Emerson 16E09-101 User Manual

CONTENTS

Basic Description ........................................................ 1

Precautions ................................................................. 1

Installation ................................................................... 2

Wiring .......................................................................... 3

User Menu .................................................................. 4

Operation .................................................................... 5

Specifications .............................................................. 7

Troubleshooting ........................................................... 8

www.white-rodgers.com

www.emerson.com

PRECAUTIONS

16E09-101

Universal Electronic Temperature Control

PART NO. 37-6857G

Replaces 37-6857F

1016

INSTALLATION AND

OPERATION INSTRUCTIONS

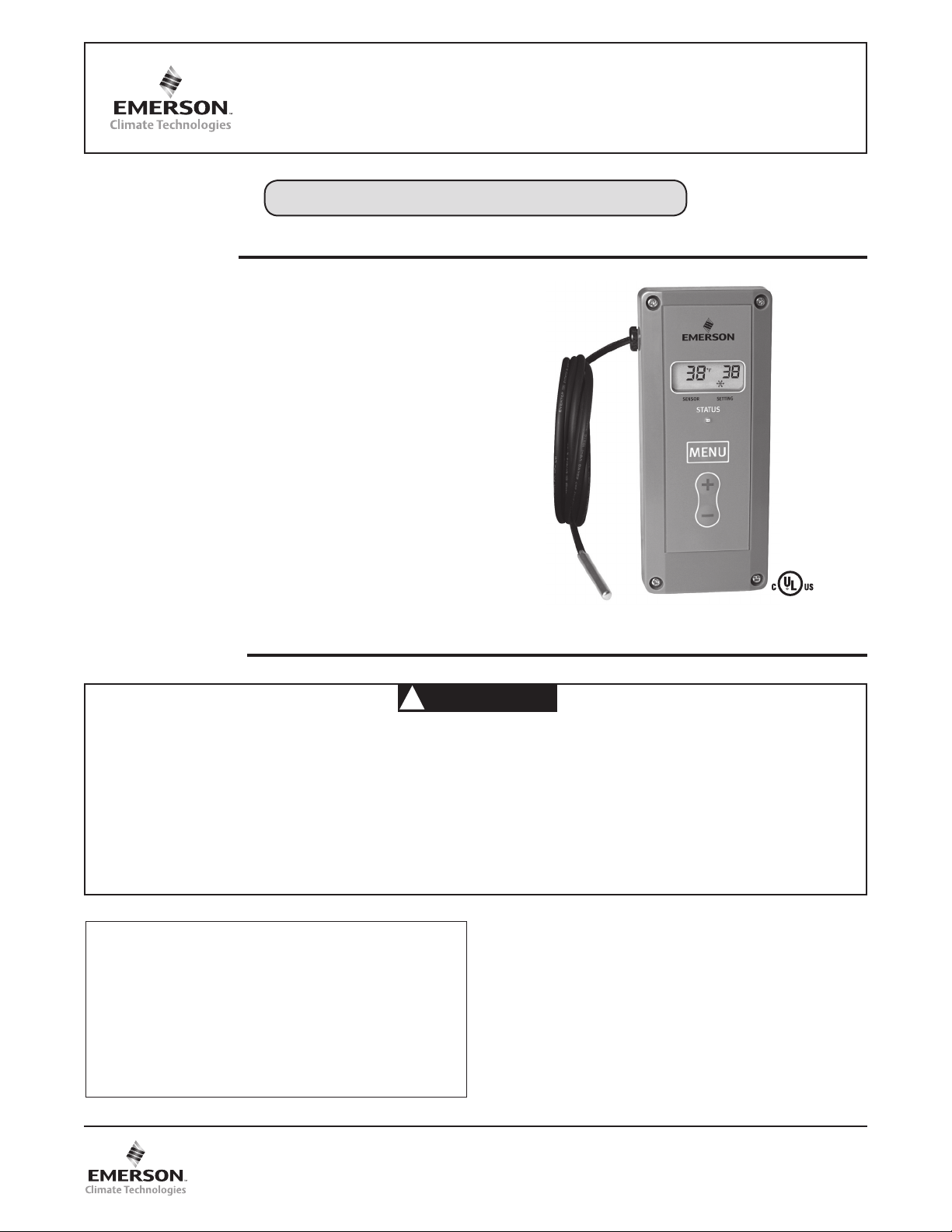

DESCRIPTION

The 16E09-101 is a single stage electronic temperature con-

trol, with a Nema 1 rated enclosure, and can be used for most

applications within the temperature control range of -40° to

220°F, (-40° to 104°C). The control has an SPDT (Single Pole

Double Throw) output load relay.

