Ducati 999, 999s User Manual

Owner’s manual

E

DUCATI999/999S

1

E

2

Hearty welcome among Ducati fans! Please accept our best compliments for choosing a Ducati motorcycle. We think you will ride your Ducati motorcycle for long journeys as well as short daily trips. Ducati Motor Holding s.p.a wishes you smooth and enjoyable riding.

We are steadily doing our best to improve our “Technical Assistance” service. For this reason, we recommend you to strictly follow the indications given in this manual, especially for motorcycle running-in. In this way, your Ducati motorbike will surely give you unforgettable emotions.

For any servicing or suggestions you might need, please contact our authorized service centres.

Enjoy your ride!

Note

Ducati Motor Holding S.p.A. declines any liability whatsoever for any mistakes incurred in drawing up this manual. The information contained herein is valid at the time of going to print. Ducati Motor Holding S.p.A. reserves the right to make any changes required by the future development of the above-mentioned products.

E

For your safety, as well as to preserve the warranty, reliability and worth of your motorcycle, use original Ducati spare parts only.

Warning

This manual forms an integral part of the motorcycle and - if a transfer of title occurs - must always be handed over to the new owner.

3

TABLE OF CONTENTS

E |

General |

6 |

Warranty |

6 |

|

|

Symbols |

6 |

Useful information for safe riding 7

Carrying the max load allowed 8

Identification data 9

Controls 10

Position of motorcycle controls 10 Instrument panel 11

LCD - main functions 12

LCD - how to set/display parameters 14 The immobilizer system 20

Keys 20 Code card 21

Procedure to disable immobilizer engine block through throttle twistgrip 22

Duplicate keys 23

Ignition switch and steering lock 24 Left switch 25

Clutch lever 26 Cold start lever 27 Right switch 28

Throttle twistgrip |

28 |

Front brake lever |

29 |

Rear brake pedal |

30 |

Gear change pedal |

30 |

Adjusting the gear change and rear brake pegs 31 Gear change pedal adjustment 32

Rear brake pedal adjustment 33

Main components and devices 34

Location 34

Tank filler plug 35

Seat/fuel tank adjustment 36 Seat catch and helmet hook 37 Side stand 39

Steering damper 40 Front fork adjusters 41

Shock absorber adjusters 43

Changing motorcycle track alignment 45

Directions for use 47

Running-in recommendations 47

Pre-ride checks 49

Starting the engine 50

Moving off 52

Braking 52

Stopping the motorcycle 53

Parking 53

Refueling 54

Tool kit and accessories 55

4

Main maintenance operations |

56 |

Engine |

87 |

|

|

|

|||||

Removing the fairing |

56 |

|

|

|

Timing system |

87 |

|

||||

Checking and topping up the coolant level 59 |

Performance data |

88 |

|

||||||||

Checking brake and clutch fluid level |

61 |

Spark plugs 88 |

|

|

|

||||||

Checking brake pads for wear |

62 |

|

|

Brakes |

88 |

|

|

|

|||

Lubricating cables and joints |

63 |

|

|

Transmission 89 |

|

|

|

||||

Throttle cable tension adjustment 64 |

|

Frame |

90 |

|

|

|

|||||

Charging the battery |

65 |

|

|

|

Wheels |

90 |

|

|

|

||

Adjusting steering head angle (999) |

67 |

|

Tyres 90 |

|

|

|

|||||

|

|

|

E |

||||||||

Adjusting steering head angle (999S) |

69 |

Suspensions 91 |

91 |

||||||||

Chain tension inspection 70 |

|

|

|

Exhaust system |

|

|

|||||

Chain lubrication |

70 |

|

|

|

|

Available colours |

91 |

|

|||

Changing the high and low beam bulbs |

71 |

Electric system |

92 |

|

|||||||

Changing the parking light bulb 73 |

|

|

For United States of America version only 96 |

||||||||

Front turn indicators |

74 |

|

|

|

|||||||

Rear turn indicators |

74 |

|

|

|

Routine maintenance record 105 |

||||||

Stop light |

75 |

|

|

|

|

|

|||||

Number plate light 75 |

|

|

|

|

|

|

|

|

|||

Beam setting 76 |

|

|

|

|

|

|

|

|

|

|

|

Rear view mirror adjustment |

77 |

|

|

|

|

|

|

|

|||

Tubeless tyres 78 |

|

|

|

|

|

|

|

|

|

||

Checking engine oil level 80 |

|

|

|

|

|

|

|

|

|||

Cleaning and replacing the spark plugs |

82 |

|

|

|

|

|

|||||

Cleaning the motorcycle 83 |

|

|

|

|

|

|

|

|

|||

Storing the bike away 84 |

|

|

|

|

|

|

|

|

|||

Important notes |

84 |

|

|

|

|

|

|

|

|

|

|

Technical data |

85 |

|

|

|

|

|

|

|

|

||

Overall dimensions 85 |

|

|

|

|

|

|

|

|

|||

Weights |

85 |

|

|

|

|

|

|

|

|

|

|

Top-ups |

86 |

|

|

|

|

|

|

|

|

|

|

5

GENERAL

Warranty

E In your own interest, and in order to guarantee product reliability, you are strongly advised to refer to a Ducati Dealer or Authorized Workshop for any servicing requiring particular technical expertise. Our highly skilled staff have access to the implements required to perform any servicing job at best, using Ducati original spare parts only as the best guarantee for full interchangeability, smooth running and long life.

