Craftsman 139.18453D, 139.18473D, 139.18451D, 139.18452D User Manual

Owner’s Manual

®

1/2 HP

GARAGE DOOR OPENER

GARAGE DOOR OPENER

For Residential Use Only

Models • 139.18451D • 139.18452D • 139.18453D • 139.18473D

ENGLISH

Read and follow all safety rules and operating instructions before first use of this product.

Fasten the manual near the garage door after installation.

Periodic checks of the opener are required to ensure safe operation.

■Safety Precautions

■Assembly

■Installation

■Adjustment

■Maintenance

■Operation

■Troubleshooting

■Parts List

Sears Canada, Inc., Toronto, Ontario M5B 2B8

TABLE OF CONTENTS |

|

Introduction |

2-7 |

Safety symbol and signal word review........................ |

2 |

Preparing your garage door ........................................ |

3 |

Tools needed ............................................................... |

3 |

Planning .................................................................. |

4-5 |

Carton inventory .......................................................... |

6 |

Hardware inventory ..................................................... |

7 |

Assembly |

8-11 |

Assemble the rail and install the trolley ...................... |

8 |

Fasten the rail to the motor unit and |

|

install the idler pulley................................................... |

9 |

Install the chain/cable................................................ |

10 |

Tighten the chain ....................................................... |

11 |

Adjustment |

27-29 |

Adjust the travel limits ............................................... |

27 |

Adjust the force ......................................................... |

28 |

Test the safety reversal system................................. |

29 |

Test The Protector System® ...................................... |

29 |

Operation |

30-34 |

Operation safety instructions..................................... |

30 |

Using your garage door opener ................................ |

30 |

Using the wall-mounted Door Control ....................... |

31 |

To open the door manually........................................ |

31 |

Care of your garage door opener.............................. |

32 |

Having a problem? .................................................... |

33 |

Diagnostic chart......................................................... |

34 |

Installation |

11-26 |

|

Installation safety instructions.................................... |

|

11 |

Determine the header bracket location ..................... |

|

12 |

Install the header bracket.......................................... |

|

13 |

Attach the rail to the header bracket......................... |

|

14 |

Position the opener ................................................... |

|

15 |

Hang the opener ....................................................... |

|

16 |

Install the door control............................................... |

|

17 |

Install the light ........................................................... |

|

18 |

Attach the emergency release rope and handle |

.......18 |

|

Electrical requirements.............................................. |

|

19 |

Install The Protector System® .............................. |

|

20-22 |

Fasten the door bracket ....................................... |

|

23-24 |

Connect the door arm to the trolley ..................... |

|

25-26 |

Programming |

35-36 |

To add or reprogram a hand-held remote control .....35 |

|

To erase all codes ..................................................... |

35 |

3-Function Remotes .................................................. |

35 |

To add, reprogram or change |

|

a Keyless Entry PIN .................................................. |

36 |

Repair Parts |

37-38 |

Rail assembly parts................................................... |

37 |

Installation parts ........................................................ |

37 |

Motor unit assembly parts ......................................... |

38 |

Accessories |

39 |

Warranty |

39 |

Repair Parts and Service |

40 |

INTRODUCTION

Safety Symbol

and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated, maintained and tested in strict accordance with the instructions and warnings contained in this manual.

WARNING

WARNING

Mechanical

WARNING

WARNING

Electrical

CAUTION

When you see these Safety Symbols and Signal Words on the following pages, they will alert you to the possibility of serious injury or death if you do not comply with the warnings that accompany them. The hazard may come from something mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the possibility of damage to your garage door and/or the garage door opener if you do not comply with the cautionary statements that accompany it. Read them carefully.

2

Preparing your garage door

Before you begin:

•Disable locks.

•Remove any ropes connected to garage door.

•Complete the following test to make sure your garage door is balanced and is not sticking or binding:

1.Lift the door about halfway as shown. Release the door. If balanced, it should stay in place, supported entirely by its springs.

2.Raise and lower the door to see if there is any binding or sticking.

If your door binds, sticks, or is out of balance, call a trained door systems technician.

Sectional Door |

One-Piece Door

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH:

•ALWAYS call a trained door systems technician if garage door binds, sticks, or is out of balance. An unbalanced garage door may not reverse when required.

•NEVER try to loosen, move or adjust garage door, door springs, cables, pulleys, brackets or their hardware, all of which are under EXTREME tension.

•Disable ALL locks and remove ALL ropes connected to garage door BEFORE installing and operating garage door opener to avoid entanglement.

CAUTION

To prevent damage to garage door and opener:

•ALWAYS disable locks BEFORE installing and operating the opener.

•ONLY operate garage door opener at 120V, 60 Hz to avoid malfunction and damage.

Tools needed

During assembly, installation and adjustment of the opener, instructions will call for hand tools as illustrated below.

Carpenter's

Level (optional) |

1 |

2 |

|

|

Tape Measure

Drill Bits

Drill 3/16", 5/16"

and 5/32"

Stepladder |

Sockets and Wrench |

|

1/2", 5/8", 7/16", 9/16" |

||

|

||

|

and 1/4" |

Pencil

Hack Saw

Claw Hammer

Wire Cutters

Screwdriver

Pliers

Adjustable End Wrench

3

Planning

Identify the type and height of your garage door. Survey your garage area to see if any of the conditions below apply to your installation. Additional materials may be required. You may find it helpful to refer back to this page and the accompanying illustrations as you proceed with the installation of your opener.

Depending on your requirements, there are several installation steps which may call for materials or hardware not included in the carton.

•Installation Step 1 – Look at the wall or ceiling above the garage door. The header bracket must be securely fastened to structural supports.

•Installation Step 5 – Do you have a finished ceiling in your garage? If so, a support bracket and additional fastening hardware may be required.

•Installation Step 10 – Depending upon garage construction, extension brackets or wood blocks may be needed to install sensors.

•Installation Step 10 – Alternate floor mounting of the safety reversing sensor will require hardware not provided.

•Do you have an access door in addition to the garage door? If not, Model 18752 Emergency Key Release is required. See Accessories page.

•Look at the garage door where it meets the floor. Any gap between the floor and the bottom of the door must not exceed 1/4" (6 mm). Otherwise, the safety reversal system may not work properly. See Adjustment Step 3. Floor or door should be repaired.

SECTIONAL DOOR INSTALLATIONS

•Do you have a steel, aluminum, fiberglass or glass panel door? If so, horizontal and vertical reinforcement is required (Installation Step 11).

•The opener should be installed above the center of the door. If there is a torsion spring or center bearing plate in the way of the header bracket, it may be installed within 4 feet (1.22 m) to the left or right of the door center. See Installation Steps 1 and 11.

•If your door is more than 7 feet (2.13 m) high, see rail extension kits listed on Accessories page.

SECTIONAL DOOR INSTALLATION

Horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass, steel, aluminum, door with

glass panels, etc.). See page 23 for details.

Header Wall

Slack in chain tension is normal when garage door is closed.

Extension Spring

OR

Torsion Spring

FINISHED CEILING

Support bracket & fastening hardware is required.

See page 16.

Motor unit

|

|

|

Wall- |

|

|

|

|

|

|

|

mounted |

Access Door |

|

|

|

|

|

|

Door |

|

|

|

|

Vertical |

|

— |

Control |

|

Header |

CLOSED POSITION |

|

|

|

|

|

|

|||

|

|

|

Bracket |

|

|

||

Centerline |

|

|

|

|

|||

|

|

|

|

|

|||

of Garage |

— |

|

|

Trolley |

|

|

|

— |

|

|

Trolley |

|

|||

Door |

|

|

|

Stop Bolt |

|

||

|

|

— — |

|

|

Garage |

|

|

|

|

— |

|

|

|

|

|

|

|

|

|

Door |

|

Chain |

|

|

|

|

|

|

|

||

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

— |

|

|

|

Straight |

Emergency |

|

|

— |

|

|

|

||

|

|

|

|

|

Door |

||

|

|

|

|

|

Release |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

Arm |

|

|

|

|

Safety Reversing |

|

|

Rope & Handle |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Gap between floor |

Sensor |

|

Curved |

|

||

|

and bottom of door |

|

|

|

|||

|

|

Header |

Door |

|

|||

Safety Reversing Sensor |

must not exceed 1/4" (6 mm). |

|

|||||

Arm |

|

||||||

|

|

|

|

Wall |

|

||

|

|

|

|

Door |

|

|

|

|

|

|

|

Garage |

|

|

|

|

|

|

|

Bracket |

|

|

|

|

|

|

|

Door |

|

|

|

|

|

|

4 |

|

|

|

|

Planning (Continued)

ONE-PIECE DOOR INSTALLATIONS

•Generally, a one-piece door does not require reinforcement. If your door is lightweight, refer to the information relating to sectional doors in Installation Step 11.

•Depending on your door’s construction, you may need additional mounting hardware for the door bracket (Step 11).

