Emerson 1F95EZ-0671 User Manual

Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATINGTHIS CONTROL COULD CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Blue Easy Reader Thermostat

Single Stage, Multi-Stage, Heat Pump Installation and Operating Instructions for Model:

Model |

Programming Choices |

|

|

|

|

1F95EZ-0671 |

Non-Programmable |

7 Day |

|

|

|

APPLICATIONS

THERMOSTAT APPLICATION GUIDE

1F95EZ-0671 Thermostat

Thermostat |

Thermostat |

Maximum |

|

Stages |

|||

Configuration Options |

Applications |

||

Heat/Cool |

|||

|

|

||

Single Stage 1 |

Gas, Oil, Electric, Heat Only, |

1/1 |

|

No Heat Pump (SS1) |

Cool Only or Heat/Cool |

||

|

|||

|

Systems, 2 or 3 wire Hydronic |

|

|

|

|

||

Multi Stage 2 |

Zone (Hot Water or Steam) |

2/2 |

|

No Heat Pump (MS2) |

Systems, 24 Volt or Millivolt |

||

|

|||

|

|

|

|

Heat Pump 1 |

Single Stage Compressor |

|

|

Single Stage Compressor |

Heat Pump Systems - up to 2 |

3/1 |

|

Heat Pump (HP1) |

Stages Aux./Emergency Heat |

|

|

|

|

|

|

Heat Pump 2 |

Two Stage or Two Compressor |

|

|

Two Stage or Two |

|

||

Heat Pump systems - up to 2 |

4/2 |

||

Compressor Heat Pump |

|||

Stages Aux./Emergency Heat |

|

||

(HP2) |

|

||

|

|

||

|

|

|

SPECIFICATIONS

Electrical Rating:

Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . mV to 30 VAC, NEC Class II, 50/60 Hz or DC Input-Hardwire . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 30 VAC

Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5A per terminal, 2.5A maximum all terminals combined Setpoint Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 to 99°F (7 to 32°C)

Differential (Single Stage) . . . . . . . . . . . . . . . . . . . . Heat 0.6°F; Cool 1.2°F Differential (Multi-Stage) . . . . . . . . . . . . . . . . . . . . . Heat 0.6°F; Cool 1.2°F Differential (Heat Pump) . . . . . . . . . . . . . . . . . . . . . Heat 1.2°F; Cool 1.2°F Operating Ambient. . . . . . . . . . . . . . . . . . . . . . . . . . 32°F to +105°F (0 to +41°C) Operating Humidity . . . . . . . . . . . . . . . . . . . . . . . . . 90% non-condensing max. Shipping Temperature Range . . . . . . . . . . . . . . . . . -40 to +150°F (-40 to +65°C) Dimensions Thermostat. . . . . . . . . . . . . . . . . . . . . . 4.2"H x 6.4"W x 1.7"D

! CAUTION

To prevent electrical shock and/or equipment damage, disconnect electric power to system at main fuse or circuit breaker box until installation is complete.

Index |

Page |

Installation |

2 |

Wiring Connections |

2 |

Wiring Diagrams |

3 |

Thermostat Quick Reference |

4 |

Installer Configuration Menu |

5 |

Operating Your Thermostat |

7 |

Troubleshooting |

8 |

ATTENTION: MERCURY NOTICE

This product does not contain mercury. However, this product may replace a product that contains mercury.

Mercury and products containing mercury must not be discarded in household trash. Do not touch any spilled mercury. Wearing non-absorbent gloves, clean up any spilled mercury and place in a sealed container. For proper disposal of a product containing mercury or a sealed container of spilled mercury, place it in a suitable shipping container. Refer to www.white-rodgers.com for location to send product containing mercury.

PART NO. 37-6986A

www.white-rodgers.com

0846

INSTALLATION

!WARNING

Thermostat installation and all components of the control system shall conform to Class II circuits per the NEC code.

Remove Old Thermostat

Before removing wires from old thermostat, mark wires for terminal identification so the proper connections will be made to the new thermostat.

Installing New Thermostat

1.Pull the thermostat body off the thermostat base. Forcing or prying on the thermostat will cause damage to the unit.

