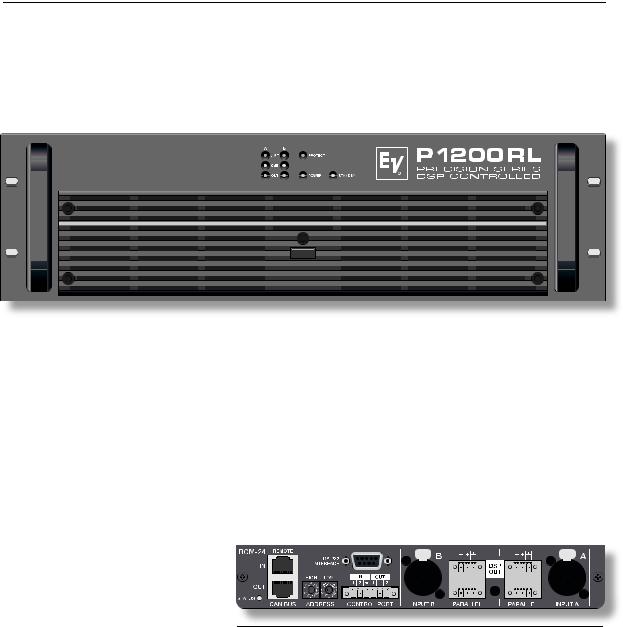

Electro-Voice P1200RL, P900RL User Manual

OWNER‘S MANUAL BEDIENUNGSANLEITUNG

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS |

3 |

IMPORTANT SERVICE INSTRUCTIONS |

3 |

DESCRIPTION |

4 |

UNPACKING & WARRANTY |

5 |

INSTALLATION NOTES |

5 |

FRONT VIEW |

6 |

REAR VIEW |

7 |

INPUT A / INPUT B |

7 |

PARALLEL CONNECTION |

7 |

DSP OUT |

7 |

CONTROL PORT |

7 |

RS-232 INTERFACE |

8 |

ADDRESS |

8 |

REMOTE CAN-BUS |

8 |

EASY REMOTE |

9 |

POWER AMP OUTPUT |

9 |

GROUND-LIFT SWITCH |

9 |

MAINS INPUT |

9 |

CABLING |

10 |

LF-CONNECTION CORDS |

10 |

REMOTE CONTROL NETWORK |

10 |

NETWORK EXAMPLES |

1 |

CAN-BUS |

13 |

MAINS OPERATION & RESULTING TEMP |

14 |

SPECIFICATIONS / TECHNISCHE DATEN |

29 |

BLOCK DIAGRAM AMPLIFIER |

3 |

BLOCK DIAGRAM RCM-24 |

32 |

DIMENSIONS / ABMESSUNGEN |

33 |

2

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol, within an equilateral triangle is intended to alert the user to the presence of uninsulated „dangerous voltage“ within the product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

|

|

persons |

|

|

The exclamation point within an equilateral |

|

|

triangle is intended to alert the user to |

|

|

the presence of important operating and |

|

|

maintance (servicing) instructions in the |

1. |

Read these instructions. |

literature accompanying the appliance. |

2.Keep these instructions.

3.Heed all warnings.

4.Follow all instructions.

5.Do not use this apparatus near water. Do not expose this apparatus to dripping or splahing and ensure that no objects filled with liquids, such as vases, are placed on this apparatus.

6.Clean only with a dry cloth.

7.Do not block any of the ventilation openings. Install in accordance with the anufactures instructions.

8.Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

9.Only use attachments/accessories specified by the manufacturer.

10.Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped

11.To completely disconnect mains power from this apparatus, the power supply cord must be unplugged.

For US and CANADA only:

Do not defeat the safety purpose of the grounding-type plug. A grounding type plug has two blades and a third grounding prong. The wide blade or the third prong are provided for your safety. When the provided plug does not fit into your outlet, consult an electrican for replacement of the absolete outlet.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualifi ed personnel only.To reduce the risk of electric shock, do not perform any servicing other than that ontained in the Operating Instructions unless you are qualifi ed to do so. Refer all ervicing to qualifi ed service personnel.