WARNING

WARNING

Without a properly working safety reversal system, persons (particularly small children) could be SERIOUSLY INJURED or KILLED by a closing garage door.

•The gap between the bottom of the garage door and the floor MUST NOT exceed 1/4" (6 mm). Otherwise, the safety reversal system may not work properly.

•The floor or the garage door MUST be repaired to eliminate the gap.

ONE-PIECE DOOR WITHOUT TRACK

FINISHED CEILING

Support bracket & fastening hardware is required. See page 16.

Header Wall |

Rail |

|

|

|

|

|

|

|

|

|

|

|

Slack in chain tension |

|

|

|

|

|

is normal when garage |

Motor Unit |

|

|

|

|

door is closed. |

|

|

|

|

|

|

|

|

|

|

|

Wall-mounted |

|

|

|

|

|

Door Control |

|

|

|

|

|

Access |

|

|

|

|

|

Door |

CLOSED POSITION |

|

||

|

|

Trolley Stop Bolt |

|

Cable |

Trolley |

|

|

|

|

||

|

|

Header |

|

|

|

|

|

Bracket |

Rail |

|

|

|

|

|

|

|

|

|

Safety Reversing |

Door Bracket |

|

|

|

|

|

|

|

|

|

Gap between floor |

Sensor |

|

|

|

Emergency |

|

|

|

|

Release |

|

and bottom of door must not exceed 1/4" (6 mm). |

Straight |

|

|

||

|

Curved |

Rope & Handle |

|||

Safety Reversing Sensor |

|

|

|||

|

|

Door |

|

Door |

|

|

Header |

Arm |

|

Arm |

|

|

|

|

|

|

|

|

Wall |

Garage Door |

|

|

|

|

|

|

|

||

ONE-PIECE DOOR WITH TRACK

Safety

Reversing Sensor

Access

Door

|

Safety |

|

Gap between floor |

Reversing |

|

Sensor |

||

and bottom of door |

||

|

||

must not exceed 1/4" (6 mm). |

||

|

CLOSED POSITION |

|

|

|

Trolley Stop Bolt |

Cable |

Chain |

Header |

|

|

|

Wall |

Header |

Curved |

|

|

Rail |

||

|

Bracket |

Door Arm |

|

|

Door |

|

Emergency |

|

Straight |

Release |

|

|

Bracket |

||

|

Rope & |

||

|

|

Door |

|

|

|

Handle |

|

|

Garage |

Arm |

|

|

|

||

|

Door |

|

|

5

Carton Inventory

Your garage door opener is packaged in one carton which contains the motor unit and all parts illustrated below. Accessories will depend on the model purchased. If anything is missing, carefully check the packing

material. Parts may be stuck in the foam. Hardware for assembly and installation is shown on the next page. Save the carton and packing material until installation and adjustment is complete.

Chain Spreader

|

SECURITY ® |

|

3-Function Remote Control |

Standard Control Console |

Models 18453D (2), 18473D (2) |

|

|

Models 18452D, 18453D, 18473D |

|

|

|

Door Control Button

Model 18451D

SECURITY ®

Single-Function Remote Control

Models 18451D (1), 18452D (2)

Motor Unit with a Light Lens

Idler Pulley

Rail

Front (header)

Section

Header Bracket

Trolley

Garage Door Monitor System

Model 18473D

Rail

Center/Back

Sections

"U" Bracket

Hanging Brackets

Chain and Cable

Curved Door

Arm Section

Door Bracket

2-Conductor Bell Wire

White & White/Red

Safety Sensor

Bracket (2)

The Protector System®

(2) Safety Reversing Sensors

(1 Sending Eye and 1 Receiving Eye) with 2-Conductor White & White/Black Bell Wire attached

Safety Labels

and

Literature Straight Door

Arm Section

6

Hardware Inventory

Separate all hardware and group as shown below for the assembly and installation procedures.

ASSEMBLY HARDWARE

Lock Nut |

Lock Washer |

Nut |

1/4"-20 (2) |

3/8" (1) |

3/8" (1) |

Bolt 1/4"-20x1-3/4" (2)

Master |

|

Link (2) |

Idler Bolt (1) |

Trolley Threaded Shaft (1)

|

|

INSTALLATION HARDWARE |

|

|

|

Carriage Bolt |

Wing Nut |

Ring |

Nut 5/16"-18 (8) |

|

Handle |

1/4"-20x1/2" (2) |

1/4"-20 (2) |

Fastener (3) |

|

|

|

Lag Screw |

|

Hex Bolt |

|

|

Insulated |

5/16"-9x1-5/8" (2) |

5/16"-18x7/8" (4) |

Lock Washer 5/16" (7) |

Staples (30) |

||

Lag Screw |

|

Screw |

|

Screw 6-32x1" (2) |

|

5/16"-18x1-7/8" (2) |

6ABx1-1/4" (2) |

|

|||

|

|

|

Screw 6ABx1-1/2" |

|

|

|

|

|

|

|

Rope |

Carriage Bolt |

|

|

|

|

|

5/16"-18x2-1/2" (2) |

|

|

|

|

|

|

|

Drywall Anchors (2) |

|

Spacer (2) |

|

Clevis Pin |

|

Clevis Pin |

|

Clevis Pin |

|

5/16"x1-1/2" (1) |

|

5/16"x1" (1) |

|

5/16"x1-1/4" (1) |

|

|

|

7 |

|

|

|

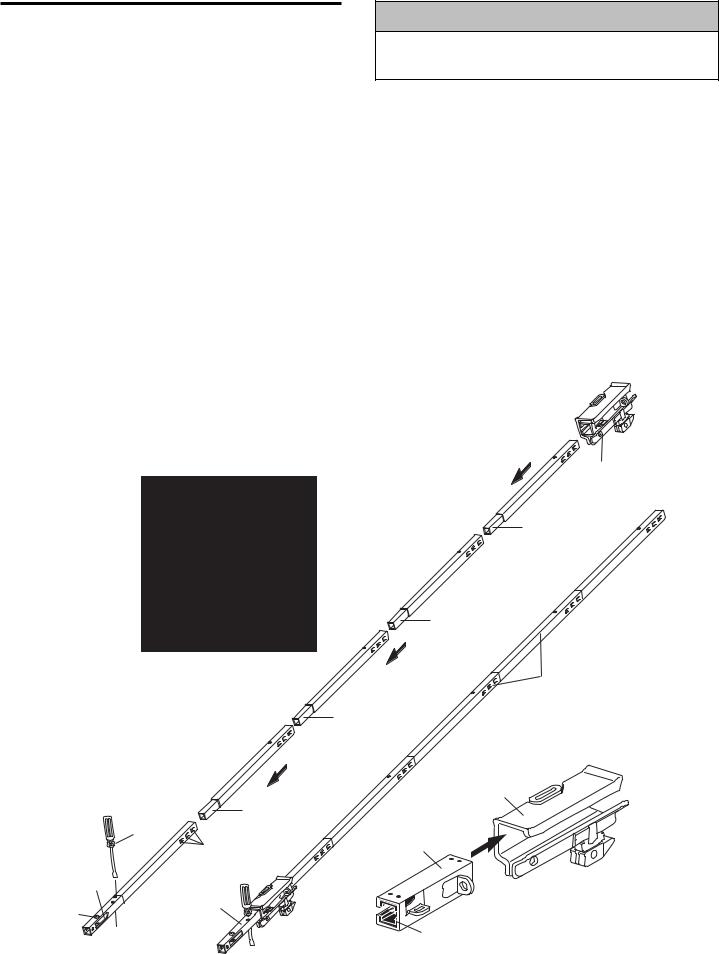

ASSEMBLY STEP 1

Assemble the Rail & Install the Trolley

To avoid installation difficulties, do not run the garage door opener until instructed to do so.

The front rail has a cut out “window” at the door end (see illustration). The hole above this window is larger on the top of the rail than on the bottom. A smaller hole 3- 1/2" (8.9 cm) away is close to the rail edge. Rotate the back rail so it has a similar hole close to the opposite edge, about 4-3/4" (12 cm) from the far end.

1.Remove the straight door arm and hanging bracket packaged inside the front rail and set aside for Installation Step 5 and 12. NOTE: To prevent INJURY while unpacking the rail carefully remove the straight door arm stored within the rail section.

2.Align the rail sections on a flat surface as shown and slide the tapered ends into the larger ones. Tabs along the side will lock into place.

3.Place the motor unit on packing material to protect the cover, and rest the back end of the rail on top. For convenience, put a support under the front end of the rail.

CAUTION

To prevent INJURY from pinching, keep hands and fingers away from the joints while assembling the rail.

4.As a temporary stop, insert a screwdriver into the hole 10" (25 cm) from the front end of the rail, as shown.

5.Check to be sure there are 4 plastic wear pads inside the inner trolley. If they became loose during shipping, check all packing material. Snap them back into position as shown.

