Conair GB, WSB User Manual

Gravimetric

Gravimetric

Blenders

GB and WSB models

with 12-component control

Installation

Maintenance

Operation

Troubleshooting

Instant Access

Parts and Service

(800) 458-1960

(814) 437-6861

www.conairnet.com

The Conair Group, Inc.

One Conair Drive

Pittsburgh, PA 15202

Phone: (412) 312-6000

Fax: (412)-312-6320

UGB007/1103

Please record your equipment’s model and serial number(s) and the date you received it in the spaces provided.

It’s a good idea to record the model and serial number(s) of your equipment and the date you received it in the User Guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment you installed.

Please keep this User Guide and all manuals, engineering prints and parts lists together for documentation of your equipment.

Date:

Manual Number: UGB007/1103

Serial number(s):

Model number(s):

Mrev: 1/17/2003

DISCLAIMER: The Conair Group, Inc., shall not be liable for errors contained in this User Guide or for incidental, consequential damages in connection with the furnishing, performance or use of this information. Conair makes no warranty of any kind with regard to this information, including, but not limited to the implied warranties of merchantability and fitness for a particular purpose.

Copyright 2003 |

THE CONAIR GROUP, INC. |

All rights reserved |

|

|

The Conair Group Inc. |

|

|

|

|

TWELVE COMPONENT SOFTWARE |

|

|

|

|

GB and WSB Model Blenders |

|

|

|

|

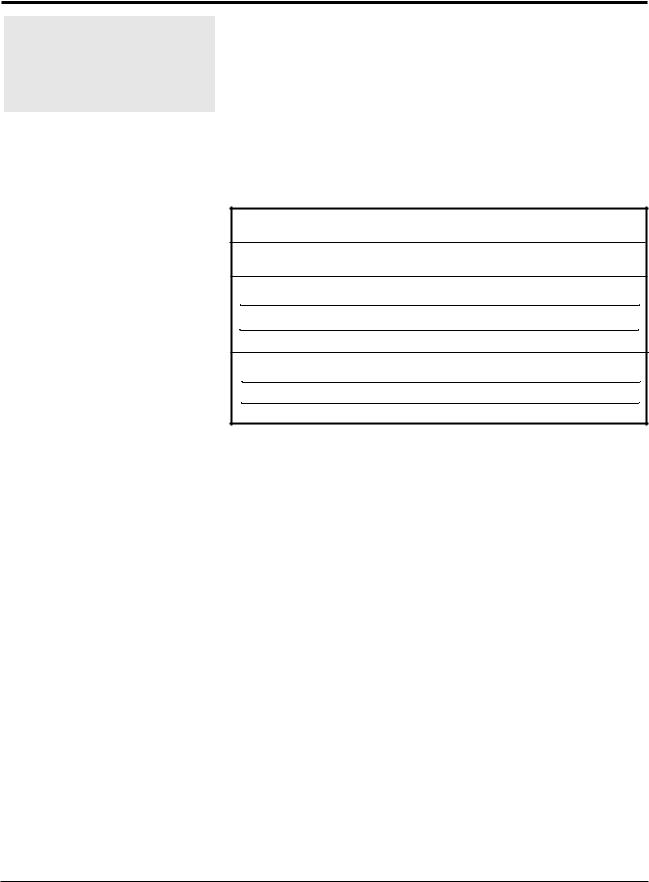

TABLE of CONTENTS |

|

|

GETTING STARTED, READ THIS PAGE ................ |

Page |

3 |

||

SAFETY HAZARDS ................................. |

Page |

4 |

||

DISCLAIMERS |

.................................... |

Page |

5 |

|

PART I |

- |

ASSEMBLY |

|

|

Assembly and Installation Instructions ......... |

Page |

6 |

||

Wiring Considerations .......................... |

Page |

10 |

||

Check Out Procedure / Diagnostics .............. |

Page |

11 |

||

Selecting |

Correct Model ........................ |

Page |

14 |

|

PART II |

- |

OPERATION |

|

|

Load Cell Calibration .......................... |

Page |

15 |

||

Turning on Outputs - Material Types ............ |

Page |

16 |

||

Setting Material Types ......................... |

Page |

18 |

||

Rate Calibration ............................... |

Page |

19 |

||

Entering Settings .............................. |

Page |

20 |

||

Special Instructions (Micro-Pulse) ............. |

Page |

21 |

||

Instructions for Normal Operation .............. |

Page |

22 |

||

Special Features ............................... |

Page |

23 |

||

Controls and Outputs ........................... |

