Electrolux WFGROAOOOO, 9CHG584103, 9CHG584101, 9CHG584102, WFGUOFOOOO User Manual

...

thermaline S90

GAS FRYERS - FRITEUSE POUR GAZ

Doc. 62.9679.01_UL

Edition 1 01.2006

US |

INSTALLATIONAND OPERATING INSTRUCTIONS |

page 3 |

|

FR |

INSTRUCTIONS D’INSTALLATION ET D’EMPLOI |

page 13 |

|

|

|

||

FOR YOUR SAFETY |

POUR VOTRE SÉCURITÉ |

||

Do not store or use gasoline or |

Ne déposez pas ou n'employez |

||

other flammable vapors or liquids |

pas l'essence ou d'autres vapeurs |

||

in the vicinity of this or any other |

ou liquides inflammables à pro- |

||

appliance. |

|

ximité de ceci ou d'aucun autre |

|

|

|

appareil. |

|

|

|

|

|

|

|

|

|

WARNING |

AVERTISSEMENT |

|

|

Improper installation, adjust- |

L'installation inexacte, l'ajuste- |

||

ment, alteration, service or |

ment, le changement, le service |

||

maintenance can cause property |

ou l'entretien peuvent causer des |

||

damage, injury or death. Read the |

blessures matériels, des domma- |

||

installation, operating and |

ges ou la mort. Lisez les instruc- |

||

maintenance instructions thorou- |

tions d'installation, d'opération et |

||

ghly before installing or servicing |

d'entretien complètement avant |

||

this equipment. |

d'installer ou entretenir cet |

|

|

|

|

équipement. |

|

|

|

|

|

INSTRUCTION

Post in a prominent location instructions to be followed if the user smells gas. Consult the local gas supplier to obtain the information.

Présentez dans des instructions en avant d'un endroit d'être suivi si l'utilisateur sent le gaz. Consultez le fournisseur local de gaz pour obtenir l'information.