The control has user options to control differential, anti-short

cycle delay, set back, offset, alarms and more. It includes an

NTC (Negative Temperature Coefficient) thermistor tempera-

ture sensor, and can be used with certain other NTC or PTC

(Positive Temperature Coefficient) thermistors that meet the

specified resistance vs. temperature specifications. See the

tables on page 7.

The control can fit many applications, which range from

refrigeration to heating due to the wide temperature range of

the control stated above. Typical applications include walk-

in freezers, beverage coolers, supermarket display cases

for flowers, produce, meats, convenience store refrigerated

cases, food warmers, boiler control, and certain industrial

applications.

Save these instructions for future use!

WARNING

!

16E09-101 Optional Accessories / Service Items:

Immerson Well .................................................... F89-0286

Replacement 7.5' NTC Remote Sensor .............. F136-0114

Well Heat Transfer Compound ............................. F145-0163

• Failure to read and follow all instructions carefully before

installing or operating this control could cause personal

injury and/or property damage.

• To prevent electrical shock, personal injury and/or

equipment damage, disconnect electric power to system

at main fuse or circuit breaker box prior to installation

or service.

• To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

• Where failure of this control may result in personal

injury and/or property damage, additional alarms or limit

controls must be installed.

• This control is a temperature control and is not to be

used as a temperature limit control.

