |

INCH |

|

DWG. NO. |

REV. |

|

40396P01 |

D |

|

|

|

|

|

|

|

|

|

8 |

Installation |

396P + 396PVP Sensors Instruction Manual |

Section 2: Installation |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

Figure 2-2. Flow-Through Tee with Adapter (PN 915240-xx*)

MILLIMETER |

INCH |

|

xx* |

process Connection |

|

|

|

|

Threads |

|

|

|

03 |

3/4 inch |

|

|

|

04 |

1 inch |

|

|

05 |

1-1/2 inch |

|

||

|

|

|

|

|

|

|

|

|

|

Figure 2-3. Flow-Through and Insertion Installations |

|

|

|||

|

|

|

|

|

|

|

1-1/2” x 1” |

|

|

|

|

|

|

1-1/2” x 1” |

|

|

|

|

|

|

sTRaIgHT |

||

|

Reducing |

|

|

||

|

|

Reducing |

|

||

|

|

|

fLow |

||

|

Bushing |

|

|

||

|

|

Bushing |

|

||

|

|

|

sHowN |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/2” Pipe Tee |

|

|

|

|

|

|

|

|

|

|

1-1/2” Pipe Tee |

|

||||

|

PN 2002011 |

|

|

|

PN 2002011 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/2” x 1” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

aNgLE |

|

Reducing |

|

|

|

|

|

|

fLow |

|

Bushing |

|

|

|

|

|

|

|

|

|

pIpE “y” |

||||

|

sHowN |

|

|

|

|

|

|

|

|

|

|

|

|

INsTaLLaTIoN |

|||

|

|

|

|

|||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

sHowN |

|

|

|

|

|

|

|

|

|

|

1-1/2” PiPE “Y” |

|

fLow |

|

|

|

|

|

|

|

|

CH aND METRIC DIMs |

aRE gIVEN |

MILLIMETER |

INCH |

Installation |

9 |

Section 2: Installation |

396P + 396PVP Sensors Instruction Manual |

August 2013 |

LIQ_MAN_396P_396PVP |

|

|

Figure 2-4. 396P with Insertion Mounting Adapter (PN 23242-02). Not for use with 396PVP. Mounting adapter allows for sensor removal without twisting or disconnecting interconnecting cable for ease of maintenance.

DWG. NO. |

REV. |

40396P02 |

A |

|

|

Figure 2-5. Low flow cell PN 24091-00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

396P + 396PVP Sensors Instruction Manual |

Section 2: Installation |

LIQ_MAN_396P_396PVP |

August 2013 |

|

|

|

|

Figure 2-6. Submersion Installations |

|

DWG. NO. |

REV. |

40396P03 |

A |

|

|

wHEN INCH aND METRIC DIMs

aRE gIVEN

MILLIMETER

INCH

|

DWG. NO. |

REV. |

|

|

40396P04 |

A |

|

|

|

|

|

|

|

|

|

Installation |

11 |

Loading...

Loading...