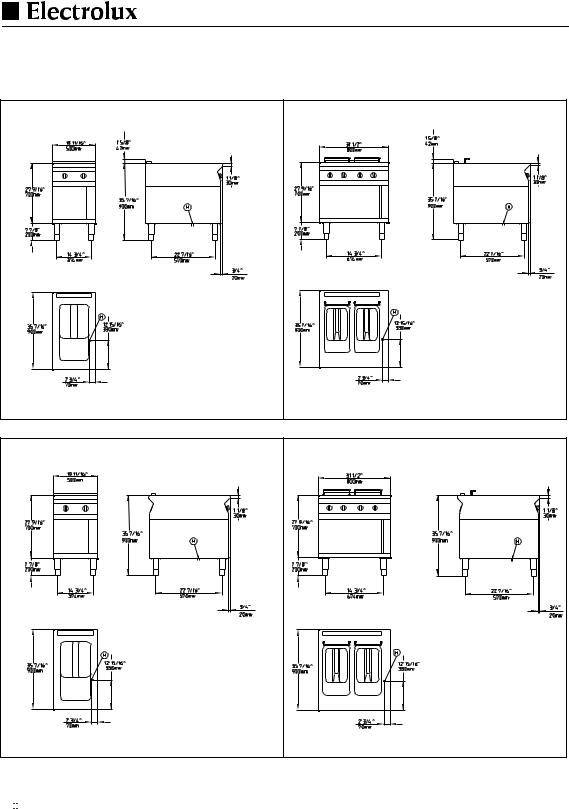

Against wall - contre une paroi

Free standing - isolé

Connections - Raccordement

Gas - Gaz

Gas - Gaz

Fig.1 INSTALLATION DRAWINGS - PLANS D'INSTALLATION

Doc. 62.9679.01_UL

CONTENTS |

|

|

I. |

GENERAL INFORMATION ................................................................................................. |

3 |

II. |

INSTALLATION INSTRUCTIONS ....................................................................................... |

5 |

III. |

OPERATING INSTRUCTIONS ............................................................................................ |

9 |

SOMMAIRE |

|

|

IV. |

INSTRUCTIONS GÉNÉRALES ......................................................................................... |

13 |

V. |

INSTRUCTIONS RELATIVES À L'INSTALLATION ......................................................... |

15 |

VI. |

INSTRUCTIONS DE FONCTIONNEMENT ....................................................................... |

19 |

APPENDIX

VII. Table of nozzle - Tableau de gigleur

62.9679.01_UL |

Page 1 |

Page 2 |

62.9679.01_UL |

GENERAL INFORMATION

I . GENERAL INFORMATION

1.INSTRUCTIONS FOR SAFETY AND USE

1.1INSTALLATION AND INITIAL OPERATION

SThe installation, adjustment and initial operation of the appliance must be carried out according to the manufacturer's instructions and may only be done by an authorised specialist.

SInstallations for the supply of electricity and gas must be carried out by approved specialists in compliance with specific national and local regulations. They bear the responsibility.

SThe installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B1 49.1.

SThe appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at pressures in excess of 1/2 psi (3.5 kPA).

SThe appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piiping system at test pressures equal to or less than 1/2 psi (3.5 kPA).

SThe appliance must not be placed in operation until the user has become familiar with its operation. The operating instructions and the related safety precautions must be followed precisely. Follow strictly the attention and warning label indications on the appliances.

1.2OPERATOR'S OBLIGATIONS

SThe manager is responsible for ensuring that all components relevant to safety are in perfect working order at all times. The operating condition of these components must be examined by an authorised specialist at least once a year and any defects remedied if required.

SThe operator of this appliance is responsible for total observation of the national regulations concerning operating safety.

SRemain the manual for future reference.

1.3USE AS PRESCRIBED

SClosed containers (jars, cans, bottles, tubes, etc.) must not be heated owing to the danger of bursting and injuries.

1.4SAFETY-CONSCIOUS WORKING

SThe trough heating must not be switched on if there is no oil in the trough or the oil level has fallen below the minimum. - Risk of fire.

SFood must be placed slowly in the heated trough, to prevent the oil from bubbling over.

SMounting a mixer tap near a fryer is prohibited. There is a great danger of explosion if water sprays into hot oil.

SWhen the oil trough temperature is high and food with a high water content is to be fried, the hot oil may froth up and spit out. - Danger of injury!

SUsed oil has a lower ignition point and tends to bubble up. - Danger of injury!

SOil must not be allowed to drain into the discharge vessel or transported before it is cooled down fully.

STouching the hot cooking zones can cause burns.

SThe escape of burnable gases represents a fire and explosion hazard. Action in the case of a gas leak and a smell of gas:

-No smoking, no fire

-Do not operate electric switches or bells.

-Do not operate the piezo igniter

-Close gas cylinder valves and the main gas valve on the appliance.

-Ventilate the room thoroughly

-Place the leaking gas cylinders upright in the open with valves closed.

SThe waste-gas outlets of the fryer become hot. Avoid touching them.

SThe waste-gas outlets of the fryer are not to be covered by any objects.

SSpraying the appliance or parts of it with a high-pressure cleaning device may cause malfunctions and is not to be done.

SKeep the appliance area free and clear from combustibles

SDo not obstruct the flow of combustion and ventilation air.

SFor appliances with a downpipe, the hose should lead into a drain opening which is covered by a grating such that it cannot be kicked or tipped, or a drain gutter should run underneath the appliance.

SDevices on wheels set up in block configuration must be checked before each start-up whether the potential equalization is connected with the neighbour equipment. The connection may be done only by authorized technical personnel.

SAppliances on wheels must be fastened to the building.

62.9679.01_UL |

Seite 3 |

GENERAL INFORMATION

1.5AFTER-SALES SERVICE AND REPAIR

SIn the event of a permanent fault which interferes with operation, the appliance must be switched off and disconnected from the power supply.

STo perform maintenance and repairs contact the factory, the factory representative or a local service company.