Page |

25 |

||

Keypad - Summary description ................... |

Page |

29 |

||

|

Automatic mode ........................ |

Page |

30 |

|

|

Manual Mode ........................... |

Page |

34 |

|

|

Program Mode .......................... |

Page |

37 |

|

Parameters - Short & Long Explanations ......... |

Page |

48 |

||

|

|

Default Settings .................. |

Page |

71 |

|

|

Changing / Saving Parameters ...... |

Page |

73 |

PART III |

- |

PRINTER OUTPUTS |

|

|

Monitoring System Accuracy ..................... |

Page |

74 |

||

Special Tests .................................. |

Page |

75 |

||

Material |

Usage Information ..................... |

Page |

81 |

|

PART IV |

- |

TROUBLESHOOTING / SOFTWARE |

|

|

What To Do |

..................................... |

Page |

82 |

|

Typical Problems ............................... |

Page |

83 |

||

Normal Operating Sequence ...................... |

Page |

85 |

||

Verifying Load Cell Function ................... |

Page |

87 |

||

Clear & Clear All Routines ..................... |

Page |

90 |

||

PART V - |

|

HARDWARE MAINTENANCE |

|

|

Hardware Adjustments ........................... |

Page |

91 |

||

Mix Problems ................................... |

Page |

92 |

||

Recalibration of Load Cells .................... |

Page |

94 |

||

Preventive Maintenance ......................... |

Page |

95 |

||

Wiring diagram & Supplements ................... |

Page |

98 |

||

Exploded View Diagrams - Parts ................. |

Page |

99 |

||

Warranty |

....................................... |

|

Page 100 |

|

The Conair Group Inc.

One Conair Drive

Pittsburgh, PA 15202

412-312-6000

FAX # 412-312-6227

Page 2

GETTING STARTED, READ THIS PAGE.

THE NEXT 13 PAGES OF THIS MANUAL WILL GUIDE YOU, STEP BY STEP, TO A SUCCESSFUL STARTUP.

IT WON'T |

TAKE LONG; |

SO.... |

PLEASE, DON'T SKIP AHEAD. |

||

HERE |

ARE |

THE STEPS YOU WILL FOLLOW. |

|

||

SAFETY HAZARDS: |

TWO HAZARDS exist on this unit: MIX BLADES and |

||||

Page |

4 |

|

SLIDE |

VALVES. |

Read this short sensible page |

|

|

|

so no |

one gets |

hurt. |

ASSEMBLY INSTRUCTIONS: Very little assembly is required. But you Page 6 might as well get it right the first time.

ALSO: Pay attention to the section on WIRING.

CHECK OUT PROCEDURE: |

This |

is to see if you |

did |

it right. |

It also |

Page 11 |

will |

tell if anything |

was |

damaged in |

shipping. |

LOAD CELL CALIBRATION: We already did this. But shipping or rough Page 15 handling during assembly sometimes creates

load cell problems. If weight readings are not correct, you MUST recalibrate the load cells.