2.Place base over hole in wall and mark mounting hole locations on wall using base as a template.

3.Move base out of the way. Drill mounting holes. If you are using existing mounting holes and the holes drilled are too large and do not allow you to tighten base snugly, use plastic screw anchors to secure the base.

4.Fasten base snugly to wall using mounting holes shown in Figure 1 and two mounting screws. Leveling is for appearance only and will not affect thermostat operation.

5.Connect wires to terminal block on base using appropriate wiring schematic.

6.Push excess wire into wall and plug hole with a fire resistant material (such as fiberglass insulation) to prevent drafts from affecting thermostat operation.

7.Carefully line the thermostat up with the base and snap into place.

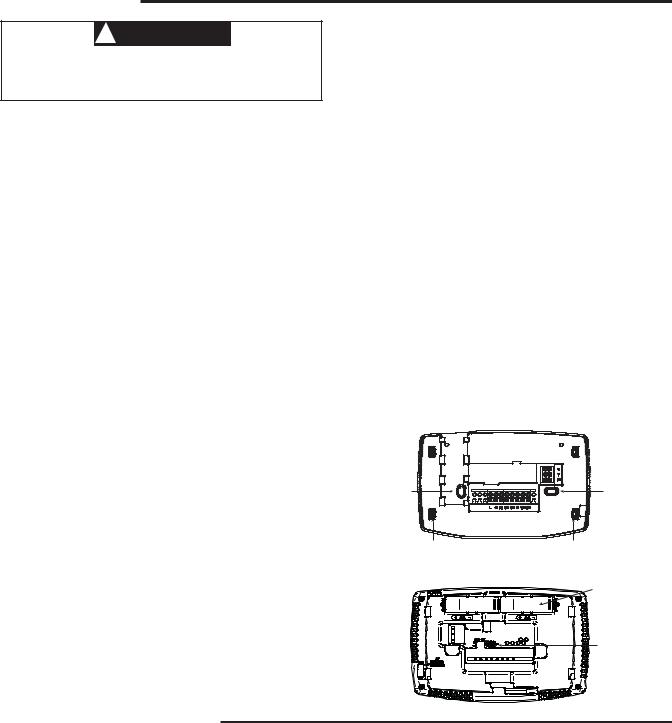

Battery Location

2 "AA" alkaline batteries are included in the thermostat at the factory with a battery tag to prevent power drainage. Remove the battery tag to engage the batteries.

To replace batteries, set system to OFF, remove thermostat from wall and install the batteries in the rear along the top of the thermostat (see Figure 1). For best results, use a premium brand "AA" alkaline battery such as Duracell® or Energizer®. If the home is going to be unoccupied for an extended period (over 3 months) and  is displayed, the batteries should be replaced before leaving.

is displayed, the batteries should be replaced before leaving.

Power Stealing Switch

The Power Stealing Switches (Fig. 1) should be left in the "On" position for most systems. The information in the following table details the thermostat power method and switch options.

WIRING CONNECTIONS

Thermostat Power Method |

Switch Position/Description |

|

|

Battery Powered, no 24 Volt |

Switches "On", thermostat runs |

system power available. |

on batteries. |

|

|

Hardwired with Battery |

Switches "On", thermostat |

Back-up, for 24 Volt systems |

runs on power directly from |

with common connection from |

transformer with battery back- |

transformer to "C" terminal on |

up. |

thermostat. |

|

|

|

*Battery Powered with Power |

Switches "On", thermostat runs |

Stealing Assist, for 24 Volt |

on batteries and supplemental |

systems with no common |

power drawn through the heat |

connection from transformer to |

or cool circuit. |

"C" terminal on thermostat. |

|

|

|

*Power Stealing Assist is very reliable to increase battery life, but on a small number of heating or cooling systems with high impedance electronic modules you may observe one of the following conditions:

1.The furnace draft inducer motor may run with no call for heat.

2.The furnace fan may turn on with no call for heat or may not turn off.

3.The furnace may not turn off when the call for heat ends.

4.The air conditioner may not turn off when the call for cool ends.

If the Power Stealing Assist method is not compatible with your system, place the Power Stealing Switches to "Off". This cancels Power Stealing Assist, operates the thermostat on batteries and corrects the condition.