6.Slide the trolley assembly along the rail from the back end to the screwdriver.

|

|

Trolley |

|

|

Tapered |

|

|

End |

|

KEEP LARGER |

|

|

HOLE ON TOP |

|

|

FRONT RAIL |

Tapered |

|

(TOP) |

End |

|

|

Back Rails |

|

|

(TO MOTOR UNIT) |

|

|

Tapered |

|

|

End |

|

|

Outer Trolley |

|

Tapered |

|

|

End |

|

|

Screwdriver |

|

|

Tabs |

Inner Trolley |

|

|

|

Window |

|

|

Cut-Out |

Front Rail |

|

|

|

|

Idler |

(TO DOOR) |

|

Pulley |

|

|

Hole |

|

Wear Pads |

|

|

8

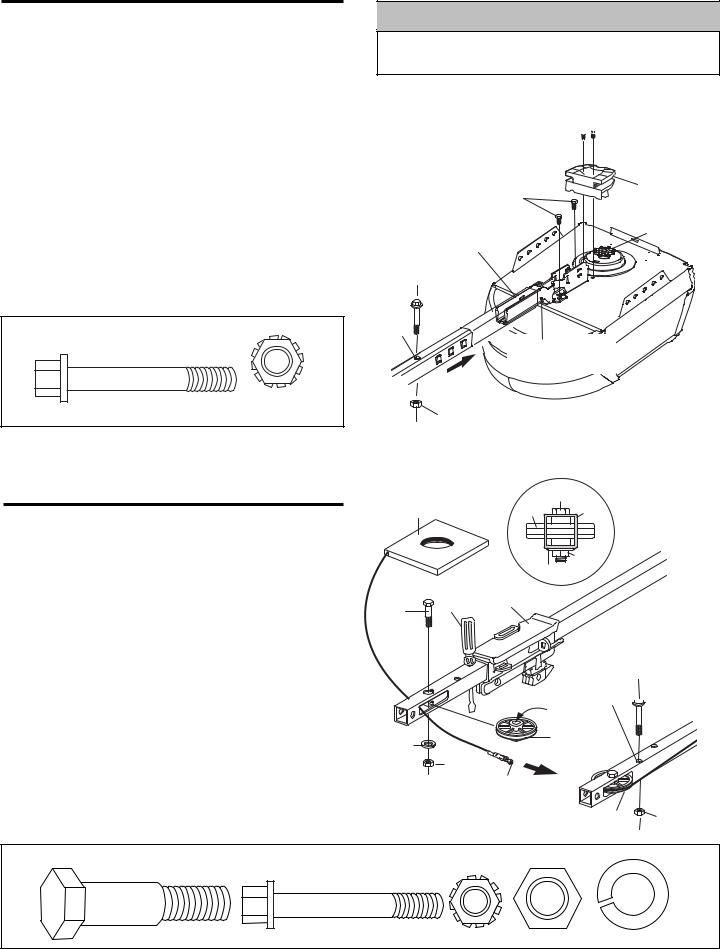

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

•Insert a 1/4"-20x1-3/4 bolt into the cover protection bolt hole on the back end of the rail as shown. Tighten securely with a 1/4"-20 lock nut. Do NOT overtighten.

•Remove the two bolts from the top of the motor unit.

•Place the “U” bracket, flat side down onto the motor unit and align the bracket hole with the bolt holes. Fasten with the previously removed bolts.

•Align the rail assembly with the top of the motor unit. Slide the rail end onto the “U” bracket, all the way to the stops that protrude on the top and sides of the bracket.

•Attach spreader to the motor unit with two screws.

HARDWARE SHOWN ACTUAL SIZE

|

Lock Nut |

Bolt 1/4"-20x1-3/4" |

1/4"-20 |

ASSEMBLY STEP 3

Install the Idler Pulley

•Lay the chain/cable beside the rail, as shown. Grasp the end of the cable and pass approximately 12" (30 cm) of cable through the window. Allow it to hang until Assembly Step 5.

•Remove the tape from the idler pulley. The inside center should be pre-greased. If dry, regrease to ensure proper operation.

•Place the idler pulley into the window as shown.

•Insert the idler bolt from the top through the rail and pulley. Tighten with a 3/8" lock washer and nut underneath the rail until the lock washer is compressed.

•Rotate the pulley to be sure it spins freely.

•Insert a 1/4"-20x1-3/4 bolt into the trolley stop hole in the front of the rail as shown. Tighten securely with a 1/4"-20 lock nut.

CAUTION

To avoid SERIOUS damage to garage door opener, use ONLY those bolts/fasteners mounted in the top of the opener.

Hex Screws

8-32x7/16"

8-32x7/16"

|

Chain |

Bolt |

Spreader |

|

|

|

Motor Unit |

|

Sprocket |

"U" Bracket |

|

Bolt

Cover

Protection

Bolt Hole

SLIDE RAIL TO STOPS

ON TOP AND SIDES

OF BRACKET

OF BRACKET

Lock Nut

Chain and |

|

Bolt |

|

Pulley |

Rail |

||

Cable |

|||

|

|

Nut

Washer

Idler |

Screwdriver Trolley |

Bolt |

|

Bolt

Trolley

Stop Hole

|

Grease |

|

Inside Pulley |

Lock |

Idler |

Washer |

Pulley |

3/8" |

Nut 3/8" |

|

|

|

Cable Link |

Lock

Idler Nut

Pulley

HARDWARE SHOWN ACTUAL SIZE

Idler Bolt |

Bolt 1/4"-20x1-3/4 |

Lock Nut 1/4"-20 |

Nut 3/8" |

Lock Washer 3/8" |

9

ASSEMBLY STEP 4

Install the Chain/Cable

1.Pull the cable around the idler pulley and toward the trolley.

2.Connect the cable to the retaining slot on the trolley, as shown (Figure 1):

•From below, push pins of master link bar up through cable link and trolley slot.

•Push master link cap over pins and past pin notches.

•Slide clip-on spring over cap and onto pin notches until both pins are securely locked in place.

3.With the trolley against the screwdriver, dispense the remainder of the cable/chain along the rail toward the motor unit into the slot on the chain spreader, around the sprocket onto the chain spreader and continuing to the trolley assembly. The sprocket teeth must engage the chain (Figure 2).

4.Check to make sure the chain is not twisted, then connect it to the threaded shaft with the remaining master link.

5.Thread the inner nut and lock washer onto the trolley threaded shaft (Figure 3).

6.Insert the trolley threaded shaft through the hole in the trolley. Be sure the chain is not twisted (Figure 4).

7.Loosely thread the outer nut onto the trolley threaded shaft.

8.Remove the screwdriver.

Figure 2 |

Chain |

|

|

Spreader |

Motor Unit |

|

"U" Bracket |

Sprocket |

|

|

WARNING

WARNING

To avoid possible SERIOUS INJURY to fingers from moving garage door opener:

•ALWAYS keep hand clear of sprocket while operating opener.

•Securely attach chain spreader BEFORE operating.

Dispensing Carton

Leave Chain and Cable

Inside Dispensing

Carton to Prevent Kinking.

Keep Chain and Cable

Taut When Dispensing

|

Figure 1 |

|

|

|

Master Link |

|

|

|

Clip-On Spring |

Master |

|

|

|

||

|

|

Link Cap |

|

Master Link |

|

|

|

Clip-On Spring |

Master |

|

|

|

Link Cap |

|

|

|

Trolley |

Pin |

|

Cable |

Threaded |

||

Shaft |

Notch |

||

Link |

|||

|

Master |

||

|

Round |

||

|

Link Bar |

||

Idler |

Hole |

|

|

Slotted |

|

||

Pulley |

Hole |

|

|

Cable |

Master |

|

|

Link Bar |

|

Bolt

Figure 3

|

Trolley |

|

Threaded |

|

Shaft |

|

Inner Nut |

Lock |

5/16" |

Washer |

|

5/16" |

|

Figure 4

Trolley

Threaded

Shaft

Round

Hole

10

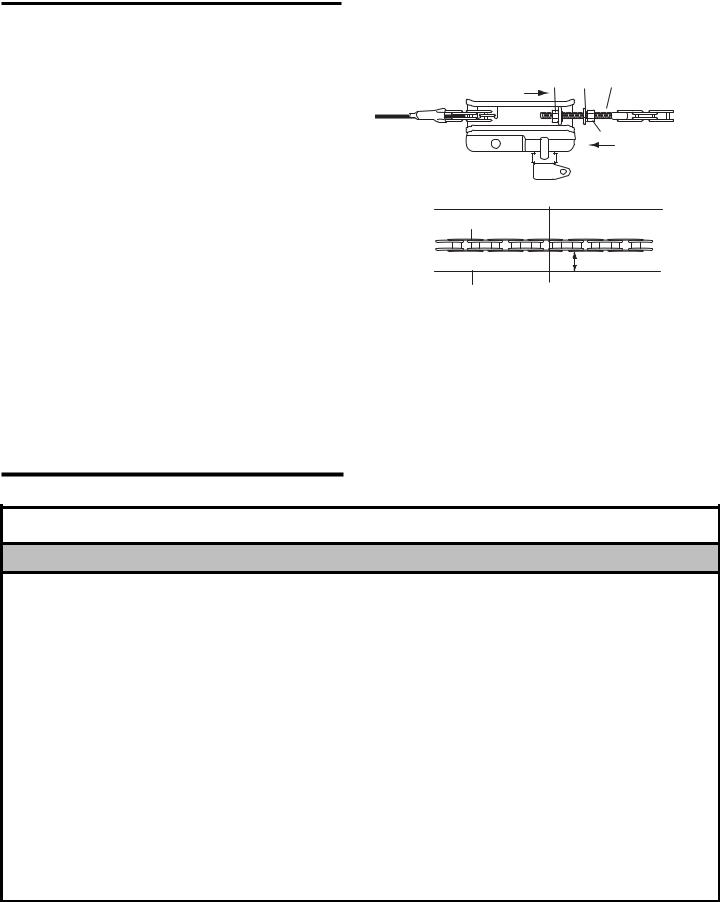

ASSEMBLY STEP 5

Tighten the Chain

•Spin the inner nut and lock washer down the trolley threaded shaft, away from the trolley.