1.Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 have to be obeyed when servicing the appliance

2.Use of a mains separator transformer is mandatory during maintenance while the appliance is opened, needs to be operated and is connected to the mains

3.Switch off the power before retrofitting any extensions, changing the mains voltage or the output voltage.

4.The minimum distance between parts carrying mains voltage and any accessible metal piece (metal enclosure), respectively between the mains poles has to be 3 mm and needs to be minded at all times.

The minimum distance between parts carrying mains voltage and any switches or breakers that are not connected to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5.Replacing special components that are marked in the circuit diagram using the security symbol (Note) is only rmissible when using original parts.

6.Altering the circuitry without prior consent or advice is not legitimate.

7.Any work security regulations that are applicable at the location where the appliance is being serviced have to be strictly obeyed. This applies also to any regulations about the work place itself.

8.All instructions concerning the handling of MOS - circuits have to be observed.

NOTE: |

SAFETY COMPONENT ( MUST BE REPLACED BY ORIGINAL PART ) |

3

DESCRIPTION

Congratulations! With buying an Electro-Voice PRECISION SERIES power amplifier you have chosen an appliance that employs the most advanced technology.

P-Series power amps combine outstanding audio performance, highest reliability and operational stability. Each power amplifier employs an RCM-24 Remote Control module allowing centralized configuration, control and monitoring of all relevant power amp parameters (like output current, output voltage, load impedance, etc.).

The gapless protection circuitry concept not only prevents the power amp itself but also the connected loudspeaker systems from being damaged. These extensive protections include Dynamic Audio

Limiters, DC/HF-Protections, Back-EMF-Protection, Inrush Current Limiter, Short Circuit Protection and of course Thermal Overload Protection for the output transistors and mains transformers.

Three-speed high performance fans guarantee outstanding thermal stability at absolute low running noise. The ventilation is directed front-to-rear allowing trouble-free operation even in smaller amp-racks.

Comprehensively dimensioned power supply units with low-leakage toroidal transformers provide extensive headroom far above the stated nominal power.

Mechanical construction and workmanship also comply with the highest precision manufacturing standards. The rigid sheet steel chassis resists even the most wearing tour operation.

The RCM-24 provides full-size overview of the system’s entire status

and control over all relevant system parameters at any time. The RCM-

24 module allows integration into a

Remote Control Network consisting of up to 250 power amps. The Windows Software IRIS – Intelligent Remote & Integrated Supervision – allows controlling and monitoring an entire PA-system from a single or several PCs. Any operational status like initial power-on status, temperature, modulation, limiting, activation of protections, deviation in the load impedance, etc., are centrally registered and displayed, which provides the opportunity to take specific measures prior to the occurrence of critical operational states. Programming an automatic response for exceeding or falling below specific limits is possible as well. All parameters, e.g. power-on/off, levels, muting, filters, etc. can be controlled in realtime and saved in any power amp.

Monitoring the connected loudspeaker systems is performed through measuring output currents and –voltages of the two power amplifier channels. Each time the signal falls below or exceeds set limit values is immediately indicated and logged, thus detecting and indicating short circuits and line interruption during normal operation. The integrated impedance test function allows more precise checking the connected loudspeaker systems. The integrated signal generator is employed together with the current/voltage testing to measure the connected loudspeakers’ and cable’s impedance plus over the entire frequency range. The resulting impedance graph is displayed on the PC-screen. Comparing the measured impedance progression to a reference value is possible at all times, which allows recognizing even the slightest loudspeaker defects or irregularities.

4

DESCRIPTION

Next to controlling and monitoring, the RCM-24 Remote Control module provides comprehensive signal processing functions. It includes a total of 20 parametric filter–, X-over functions, delays, routing and level control as well as compressors and limiters per channel. All parameters can be freely edited and stored in the module’s 8 user presets. Independent from network control all DSP-settings (filter, delay, level) are maintained in case of failure. Additionally, the control inputs of the power amps can be used for network-independent switching to another preset (e.g. alarm settings with maximum energy for voice and text announcements).

Therefore, P-Series amps with RCM-24 modules installed fulfil even the highest safety requirements.

When designing the RCM-24, uncompromising audio quality was the highest maxim. AD/DAconversion is performed at a resolution of 24-bit and 128-times oversampling with linear phase; the internal word length is 48 bits. With this the RCM-24‘s dynamic range reaches 115 dB, which is an absolute peak value for digital audio appliances.