2

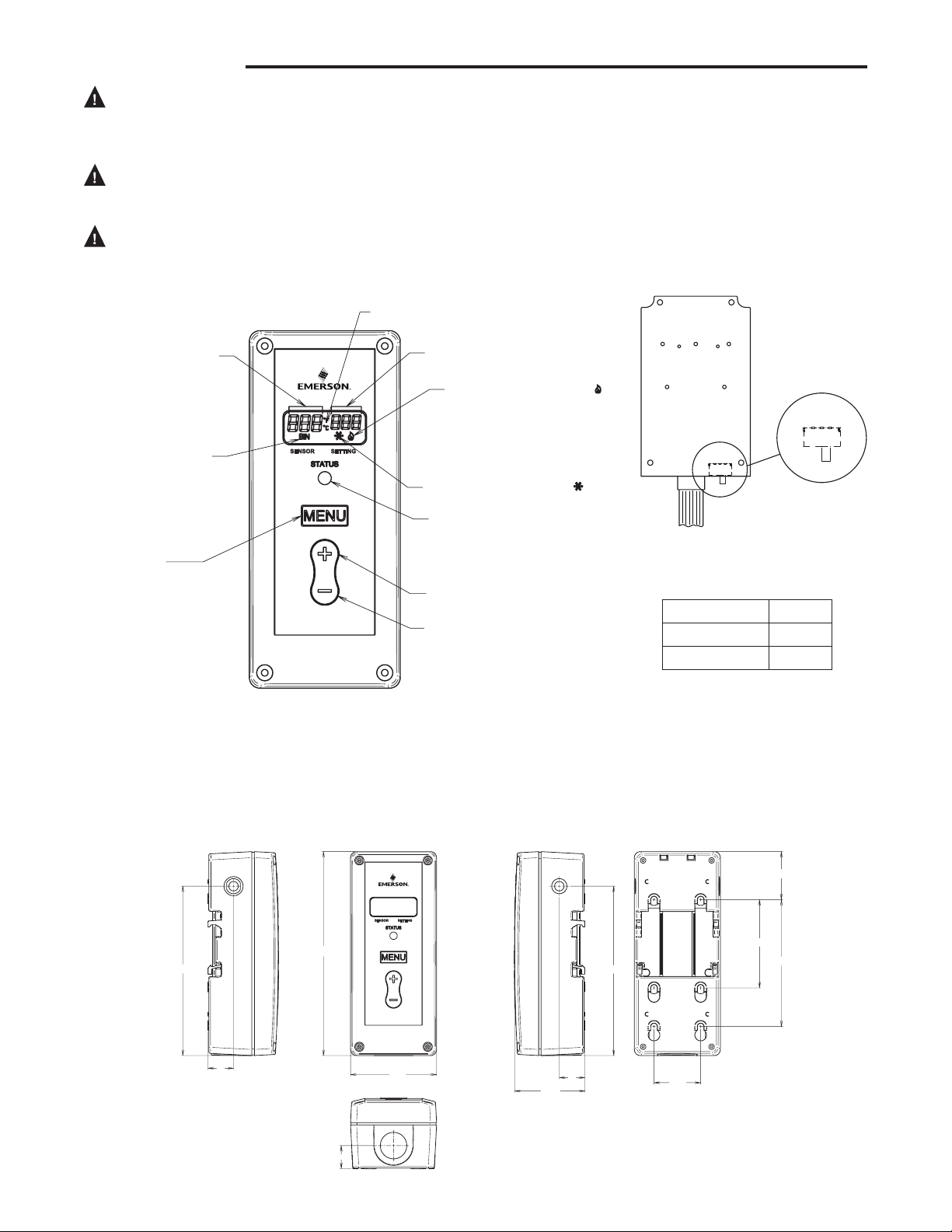

Fig. 1 Control Front View and Description

Fig. 2 Control Dimensions and Mounting Information

FRONT VIEW

BOTTOM VIEW

RIGHT SIDE VIEW

REAR VIEW

6.73”

2.8”

.76”

5.59”

.85”

2.54”

1.54”

2.91”

4.19”

1.58”

LEFT SIDE VIEW

.85”

5.59”

The control has a user selection for changing the setpoint to

be either the Cut In or the Cut Out setting. The user must be

careful to understand how this effects the “range” in which

the control will operate when the differential value is entered.

If entered values are incorrect, the control could operate

outside the user’s intended settings due to set-up error. See

section titled "Operation".

COOL

HEAT

SW1

COOL

HEAT

SW1

Circuit Board

Inside Cover

TEMPERATURE UNITS INDICATOR (°F or °C)

ACTUAL TEMPERTURE

AT TEMPERATURE SENSOR

SETPOINT TEMPERATURE

HEATING MODE INDICATOR ( )

COOLING MODE INDICATOR ( )

BINARY INPUT INDICATOR

LIT WHEN UNIT IS IN

“SETBACK” MODE

REFER TO PAGE 6

STATUS INDICATOR LED

LIT WHEN CONTROLLED LOAD

IS ENERGIZED (ON).

(SEE NOTE)

TEMPERATURE “UP” BUTTON

TEMPERATURE “DOWN” BUTTON

MENU BUTTON

PRESS TO ENTER MENU MODE

REFER TO PAGES 4 & 5

SW1

Refrigeration Cool

Heating Heat

Switch SW1 must be set for

system mode as shown:

To prevent electrical shock and/or equipment dam-

age, disconnect electric power to system at main

fuse or circuit breaker box prior to installation or

service.

Where failure of this control may result in personal

injury and/or property damage, additional alarms or

limit controls must be installed.

This control is a temperature control and is not to

be used as a temperature limit control.