•To tighten the chain, turn outer nut in the direction shown (Figure 1).

•When the chain is approximately 1/4" (6 mm) above the base of the rail at its midpoint, re-tighten the inner nut to secure the adjustment.

Sprocket noise can result if chain is too loose.

When installation is complete, you may notice some chain droop with the door closed. This is normal. If the chain returns to the position shown in Figure 2 when the door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS pull the emergency release handle to disconnect trolley before adjusting chain.

NOTE: You may notice loosening of chain after Adjustment Step 3 (Test the Safety Reversal System). Check for proper tension and readjust chain if necessary. Then repeat Adjustment Step 3.

You have now finished assembling your garage door opener. Please read the following warnings before proceeding to the installation section.

Figure 1

Trolley

Outer Lock Threaded

Nut Washer Shaft

To Tighten Outer Nut

Inner Nut

To Tighten

Inner Nut

Figure 2

Chain

1/4" (6 mm)

Base of Rail |

Mid length of Rail |

INSTALLATION

IMPORTANT INSTALLATION INSTRUCTIONS

WARNING

WARNING

To reduce the risk of SEVERE INJURY or DEATH:

1.READ AND FOLLOW ALL INSTALLATION WARNINGS AND INSTRUCTIONS.

2.Install garage door opener only on properly balanced and lubricated garage door. An improperly balanced door may not reverse when required and could result in SEVERE INJURY or DEATH.

3.ALL repairs to cables, spring assemblies and other hardware MUST be made by a trained door systems technician BEFORE installing opener.

4.Disable ALL locks and remove ALL ropes connected to garage door BEFORE installing opener to avoid entanglement.

5.Install garage door opener 7 feet (2.13 m) or more above floor.

6.Mount emergency release handle 6 feet (1.83 m) above floor.

7.NEVER connect garage door opener to power source until instructed to do so.

8.NEVER wear watches, rings or loose clothing while installing or servicing opener. They could be caught in garage door or opener mechanisms.

9.Install wall-mounted garage door control:

•within sight of the garage door.

•out of reach of children at minimum height of 5 feet (1.5 m).

•away from ALL moving parts of the door.

10.Place entrapment warning label on wall next to garage door control.

11.Place manual release/safety reverse test label in plain view on inside of garage door.

12.Upon completion of installation, test safety reversal system. Door MUST reverse on contact with a 1-1/2" (3.8 cm) high object (or a 2x4 laid flat) on the floor.

11

INSTALLATION STEP 1

Determine the Header Bracket

Location

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH:

•Header bracket MUST be RIGIDLY fastened to structural support on header wall or ceiling, otherwise garage door might not reverse when required. DO NOT install header bracket over drywall.

•Concrete anchors MUST be used if mounting header bracket or 2x4 into masonry.

•NEVER try to loosen, move or adjust garage door, springs, cables, pulleys, brackets, or their hardware, all of which are under EXTREME tension.

•ALWAYS call a trained door systems technician if garage door binds, sticks, or is out of balance. An unbalanced garage door might not reverse when required.

Installation procedures vary according to garage door types. Follow the instructions which apply to your door.

1.Close the door and mark the inside vertical centerline of the garage door.

2.Extend the line onto the header wall above the door.

You can fasten the header bracket within 4 feet (1.22 m) of the left or right of the door center only if a torsion spring or center bearing plate is in the way; or you can attach it to the ceiling (see

page 13) when clearance is minimal. (It may be mounted on the wall upside down if necessary, to gain approximately 1/2" (1 cm).

If you need to install the header bracket on a 2x4 (on wall or ceiling), use lag screws (not provided) to securely fasten the 2x4 to structural supports as shown here and on page 13.

3.Open your door to the highest point of travel as shown. Draw an intersecting horizontal line on the header wall above the high point:

•2" (5 cm) above the high point for sectional door and one-piece door with track.

•8" (20 cm) above the high point for one-piece door without track.

This height will provide travel clearance for the top edge of the door.

NOTE: If the total number of inches exceeds the height available in your garage, use the maximum height possible, or refer to page 13 for ceiling installation.

Unfinished

Ceiling

OPTIONAL

CEILING

MOUNT

FOR

HEADER

BRACKET

Header Wall |

2x4 |

Vertical Centerline

of Garage Door

2x4 Structural

Supports

Level  (optional)

(optional)

Header Wall |

|

|

|

2" (5 cm) |

Track |

Header Wall |

Track |

|

|

2" (5 cm) |

|

Highest Point |

|

|

|

of Travel |

|

Highest Point |

|

|

|

||

|

|

of Travel |

|

|

|

Door |

|

Door |

|

|

|

Sectional door with curved track |

One-piece door with horizontal track |

|

|

Header Wall |

|

Header Wall |

8" (20 cm) |

|

8" (20 cm) |

|

|

Highest |

Highest |

Door |

Point |

|

|

Point |

of Travel |

|

of Travel |

Door |

Jamb |

|

|

Hardware |

|

|

|

|

Pivot |

One-piece door without track: |

One-piece door without track: |

|

jamb hardware |

pivot hardware |

|

12

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall above the garage door, or to the ceiling. Follow the instructions which will work best for your particular requirements. Do not install the header bracket over drywall. If installing into masonry, use concrete anchors (not provided).

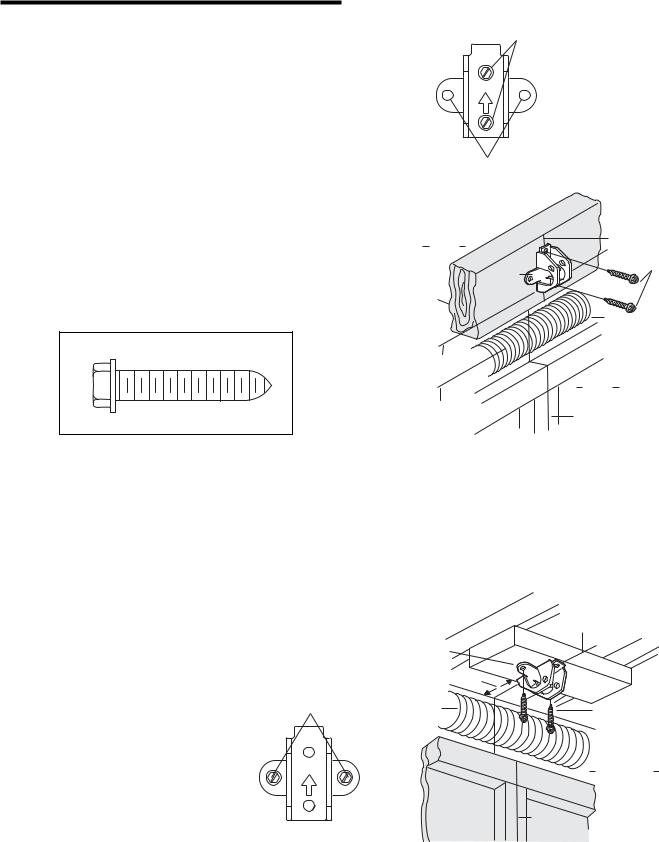

WALL HEADER BRACKET INSTALLATION

•Center the bracket on the vertical centerline with the bottom edge of the bracket on the horizontal line as shown (with the arrow pointing toward the ceiling).

•Mark the vertical set of bracket holes. Drill 3/16" pilot holes and fasten the bracket securely to a structural support with the hardware provided.