All configuration, control and monitoring details of P-Series power amps are explained in the documentation accompanying the PC Windows software IRIS.

UNPACKING & WARRANTY

Carefully open the packaging and take out the power amplifier. Next to the power amplifier itself, the package also includes this owner’s manual, a mains cord, the warranty certificate, four stand-feet, six screw-on connectors (1x 2-pole, 4x 3-pole, 1x 6-pole) plus a set of rack shelf mounting adapters.

Please inspect carefully whether all information in the warranty certificate has been filled in completely, since only a completely filled in warranty certificate entitles you to stake any warranty claims. The appliance comes with a 36 months warranty, starting with the date when receiving the good from your dealer. Therefore, keep the original invoice together with the warranty certificate at a safe place.

INSTALLATION NOTES

Generally, installing or mounting power amps should be carried out in a way that guarantees continuously unopposed front-to-rear air circulation. When including an appliance in a closed cabinet or rack shelf system make sure to provide sufficient ventilation. Leave a gap of at least 60mm x

330mm (up to the cabinet’s top ventilation louvers) for air circulation between the rear of the power amplifier and the cabinet’s/rack’s rear wall. Make sure to leave at least 100mm of space above the cabinet or rack shelf system. Since the temperature inside of the cabinet or rack shelf system can easily rise up to 40°C during operation, bearing in mind the maximally allowable environmental temperature during operation for all other appliances installed in the same rack shelf system is mandatory.

(also refer to “MAINS OPERATION & RESULTING TEMPERATURE”)

4.4 |

3/4 |

Caution:

The use of rails or optionally available rack adapters – NRS 90235 (112733) – is mandatory as well when installing the appliance in a rack shelf system to prevent the front panel from bending.

For problem-free operation exceeding the maximally allowable environmental temperature or +40°C is not permissible.

The power amplifier has to be protected against: dripping or splashing water, direct sunlight, high temperatures or direct influence of heat sources, high humidity, extensive dust and vibrations.

Condensation on internal parts may occur after transporting the power amplifier from a cold into a warmer environment. In that case operation is only permissible after the appliance has gained the new temperature (after approximately one hour). If foreign objects or liquids have entered the power amplifier’s enclosure make sure to instantly separate the appliance from the mains power and contact an authorised DYNACORD service centre for inspection before continuing operation.

Do not use any sprays or solvents for cleaning the appliance, because they might severely damage the surface of the enclosure or lead to dangerous fire hazard.

5

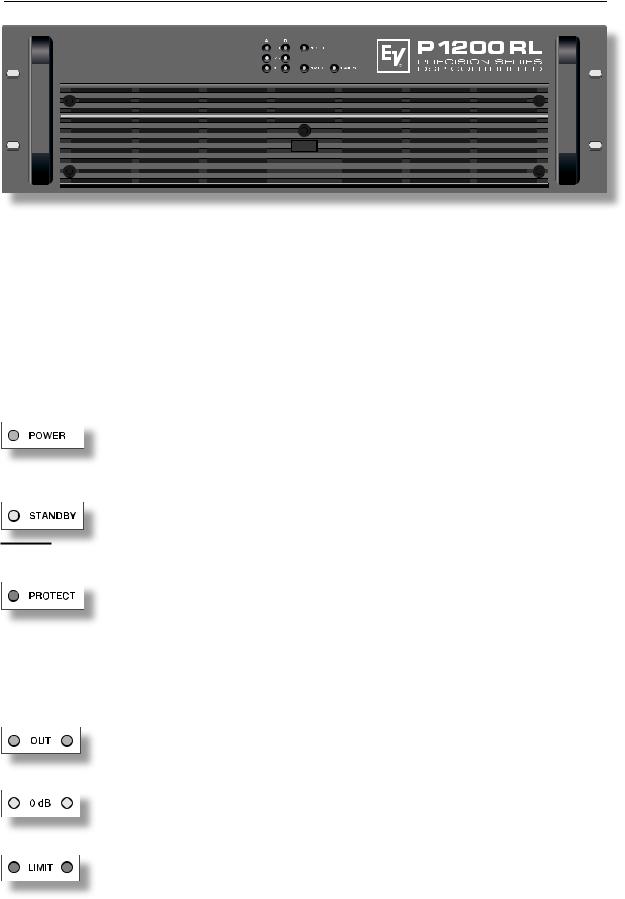

FRONT VIEW

Use the POWER switch located in the centre of the front panel to switch the appliance’s power on. The soft-start function prevents current inrush peaks on the mains, which in addition prevents the mains line protection switch from activating during power-on operation of the power amplifier. The loudspeaker outputs are activated via relay switching with a delay of approximately 2 seconds