All Ducati motorcycles come with a “Warranty Card”. However, warranty does not apply to the motorcycles used in competitions. No motorcycle part may be tampered with, altered, or replaced with parts other than original Ducati spare parts during the warranty period, or the warranty will be automatically invalidated.

Symbols

Ducati Motor Holding S.p.A. advises you to read this manual carefully so as to become familiar with your motorcycle. In case of any doubts, please call a Ducati Dealer or Authorized Workshop. The information contained herein will prove useful on your trips - and Ducati Motor Holding S.p.A. wishes you smooth, enjoyable riding - and will help you keep the performance of your motorcycle unchanged for a long time.

Warning

Failure to comply with these instructions may put you at risk and lead to severe injury or death.

Important

Possibility of damaging the motorcycle and/or its components.

Note

Additional information concerning the job being carried out.

The terms right and left are referred to the motorcycle viewed from the riding position.

6

Useful information for safe riding

Warning

Read this section before riding your motorcycle.

Accidents are frequently due to inexperience. Always make sure you have your licence with you when riding; you need a valid licence to be entitled to ride your motorcycle.

Do not lend your motorcycle to inexperienced riders or who do not hold a valid licence.

Both rider and pillion passenger must always wear a safety helmet.

Wear proper clothing, with no loose items or accessories that may become tangled in the controls or limit your zone of vision.

Never start or run the engine indoors. Exhaust gases are poisonous and may lead to loss of consciousness or even death within a short time.

Both rider and pillion passenger should keep their feet on the footpegs when the motorcycle is in motion.

Always hold the handlebars firmly with both hands so you will be ready for sudden changes of direction or in the road surface. The pillion passenger should always hold on to the suitable belt on the rear seat with both hands.

Ride within the law and observe national and local rules. Always respect speed limits where these are posted. However, always adjust your speed to the visibility, road and traffic conditions you are riding in.

Always signal your intention to turn or pull to the next

lane in good time using the suitable turn indicators.

Be sure you are clearly visible and do not ride within the blind spot of vehicles ahead.

Be very careful when tackling road junctions, or when riding in the areas near exits from private grounds, car parks or on slip roads to access motorways.

Always turn off the engine when refueling.

Be extremely careful not to spill fuel on the engine or on the exhaust pipe when refueling.

Do not smoke when refueling. E While refueling, you may inhale noxious fuel vapors.

Should any fuel drops be spilled on your skin or clothing, immediately wash with soap and water and change your clothing.

Always remove the key when you leave your motorcycle unattended.

The engine, exhaust pipes, and mufflers stay hot for a long time.

Warning

The exhaust system might be hot, even after engine is switched off; pay particular attention not to touch exhaust system with any body part and do not park the vehicle next to inflammable material (wood, leaves etc.).

Park your motorcycle where no one is likely to hit it and use the side stand.

Never park on uneven or soft ground or your motorcycle may fall over.

7

Carrying the maximum load allowed

Your motorcycle is designed for long-distance riding, carrying the maximum load allowed in full safety. Even weight distribution is critical to preserving safety

features and avoiding trouble when performing sudden manoeuvres or riding on bumpy roads.

Information about carrying capacity

The total weight of the motorcycle in running order

E including rider, pillion passenger, luggage and additional accessories should not exceed 375 Kg.

Arrange your luggage or heavy accessories in the lowest possible position and close to motorcycle centre.

Be sure to secure the luggage to the supports provided on the motorcycle as firmly as possible. Improperly secured luggage may affect stability.

Never fix bulky or heavy objects to the handlebar or to the front mud guard as this would affect stability and cause danger.

Do not insert any objects you may need to carry into the gaps of the frame as these may foul moving parts. Make sure the tyres are inflated to the proper pressure indicated at page 78 and that they are in good condition.

8

Identification data

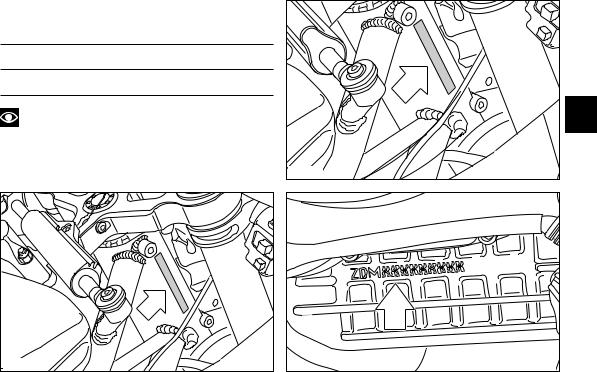

All Ducati motorcycles have two identification numbers, for frame (fig. 1.1 and fig. 1.2) and engine (fig. 2).