INSTALLATION

NOTE:

Green Status Indicator LED and display backlight operation

It may be observed from time to time that the green status indicator LED and

display back-light will briefly turn off during a call for heating or cooling. During this

time, the control is performing a self-check lasting up to 15 seconds. This is normal

operation of the control and the load power will be maintained

3

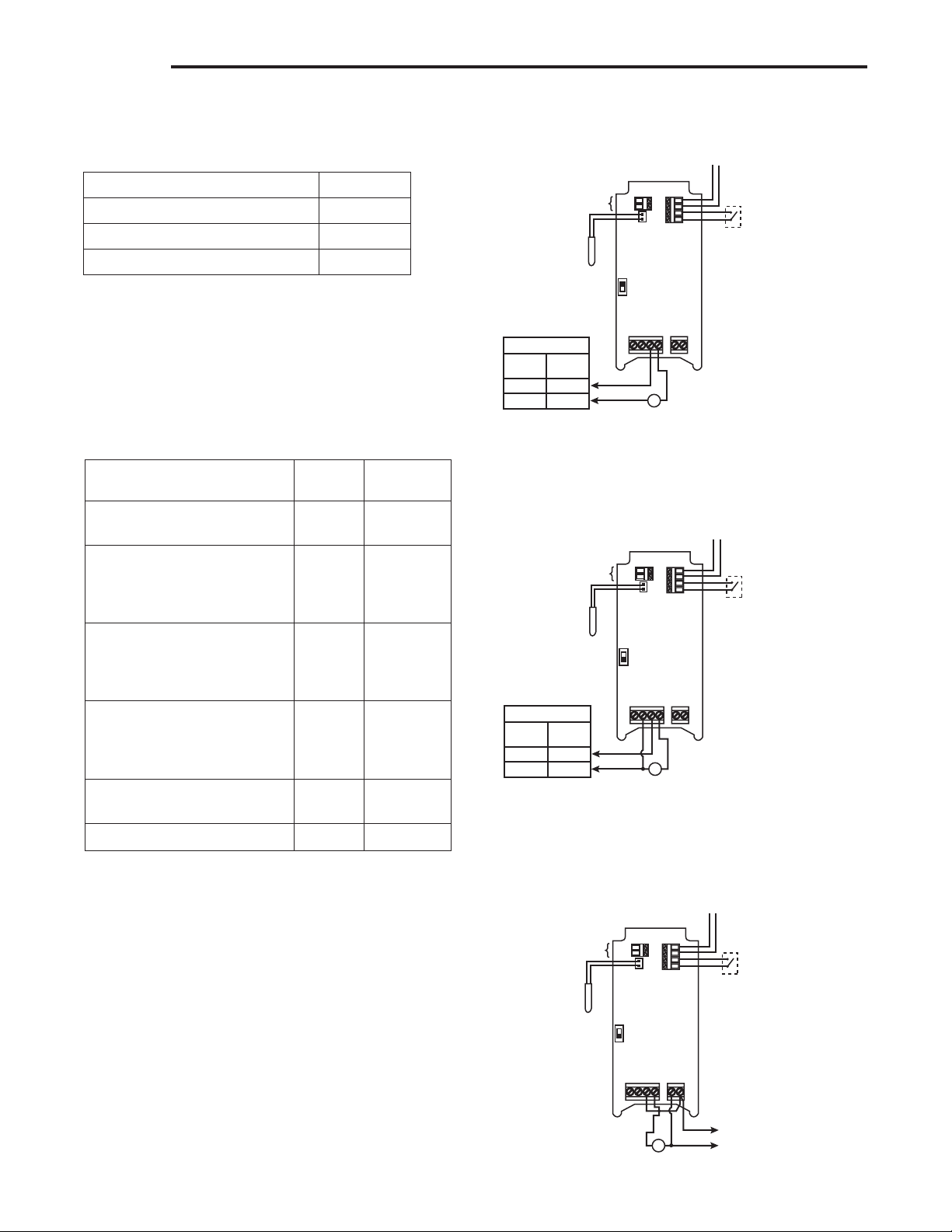

WIRING

Wiring Instruction Notes

Switch Settings

Switch SW2 must be set for applications as shown:

SW2

Line Voltage (Power Stealing) PS

Line Voltage (Non Power Stealing) Non PS

24 VAC (Non Power Stealing) Non PS

Fig. 4 Line Voltage Application

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Binary Input

(Gold Plated

Contacts)