TURNING ON OUTPUTS and

SETTING MATERIAL TYPES: To "TURN ON" a component, it must be

Page 16 |

designated as to |

TYPE, |

either REGRIND, |

|||

|

NATURAL, or |

ADDITIVE. |

Each is handled |

|||

|

differently |

by the MATH routines. The |

||||

|

controller MUST know the |

material TYPE to know |

||||

|

what |

the setting |

means. |

|

This is IMPORTANT. Be |

|

|

SURE |

you UNDERSTAND this |

section before trying |

|||

|

to operate your system. |

|

|

|||

RATE CALIBRATION: |

This |

is NOT |

really necessary. But if your |

|||

Page 19 |

system uses |

non-standard |

equipment, you MAY |

|||

|

want |

to do this. |

|

|

|

|

SETTINGS and NORMAL OPERATION: |

|

|

|

|

||

Page 20 |

From |

this point forward, |

operating your system |

|||

|

is a |

snap. |

This |

section |

tells you just how |

|

|

simple it is and |

exactly |

what to expect under |

|||

|

normal operating |

conditions. |

||||

SPECIAL FEATURES: |

Your |

system |

can do much more then you may |

|||

Page 23 |

know. |

This |

page |

reviews |

briefly some of the |

|

|

added features that are available to you and |

|||||

|

where in this manual you |

can find them. |

||||

PROCEED TO: |

SAFETY HAZARDS |

NEXT PAGE |

|

Page 3 |

|

|

SAFETY HAZARDS |

|

+ |

----------------------------------------------------------- |

+ |

¦ |

MIX BLADES |

¦ |

¦ |

|

¦ |

¦ |

Mix blades are driven with substantial torque. |

¦ |

¦ |

|

¦ |

¦ |

NEVER place your hand in the mix chamber |

¦ |

¦ |

while blades are turning. |

¦ |

¦ |

|

¦ |

¦ |

SERIOUS INJURY will result. |

¦ |

+----------------------------------------------------------- |

|

+ |

+----------------------------------------------------------- |

|

+ |

¦ |

ADDITIONAL MIX BLADE HAZARD |

¦ |

¦ |

|

¦ |

¦ |

Over time, mix blades may become RAZOR SHARP. |

¦ |

¦ |

|

¦ |

¦ Always be careful when TOUCHING or CLEANING these blades. ¦

¦ |

Check for sharp edges frequently. |

¦ |

¦ |

Replace blade if a hazard exists. |

¦ |

+ |

----------------------------------------------------------- |

+ |

+----------------------------------------------------------- |

|

+ |

¦ |

SLIDE VALVES |

¦ |

¦ |

|

¦ |

¦Slide valves in hoppers SLAM CLOSED without warning. ¦

¦ |

|

They WILL injure |

your fingers. |

|

¦ |

¦ |

|

|

|

|

¦ |

¦ |

ALWAYS |

keep fingers clear |

of slide gate |

openings. |

¦ |

¦ |

NEVER |

use your fingers to clear an obstruction. |

¦ |

||

¦NEVER use your fingers to move a sticking slide gate. ¦

+ |

----------------------------------------------------------- |

+ |

|

SAFETY FEATURES |

|

+----------------------------------------------------------- |

|

+ |

¦ |

SAFETY INTERLOCK SWITCH |

¦ |

¦ |

|

¦ |

¦ |

The ACCESS DOOR is equipped with a safety interlock |

¦ |

¦ |

switch that prevents the mix motor from running and |

¦ |

¦ |

the slide valves from opening. |

¦ |

¦ |

|

¦ |

¦ |

DO NOT defeat this safety switch. |

¦ |

+----------------------------------------------------------- |

|

+ |

+----------------------------------------------------------- |

|

+ |

¦ |

HOPPER FINGER GUARDS |

¦ |

¦ |

|

¦ |

¦Finger guards are fitted into each hopper compartment. ¦

¦ |

DO NOT reach through these guards. |

¦ |

¦ |

DO NOT use your fingers to clear an |

¦ |

¦ |

obstruction below these guards. |

¦ |

¦ |

|

¦ |

¦ |

DO NOT remove these guards. |

¦ |

+ |

----------------------------------------------------------- |

+ |

+ |

--------------------------------------------- |

|

|

+ |

¦ |

PROCEED TO: |

ASSEMBLY |

NEXT PAGE |

¦ |

+--------------------------------------------- |

|

Part 4 |

|

+ |

|

|

|

|

DISCLAIMERS

PRODUCTION of FAULTY PRODUCT

Processing conditions and materials vary widely from customer to customer and from product to product. It is IMPOSSIBLE for us to anticipate ALL processing conditions and requirements, or to be certain that our equipment will perform properly in all instances. You, the customer, must observe and verify the performance level of our equipment in your plant as part of your overall manufacturing process. You must verify to your own satisfaction that this level of performance meets your requirements. We CAN NOT be responsible for losses due to product that is blended incorrectly, even when due to equipment malfunction or design incorrect for your requirements; and/or for any consequential losses due to our equipment not blending to your requirements.

We will only be responsible to correct, repair, replace, or accept return for full refund if our equipment fails to perform as designed, or we have inadvertently misrepresented our equipment for your application.