Frame number

Engine number

Note

These numbers identify the motorcycle model and are required when ordering spare parts.

|

E |

999S |

fig. 1.2 |

999 |

fig. 1.1 |

fig. 2 |

9 |

CONTROLS

5 |

4

E |

Warning |

3 |

This section details the position and function of all |

|

|

|

the controls you need to drive your motorcycle. Be sure |

|

|

to read this information carefully before you use the |

|

|

controls. |

|

|

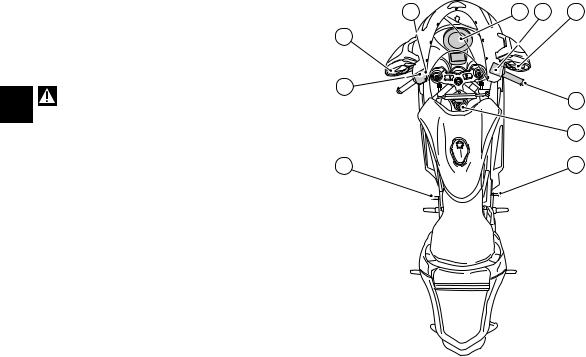

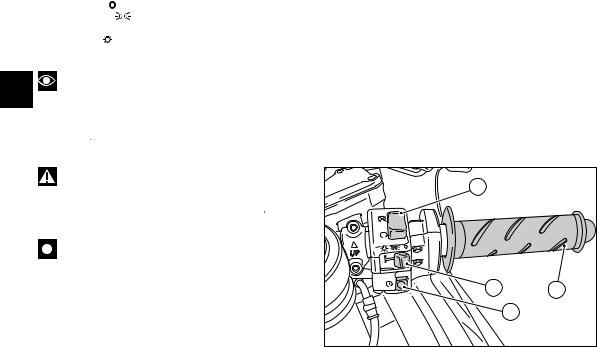

Position of motorcycle controls (fig. 3) |

9 |

|

|

1)Instrument panel.

2)Key-operated ignition switch and steering lock.

3)Left switch.

4)Clutch lever.

5)Cold start control.

6)Right switch.

7)Throttle twistgrip.

8)Front brake lever.

9)Gear change pedal.

10)Rear brake pedal.

1 |

6 |

8 |

7

2

10 |

fig. 3

10

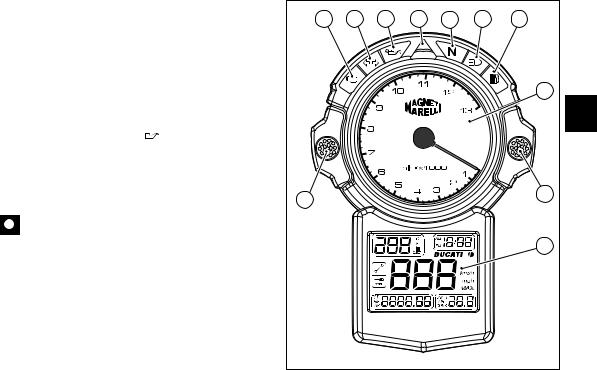

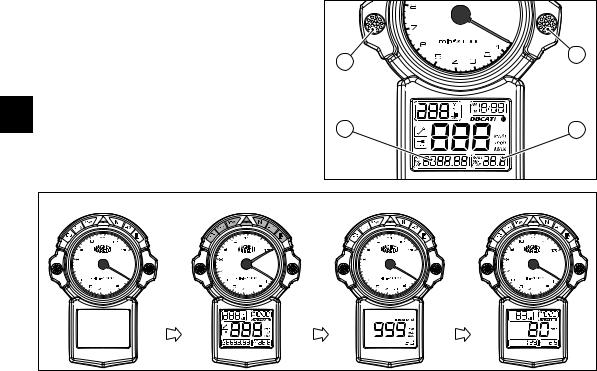

Instrument panel (fig. 4)

1)LCD (see page 12).

2)Engine revolution meter (rpm) Indicates engine rpm.

3)Neutral light N (green).

Comes on when gearbox is in neutral. 4) Low fuel light  (yellow).

(yellow).

Comes on when there are about 3 liters fuel left in the tank.

5) Turn indicator light  (green).

(green).

Comes on and flashes when a turn indicator is on. 6) Engine oil pressure light  (red).

(red).

Comes on when engine oil pressure is too low. It comes on when the ignition is switched to ON and normally goes out a few seconds after engine starts.

It may shortly come on when the engine is hot, however, it should go out as the engine revs up.

Important

If this light (6) stays on, stop the engine or it may suffer severe damage.

7) High beam light  (blue). Comes on when high beam is on.

(blue). Comes on when high beam is on.