Figure 1 – Thermostat Base Multi-Stage 1F95EZ-0671

Mounting |

Mounting |

Hole |

Hole |

Place Level |

Place Level |

across Mounting Tabs |

across Mounting Tabs |

(for appearance only) |

(for appearance only) |

Rear view of thermostat |

|

|

2 "AA" Batteries |

|

Power Stealing |

* |

Switches |

|

|

* A1 For Damper Control Not Applicable To This Model. |

|

Refer to equipment manufacturers' instructions for specific system wiring information. After wiring, see CONFIGURATION section for proper thermostat configuration.

Wiring diagrams shown are for typical systems and describe the thermostat terminal functions.

|

TERMINAL DESIGNATION DESCRIPTIONS |

Terminal Designation |

Description |

|

|

O/B ............................... |

Changeover valve for heat pump energized constantly in cooling and off/heating |

Y2 ............................... |

2nd Stage Compressor |

Y ............................... |

Compressor Relay |

G ............................... |

Fan Relay |

RC ............................... |

Power for Cooling |

RH ............................... |

Power for Heating |

C ............................... |

Common wire from secondary side of cooling (Optional). Required for fault indication, continuous back- |

|

light operation or remote temperature sensor operation 6 Powered closed 3rd wire for 3-wire zone valve |

W/E ................................ |

Heat Relay/Auxiliary Heat Relay (Stage 1) (3rd Stage Heat in HP2) |

W2 ............................... |

2nd Stage Heat (4th Stage Heat in HP2) |

L ............................... |

Compressor diagnostic indicator for systems with diagnostic connection typically found on Heat pump |

|

systems or with Copeland's Comfort Alert |

|

|

2

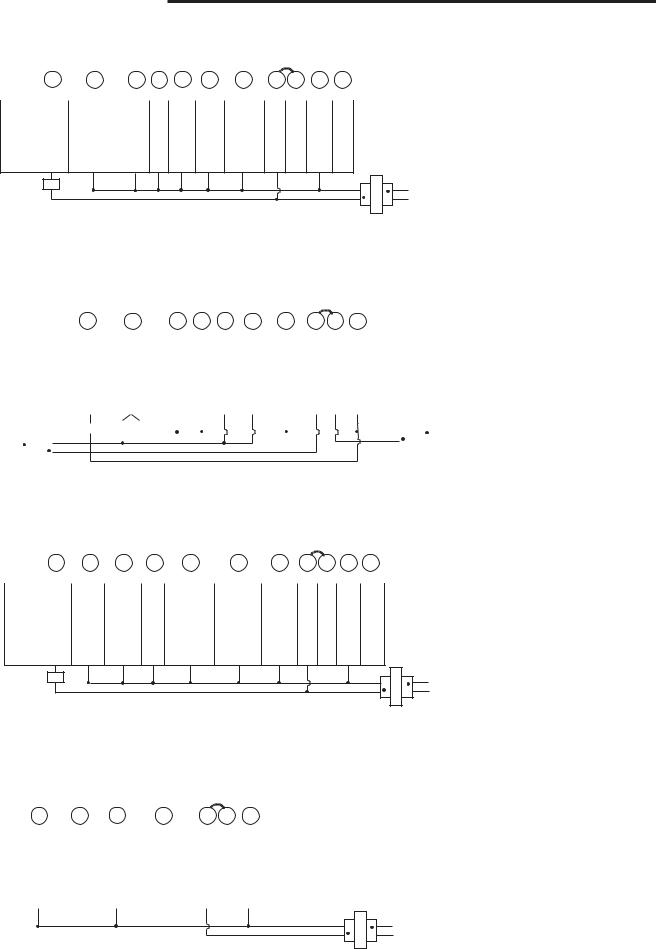

WIRING DIAGRAMS

Figure 2 – Single Stage or Multi-Stage System (No Heat Pump) with Single Transformer