HARDWARE SHOWN ACTUAL SIZE

Lag Screw 5/16"-9x1-5/8"

Wall Mount

UP

Optional

Mounting Holes

|

Vertical |

|

|

Centerline |

|

|

of Garage Door |

|

Wall |

Lag Screws |

|

|

||

2x4 |

5/16"-9x1-5/8" |

|

Header |

||

Structural |

||

Bracket |

||

Support |

||

|

||

|

Door Spring |

Horizontal

Line

Garage

Door

Highest Point of

Garage Door Travel Vertical

Centerline

of Garage Door

CEILING HEADER BRACKET INSTALLATION

•Extend the vertical centerline onto the ceiling as shown.

•Center the bracket on the vertical mark, no more than 6" (15 cm) from the wall. Make sure the arrow is pointing away from the wall. The bracket can be mounted flush against the ceiling when clearance

is minimal.

•Mark the side holes. Drill 3/16" pilot holes and fasten bracket securely to a structural support with the hardware provided.

Ceiling Mounting Holes

UP

– Finished Ceiling –

Vertical Centerline

of Garage Door

Header

Bracket

6" (15 cm) Maximum

Door |

Lag Screws |

Spring |

|

|

5/16"-9x1-5/8" |

|

Header Wall |

Garage Door |

Vertical |

|

Centerline |

|

of Garage Door |

13

Header Wall

Header Wall

Header Bracket

Idler Pulley

INSTALLATION STEP 3

Attach the Rail to the Header Bracket

NOTE: (Optional) With some existing installations, you may re-use the old header bracket with the two plastic spacers included in the hardware bag. Place the spacers inside the bracket on each side of the rail, as illustrated.

•Position the opener on the garage floor below the header bracket. Use packing material as a protective base. NOTE: If the door spring is in the way you’ll need help. Have someone hold the opener securely on a temporary support to allow the rail to clear the spring.

•Position the rail bracket against the header bracket.

•Align the bracket holes and join with a clevis pin 5/16"x1-1/2" as shown.

•Insert a ring fastener to secure.

Header |

Bracket |

Mounting |

Hole |

Existing |

Header Bracket |

Existing |

Clevis Pin |

Spacer |

Mounting |

Hole |

WITH |

EXISTING |

INSTALLATIONS |

Garage |

Door |

Opener Carton or |

Temporary |

Support |

HARDWARE SHOWN ACTUAL SIZE

Clevis Pin 5/16"x1-1/2" |

Ring Fastener |

14

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH TRACK

A 2x4 laid flat is convenient for setting an ideal door-to-rail distance.

•Remove foam packaging.

•Raise the opener onto a stepladder. You will need help at this point if the ladder is not tall enough.

•Open the door all the way and place a 2x4 laid flat on the top section beneath the rail.

•If the top section or panel hits the trolley when you raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the outer trolley toward the motor unit. The trolley can remain disconnected until Installation Step 12 is completed.

|

Trolley |

|

Release Arm |

ENGAGED |

RELEASED |

CAUTION

To prevent damage to garage door, rest garage door opener rail on 2x4 placed on top section of door.

Rail

Door |

2x4 is used to determine |

|

the correct mounting height |

|

from ceiling. |

ONE-PIECE DOOR WITHOUT TRACK

A 2x4 on its side is convenient for setting an ideal door- to-rail distance.

•Remove foam packaging.

•Raise the opener onto a stepladder. You will need help at this point if the ladder is not tall enough.

•Open the door all the way and place a 2x4 on its side on the top section of the door beneath the rail.

•The top of the door should be level with the top of the motor unit. Do not position the opener more than 4" (10 cm) above this point.

Header

Bracket

Bracket

Top of Door

2x4 is used to determine the correct mounting height from ceiling.

15

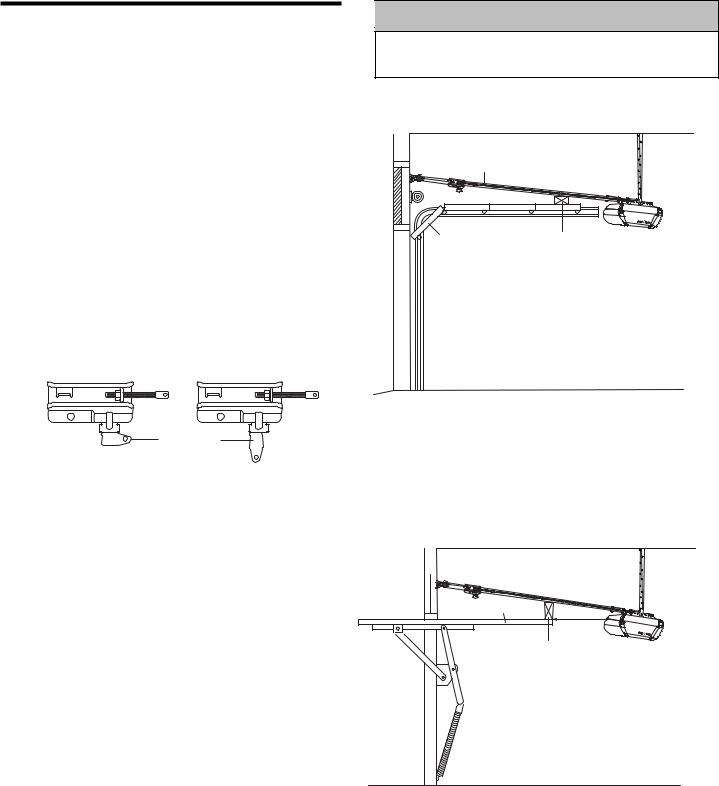

INSTALLATION STEP 5

Hang the Opener

Three representative installations are shown. Yours may be different. Hanging brackets should be angled (Figure 1) to provide rigid support. On finished ceilings (Figure 2 and Figure 3), attach a sturdy metal bracket to structural supports before installing the opener. This bracket and fastening hardware are not provided.

1.Measure the distance from each side of the motor unit to the structural support.

2.Cut both pieces of the hanging bracket to required lengths.

3.Drill 3/16" pilot holes in the structural supports.

4.Attach one end of each bracket to a support with 5/16"-18x1-7/8" lag screws.

5.Fasten the opener to the hanging brackets with 5/16"- 18x7/8" hex bolts, lock washers and nuts.

6.Check to make sure the rail is centered over the door (or in line with the header bracket if the bracket is not centered above the door).

7.Remove the 2x4. Operate the door manually. If the door hits the rail, raise the header bracket.

NOTE: DO NOT connect power to opener at this time.

HARDWARE SHOWN ACTUAL SIZE

Lag Screw 5/16"-18x1-7/8"

Hex Bolt |

|

Lock Washer 5/16" |

5/16"-18x7/8" |

Nut 5/16"-18 |

WARNING

WARNING

To avoid possible SERIOUS INJURY from a falling garage door opener, fasten it SECURELY to structural supports of the garage. Concrete anchors MUST be used if installing any brackets into masonry.

Figure 1

Structural |

|

Supports |

|

Lag Screws |

|

5/16"-18x1-7/8" |

Measure |

|

Distance |

Bolt 5/16"-18x7/8" |

|

Lock Washer 5/16" |

|

Nut 5/16"-18 |

|

Figure 2

Hidden |

|

Support |

Lag Screws |

|

5/16"-18x1-7/8" |

Bracket |

FINISHED CEILING |

|

|

(Not |

|

|

(Not Provided) |

|

Bolt 5/16"-18x7/8" |

|

Lock Washer 5/16" |

|

Nut 5/16"-18 |

Bolt 5/16"-18x7/8" |

|

Lock Washer 5/16" |

|

Nut 5/16"-18 |

|

Figure 3

Lag Screws |

FINISHED CEILING |

|

5/16"-18x1-7/8" |

||

|

(Not Provided) |

Bolt 5/16"-18x7/8" |

|

Bolt 5/16"-18x7/8" |

||

Lock Washer 5/16" |

||

Lock Washer 5/16" |

||

Nut 5/16"-18 |

||

Nut 5/16"-18 |

||

|

16

INSTALLATION STEP 6

Install the Door Control

Locate door control within sight of door, at a minimum height of 5 feet (1.5 m) where small children cannot reach, away from moving parts of door and door hardware. If installing into drywall, drill 5/32" holes and use the anchors provided. For

pre-wired installations (as in new home construction), it may be mounted to a single gang box (Figure 2).

1.Strip 7/16" (11 mm) of insulation from one end of bell wire and connect to the two screw terminals on back of door control by color: white wire to 2 and white/red wire to the 1.

2.Door Control Button: Fasten securely with 6ABx1-1/2" screws.

Console Model: Remove cover by gently prying along one side with a screwdriver (Figure 1). Fasten with 6ABx1-1/4" self-tapping screws (drywall installation) or 6-32x1" machine screws (into gang box) as follows:

•Install bottom screw, allowing 1/8" (3 mm) to protrude above wall surface.

•Position bottom of door control on screw head and slide down to secure. Adjust screw for snug fit.

•Drill and install top screw with care to avoid cracking plastic housing. Do not overtighten.

•Insert top tabs and snap on cover.

3.(For standard installation only) Run bell wire up wall and across ceiling to motor unit. Use insulated staples to secure wire in several places. Do not pierce wire with a staple, creating a short or open circuit.