ACCURACY of THIS MANUAL

We make every effort to keep this manual as correct and current as possible. However, technology and product changes occur more rapidly then the reprinting of this manual. Generally, modifications made to the design of the blender or to the operation of the software are not reflected in the manual for 3 to 6 months. We always reserve the right to make these changes without notice, and we do not guarantee the manual to be entirely accurate. If you question any information in this manual, or find errors, please let us know so that we may make the required corrections. We will gladly provide you with updated manuals.

Part 5

+ |

-------------------------------------------------------------------- |

+ |

¦ |

PART I - ASSEMBLY |

¦ |

+-------------------------------------------------------------------- |

|

+ |

ASSEMBLY and INSTALLATION INSTRUCTIONS

CAUTION: LOAD CELLS ARE EASILY DAMAGED.

If the FRAME is dropped from TWO FEET, the load cells WILL BE DAMAGED. THE WARRANTY DOES NOT COVER DAMAGED LOAD CELLS.

The following items have been shipped to you:

1.FRAME and HOPPER assembly: (bolted to skid)

2.CONTROLLER BOX: with the instruction manual.

3.FEEDER BOX: contains a COLOR or ADDITIVE feeder: optional.

4.FLOW CONTROL ASSEMBLY: optional

5.FLOOR STAND or VACUUM TAKEOFF ASSEMBLY: optional

RED INSTRUCTION STICKERS will assist you during assembly.

LIFT HANGERS are available to allow lifting the blender with a strap or chain. Call us if you require them.

1A. If your |

unit |

is |

to be MACHINE mounted: |

|

For GB/WSB |

GBM, 100, 200, |

and 400 series models: |

||

Two |

ways |

to |

do this are |

suggested ON THE NEXT PAGE: (4a) |

The LEFT diagram shows the FRAME and SLIDE GATE both drilled with the proper bolt pattern for your machine and THROUGHBOLTED to your press.

The RIGHT diagram shows only the 10 x 10 steel slide-gate plate drilled for your bolt pattern and bolted to your press. The FRAME is then bolted to it using the existing 8 x 8 inch bolt pattern holes and bolts provided. With this method, bolt head clearance holes are required in the poly-pro slide gate plate. This mounting works well on smaller machines.

For GB/WSB 900 and 1800 series models:

An additional machine mount adaptor plate may be required. If you have ANY DOUBT about the STABILITY of the unit when bolted directly to your machine throat, please call us for advice.

NOTE: When choosing proper orientation, be sure to retain access to the controller and weigh chamber, clearance for hinged doors, and access to removable feeder hoppers.

1B. If your unit is STAND mounted:

A stand is provided and your unit will bolt directly to it. An assembly DIAGRAM is provided on the following pages.

An air operated FLOW CONTROL ASSEMBLY is provided for dispensing into a container. The purpose of this unit is to allow time for mixing to occur after each dispense. This flow valve keeps the mix chamber full to just below the sensor. This assembly bolts directly to the bottom of the Blender frame.

Page 6

2.Slide the WEIGH BIN into position. It rests behind the clear hinged access window. Install with the air cylinder toward you. If bin is already in place, remove any shipping materials, packing tape or string.

3.Hang the Color and Additive Feeders:

a.Lift side latches and fully extend slide assembly. Remove the hopper. Leave slide extended.

b.Tilting the entire slide assembly, motor end up, insert one corner of hanger cross bar behind frame corner post.

c.Rotate assembly into place so both ends of cross bar are behind corner posts.

d.Lower into place, bottom edge resting on frame and cross bar properly positioned behind corner posts.

e.Re-install hopper. Slide motor forward until latches engage.

4.Place the controller on the support tray and plug in all cords:

a.Air solenoid 8 or 14 pin plug into the matching receptacle.

b.Auger feeder drive motors into duplex receptacle.

c.Mixer motor into right side of controller.

d.Sensor cord plug into right side of controller.

e.Load Cell plug into port on left side of controller.

5.Plug the CONTROLLER into the receptacle located under the controller tray.

IMPORTANT: Do NOT plug the controller into a separate power source. The controller ground path MUST be the same as the blender frame ground path. If your system has the controller located in a remote location, MAKE CERTAIN that the power to the controller comes from the receptacle mounted on the Blender frame.

6.Plug the power cord coming from this box into a 110 volt power source (220 volt outside U.S.). This cord MUST provide the ONLY power source for the entire system, including the controller. See: WIRING CONSIDERATIONS, next page. 1800 series blenders also require a 240 volt power source for the mix motors.