effectively attenuating eventual power-on noise. The PROTECT LED lights during the delay time and the fans run at maximum speed. This is normal to confirm the immaculate operation of the protection circuitry. Upon power-on, all power amps with RCM-24 Module installed regain the state of operation prior to the last power-off.

For example: if a power amplifier had been switched off using the POWER-switch while being in Standby mode, upon power-on it restarts in this exact mode.

This indicator lights when the power amplifier has been switched on. Causes for the POWER-indicator not lighting are: the appliance is not connected to the mains network, a defective primary fuse, or the power amplifier is set to stand-by operation

(STAND-BY LED lights).

This indicator light when the power amplifi er is in stand-by mode, which can be

This indicator light when the power amplifi er is in stand-by mode, which can be  activated from the RCM-24 or via Easy Remote. In stand-by operation only the

activated from the RCM-24 or via Easy Remote. In stand-by operation only the

internal auxiliary power supply unit is activated.The main power supply unit is separated from the mains.

internal auxiliary power supply unit is activated.The main power supply unit is separated from the mains.

The PROTECT LED lights indicating that one of the internal protection circuits against thermal overload, short-circuit, Back-EMF, HF-occurrence at the output, etc., has been activated. In that case, the output relays separate the power amps from the load connected to prevent the connected loudspeaker systems and the power amplifiers as well from being damaged. Whatever caused the fault – e.g. a shortcircuited speaker cable – needs to be remedied. In case of thermal overload you have to wait until the power amplifi er automatically regains normal operation

The OUT LED lights as soon as an audio signal of approximately 30dB below full modulation is present. The LED is dimmed when speaker cables are short-circuited or a protection circuit has been activated

The 0dB LED lights when the power amplifier is driven at its maximum. Higher input voltage does not result in higher peak output voltage.

This indicator lights as soon as the integrated dynamic limiter is activated and the power amplifier is driven at the clipping limit or generally at its maximum capacity.

Short-term blinking is not a problem, since the internal limiter trims input levels of up to +21dBu down to a S/N-ratio of approximately 1%. If, on the other hand, this LED lights constantly, reducing the volume is recommended to prevent the loudspeaker systems connected from being damaged by probable overload

6

REAR PANEL

INPUT A / INPUT B

This indicator lights as soon as the integrated dynamic

limiter is activated and the power amplifier is driven at

the clipping limit or generally at its maximum capacity. Short-term blinking is not a problem, since the internal limiter trims input levels of up to +21dBu down to a S/N-ratio of approximately 1%. If, on the

the clipping limit or generally at its maximum capacity. Short-term blinking is not a problem, since the internal limiter trims input levels of up to +21dBu down to a S/N-ratio of approximately 1%. If, on the  the volume is recommended to prevent the loudspeak-

the volume is recommended to prevent the loudspeak-

er systems connected from being damaged by probable overload

PARALLEL CONNECTION

Connection can be established via the XLR-type input connectors INPUT A / INPUT B or the supplied screw-on connectors which are connected in parallel. In addition, using the PARALLEL-connectors provides the possibility for connecting the input signal through to feed additional power amplifiers, without the need for extra splitter-cables

DSP OUT

The DSP output signal – i.e. the post-digital-signal-processing-unit audio signal – is present at the DSP OUT. The DSP output signal is simultaneously fed to the power amplifier output stage and is correspondingly amplified present at the power amp’s main outputs.