4.Strip 7/16" (11 mm) of insulation from end of bell wire. Connect bell wire to the quick-connect terminals as follows: white to white and white/red to red.

NOTE: When connecting multiple door controls to the opener, twist same color wires together. Insert wires into quick-connect holes: white to white and red/white to red.

5.Position the antenna wire as shown.

6.Use tacks or staples to permanently attach entrapment warning label to wall near door control, and manual release/safety reverse test label in

a prominent location on inside of garage

NOTE: DO NOT connect power and opener at this time. The trolley will travel full open position but will not return to the position until the sensor beam is connected properly aligned.

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from electrocution:

•Be sure power is not connected BEFORE installing door control.

•Connect ONLY to 24 VOLT low voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a closing garage door:

•Install door control within sight of garage door, out of reach of children at a minimum height of 5 feet (1.5 m), and away from all moving parts of door.

•NEVER permit children to operate or play with door control push buttons or remote control transmitters.

•Activate door ONLY when it can be seen clearly, is properly adjusted, and there are no obstructions to door travel.

•ALWAYS keep garage door in sight until completely closed. NEVER permit anyone to cross path of closing garage door.

Outside Keylock Accessory Connections

To opener quick-connect terminals: white to white; white/red to red.

|

HARDWARE SHOWN |

Screw 6ABx1-1/2" |

ACTUAL SIZE |

|

|

Door Control Button |

|

Screw 6ABx1-1/4" |

Insulated |

Control Console (std installation) |

Staples |

Screw 6-32x1" |

|

Control Console (pre-wired) |

Drywall Anchors |

Figure 1 |

|

Figure 2 |

|

REMOVE & REPLACE COVER |

PRE-WIRED |

||

INSTALLATION |

|||

To Replace, |

|

||

To Remove, |

|||

Insert |

|||

Twist |

|

||

Top Tabs |

|

||

Here |

|

||

First |

|

||

|

|

||

|

|

24 Volt |

|

|

|

2-Conductor |

|

|

|

Bell Wire |

|

Lighted |

Quick-Connect |

DOOR CONTROL |

|

Push Button |

2-Conductor Terminals |

BUTTON (BACK VIEW) |

|

|

Bell Wire |

|

|

|

|

WHT |

|

|

|

2 |

|

|

|

1 |

D |

|

|

RE |

|

|

|

Bell |

|

|

|

|

|

|

|

|

Wire |

DOOR |

|

Terminal Screws |

|

CONTROL |

STANDARD |

||

|

|||

BUTTON |

|

||

CONTROL CONSOLE |

STANDARD CONTROL |

||

|

|||

|

|

(BACK VIEW) |

Door Control |

To release wire, push in |

|

|

|

Top |

|

Connections |

tab with screwdriver tip |

|

|

|

||

|

|

|

|

|

|

Mounting |

Strip wire 7/16" (11 mm) |

|

|

|

WHITE RED |

Hole |

|

|

|

|

Terminal |

|||

7/16" (11 mm) |

|

|

|

2 |

1 |

|

|

|

|

|

|

|

Screws |

|

|

|

Antenna |

|

|

Bottom |

|

|

|

|

|

|

|

|

White |

Grey |

Bell |

|

|

Mounting |

|

Wire |

|

|

Hole |

||

|

|

|

|

|

||

17

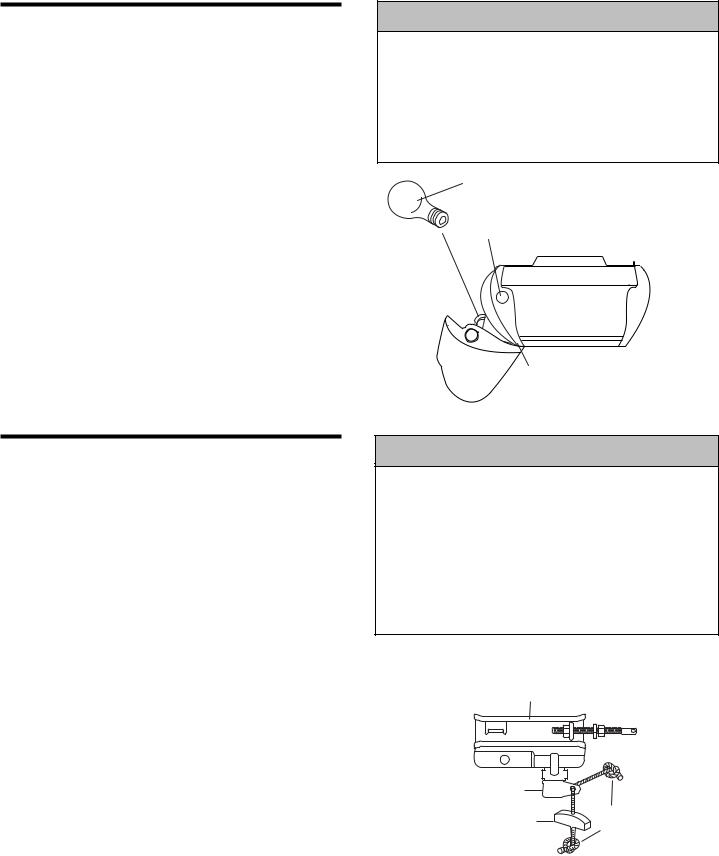

INSTALLATION STEP 7

Install the Light

•Press the release tabs on both sides of lens. Gently rotate lens back and downward until the lens hinge is in the fully open position. Do not remove the lens.

•Install a 100 watt maximum light bulb in the socket. Light bulb size should be A19, standard neck only. The light will turn ON and remain lit for approximately 4-1/2 minutes when power is connected. Then the light will turn OFF.

•Reverse the procedure to close the lens.

•Use A19, standard neck garage door opener bulb for replacement.

NOTE: Use only standard light bulbs. The use of short neck or speciality light bulbs may overheat the endpanel or light socket.

CAUTION

To prevent possible OVERHEATING of the endpanel or light socket:

•DO NOT use short neck or specialty light bulbs.

•DO NOT use halogen bulbs. Use ONLY incandescent. To prevent damage to the opener:

•DO NOT use bulbs larger than 100W.

•ONLY use A19 size bulbs.

100 Watt (Max)

Standard

Light Bulb

Release Tab

Lens

Hinge

INSTALLATION STEP 8

Attach the Emergency Release Rope

and Handle

•Thread one end of the rope through the hole in the top of the red handle so “NOTICE” reads right side up as shown. Secure with an overhand knot at least 1" (2.5 cm) from the end of the rope to prevent slipping.

•Thread the other end of the rope through the hole in the release arm of the outer trolley.

•Adjust rope length so the handle is 6 feet (1.83 m) above the floor. Ensure that the rope and handle clear the tops of all vehicles to avoid entanglement. Secure with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal the cut end with a match or lighter to prevent unraveling.

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from a falling garage door:

•If possible, use emergency release handle to disengage trolley ONLY when garage door is CLOSED. Weak or broken springs or unbalanced door could result in an open door falling rapidly and/or unexpectedly.

•NEVER use emergency release handle unless garage doorway is clear of persons and obstructions.

•NEVER use handle to pull door open or closed. If rope knot becomes untied, you could fall.

Trolley

Trolley

Release arm

Emergency

Release Handle

NOTICE

Overhand

Knot

18

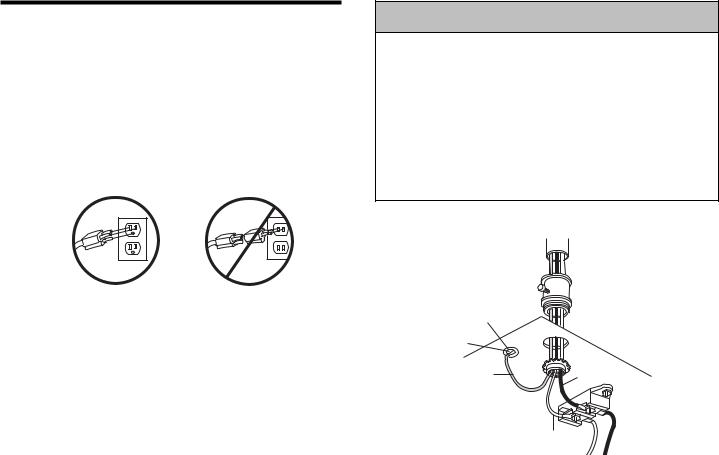

INSTALLATION STEP 9

Electrical Requirements

To avoid installation difficulties, do not run the opener at this time.

To reduce the risk of electric shock, your garage door opener has a grounding type plug with a third grounding pin. This plug will only fit into a grounding type outlet. If the plug doesn’t fit into the outlet you have, contact a qualified electrician to install the proper outlet.

RIGHT |

WRONG |

If permanent wiring is required by your local code, refer to the following procedure.