8 |

5 |

6 |

9 |

3 |

7 |

4 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

E |

10 |

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

fig. 4 |

|

|

|

|

|

|

11 |

|

8) EOBD light |

(amber) |

LCD – Main functions |

|||

|

The engine control unit turns on this light permanently to |

|

|

Warning |

||

|

indicate an error leading to engine block. |

|

|

|||

|

|

|

||||

|

The light doubles as an indicator for the immobilizer |

|

|

Stop the motorcycle before using the instrument |

||

|

|

|

||||

|

override procedure using the throttle twistgrip. |

panel controls. Never operate the instrument panel |

||||

|

When no errors are present, the light should come on |

controls while riding. |

||||

|

when the ignition switch is set to ON and should go out |

|

|

|

||

|

after a few seconds (normally after 1.8 – 2 sec.). |

1) |

Speedometer |

|||

|

9) Gear change threshold light (red) |

Gives road speed. |

||||

E |

||||||

Indicates that control unit has activated the injection |

2) |

Odometer |

||||

|

limiter. The lower portion of the light comes on 200 rpm |

Gives total distance covered. |

||||

|

below injection limiter switch-on rpm; the top portion of |

3) |

Trip meter |

|||

|

the light comes on 100 rpm below injection limiter |

Gives distance covered since last resetting. |

||||

|

switch-on rpm. |

|

4) |

Clock. |

||

|

10) Control buttons |

5) |

Lap time. |

|||

|

These buttons are used to display and set instrument |

6) |

Lap top speed recording. |

|||

|

panel parameters. |

|

7) |

Battery voltage indicator. |

||

|

|

|

8) |

Air temperature indicator. |

||

|

|

|

9) |

Consumption indicator. |

||

|

|

|

10) Coolant temperature indicator. |

|||

|

|

|

Gives engine coolant temperature. |

|||

Important

Stop riding if the temperature reaches the max. value, otherwise the engine might damage.

12

11) Maintenance counter.

This light comes on upon reaching the mileage specified for preventive maintenance. The light will keep flashing until the motorcycle covers the next 50 km and then will stay on permanently until the counter is reset at an DUCATI Authorized Workshop within the preventive maintenance procedure.

12) Immobilizer indicator.

The indicator stays on when key code is wrong or is not acknowledged, and will flash after the immobilizer has been overridden using the throttle twistgrip (see page 22).

Important

The instrument panel is part of the on-board electronic injection/ignition system diagnostics. The relevant menus are for use by trained personnel only. If you accidentally access this function, turn the key to OFF and have the motorcycle inspected at an authorized Ducati Service Center.

10 |

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

11 |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

E |

2 |

3 |

5 |

7 |

8 |

9 |

fig. 5 |

13

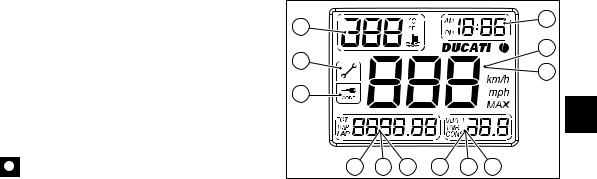

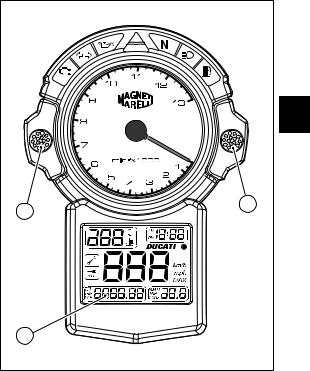

LCD – How to set/display parameters |

|

|

|

When the key is turned from OFF to ON, the instrument |

|

|

|

panel runs a check-up routine of all instruments |

|

|

|

(pointers, display, lights) (See fig. 7). |

|

|

|

Calling up the left display functions (A). |

1 |

2 |

|

|

|||

Press the button (1) (fig. 6) with the key turned to ON to |

|

|

|

cycle through trip meter, odometer and lap time |

|

|

|

indication. |

|

|

|

E |

|

|

|

Calling up the right display functions (B) |

A |

B |

|

Press the button (2) (fig. 6) with the key turned to ON to |

|||

|

|

||

cycle through battery voltage, air temperature and |

|

|

|

consumption indication. |

|

fig. 6 |

|

|

|

OFF |

CHECK 1 |

CHECK 2 |

ON |

|

|

|

fig. 7 |

14 |

|

|

|

Clock setting

Hold down the button (1) for at least 2 seconds.

Press the button (2) to select AM/PM. Press the button (1) to confirm selection and enter hours setting mode. Set hours using the button (2). Press the button (1) to confirm and enter minutes setting mode.

Set minutes using the button (2). Press the button (1) to confirm and exit the clock setting mode.

Resetting the trip meter

Select TRIP indication in the display (3). Hold down the button (2) for at least 2 seconds to reset displayed trip meter indication.