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

120 VAC

Hot

Neutral

L1

L2

208/240

VAC

Voltage Input

Load

NON

PS

Alarm Output

For optional connection

to customer alarm equipment

24 VAC (Block not used)

TH - Thermostat Hot

TR - Thermostat Return

Fig. 5 24 VAC Applications

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Binary Input

(Gold Plated

Contacts)

Note: Do not use Output

Relay to control Line Voltage

when using 24 VAC Power

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

24 VAC

Class 2

Transformer

Load

NON

PS

Alarm Output

For optional connection

to customer alarm equipment

24 VAC

TH - Thermostat Hot

TR - Thermostat Return

NC contact

operates opposite

of load contact

* NTC – Negative Temperature Coefficient

PTC – Positive Temperature Coefficient

NOTE: Only one sensor (PTC or NTC) may be connected. Sensor must

meet specific temperature vs. resistance specifications.

PTC

BIN

GND

ALARM

NTC

SW2

PS

NON

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Alarm Output

For optional connection

to customer alarm equipment

Binary Input

(Gold Plated

Contacts)

24 VAC (Block not used)

TH - Thermostat Hot

TR - Thermostat Return

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

Fig. 3 Line Voltage Application

(Power Stealing)

120 VAC

Hot

Neutral

L1

L2

208/240

VAC

Voltage Input

Load

Power Stealing

Power Stealing is an electronic design within the control that

can eliminate the need to connect a neutral line to power the

control. The control receives power from the unit it is control-

ling. Power Stealing saves time and money by often eliminat-

ing the labor to run a neutral wire to the control for power. See

compatibility chart below for certain limitations.