To make a permanent connection through the 7/8" hole in the top of the motor unit:

•Remove the motor unit cover screws and set the cover aside.

•Remove the attached 3-prong cord.

•Connect the black (line) wire to the screw on the brass terminal; the white (neutral) wire to the screw on the silver terminal; and the ground wire to the green ground screw. The opener must be grounded.

•Reinstall the cover.

To avoid installation difficulties, do not run the opener at this time.

WARNING

WARNING

To prevent possible SERIOUS INJURY or DEATH from electrocution or fire:

•Be sure power is not connected to the opener, and disconnect power to circuit BEFORE removing cover to establish permanent wiring connection.

•Garage door installation and wiring MUST be in compliance with all local electrical and building codes.

•NEVER use an extension cord, 2-wire adapter, or change plug in any way to make it fit outlet. Be sure the opener is grounded.

PERMANENT WIRING

CONNECTION

Ground Tab

Green

Ground Screw

Ground Wire |

Black |

Wire |

White Wire |

|

|

|

Black Wire |

|

|

19

INSTALLATION STEP 10

Install The Protector System®

The safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction.

IMPORTANT INFORMATION ABOUT

THE SAFETY REVERSING SENSOR

When properly connected and aligned, the sensor will detect an obstacle in the path of its electronic beam. The sending eye (with an amber indicator light) transmits an invisible light beam to the receiving eye (with a green indicator light). If an obstruction breaks the light beam while the door is closing, the door will stop and reverse to full open position, and the opener lights will flash

10 times.

The units must be installed inside the garage so that the sending and receiving eyes face each other across the door, no more than 6" (15 cm) above the floor. Either can be installed on the left or right of the door as long as the sun never shines directly into the receiving eye lens.

The mounting brackets are designed to clip onto the track of sectional garage doors without additional hardware.

WARNING

WARNING

Be sure power is not connected to the garage door opener BEFORE installing the safety reversing sensor.

To prevent SERIOUS INJURY or DEATH from a closing garage door:

•Correctly connect and align the safety reversing sensor. This required safety device MUST NOT be disabled.

•Install the safety reversing sensor so beam is NO HIGHER than 6" (15 cm) above garage floor.

If it is necessary to mount the units on the wall, the brackets must be securely fastened to a solid surface such as the wall framing. Extension brackets (see accessories) are available if needed. If installing in masonry construction, add a piece of wood at each location to avoid drilling extra holes in masonry if repositioning is necessary.

The invisible light beam path must be unobstructed. No part of the garage door (or door tracks, springs, hinges, rollers or other hardware) may interrupt the beam while the door is closing.

Safety Reversing Sensor |

Invisible Light Beam |

Safety Reversing Sensor |

|

6" (15 cm) max. above floor |

|||

6" (15 cm) max. above floor |

|||

|

Protection Area |

||

|

|

Facing the door from inside the garage

20

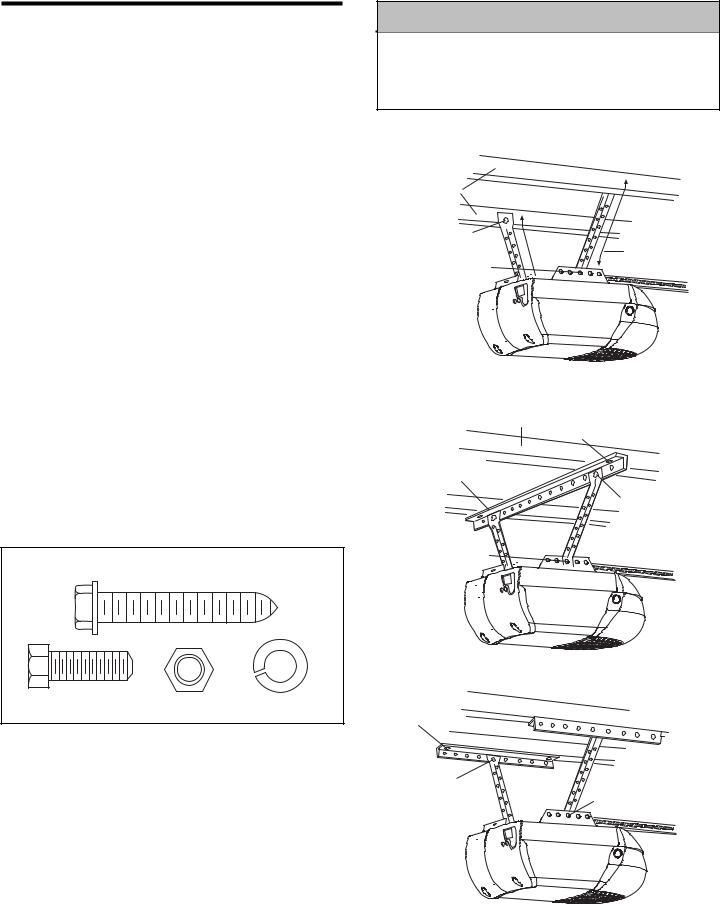

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected. Install and align the brackets so the sensors will face each other across the garage door, with the beam no higher than 6" (15 cm) above the floor. They may be installed in one of three ways, as follows.

Garage door track installation (preferred):

•Slip the curved arms over the rounded edge of each door track, with the curved arms facing the door. Snap into place against the side of the track. It should lie flush, with the lip hugging the back edge of the track, as shown in Figure 1.

If your door track will not support the bracket securely, wall installation is recommended.

Wall installation (Figure 2 & 3):

•Place the bracket against the wall with curved arms facing the door. Be sure there is enough clearance for the sensor beam to be unobstructed.

•If additional depth is needed, an extension bracket (See Accessories) or wood blocks can be used.

•Use bracket mounting holes as a template to locate and drill (2) 3/16" diameter pilot holes on the wall at each side of the door, no higher than 6" (15 cm) above the floor.

•Attach brackets to wall with lag screws (Not provided).

•If using extension brackets or wood blocks, adjust right and left assemblies to the same distance out from the mounting surface. Make sure all door hardware obstructions are cleared.

Floor installation (Figure 4):

•Use wood blocks or extension brackets

(See Accessories) to elevate sensor brackets so the lenses will be no higher than 6" (15 cm) above the floor.

•Carefully measure and place right and left assemblies at the same distance out from the wall. Be sure all door hardware obstructions are cleared.

•Fasten to the floor with concrete anchors as shown.

HARDWARE SHOWN ACTUAL SIZE

Carriage Bolt |

Wing Nut |

Staples |

1/4"-20x1/2" |

1/4"-20 |

|

Figure 1 |

DOOR TRACK MOUNT (RIGHT SIDE) |

Door

Track

Lip

Indicator

Light

Sensor |

|

Bracket |

Lens |

|

Figure 2

Inside |

||

G |

arage |

|

l |

||

|

||

|

al |

|

W |

||

WALL MOUNT (RIGHT SIDE)

Fasten Wood Block to Wall with Lag Screws (Not Provided)

Indicator

Light Sensor

Bracket

Lag Screws

(Not Provided)

Lens

Figure 3 |

|

WALL MOUNT (RIGHT SIDE) |

|

Inside |

Extension |

||

G |

arage |

||

l |

Bracket |

||

|

|||

|

al |

||

W |

(See Accessories) |

||

|

|

||

|

|

(Provided with |

|

|

|

Extension Bracket) |

|

(Provided with |

Sensor |

Bracket |

|

Extension |

|

Bracket) |

Indicator |

|

Lens Light |

Figure 4 |

FLOOR MOUNT (RIGHT SIDE) |

Inside |

Attach with |

|

Concrete Anchors |

||

arage |

(Not Provided) |

|

G |

l |

|

|

al |

|

W |

|

|

|

|

Lens |

|

|

Indicator |

|

|

Light |

|

|

Sensor |

|

|

Bracket |

21

MOUNTING AND WIRING THE SAFETY SENSORS

•Slide a 1/4"-20x1/2" carriage bolt head into the slot on each sensor. Use wing nuts to fasten sensors to brackets, with lenses pointing toward each other across the door. Be sure the lens is not obstructed by a bracket extension (Figure 5).

•Finger tighten the wing nuts.

•Run the wires from both sensors to the opener. Use insulated staples to secure wire to wall and ceiling.

•Strip 7/16" (11 mm) of insulation from each set of wires. Separate white and white/black wires sufficiently to connect to the opener quick-connect terminals. Twist like colored wires together. Insert wires into quick-connect holes: white to white and white/black to grey (Figure 6).

ALIGNING THE SAFETY SENSORS

•Plug in the opener. The indicator lights in both the sending and receiving eyes will glow steadily if wiring connections and alignment are correct.

The sending eye amber indicator light will glow regardless of alignment or obstruction. If the green indicator light in the receiving eye is off, dim, or flickering (and the invisible light beam path is not obstructed), alignment is required.

•Loosen the sending eye wing nut and readjust, aiming directly at the receiving eye. Lock in place.