E |

2 |

1 |

3 |

fig. 8 |

15 |

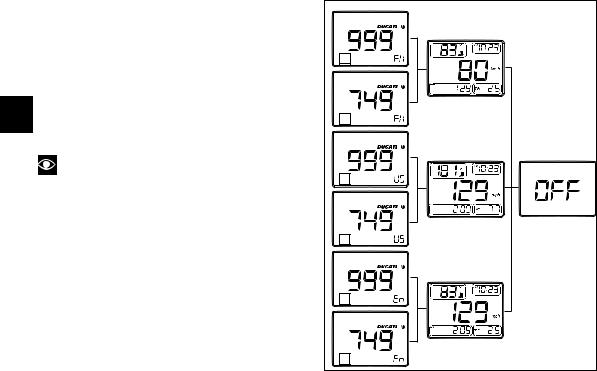

Setting special function (vehicle model and units of measurement)

The engine control unit transmits the correct vehicle model and unit measurement information automatically for the instrument panel to display. To force a change of these parameters, turn the key from OFF to ON while holding down both buttons (1) and (2).

Press the button (1) to scroll through available configurations.

E To store your selection, hold down the button (2) for 5 seconds, until the display will read OFF. Set the key to

OFF.

Note

The dotted boxes in the figure are the display areas for vehicle version (normal, R or S).

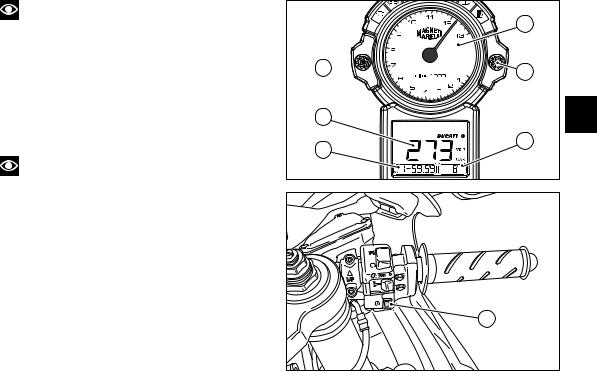

Lap time recording (fig. 10 and 11)

This function lets you record lap time and displays top speed and engine rpm during that lap.

Select the LAP mode in the display (A) (see page 14). Press the engine start button (5) while riding to start the on-board chronometer. Pressing the button (5) again will stop the chronometer.

fig. 9 |

16

Note

In the LAP mode, the engine may not be started using the starter button (5).

After measuring lap times, up to 19 times may be retrieved and displayed on the LCD. Pressing the button (1) will scroll through recorded times. The instrument panel provides the following information:

-Lap number (6)

-Top engine rpm (7) during selected lap

-Lap time (4)

-Top speed (8) during that lap.

Note

The tachometer reads a speed higher than the actual one, on average there is 8% difference. Maximum speed stored on the LCD is the actual speed of the vehicle during the lap concerned.

To wipe off recorded lap times, hold down the button (2) for over 5 seconds.

1

8

4 |

7 |

2 |

E

6 |

fig. 10

5 |

fig. 11 |

17 |

|

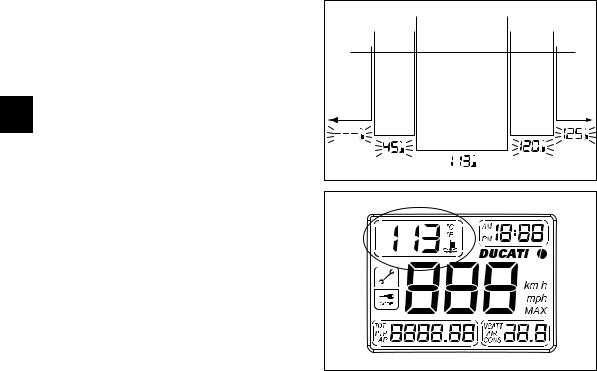

Coolant temperature function (fig. 12 and 13) |

|

+ 46 °C |

+ 119 °C |

|

|

When coolant temperature drops below -40 °C/-40 °F, |

|

|

||

|

- 39 °C |

+ 45 °C |

|

+ 124 °C |

|

|

some flashing dots appear on the display and the amber |

+ 120 °C |

|||

|

EOBD light comes on (8, fig. 4). |

- 40 °C |

|

|

+ 125 °C |

|

When coolant temperature is between -39 °C /-38.2 °F |

|

|

|

|

|

and +45 °C/+113 °F or between +120 °C/+248 °F and |

|

|

|

|

|

+124 °C/+255.2 °F, the display provides a flashing |

|

|

|

|

|

temperature indication. |

|

|

|

|

E |

When coolant temperature is between +46° C/+114.8 °F |

|

|

|

|

and +119 °C/+246.2 °F, temperature indication stays on |

|

|

|

|

|

|

permanently. |

|

|

|

|

|

When coolant temperature exceeds +125 °C/+257 °F, a |

|

|

|

|

|

flashing 125 °C/257 °F temperature indication appears on |

|

|

|

|

|

the display, and the amber EOBD light comes on (8, fig. |

|

|

|

fig. 12 |

|

4). |

|

|

|

fig. 13

18

Warning lights brilliancy

Warning lights brilliancy is automatically adjusted by the instrument panel depending on the quantity of outer light detected.