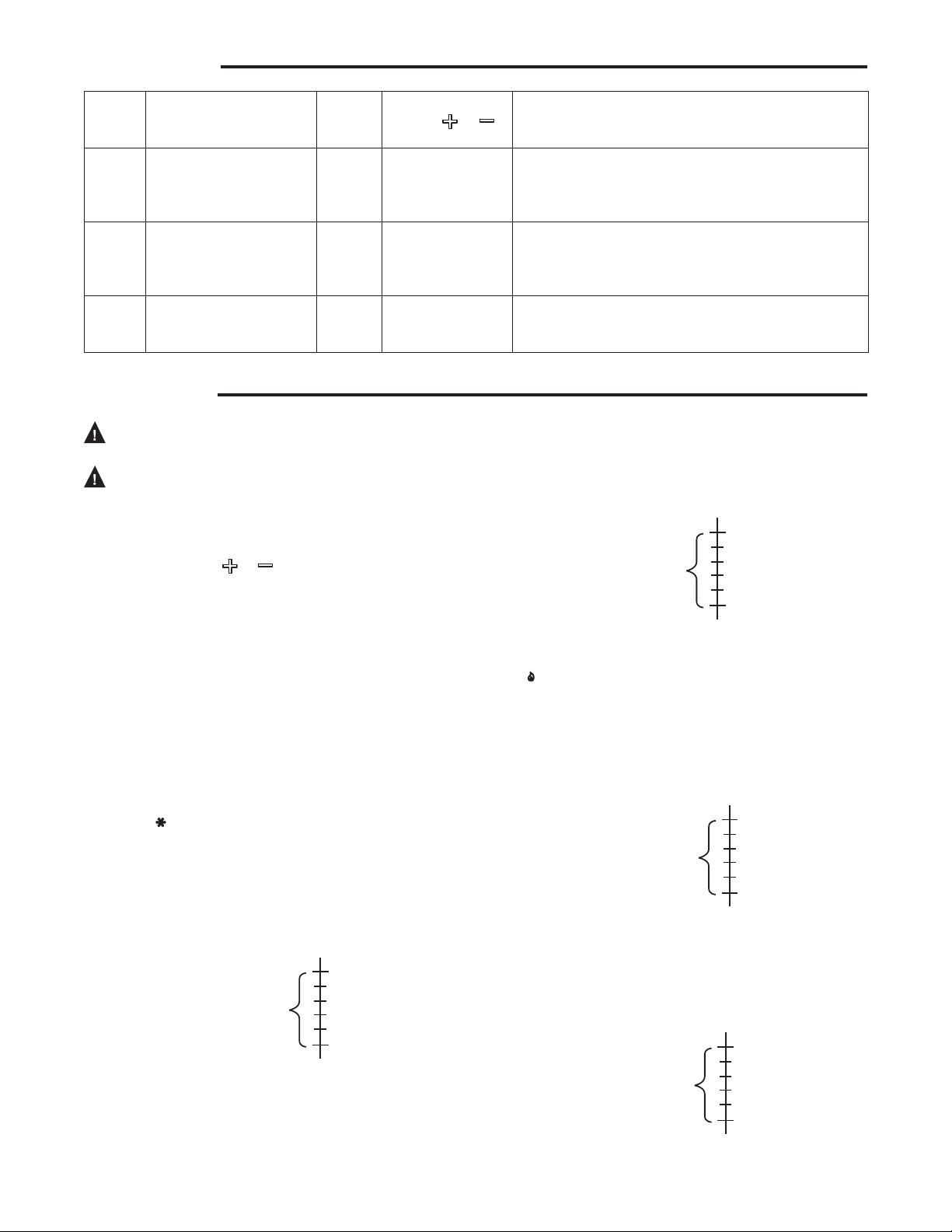

Power Stealing Compatibility Chart

Application

Power

Stealing

Non-Power

Stealing

Line Voltage, replacing existing

control that has a common wire

Yes Yes

Line Voltage, with load greater

than 2.5 amps, without Defrost

timer or other power interruption

circuit, with or without alarm

Yes Yes

Line Voltage, with load greater

than 2.5 amps, with Defrost

timer of other power interruption

circuit, no alarm

See

Note 1

Yes

Line Voltage with load greater

than 2.5 amps, with Defrost

timer or other power Interruption

circuit, with alarm

No Yes

Line Voltage with load less than 2.5

amps

No Yes

24 VAC Application No Yes

NOTE 1: During defrost or time when load circuit is broke,

display will be blank because power has been

interrupted to the control. All menu settings and

setpoint will be restored when power is returned.

(See "Special Note"

in "Operation Section"

for Alarm)