7.Connect air pressure to the unit. About 80 psi (5.5 bar) is recommended (40 psi for the Micro Blender). Lubricated air is NOT recommended.

NOTE: GBM Micro Blenders should be set to 40 psi (2.7 bar). The Vertical Valves used in removable hoppers on Micro

Blenders, 100, and 200 series blenders are more accurate at the lower 40 psi pressure setting.

8. Remove all protective paper from the plastic windows.

Page 9

WIRING CONSIDERATIONS

The wiring of your blender is very important to its proper operation. Electronics are very susceptible to voltage spikes and static charges, both of which are very common in plastics factories.

To MINIMIZE these things, consider the following.

1.The power supply should be solid; a strong supply, not limited by a "just adequate" control transformer. A source of voltage that comes from a large transformer that supplies a large portion of the plant is better then a small power supply transformer that is intended to supply only this device. Power supplies, even though they may be "isolation" transformers, will still pass all voltage spikes right through. Their small size limits their ability to dampen RF (Radio Frequency) noise that is often induced into the system from outside sources. This proves worse then connection to larger central transformers.

2.Avoid running the power supply line along side any heavy power lines. An unshielded power supply in a raceway along side other heavy power lines will pick up induced RF noise and transfer it into the GB/WSB steel enclosure causing computer trouble.

3.Long extension cords should be avoided. They also reduce the ability to provide a dampening effect on spikes and static. The further the equipment is from a substantial power source, the more susceptible it is to spikes.

4.The CONTROLLER and the GB/WSB frame MUST share the same GROUND PATH. This is why you MUST plug the controller into the OUTLET that is provided ON THE FRAME.

5.REMOTE SYSTEMS. If you have your controller mounted in a remote location, you will have a number of power and signal cords running between the frame and the controller. BE SURE that the LOW VOLTAGE lines are NOT BUNDLED to the HIGH VOLTAGE lines and keep them away from other nearby electrical lines.

LOW VOLTAGE lines are: Load Cell cable, Level Sensor cord, Air Solenoid cable, and Printer and Computer cables.

HIGH VOLTAGE lines are: Mixer motor cable, Feeder motors, and MAIN POWER line.

Keep these sets of cables SEPARATED.

6.VACUUM LOADER CONVEYING LINES. Keep them away from all electrical lines, particularly the Load Cell lines. Conveying plastic produces extreme static sources. A power supply line, even in conduit, that runs next to a vacuum line, can introduce extreme static pulses into the processor. Keep conveying lines SEPARATED from electrical supply lines.

7.We use many internal tooth "STAR" washers in assembling the GB/WSB to ensure good ground between painted parts. Do not remove them.

+---------------------------------------------------- |

|

|

+ |

¦ PROCEED TO: |

CHECK OUT |

PROCEDURE |

NEXT PAGE ¦ |

+---------------------------------------------------- |

|

|

+ |

|

Page |

10 |

|

CHECK OUT PROCEDURE

As you go through this procedure, if WHAT SHOULD HAPPEN, doesn't happen, see next section, DIAGNOSTICS, for what to check.

NOTE: 100/200 series models (3K load cells), display all weights in 1/10 grams ( x.x). 400/900/1800 series models (10K load cells) display weights in FULL grams, NO decimal point. On this page we show all weights with NO decimal point.

Start with NO MATERIAL in any hoppers. Be sure an AIR SUPPLY is connected.

Place ALL switches DOWN; POWER (on front); STOP and PAUSE (on left).