Backlighting

Instrument panel backlighting is on only if the parking lights or the low/high beams are turned on.

In this case the instrument panel, thanks to some sensors measuring ambient temperature and light intensity, can automatically turn the backlighting on or off.

Lights self-disabling

This function allows a lower voltage consumption from the battery, by automatically switching off the headlight. The device is triggered in two cases:

-in the first case, if you turn the key from OFF to ON and do not start the engine within 60 Sec. the headlight is turned off and will be turned on again only at next key OFF/ key ON.

-in the second case, after the daily use of the vehicle with the lights on, if the engine is killed via the RUNSTOP button on the RH switch.

In this case, after 60 Sec. from engine killing, the headlight will be turned off and will be turned on again only upon next engine starting.

E

19

The immobilizer system

For improved anti-theft protection, the motorcycle is equipped with an IMMOBILIZER, an electronic system that inhibits engine operation whenever the ignition switch is turned off.

Accommodated in the handgrip of each ignition key is an electronic device that modulates an output signal. This signal is generated by a special antenna incorporated in the switch when the ignition is turned on and changes

E every time. The modulated signal acts as a “password” and tells the CPU that an "authorised" ignition key is being used to start up the engine. When the CPU recognises the signal, it enables engine start-up.

The key A performs the same functions as the keys B, and is also used to wipe off and re-program other black keys, if needed.

Note

The three keys have a small plate (1) attached that reports their identification number.

Warning

Keep the keys in different places. Store the plate

(1) and the key A in a safe place.

It is also recommended to use always the same black key to use the bike.

Keys (fig. 14) |

B |

||

The Owner receives a set of keys comprising: |

|||

- 1 RED key A |

A |

||

- 2 BLACK keys B |

|||

|

|||

|

Warning |

|

|

|

|

||

|

Red key A has a rubber cover for preserving it in |

|

|

|

|

||

perfect conditions and avoiding contact with other keys. |

|

||

Never remove this protection unless really needed. |

|

||

The keys B are regular ignition keys and are used to:

-start up the engine

-open the lock of the fuel tank filler plug

- open the seat lock (Biposto). |

1 |

|

|

fig. 14 |

|

|

|

20

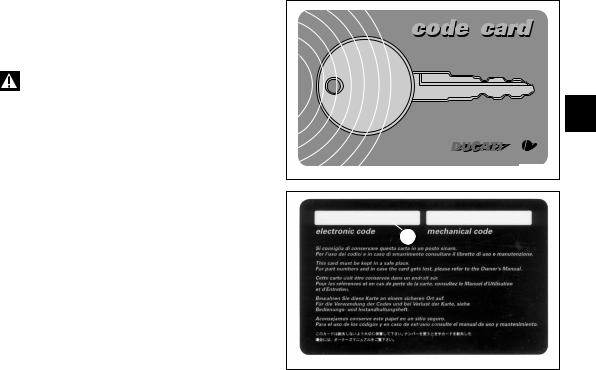

Code card

The keys come with a CODE CARD (fig. 15) that reports:

A) (fig. 16) the electronic code to be used in case of engine block, i.e. bike did not start after key-ON.

Warning

Keep the CODE CARD in a safe place. However, it is advisable to keep the electronic code printed on the CODE CARD handy when you ride your motorcycle, in case it is necessary to override engine block through the procedure that uses the throttle twistgrip.

In case of faulty immobilizer system, the following procedure gives the chance to disable "engine block" function -signalled by the orange EOBD warning light that comes on (8, fig. 4).

But this operation can be carried out only if the electronic code indicated on the code card is known.

E |

fig. 15 |

A |

fig. 16

21

Procedure to disable immobilizer engine block through throttle twistgrip

1)Turn the key to ON and fully open throttle. Keep it open. The EOBD warning light turns off after 8 seconds.

2)Release the throttle as soon as the EOBD warning light turns off.

3)EOBD pilot light will flash. Count a number of flashes corresponding to the first figure of the code, open full throttle and keep the position for 2 seconds, then

E release. In this way the input of one figure is acknowledged, EOBD pilot light comes on and stays on for 4 seconds. Carry out the same procedure for the following figures of the code. Failure to do so will cause the EOBD pilot light to flash 20 times, then it will stay on. This means that the procedure has been aborted. It will be necessary to turn the key to OFF and restart from point (1).

4)Repeat operations described in point (3) up to the last figure of the code.

5)When you release the throttle, if the code was inserted in the correct way, you can have two situations, A or B:

A) the EOBD light starts flashing to indicate that engine is enabled. The light goes off after 4 seconds, or if the engine runs faster than 1000 rpm.

B) the CODE light flashes until engine rpm stays below 1000, or until the vehicle is restarted.

6)Should the code NOT be entered correctly both the EOBD and CODE lights stay on and it is possible to repeat the procedure starting again from point 2 for as many times as necessary.

Note

Should the throttle twistgrip be released before the set time, the warning light turns on again. It is then necessary to bring the key to OFF and restart the procedure from point (1).