4

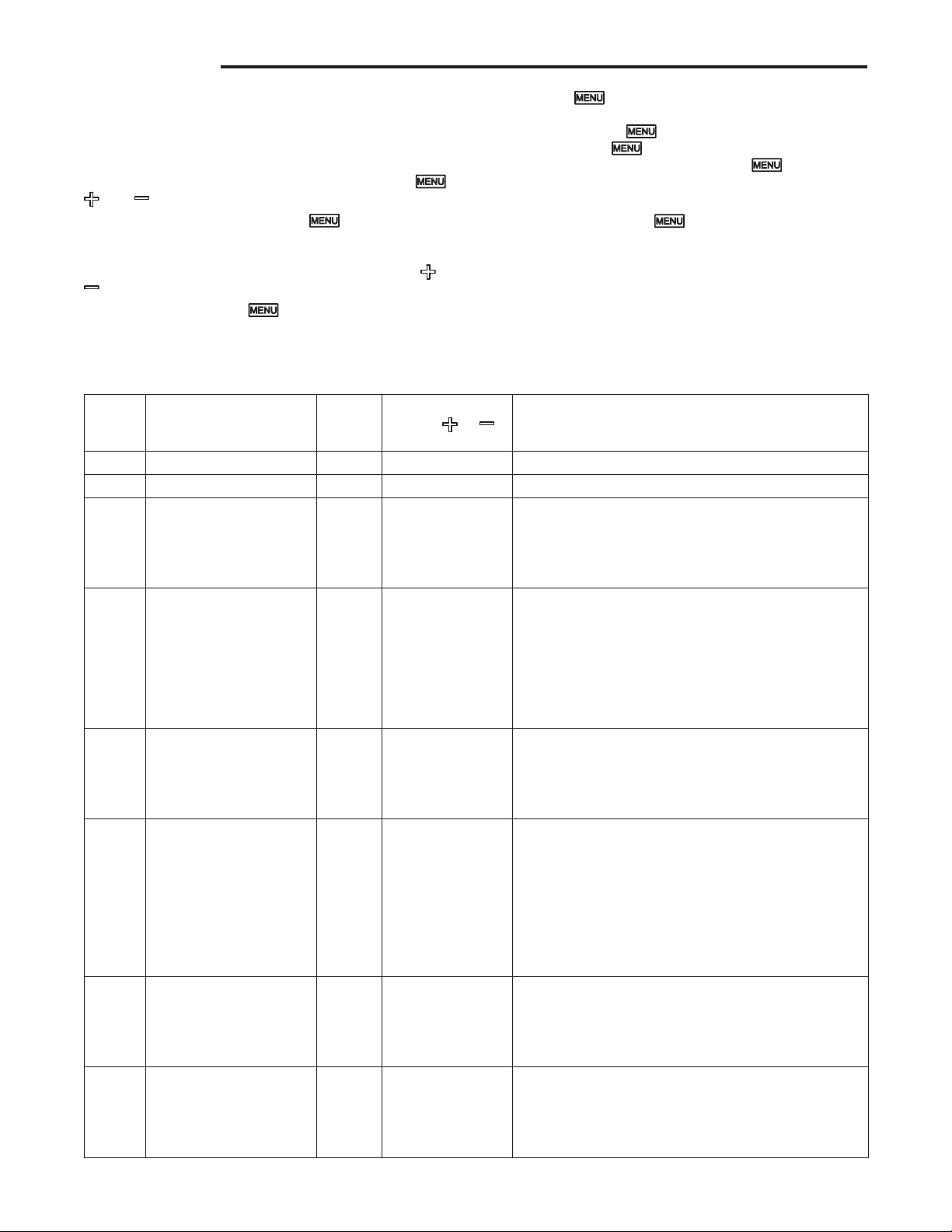

USER MENU OPERATION SETTINGS:

The control has user Menu settings that will determine how

the control operates. The unit is shipped with factory de-

fault settings. The user must change any of the settings as

required for the application. To reset all settings to factory

defaults, press and hold all 3 buttons simultaneously (

,

, and buttons) for approximately 5 seconds.

To view Menu items, press and hold for 5 seconds.

The unit will display the first Menu item on the left side of the

display. The right side of the display indicates the Menu item

settings. To change the setting, momentarily press the

or

key.

A momentary press of the

key advances the display to

the next Menu item, and continues, till the last menu item is

displayed. Pressing the key one more time with the last menu

item, (aL) displayed returns the control to the operating mode.

USER MENU

Each press of results in forward movement to the next

Menu item. If you need to change an item “passed”, you

must repeatedly press , return to the operating mode,

then press and hold for 5 seconds to re-enter the Menu

mode. Then repeatedly, momentarily press until the

desired Menu item is again displayed.

To store any changes made to any Menu items, the Menu

must be exited by pressing when the last item is

displayed. If no buttons are pressed for ten minutes while in

the menu, the control will return to operating mode and any

changes that were made will be lost.

The following table shows the menu items, default settings

and optional settings.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

Menu

Item Description

Factory

Default

Options

Press or

to select Comments

CF Temperature Scale F C or F Selects temperature display in Fahrenheit or Celsius

dFF Differential 5 1 to 30 Selects the range between Cut In and Cut Out.

SP Set Point Mode

Cool

Heat

Cl

CO

CO or CI

CI or CO

Selects how the set point temperature will operate the

load terminal. CI indicates the setpoint temperature

will be the Cut In temperature. CO indicates the

temperature will be the Cut Out temperature. See

Operation section.

SOF Sensor Operation Failure

Cool

Heat

1

0

0 or 1

None

Cooling - Selects the operation of the Control Load

relay in the event of a sensor failure in Cool mode. 1

(default) will cause the load contacts of the relay to

close and remain closed if the sensor either opens or

shorts. 0 causes the load contacts of the relay to open

and remain open.