SRepair, maintenance work and other adjustments are only to be carried out by an authorised specialist. The valid local and national regulations must be observed. This applies especially to burners, ignition, safety and control elements. Parts requiring replacement are only to be replaced by original spare parts. Periodic tests for gas leaks must be carried out. A service contract is therefore recommended.

SCleaning and maintenance must be done only when the heating surfaces are cold. Do not use inflammable liquids to clean the appliance.

SAn obligatory service check is required annually.

2.TECHNICAL DATA

|

|

Width |

Trough |

Power |

||

PNC Appliances |

Appliance type |

Depth |

contents |

Gas |

||

|

|

Height |

|

consumption |

||

|

|

|

|

|

|

|

|

|

inch |

mm |

|

|

|

|

|

|

|

|

|

|

9CHG584101 |

WFGROFOOOO |

19.7 |

500 |

6.1 gal |

22 kW |

|

|

|

35.4 |

900 |

|||

9CHG584102 |

WFGROAOOOO |

1 x 23 l |

75000 BTU |

|||

35.4 |

900 |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

9CHG584103 |

WFGUOFOOOO |

31.5 |

800 |

3.7 gal |

29 4 kW |

|

|

|

35.4 |

900 |

|||

9CHG584104 |

WFGUOAOOOO |

2 x 14 l |

100000 BTU |

|||

35.4 |

900 |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

3.PACKAGING

All the packaging materials used are environmentally friendly. They may burnt at an incineration plant or sent for recycling.

4.TESTS / CERTIFICATES

All gas appliances are tested according to the standard ANSI Z83.11-2002 and CSA 1.8-2002 of Gas Food Service Equipment.

5.SPECIFICATION PLATE

The specification plate (E) is located in each case inside and outside on the right of the operator panel (C) (Seite 6 Fig. 5).

The serial number is marked on the type plate. The 8 digits give following information:

Y |

last digit of the year of production |

WW |

week of production |

XXXXX |

running number |

Seite 4 |

62.9679.01_UL |

INSTALLATION INSTRUCTIONS

II . INSTALLATION INSTRUCTIONS

1. |

INSTALLATION |

1.3 |

ASSEMBLING TWO APPLIANCES |

The appliance is designed for connection to fixed lines. The appliances are suitable for setting up as single appliances or as a group of appliances. They can be set up freely in the room, side by side, at the side and/or at the back against a wall.

Gaps between two appliances or appliance and sidewall should be filled with a FDA approved silicone such as Samco RTV103.

1.1DISTANCES

If an appliance is set up next to or against temperature-sensi- tive furniture or similar, a safety gap of approximately 6“ (150 mm) should be maintained or some form of heat insulation fitted.

The walls must be made up of non-combustible material like tiles or steel.

1.2HEIGHT ADJUSTMENT

Appliance on feet: Alignment is carried out by screwing the lower foot parts in or out.

Appliance on |

Irregularities or differences in height can |

steel plinth: |

be equalized by inserting one or several |

|

strips of chrome nickel steel. |

Appliance on feet.

D Turn the lower part of the feed to adjust the appliance high.

The feet are adjustable from 4“ to 8“ (100 to 200 mm). A high of 8“ (200 mm) can be recommended and results in an appliance high of 35,4“ (900 mm).

Note:

Adjustment of the legs shall provide an unobstructed clearance of minimal 6“ (150 mm) and maximal 8“ (200 mm) beneath the unit due to sanitary and stability aspects.

The lower part of the foot must not be unscrewed too far. The exposure of threads is prohibited.