22

Operation

When the ignition key is turned to OFF, the immobilizer inhibits engine operation.

When the ignition key is turned back to ON to start the engine, the following happens:

1)if the CPU recognised the code, the CODE light on the instrument panel will flash briefly. This means that the immobilizer system has recognised the key code and enabled engine ignition. When you press the START button, the engine will start up.

2)If the CODE light stays on, it means that the code has not been recognised. When this is the case, turn the ignition key back to OFF and then to ON again. If the engine still does not start, try with another black key.

If the other key does not work out either, contact the DUCATI Service network.

3)Should the CODE pilot light still be flashing, it means that an immobilizer system fault was reset (e.g. with the overriding procedure through throttle grip). Turn the key to OFF and back to ON, the immobilizer pilot light should go back to its normal operation (see point 1).

Warning

The keys accommodate electronic components inside. If dropped or hit, they might damage.

Use only one key during the procedure. Failure to do so might prevent the system from recognizing the code of the key in use.

Duplicate keys

If you need any duplicate keys, contact the DUCATI Service network with all the keys you have left and your CODE CARD.

DUCATI Service will program new keys and re-program your original keys, up to 8 keys in total.

You may be asked to identify yourself as the legitimate owner of the motorcycle. Be sure you have any documents you might need to this end ready.

The codes of any keys not submitted will be wiped off E from the memory to make those keys unserviceable in

case they have been lost.

Note

If you sell your motorcycle, do not forget to give all keys and the CODE CARD to the new owner.

23

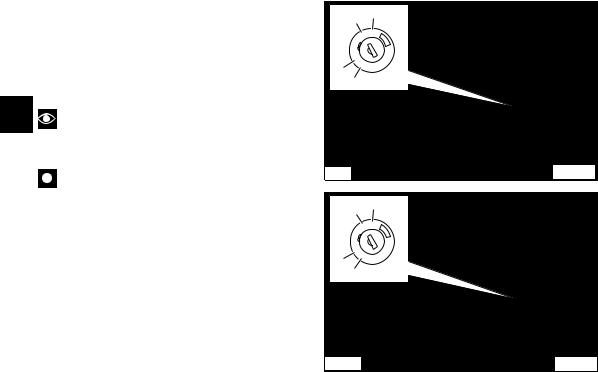

Ignition switch and steering lock (fig. 17.1 and fig. 17.2)

It is located in front of the fuel tank and has four positions:

A)ON: lights and engine on;

B)OFF: lights and engine off;

C)LOCK: steering locked;

D)P: parking light on and steering lock.

E Note

To move the key to the last two positions, press it down before turning it. Switching to (B), (C) and (D), you will be able to take the key out.

Important

This vehicle is equipped with an energy-saving CPU. If the key stays ON for a long period but the ignition button is not pressed within 15 seconds, the CPU will stop operating to avoid current absorption. Move the key to OFF and then to ON again.

B |

A |

|

|

FF |

ON |

|

|

|

|

O |

|

S |

H |

|

U |

|

|

P |

|

|

LOCK |

|

|

C |

P |

IGNITION |

|

||

|

|

|

D |

|

|

999 |

|

fig. 17.1 |

B |

A |

|

|

FF |

ON |

|

|

|

|

O |

|

S |

H |

|

U |

|

|

P |

|

|

LOCK |

|

|

C |

P |

IGNITION |

|

||

|

|

|

D |

|

|

999S |

fig. 17.2 |

|

24

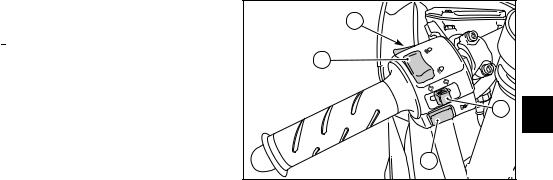

Left switch (fig. 18)

1)Dip switch, light dip switch, two positions: position  = low beam on;

= low beam on;

position  = high beam on.

= high beam on.

2)Switch  = 3-position turn indicator: centre position = OFF;

= 3-position turn indicator: centre position = OFF;

position  = left turn; position

= left turn; position  = right turn.

= right turn.

To reset turn indicators, switch returns to central position, push in.

3)Button  = warning horn.

= warning horn.

4)Button  = passing.

= passing.