The DSP OUT can be utilized for feeding the digitally processed audio signal from the RCM-24 Remote Control Module to additional power amplifiers (without DSP-module); e.g. for increasing the overall output power. With a nominal level of +6dBu and a maximum level of +21dBu (8.7V) the output signal is electronically balanced. Output impedance is 100Ω

CONTROL PORT

The CONTROL PORT offers two freely programmable control inputs and

The CONTROL PORT offers two freely programmable control inputs and  control outputs as well as the reference connections for ground potential and

control outputs as well as the reference connections for ground potential and

+5V. Using the PC Windows software IRIS, the control inputs can be

+5V. Using the PC Windows software IRIS, the control inputs can be  configured and serve for instance for Power-On / Stand-by switching, preset

configured and serve for instance for Power-On / Stand-by switching, preset

switching or parameter control.

switching or parameter control.

The two control contacts IN1 / IN2 are internally set to +5V (open) via pull-up resistors. Activating the control inputs is possible by closing the contacts to ground potential (pin 3) via external switches, pushbuttons or relays.

The two control contacts IN1 / IN2 are internally set to +5V (open) via pull-up resistors. Activating the control inputs is possible by closing the contacts to ground potential (pin 3) via external switches, pushbuttons or relays.

The two control outputs OUT1 / OUT2 are carried out as Open Collector Outputs. In non-active state (Off) they provide high ohmic resistance. In the active state (On) these outputs are connected to ground. The outputs serve for signalling internal operational states. They can be used for the direct triggering of LEDs, indication lights or relays. The +5V reference connector provides power supply for externally connected appliances with amperage of maximally 100mA. The control outputs allow signal indication of operational states (critical temperature, exceeding or decline of defined limit values, faults, etc.) at central operator desks or to other systems (fire alarm system, general alert system) even without PC. For further detail about configuring the control ports, please refer to the documentation accompanying the IRIS software.

7

REAR VIEW

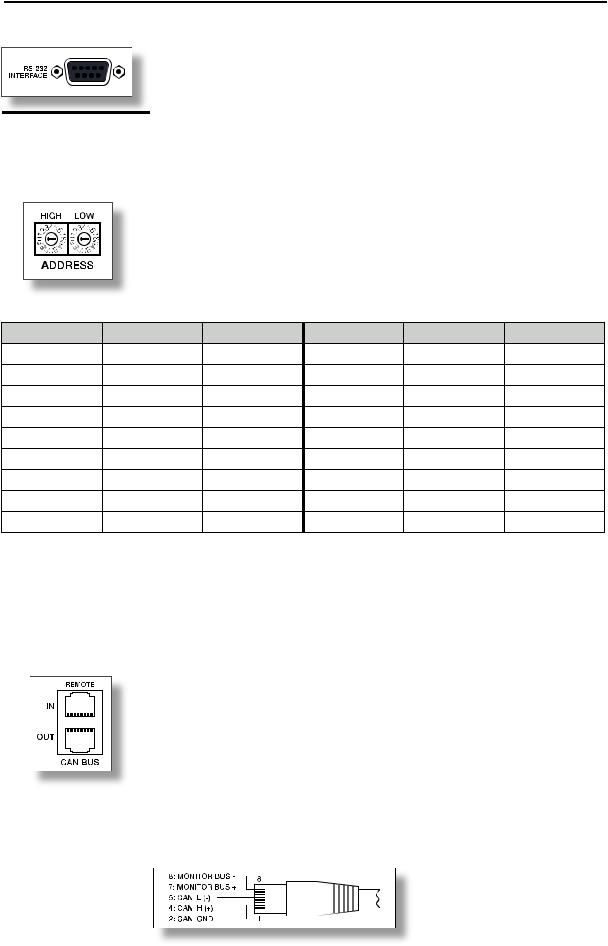

RS-232 INTERFACE

The RS-232 interface is for connecting media control systems as well as

building management systems providing control and monitoring of all parameters. Communication is established via an easily to implement ASCIIprotocol allowing trouble-free integration of Remote Amplifiers in media and

touch panel control systems. For a programmer’s guide and complete protocol description, please refer to the documentation accompanying the IRIS software

ADDRESS

The address selection switch allows setting the amplifier’s network address, which, within a CAN-network, can range from 01 to 250 (FA hex). Caution: Each address may exist only once within a network. Otherwise network conflicts might occur. Address setting has to be performed in hexadecimal code. The selection switch LOW represents the low-value digit while the HIGH-switch represents the high-value digit