Jumper

|

L |

O/B |

Y |

Y2 |

W/E |

W2 |

G |

RH |

RC |

C |

6 |

|||||||||||

System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single |

Diagnostic |

O |

|

|

|

|

|

|

|

|

Blower/ |

|

|

|

|

|

|

|

|

|||

Energized Constantly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Stage 1 |

|

|

|

|

|

|

No Output |

Circulator |

|

|

|

|

|

|

|

|

||||||

Indicator |

in |

|

|

No |

|

|

|

|

|

|

|

|

|

|

||||||||

(SS1) |

|

|

Heat |

|

|

Fan Energized |

24 Volt |

24 Volt |

Optional* |

|

|

|||||||||||

Input |

Cool Mode |

|

|

|

|

|

|

|||||||||||||||

|

Cool Mode |

Output |

Mode |

|

|

on Call for |

(Hot) |

(Hot) |

24 Volt |

|

|

|||||||||||

|

or |

|

|

|

|

|

|

|||||||||||||||

|

System |

B |

1st Stage |

|

|

1st Stage |

|

|

Cool (and |

Heat |

Cool |

(Com- |

|

|

||||||||

Multi- |

Malfunction |

|

|

Cool |

|

|

Heat Mode |

Heat if |

|

|

|

|

mon) |

|

|

|||||||

Stage 2 |

Switch |

Energized Constantly |

|

|

Mode |

|

|

2nd Stage |

configured |

|

|

|

|

|

|

|

|

|||||

in Heat, Off, |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

(MS2) |

Input |

|

|

2nd |

|

|

|

|

for Electric |

|

|

|

|

|

|

|

|

|||||

|

Emergency |

|

|

Stage |

|

|

|

|

Heat) |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Stage, Multi-Stage and Heat Pump Connections

Refer to equipment manufacturers' instructions for specific system wiring information.

This thermostat is designed to operate a single-transformer or two-transformer system.

You can configure the thermostat for use with the following systems:

SINGLE STAGE (SS 1) gas, oil or electric.

MULTI-STAGE (MS 2) gas, oil or electric.

or Similar System |

NEUTRAL |

|

HEAT PUMP TYPE 1 (HP 1). Single stage |

Comfort Alert II Module |

|

|

|

Diagnostic Module |

24VAC |

120VAC |

compressor system; gas or electric backup. |

See Module Instructions |

HOT |

|

|

for details |

|

|

HEAT PUMP TYPE 2 (HP 2). Multi-stage |

|

CLASS II |

|

|

|

|

|

|

|

TRANSFORMER |

|

compressor or two compressor system with |

* Common connection required for diagnostic or malfunction indication. |

|

|

|

|

|

gas or electric backup. |

|

|

|

|

Figure 3 – Single Stage or Multi-Stage System (No Heat Pump) with Two Transformers

Remove Jumper Wire

Jumper between RH & RC

between RH & RC

After wiring, see INSTALLER CONFIGURATION section for proper thermostat configuration.

|

|

|

|

|

|

|

|

|

L |

|

O/B |

Y |

Y2 |

W/E |

W2 |

G |

RH |

RC |

C |

|

|

||||||||||||||||

|

|

|

|

|

System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Single |

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

Blower/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Energized Constantly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

Stage 1 |

|

|

|

|

|

|

|

|

|

|

No Output |

Circulator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

in |

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

(SS1) |

|

Diagnostic |

|

|

|

Heat |

|

|

Fan Energized |

24 Volt |

24 Volt |

Optional* |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

Cool Mode |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

Indicator |

|

|

|

|

Cool Mode |

Output |

Mode |

|

|

on Call for |

(Hot) |

(Hot) |

24 Volt |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

(Optional) |

|

B |

1st Stage |

|

|

1st Stage |

|

|

Cool (and |

Heat |

Cool |

(Com- |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

Multi- |

|

|

|

|

|

|

|

Cool |

|

|

Heat Mode |

Heat if |

|

|

|

|

mon) |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

Stage 2 |

|

|

|

|

Energized Constantly |

|

|

Mode |

|

|

2nd Stage |

configured |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

(MS2) |

|

|

|

|

in Heat, Off, |

|

|

2nd |

|

|

|

|

for Electric |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Emergency |

|

|

Stage |

|

|

|

|

Heat) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NEUTRAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24VAC |

|

|

|

|

120VAC |

|

|

|

|

|

|

|

NEUTRAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOT |

|

|

|

|

|

|

120VAC |

|

|

|

|

|

24VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COOLING |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

HOT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLASS II |

|

|

|||||||

HEATING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRANSFORMER |

|

|

|||||||||

|

|

CLASS II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

* Common connection required for diagnostic or malfunction indication.