4 |

|

1 |

|

2 |

E |

|

|

3 |

|

fig. 18 |

|

25

|

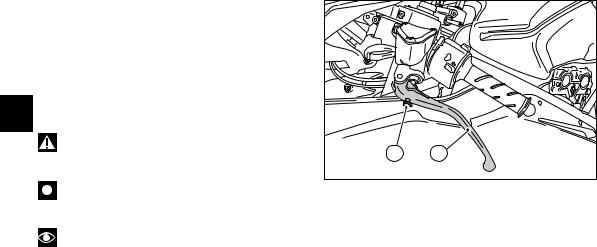

Clutch lever (fig. 19) |

|

|

|

|

Lever (1) disengages the clutch. It features a dial adjuster |

|

|

|

|

(2) for lever distance from the twistgrip on handlebar. |

|

|

|

|

Lever distance from twistgrip is set via knob (2) (10 click |

|

|

|

|

positions). Turn clockwise to push lever far from |

|

|

|

|

twistgrip, or counterclockwise to take it closer. |

|

|

|

|

When you pull in the lever (1), you will disengage the |

|

|

|

|

engine from the gearbox and therefore from the driving |

|

|

|

E |

wheel. Using the clutch properly is essential to smooth |

|

|

|

riding, especially when moving off. |

|

|

|

|

|

Warning |

|

|

|

|

Set clutch and brake lever when motorcycle is |

2 |

1 |

|

|

stopped. |

|

||

|

|

fig. |

19 |

|

|

|

|

||

|

Important |

|

|

|

|

Using the clutch properly will avoid damage to |

|

|

|

|

transmission parts and spare the engine. |

|

|

|

|

Note |

|

|

|

|

It is possible to start the engine with side stand |

|

|

|

|

down and the gearbox in neutral. When starting the bike |

|

|

|

|

with a gear engaged, pull the clutch lever (in this case the |

|

|

|

|

side stand must be up). |

|

|

|

26

Cold start lever (fig. 20)

Use this device to start the engine from cold. It will increase the engine idling speed after starting. Lever positions:

A)= closed

B)= fully open.

The lever can be opened and closed gradually to adjust speed until engine is fully warm (see page 51).

Important

Never use the cold start device when the engine is warm or leave it open when riding.

|

A |

B |

|

1 |

E |

|

|

|

fig. 20 |

27

Right switch (fig. 21)

1) Switch, light switch, three positions:

right position |

= light off; |

centre position |

= front and rear parking lights, |

number plate and instrument panel lights on; |

|

left position |

= headlight, front and rear parking lights, |

number plate and instrument panel lights on.

Note

E This device is not fitted on the Australia and Japan versions.

2) Switch for ENGINE STOP, two positions: position  (RUN) = run.

(RUN) = run.

position  (OFF) = stop.

(OFF) = stop.

Throttle twistgrip (fig. 21)

The twistgrip (4) on the right handlebar opens the throttles. When released, it will spring back to the initial position (idling speed).

Warning

This switch is mainly intended for use in emergency cases when you need to stop the engine quickly. After stopping the engine, return the switch to the  position to enable starting.

position to enable starting.

Important

Riding with the lights on, stopping the engine using switch (2) and leaving the ignition key in the ON position, may run the battery flat as the lights will remain on.

3) Button  = engine start.

= engine start.

2 |

|

1 |

4 |

|

3 |

|

fig. 21 |

28

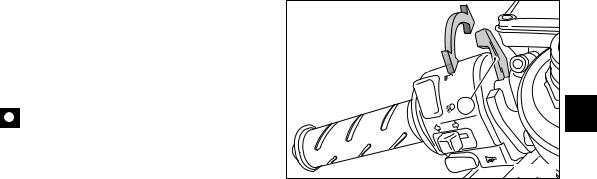

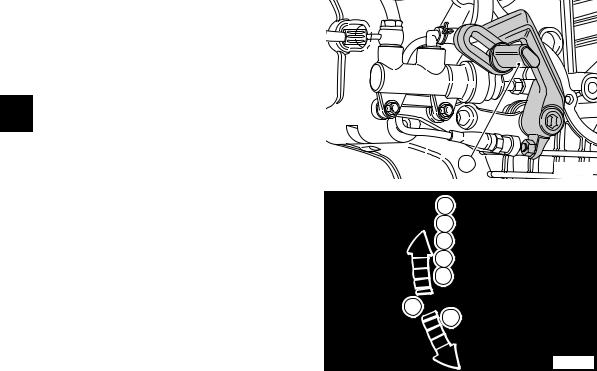

Front brake lever (fig. 22)

Pull in the lever (1) towards the twistgrip to operate the front brake. The system is hydraulically operated and you just need to pull the lever gently.

The brake lever is provided with an adjuster (2) for lever distance adjustment from twistgrip on handlebar.

Lever distance from twistgrip is set via knob (2) (10 click positions). Turn clockwise to push lever far from twistgrip, or counterclockwise to take it closer.

|

|

E |

1 |

2 |

fig. 22 |

29

Rear brake pedal (fig. 23)

Push down on the pedal (1) with your foot to operate the rear brake.

The system is hydraulically operated.

E

Gear change pedal (fig. 24)

The gear change pedal is at rest when in the central position N, and automatically returns to the central position. When in this position, light N (3, fig. 4) on istrument panel is on.

The pedal can be moved:

down = push down on the pedal to engage 1st gear and to shift down. The N light will go out.

up = lift the pedal to engage the 2nd gear and then the 3rd, 4th, 5th and 6th gear. Each time you move the pedal you will engage the next gear.

1 |

fig. 23 |

|

6

5

4

3

2

N

1

fig. 24

30

Loading...

Loading...