Adress-Table: |

|

|

|

|

|

|

|

|

|

HIGH |

LOW |

Adress |

HIGH |

LOW |

Adress |

||||

0 |

|

0 |

Stand-alone |

8 |

0 ... |

F |

128 ... |

143 |

|

0 |

1 |

... F |

1 ... |

15 |

9 |

0 ... |

F |

144 ... |

159 |

|

0 ... |

F |

16 ... |

3 |

A |

0 ... |

F |

160 ... |

175 |

2 |

0 ... |

F |

32 ... |

47 |

B |

0 ... |

F |

176 ... |

19 |

3 |

0 ... |

F |

48 ... |

63 |

C |

0 ... |

F |

192 ... |

207 |

4 |

0 ... |

F |

64 ... |

79 |

D |

0 ... |

F |

208 ... |

223 |

5 |

0 ... |

F |

80 ... |

95 |

E |

0 ... |

F |

224 ... |

239 |

6 |

0 ... |

F |

96 ... |

11 |

F |

0 ... |

A |

240 ... |

250 |

7 |

0 ... |

F |

112 ... |

127 |

F |

B ... |

F |

reserved |

|

Address 0 (00 hex, factory-pre-set) ensures that the amplifier is separated from the remote communication, so that it does not appear in the system set-up even though it might be connected to the CAN-bus. When the amplifier is powered-on with its address set to “0”, all internal parameters are set to “0” respectively to bypass and the routing is set to 2-in-2. In that case the amplifier behaves absolutely linear, i.e. signal processing is deactivated

REMOTE CAN BUS

Each amplifier employs two RJ-45 sockets for Remote CAN-bus connection.

The sockets are parallel connected and serve as input as well as for

connecting through of the Remote network. Common RJ-45 patch cables can be used for rack-shelf cabling. The CAN-bus needs to be

terminated at both ends using a 120ohms termination plug. Detailed

guidelines concerning cabling and bus length are provided in the chapter

“REMOTE CONTROL NETWORK”.

Both RJ-45 sockets additionally carry the balanced audio monitor signal. The nominal output level is +6dBu (1.55V) while the maximum output level is +21dBu (8.7V).

Connector Pin-Assignment:

(View of Contacts)

8

REAR VIEW

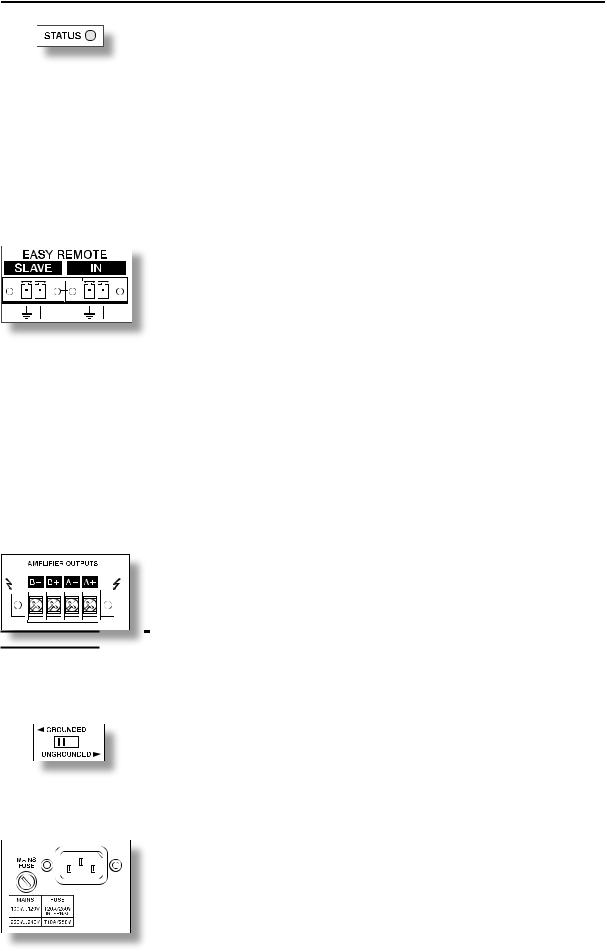

The STATUS LED provides optical indication of CAN-bus traffic. When the power amplifier’s address is set to “00” so that it is separated from the CANbus, the STATUS LED blinks every 3 seconds. When the power amplifier’s address is set between “01” and “250” and no CAN-bus activity has taken

place yet, the LED blinks every second. As soon as CAN-bus communication is recognized, the LED is activated for at least 100ms whenever the power amplifier actively sends data on the CAN-bus.