PROCEDURE: |

WHAT SHOULD HAPPEN: |

. |

||

PLUG IN CONTROLLER. |

Nothing should happen. |

|||

|

Air pressure should be holding ALL valves CLOSED. |

|||

|

This means all air cylinders are extended. If any |

|||

|

slide gate or flap is open, air lines are |

|||

|

reversed. If a FLOW CONTROL valve is installed, |

|||

|

check it. |

|

|

|

TURN POWER ON. |

Display should say ( TWELVE ), |

|||

|

followed by version date (V=xxxxxT), |

|||

|

followed by the check sum number (CKS=xxxx), |

|||

|

followed by (ROM OK |

), |

||

|

followed by (RAM = 8K), |

|||

|

followed by model number (MODEL220) or the model |

|||

|

you have (GBM, 140, 14R, 220, 240, 24R, 420, 440, |

|||

|

44R, |

940, |

184), |

|

|

followed by ( |

0), then the actual weight of |

||

|

material in the bin. This number should be zero, |

|||

|

plus or minus several grams ( 20) to (-20). |

|||

AT THIS POINT: |

Be sure the model number that was displayed |

|||

|

matches your blender model number (first digit |

|||

|

only). If this is not the case see two sections |

|||

|

ahead, SELECTING CORRECT MODEL. |

|||

TOUCH WEIGH BIN VERY |

LIGHTLY. |

|

|

|

|

Display should update the weight every second |

|||

|

reflecting the light pressure that you are |

|||

|

exerting on the bin. |

|

||

PRESS "*" KEY |

Display will say (PASSWORD) |

|||

PRESS "22222" (2 key |

five times) (entering the PROGRAM mode). |

|||

|

2's will be displayed as you enter them. |

|||

|

Display will show (P |

x) when done. |

||

PRESS "OPER" KEY |

Display will say (OPERATE ) |

|||

PRESS "1" KEY |

Device number 1 will operate. |

|||

|

LED # 1 will light. |

|

||

|

Press "1" repeatedly to observe operation. |

|||

PRESS "2" KEY |

Device number 2 will operate. |

|||

|

|

|

Page 11 |

|

LED # 2 will light.

Press "2" repeatedly to observe operation.

REPEAT THIS SEQUENCE for each dispense valve on your WEIGH SCALE BLENDER. Up to 12 outputs are possible numbered 1 through 9, A, B, and C. Only those connected to devices will operate.

AT THIS POINT: |

NOTE which component NUMBER is assigned to each |

|

|

hopper. You will |

want to know each hopper's |

|

correct component |

number. |

FACING THE CONTROLLER SIDE OF THE BLENDER: |

||

On 9000 and 18000 |

gram, FOUR hopper compartment systems: |

|

Device 1 is the |

NEAR hopper, 2 the |

FAR hopper, 3 the LEFT CENTER, |

and 4 the RIGHT |

CENTER hopper. |

|

On 1000, 2000, and 4000 gram, FOUR hopper systems, devices 1, 2, 3, and 4 are counter-clockwise starting with far left corner hopper.

On 9000 and 18000 gram SIX hopper systems, devices 1, 2, 3, 4, 7, and 8 are counter-clockwise starting with far left corner hopper.

ALL MODELS: |

|

|

|

|

|

|

|

Device 5 is the LEFT |

Panel-front OUTLET. |

|

|

||||

Device 6 is the RIGHT Panel-front OUTLET. |

|

|

|||||

PRESS "DUMP" KEY |

The |

weigh bin |

air solenoid will operate. |

|

|||

|

|

LED |

# 13 |

will |

light. |

|

|

|

|

The |

weigh bin |

dump valve will open. |

|

||

|

|

Press "DUMP" repeatedly to observe operation. |

|||||

PRESS "MIX" KEY |

This key |

controls the mix motor outlet on the |

|||||

|

|

side of the controller. The mixer motor will run. |

|||||

|

|

LED |

# 14 |

will |

light. |

|

|

|

|

(Mix blade turns CCW facing the motor shaft.) |

|||||

|

|

(Mixer switch |

must be down; timed position.) |

|

|||

PRESS "HOLD" KEY |

The |

Flow |

Control Valve will operate. |

|

|||

|

|

(Under the mix chamber) (This device is optional) |

|||||

|

|

LED |

# 15 |

will |

light. |

|

|

PRESS "ALARM" KEY |

The |

Strobe light and Beeper will operate. |

|

||||

|

|

LED |

# 16 |

will |

light. |

|

|

PRESS "EXIT" KEY |

Press twice, to return to normal mode. |

|

|||||

|

|

Verify normal |

mode by observing |

that there is NO |

|||

|

|

letter P |

in the display ( |

x). |

|

||

+-----------------------------------------------------------+ |

|||||||

¦ |

If you have made it this far, congratulations. |

¦ |

|||||

¦ |

|

|

You |

have |

done well. |

|

¦ |

¦The load cells and controller are functioning properly. ¦

+----------------------------------------------------------- |

|

+ |

+---------------------------------------------------------- |

|

+ |

¦ PROCEED TO: |

LOAD CELL CALIBRATION |

SKIP 2 PAGES ¦ |

+---------------------------------------------------------- |

|

+ |

|

Page 12 |

|

DIAGNOSTICS - for the CHECK OUT PROCEDURE

If display fails to come on at all: check for power at outlet.