Figure 4 – Heat Pump Systems

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jumper |

|

|

|

|

||

|

L |

O/B |

Y |

Y2 |

+W/E |

+W2 |

G |

RH |

RC |

C |

6 |

|||||||||||

System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Mode - 2nd |

Heat Mode - 3rd |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

O |

|

|

|

|

Stage, Emergency |

Stage, Emergency |

|

|

|

|

|

|

|

|

|

|

|||

Heat Pump 1 |

|

|

|

|

|

|

Mode - 1st Stage |

Mode - 2nd Stage |

Blower/ |

|

|

|

|

|

|

|

|

|||||

|

|

Energized in |

|

|

No |

+Note: Dual Fuel option |

+Note: Dual Fuel option |

Circulator Fan |

|

|

|

|

|

|

|

|

||||||

(HP1) |

Diagnostic |

Cool Mode |

Heat and |

Output |

de-energizes Heat mode de-energizes Heat mode |

Energized on |

|

|

|

|

Optional* |

|

|

|||||||||

|

stage 1 (compressor) |

stage 1 (compressor) |

24 Volt |

24 Volt |

|

|

||||||||||||||||

|

Indicator |

|

|

Cool Mode |

|

|

when auxiliary heat |

when auxiliary heat |

Call for Heat |

24 Volt |

|

|

||||||||||

|

B |

|

|

is energized |

is energized |

(Hot) |

(Hot) |

(Com- |

|

|

||||||||||||

|

or System |

1st Stage |

|

|

|

|

|

|

or Cool. |

|

|

|||||||||||

|

|

|

Heat Mode - 3rd |

Heat Mode-4th |

|

|

||||||||||||||||

Heat Pump 2 |

Malfunction |

Energized in |

2nd |

Set Elect/Gas Heat |

Cool |

mon) |

|

|

||||||||||||||

(Compressor) |

Stage, Emergency |

Stage. Emergency |

|

|

||||||||||||||||||

(HP2) |

Switch |

Heat, Off, |

|

|

Stage |

Mode - 1st Stage |

Mode - 2nd Stage |

Option for |

|

|

|

|

|

|

|

|

||||||

|

|

|

Emergency |

|

|

(Com- +Note: Dual Fuel option |

+Note: Dual Fuel option |

Emergency |

|

|

|

|

|

|

|

|

||||||

|

|

|

Mode |

|

|

pressor) |

de-energizes Heat mode de-energizes Heat mode |

mode |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

stage 1 (compressor) |

stage 1 (compressor) |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

when auxiliary heat |

when auxiliary heat |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

is energized |

is energized |

|

|

|

|

|

|

|

|

|

|

||

Comfort Alert II Module |

|

|

or Similar System |

NEUTRAL |

|

Diagnostic Module |

24VAC |

120VAC |

See Module Instructions |

HOT |

for details

CLASS II

* Common connection required for diagnostic or malfunction indication.

+ Dual Fuel option, if selected turns off compressor(s) when Auxiliary stages energize.

Figure 5 – 3-Wire (SPDT) Heat Only Zone Valve Wiring

Jumper

|

6 |

Y |

W |

G |

RH |

RC |

C |

|||||||

System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Stage |

|

|

|

|

|

|

|

|

|

|

|

|

Constant |

|

3-wire |

Closes |

|

|

Opens |

Blower/Circulator |

24 Volt |

24 Volt |

|||||||

|

|

24 Volt |

||||||||||||

Zone Valve |

Valve |

|

|

Valve |

Fan Energized |

(Hot) |

(Hot) |

(Com- |

||||||

application |

(6) |

|

|

|

(4) |

|

|

|

Heat |

Cool |

mon) |

|||

|

|

|

|

|

|

|

|

|

(5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NEUTRAL

24VAC |

120VAC |

HOT

CLASS II

TRANSFORMER

3

Loading...

Loading...