The STATUS LED may also be activated from the PC. In this case, the LED of the according power amplifier blinks fast and steady while all other status-LEDs within the system stay dimmed

EASY REMOTE

Easy Remote provides a simple way to remotely power-on/off the power amplifier. The Easy Remote function is only useful for appliances not employing a RCM-24 Module. Controlling appliances with RCM-24 Module installed per Easy Remote is practically pointless

EASY REMOTE IN

Leaving the pins of the EASY REMOTE IN socket open, i.e. when connecting +5V, the appliance power is switched on. When connecting the EASY REMOTE IN, i.e. when feeding 0V from the control output, the appliance enters standby mode

EASY REMOTE SLAVE

The EASY REMOTE SLAVE connector provides connection for additional appliances with EasyRemote function (e.g. for switching several devices within a rack-shelf ON/OFF).

The switching of the slave-units is delayed to prevent the mains fuses from blowing.

POWER AMPLIFIER OUTPUTS

4-pole binding-post terminals are provided for the power amplifier channels „A“ and „B“.

When connecting loudspeaker systems, please mind the polarity

When connecting loudspeaker systems, please mind the polarity

according to the here shown diagram.

according to the here shown diagram.

Since the binding-post terminals might carry high voltages during

operation that might cause shock-hazard, closing the attached cover is mandatory after establishing loudspeaker connections.

operation that might cause shock-hazard, closing the attached cover is mandatory after establishing loudspeaker connections.

GROUND-LIFT SWITCH

The ground-lift switch allows eliminating noise loops. If the power amplifier is operated together with other equipment in a 19“ rack-shelf, setting the switch to its GROUNDED position is recommended. If the power amplifier is operated together with appliances with differing ground potentials, setting the switch to its UNGROUNDED position is recommended

MAINS INPUT

Under normal circumstances, the mains fuse only blows in case of fault. Replacing the fuse is only permissible when using a new fuse of the same type with identical amperage, voltage and blow characteristics. If the mains fuse blows more often, please contact an authorized service centre.

9

CABLING

NF-VERBINDUNGSKABEL

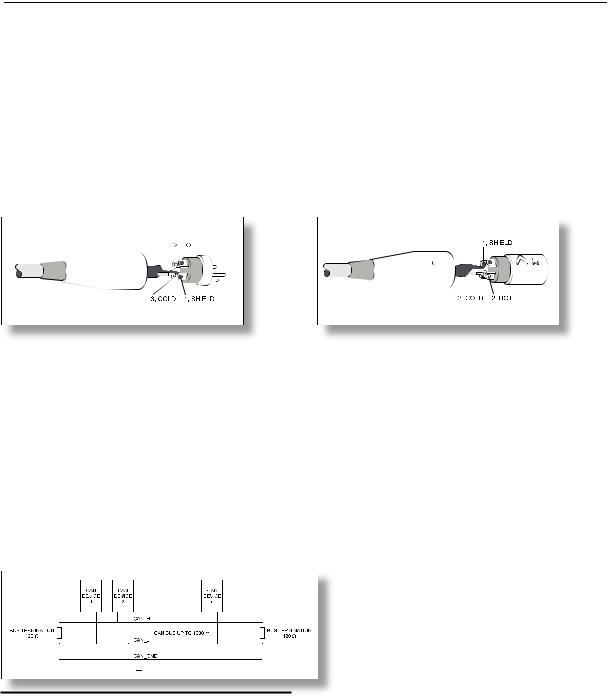

Choosing balanced cables (two conductors for the audio signal plus separate shielding mesh) with

XLR-type connectors is recommended for LF-signal connection. Although connecting unbalanced cables to the power amplifier inputs is possible as well, using balanced cabling is always preferable. A great number of today’s audio appliances employ balanced outputs. With balanced cabling, the shield connects all metal enclosure parts and thus efficiently eliminates the introduction of noise and hum