•Loosen the receiving eye wing nut and adjust sensor until it receives the sender’s beam. When the green indicator light glows steadily, tighten the wing nut.

Figure 5

Wing Nut 1/4"-20

Carriage Bolt

1/4"-20x1/2"

Lens

TROUBLESHOOTING THE SAFETY SENSORS

1.If the sending eye indicator light does not glow steadily after installation, check for:

•Electric power to the opener.

•A short in the white or white/black wires. These can occur at staples, or at opener connections.

•Incorrect wiring between sensors and opener.

•A broken wire.

2.If the sending eye indicator light glows steadily but the receiving eye indicator light doesn't:

•Check alignment.

•Check for an open wire to the receiving eye.

3.If the receiving eye indicator light is dim, realign either sensor.

NOTE: When the invisible beam path is obstructed or misaligned while the door is closing, the door will reverse. If the door is already open, it will not close. The opener lights will blink 10 times. See page 20.

Connect Wire to

Quick-Connect Terminals

Figure 6

Bell Wire |

Finished |

|

Ceiling |

||

|

Bell Wire

1. Strip wire 7/16"

(11 mm)

7/16" (11 mm)

7/16" (11 mm)

2. Twist like colored wires together

3. Insert into appropriate terminals

|

|

|

Red White Grey |

|

Invisible Light Beam |

Sensor |

Quick-Connect Terminals |

|

|

||

Sensor |

Protection Area |

|

|

22

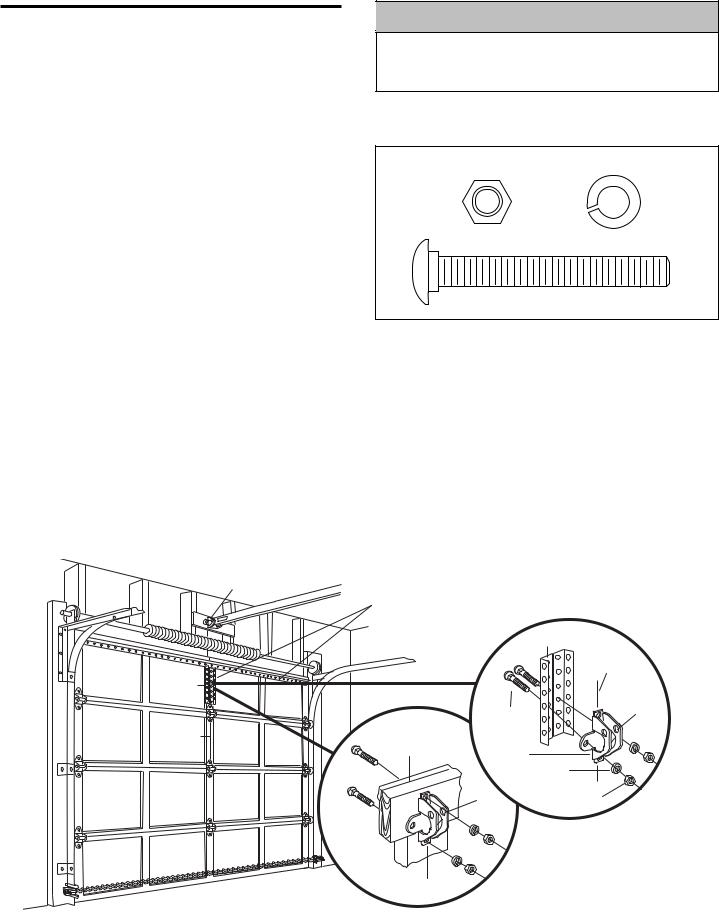

INSTALLATION STEP 11

Fasten the Door Bracket

Follow instructions which apply to your door type as illustrated below or on the following page.

A horizontal reinforcement brace should be long enough to be secured to two vertical supports. A vertical reinforcement brace should cover the height of the top panel.

The illustration shows one piece of angle iron as the horizontal brace. For the vertical brace, two pieces of angle iron are used to create a U-shaped support (Figure 1). The best solution is to check with your garage door manufacturer for an opener installation door reinforcement kit.

NOTE: Many vertical brace installations provide for direct attachment of the clevis pin and door arm. In this case you will not need the door bracket; proceed to Installation Step 12.

SECTIONAL DOORS

•Center the door bracket on the previously marked vertical centerline used for the header bracket installation. Note correct UP placement, as stamped inside the bracket (Figure 2).

•Position the bracket on the face of the door within the following limits:

A)The top edge of the bracket 2"-4" (5-10 cm) below the top edge of the door.

B)The top edge of the bracket directly below any structural support across the top of the door.

CAUTION

Fiberglass, aluminum or lightweight steel garage doors WILL REQUIRE reinforcement BEFORE installation of door bracket. Contact your door manufacturer for reinforcement kit.

HARDWARE SHOWN ACTUAL SIZE

Nut 5/16"-18 |

Lock Washer 5/16" |

Carriage Bolt 5/16"-18x2-1/2"

•Mark and drill 5/16" left and right fastening holes. Secure the bracket as shown in Figure 1 if there is vertical reinforcement.

If your installation doesn’t require vertical reinforcement but does need top and bottom fastening holes for the door bracket, fasten as shown in Figure 2.

Header Bracket

Horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass, aluminum, steel, doors with glass panel, etc.). (Not

|

|

Vertical |

|

|

Reinforcement |

|

|

Vertical |

Door |

|

Centerline |

Bracket |

|

of Garage |

Location |

|

Door |

|

|

UP |

Vertical |

Inside Edge |

Carriage Bolt |

5/16"-18x2-1/2" |

||

Centerline |

of Door or |

|

of Garage |

Reinforcement Board |

Door |

Door |

|

Bracket |

|

|

|

|

|

Lock Washer |

|

|

5/16" |

|

|

Nut |

|

|

5/16"-18 |

|

|

Figure 1 |

Door Bracket

Figure 2

23

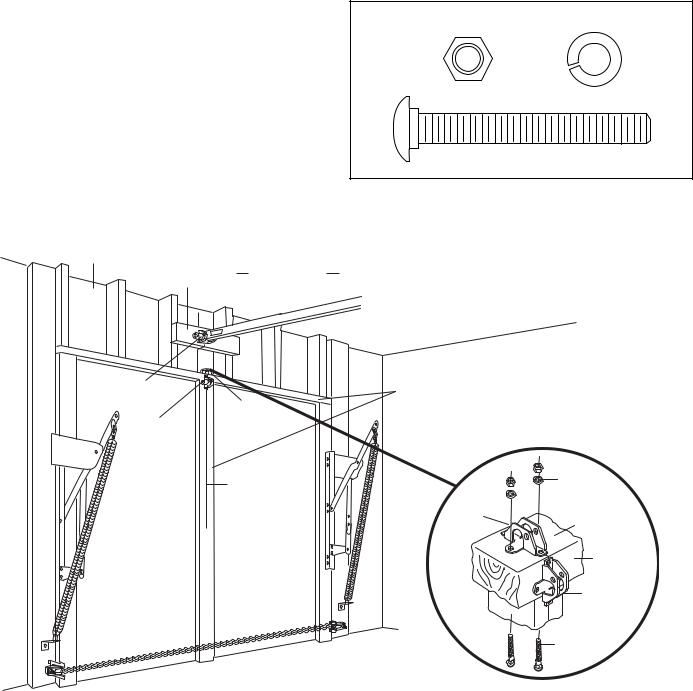

ONE-PIECE DOORS

Please read and comply with the warnings and reinforcement instructions on the previous page. They apply to one-piece doors also.

•Center the door bracket on the top of the door, in line with the header bracket as shown. Mark either the left and right, or the top and bottom holes.

•Drill 5/16" pilot holes and fasten the bracket with hardware supplied.

If the door has no exposed framing, drill 3/16" pilot holes and fasten the bracket with 5/16"x1-1/2" lag screws (not provided) to the top of the door.

NOTE: The door bracket may be installed on the top edge of the door if required for your installation. (Refer to the dotted line optional placement drawing.) Drill 3/16" pilot holes and substitute 5/16"x1-1/2" lag screws (not provided) to fasten the bracket to the door.

Header Wall

Finished Ceiling

2x4

HARDWARE SHOWN ACTUAL SIZE

Nut 5/16"-18 |

Lock Washer 5/16" |

Carriage Bolt 5/16"-18x2-1/2"

Header

Bracket

Door

Bracket

Optional

Placement

of Door

Bracket

Vertical

Centerline

of Garage

Door

Horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass, aluminum, steel, door with glass panel, etc.). (Not Provided)

Nut

5/16"-18

5/16"-18

Door

Bracket

For a door with no exposed framing, or for the optional installation, use 5/16"x1-1/2" lag screws (Not Provided) to fasten door bracket.

Lock Washer 5/16"

Top of Door

(Inside Garage)

Top Edge

of Door

Optional

Placement

Carriage Bolt 5/16"-18x2-1/2"

24

Loading...

Loading...