Check the 1/2 amp panel front fuse.

If first display says ( FOUR ), then this is NOT the correct manual for this software. Obtain and use a FOUR software manual.

Possible model numbers are:

GBM, 140, 14R, 220, 240, 24R, 420, 440, 44R, 940, 184. If model number is not correct for you unit:

see the next page, SELECTING CORRECT MODEL.

If display shows randomly drifting numbers:

check to see load cells are plugged in.

If display shows about (- 1250.0) or ( -4500):

check that the weigh bin is in place properly.

If display is steady but not near zero:

An over stressed load cell will display a permanently high or low reading. Recalibrate load cells; next section.

If there is no response from the display when the bin is touched: check for damaged wires to load cells.

check that load cell plug screws are secure.

If response is not sensitive or does not return to its start point: check for interference around weigh bin.

If pressing * does not display (PASSWORD):

you are not in the normal power-up mode or the keypad doesn't work. Normal mode is indicated by the ABSENCE of the letter M or P at the left of the display.

If display says INVALID after entering the password number:

you pressed the wrong keys or the password number has been changed and it is no longer 22222. Call us for help.

If an air solenoid does not operate: check the 1/2 amp fuse.

check solenoid cable connected properly and fully seated. check mix chamber door closed, safety interlock engaged.

If a slide or dump valve does not open:

check the air supply and regulator adjustment: (minimum 20 psi, 80 psi (5.5 bar) recommended).

check for proper air line connection to cylinder.

If an auger feeder motor does not run: check the 3 amp fuse.

check that the motor is plugged into the proper outlet. check for faulty motor by plugging it into a known source of 110 volt A.C. power (240 volt outside U.S.).

Page 13

SELECTING CORRECT MODEL

Controllers are programmed to control all sizes of Autoweigh Blenders. The MODEL number that your unit is set for will be displayed during the start up sequence every time power is turned on.

The possible models are:

MODEL |

BATCH WT |

valves |

WEIGH BIN |

|

|

|

LOAD CELL |

||||||

|

(GRAMS) |

|

DIMENSIONS |

|

|

|

RATING |

|

|||||

GBM |

400 |

4 |

|

5 x |

5 x |

|

5 high |

|

1 @ 3 K |

||||

140/14R |

1000 |

4 |

10 |

x 6 |

x |

6 |

|

high |

1 |

@ 3 |

K |

||

220 |

2000 |

2 |

10 |

x 10 |

x |

7 |

|

high |

2 |

@ 3 |

K |

||

240/24R |

2000 |

4 |

10 |

x 10 |

x |

7 |

|

high |

2 |

@ 3 |

K |

||

420 |

4000 |

2 |

10 |

x 10 |

x 10 |

high |

2 |

@ 10 K |

|||||

440/44R |

4000 |

4 |

10 |

x 10 |

|

x 10 |

high |

2 |

@ 10 |

K |

|||

940 |

9000 |

4 |

16 |

x 16 |

|

x 12 |

high |

2 |

@ 10 |

K |

|||

184 |

18000 |

4 |

16 |

x 16 |

|

x 17 |

|

high |

2 |

@ 20 |

K |

||

("R" models have 2 removable hoppers)

The addition of feeders will change the last digit of the model number. This digit can be ignored for selecting the correct Model.

400, 1000 and 2000 gram systems with 3 kg. load cells; weights are displayed in tenths of grams ( xxxx.x).

4000, 9000, and 18000 gram systems with 10 or 20 kg. load cells; weights are displayed in full grams ( xxxxx).