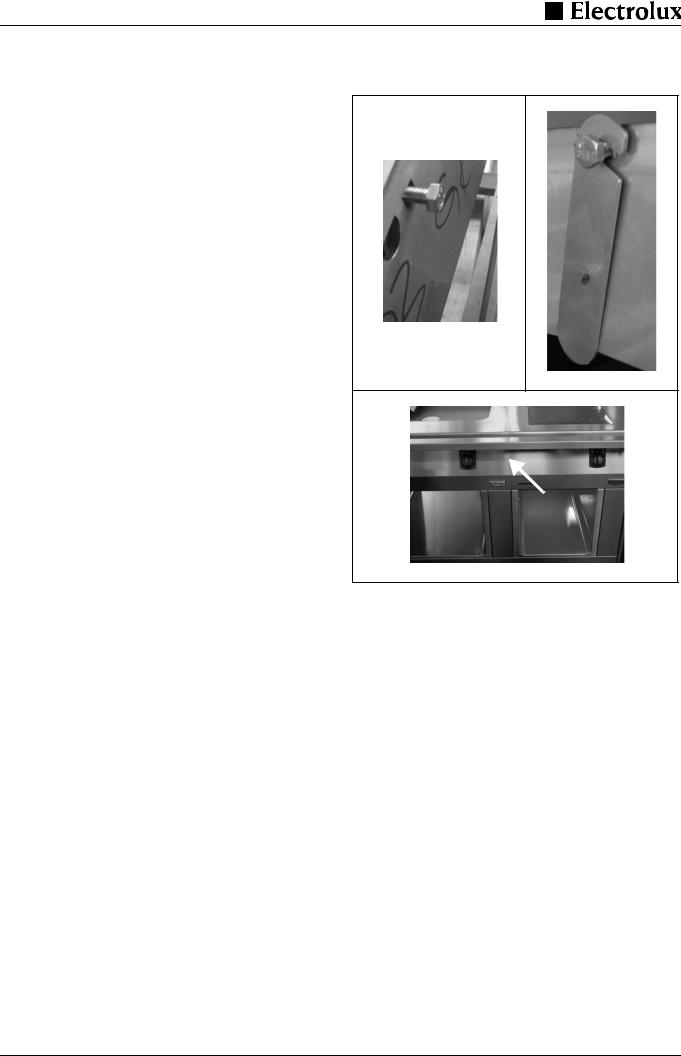

(1)

(1)

(2)

a

b

c

Fig.1 Lateral connection

The assembly kit contains two of each of the following:

caged nuts (1 / Fig.1) pre-assembled on the right-hand side of the appliance, hexagonal screws M8x25 (1 / Fig.1) and mounting links (2 / Fig.1)

DRemove the control panels from both appliances as in 2.2

DRemove the front panels from both appliances as in 2.1

DKeeping the screw (1 / Fig.1) loose, turn it until it is approximately 5 mm deep in the caged nut.

Positioning the appliances:

DPlace the appliances next to one other.

DAlign for position and height.

Connect the appliances:

DFit the mounting link (2 / Fig.1) into the inside of the second appliance's left connecting plate.

DTighten the screws.

Note

If required, the caged nuts can also be fitted on the other side of the appliance.

62.9679.01_UL |

Seite 5 |

INSTALLATION INSTRUCTIONS

1.4 SIDEWALL (D) |

1.6 ASSEMBLING ON CASTORS |

(5)

(4)

a

b

Fig.2 Assemblage of sidewall

The assembly kit contains two of each of the following: hexagonal screws M8x25 (1 / Fig.1), bolts with retaining rings

(2 / Fig.1), mounting links (3 / Fig.1), hexagonal screws M8x16 with serrated washers and hexagonal nuts M8, hexagonal screws M5 with serrated washers (4 / Fig.2)

and a fastening angle (5 / Fig.2).

DInsert the bolts with the retaining rings (2 / Fig.1a) from outside into the guide in the sidewall.

DKeeping the screw (1 / Fig.1a) loose, turn it until it is approximately 5 mm deep in the pre-assembled caged nuts in the sidewall.

DAttach the fastening angle (5 / Fig.2b) to the bottom of the frame using the screws, serrated washers and nuts.

D(4 / Fig.2).

DPosition the sidewall and screw it on from below using two hexagonal screws and the serrated washers.

DFit the mounting link (3 / Fig.1b) into the inside of the appliance's connecting plate.

DAlign the sidewall and firmly tighten all screws.