XLR-type connector pin-assignment

XLR (male) |

XLR (female) |

REMOTE CONTROL NETWORK

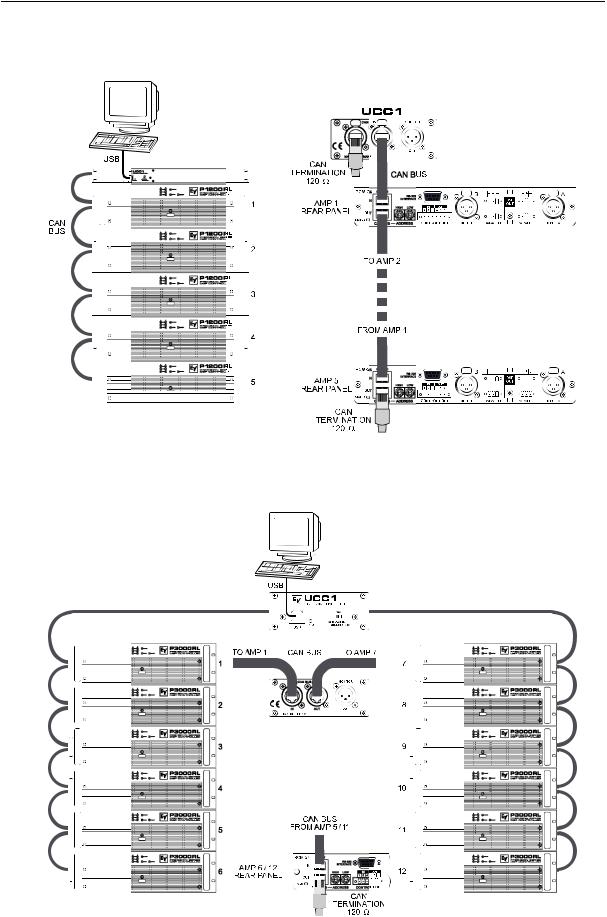

The network of the remote power amps is based on the CAN-bus standard, which for years is especially popular in automotive, industrial and security applications. The CAN-bus is a balanced serial interface for command and data transmission. Controlling the power amplifiers is performed from a PC with IRIS – Intelligent Remote & Integrated Supervision – software installed. The UCC1 USB-CAN Converter serves as interface between the PC and the CAN-bus. Connecting up to 100 power amplifiers per CAN-Bus with a maximum total cable length of 1,000 meters is possible. An additional CAN-bus is needed for controlling more than 100 power amps while the IRIS software allows administering a total of 250 power amps.

The network topology used by the CAN-bus is based on the so-called “bus or line topology”, i.e. all participants are connected via a single two-wire cable (Twisted-Pair cable, shielded or unshielded) with the cabling running from one participant on the bus to the next, allowing unlimited communication among all appliances. In general, it does not matter whether a participant on the bus is a power

amplifier or an UCC1 USB-CAN converter, so that both – UCC1 and the PC as well

– can be inserted at any position.

Incorporating several UCC1 and PCs

on a single CAN-bus is also possible.

A total of up to 100 appliances can be operated on a single CAN-bus. Since the CAN-interfaces of all appliances are

galvanically separated from the rest of the circuitry, network cabling also carries a common ground conductor (CAN_GND) ensuring that all CAN-interfaces in the network are connected to a common ground potential. The UCC1 provides the possibility for switching the CAN-ground to circuit-ground.

Each participant on the bus system has two RJ-45 connectors for the Remote CAN-bus. These sockets are connected in parallel to serve as input and output (for connecting through) for the data transfer within the remote-network. The CAN-bus has to be terminated at both ends using 120Ω terminator plugs, two of which – CAN-TERM 120 Ω – are supplied with the UCC1. Connect one of these to the RJ-45 socket of the first and the other to the socket of the last appliance on the CAN-bus

10

NETWORK EXAMPLES

The following diagrams show examples of the data-bus wiring for different order of size:

System with 5 amps and one UCC1 / PC at the beginning of the bus

Terminators at the UCC1 (fi rst unit on the bus) and at amp 5 (last unit on the bus)

System with 2 amp-racks and an UCC1 / PC in the middle

Terminators at amp 6 (fi rst unit on the bus) and amp 12 (last unit on the bus)

1

Loading...

Loading...