Heating has no optional selection. Sensor failure

in Heating will result in the relay contacts opening.

dL Display Light Off On or Off Selects the LCD display light Off or On. With this

selected Off, the display light will illuminate any time a

keypad button is pressed to provide better viewing in

low lighting conditions, and go off after 10 seconds. If

On is selected, the display light will be On continuously.

ASd Anti Short-Cycle Delay Cool

1

Heat

0

0 to 12 Selects the minimum time (in minutes) that the load

contacts will remain open after a cycle before closing

again. This will prevent the compressor or other load

from being damaged by cycling too soon. A blinking

Snowflake or Flame icon indicates that the control has

a demand to energize the load, but is waiting for the

delay time to elapse. A setting of 0 indicates no time

and the feature is disabled. SW1 must be set to the

proper position before checking this setting.

LP Lock Front Panel Keypad Off On or Off When selected Off, the keypad can be used as normal.

When selected On, prevents unauthorized access to

the control settings by locking out all keys. To unlock

the control when it is locked, press and hold the Menu

key for 5 seconds.

OFS Ambient Temperature

Offset

0 -4, -3, -2, -1, 0,

1, 2, 3, 4

This control is calibrated at the factory, but the “sensed"

temperature may read different because of mount-

ing/installation, or other factors. This item allows the

displayed temperature to be shifted the number of

degrees set to compensate for this difference

5

If control is in Cool mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Setpoint

+ Differential

Range

Temperature

(plus)

Example:

This control is a temperature control and is not to

be used as a temperature limit control.

To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

The factory default setpoint for this control is 45°F (7°C) for

Cool and 120°F (49°C) for Heat. Setpoint temperature can

be adjusted using the

or keys. A power loss does not

lose the settings. All menu item selections and setpoint set-

ting are stored in a permanent memory.

The user determines the temperature operating range. To

determine the temperature range, the user must select the

Set Point (SP) as the Cut Out or Cut In temperature, Dif-

ferential (dFF) and enter a set point temperature. Cut out

is when the load is turned off and cut in is when the load is

turned on.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

COOL/REFRIGERATION

To use as a Cooling control, SW1 must be set to Cool. The

snowflake (

) icon will display.

If control is in Cool mode, and Set Point is selected as the

Cut In:

Temperature

Operating = Setpoint – Differential

Range Temperature

(minus)

Example:

40° Setpoint (Cut In)

35°

SW1 = Cool

Set Point (SP) = Cut In

Differential = 5

Setpoint temperature = 40°

Temperature

Range

40° Setpoint (Cut Out)

45°

SW1 = Cool

Set Point (SP) = Cut Out

Differential = 5

Setpoint temperature = 40°

Temperature

Range

HEAT

To use as a Heating control, SW1 must be set to Heat. The

flame ( ) icon will display.

If control is in Heat mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Setpoint

– Differential

Range

Temperature

(minus)

Example:

If control is in Heat mode, and Set Point is selected as the

Cut In:

Temperature

Operating =

Setpoint

+ Differential

Range

Temperature

(plus)

Example:

100° Setpoint (Cut Out)

95°

SW1 = Heat

Set Point (SP) = Cut Out

Differential = 5

Setpoint temperature = 100°

Temperature

Range

100° Setpoint (Cut In)

105°

SW1 = Heat

Set Point (SP) = Cut In

Differential = 5

Setpoint temperature = 100°

emperature

ane

Menu

Item Description

Factory

Default

Options

Press or

to select Comments

bIn Binary Input Off On or Off The default setting of Off will have no affect on the

operation of the thermostat. When set to On, it allows

an external binary input (switch or relay) to start a tem-

perature set back. See Set Back (Sb).

Sb Set Back 0 0 to 50 Selects the number of degrees the thermostat will

change the setpoint temperature when the external

binary input signal is received. 0 will cause no tempera-

ture change to occur. See Binary Input (bin).

AL Alarm 0 0 to 99 Selects the time delay (in minutes) before a Tempera-

ture Out of Range alarm output is sent.

A setting of 0 disables the alarm relay.

USER MENU

OPERATION

Loading...

Loading...