1.5STEEL PLINTH

(3)

(2)b

(3) (1)

b |

(1) |

|

(2)

a

b

Fig. 3 Plinth assembly

To assemble the plinth you will need:

•Right and left side plinth (1 / Fig.3).

•Plinth for the front and, for free-standing appliances, for the rear also (2 / Fig.3).

DPush the side plinth (1 / Fig.3) onto the legs from front to rear using the fastener. The larger gap (b / Fig.3) on the fastener must be at the bottom.

DAffix the fasteners (3 / Fig.3) to the plinth (2 / Fig.3).

DThe larger gap (b / Fig.3) on the fastener must be at the bottom.

DAttach the plinth with the fasteners (3 / Fig.3) onto the feet.

a

c

b

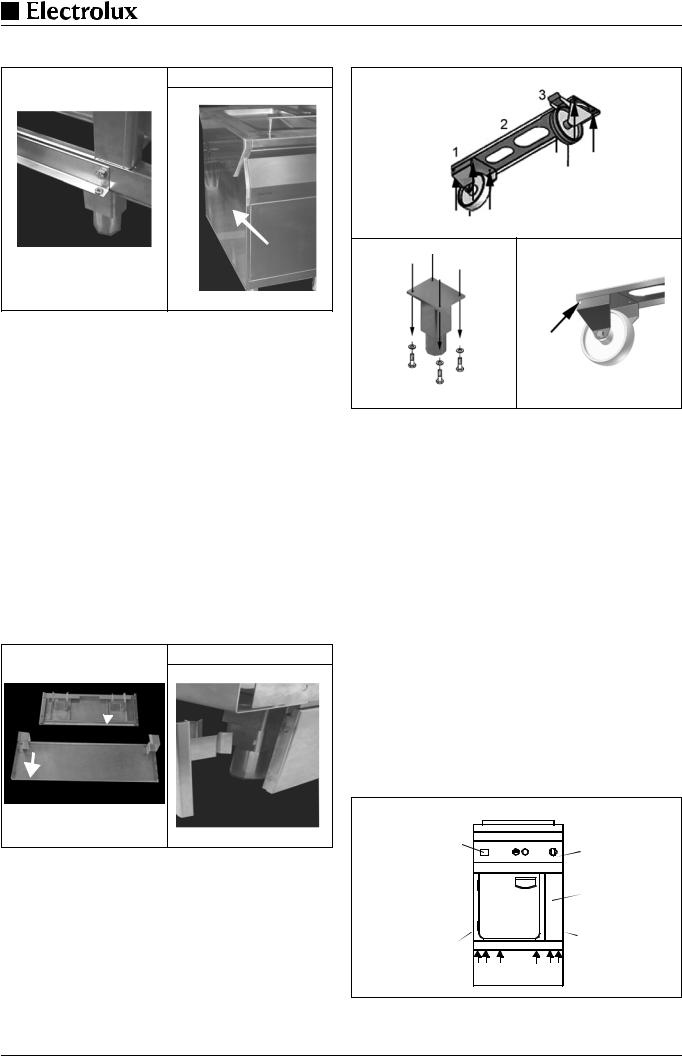

Fig.4 Assemblage on castors

The assembly kit for mounting on castors contains two cross bars (2/Fig.4a) each with a fixed rear wheel (1/Fig.4a) and a turnable front wheel (3/Fig.4a).

Mounting the castors:

DPut the appliance on supports.

DRemove the feet; each is tightened with four screws (Fig.4b).

DBring the two cross bars into the correct position below the appliance and fasten it with 8 screws arrows (Fig.4a).

DRemove the supports.

DFasten the appliance to the building. Use the hole to attach a chain descending from the wall (arrow/Fig.4c). Making sure the chain is shorter than the gas and electric connections.

Note:

Appliances on wheels must be secured by fasten it to the building.

2.ACCESS TO INTERIOR

Note:

Only authorized technicians may access the interior.

E |

C |

|

|

|

B |

D |

D |

|

|

11 3 |

3 11 |

Fig. 5 General view

Seite 6 |

62.9679.01_UL |

Loading...

Loading...