If your unit is NOT set correctly to match the hardware you have, you must change it. To do so:

Turn power on. From the NORMAL mode:

+------------------------------------------------------- |

|

|

|

+ |

¦ Press: |

* |

Display will say: |

(PASSWORD) |

¦ |

¦ |

|

|

|

¦ |

¦ Press: |

97531 |

Display will say: |

(MODEL220) |

¦ |

¦ |

|

or whatever model it is |

¦ |

|

¦ |

|

currently set for. |

|

¦ |

¦ |

|

|

|

¦ |

¦ Press: |

* |

To walk through all model sizes. |

¦ |

|

¦ |

|

When the model you want is displayed,¦ |

||

¦ |

|

then: |

|

¦ |

¦ |

|

|

|

¦ |

¦ Press: |

EXIT |

Wait a few seconds. |

|

¦ |

¦ |

|

Unit will reset and restart |

¦ |

|

¦ |

|

as the system you have selected. |

¦ |

|

+------------------------------------------------------- |

|

|

|

+ |

When switching models, all parameter table information is lost and the new "default" information for this model is loaded from ROM.

Page 14

+ |

-------------------------------------------------------------------- |

+ |

¦ |

PART II - OPERATION |

¦ |

+-------------------------------------------------------------------- |

|

+ |

LOAD CELL CALIBRATION

NOTE: Displays shown here are in full grams. 100 and 200 series models are in 1/10 grams, with a decimal.

If your load cells already display a weight close to zero, plus or minus 10 grams, you may skip this section and go directly to:

TURNING ON OUTPUTS (next page).

If your unit DOES NOT display an acceptable weight, you should recalibrate them, that is reset your ZERO weight, at this time.

To do so: |

|

|

|

|

BE SURE the weigh bin |

is EMPTY. |

|

|

|

BE SURE the load |

cell |

plug is plugged into the side of the controller. |

||

BE SURE the weigh bin |

is resting |

on the load cells freely. |

|

|

BE SURE the air line to the dump |

valve is connected as it |

would be |

||

during normal |

operation. |

A disconnected air line |

adds weight. |

|

BE SURE The load |

cells and bin are not jammed in any way. To test for |

|||

this see |

that |

a light touch on the bin causes the |

display to |

|

change. |

When |

the pressure is removed the display |

must return |

|

to exactly where it was, |

plus or minus 1 gram. |

|

||

If this does not happen, something is touching something and the bin is not entirely free to move. Check EVERYTHING around the bin.

LOAD CELL CALIBRATION:

The sequence of keystrokes is as follows:

Press: |

* |

Display will say: |

(PASSWORD) |

|

Press: |

22222 |

Display will say: |

(P |

x) |

Press: |

*99 |

Display will say: |

(CAL |

OFF) |

Press: |

* |

Display will say: |

(CAL |

ON ) |

Press: |

EXIT |

Display will say: |

(P |

x) |

Press: |

ZERO |

Display will say: |

(--WAIT--) |

|

|

|

followed by: |

(P |

0) |

Press: |

EXIT |

Display will say: |

( |

x) |

The ZERO point of the load cells is now set properly. FULL weight calibration may also be done at this time, however, it probably is NOT NECESSARY. When load cell readings shift due to rough handling, the entire range of readings from ZERO to FULL shift together. The ZERO weight calibration routine resets the full range of the cells and, therefore, corrects FULL weight readings as well. For information on FULL weight calibration, see RECALIBRATION OF LOAD CELLS.

+--------------------------------------------------- |

|

+ |

¦ PROCEED TO: |

TURNING ON OUTPUTS |

¦ |

¦ |

and MATERIAL TYPES |

NEXT PAGE ¦ |

+--------------------------------------------------- |

|

+ |

Page 15

TURNING ON OUTPUTS - MATERIAL TYPES

This controller can control up to TWELVE (12) components; 1 through 9 and A, B, and C.

You must "TURN ON" the COMPONENT outputs that you are going to use.

Components that are TURNED OFF are not part of ANY routines.

A component becomes TURNED ON when it is set to a MATERIAL TYPE.

Material TYPES are REGRIND, NATURAL, and ADDITIVE.

The AUTOWEIGH BLENDER handles each TYPE DIFFERENTLY. Settings have different meanings for each TYPE.

To enter SETTINGS correctly, you MUST UNDERSTAND how different materials are handled based on their TYPE.

So PLEASE read this page CAREFULLY.

Material TYPES are |

explained here. |

|

How to set them is |

explained on the next page. |

|

REGRIND |

(PERCENT OF MIX) |

|

Components designated REGRIND will be added as a PERCENT of the ENTIRE MIX of material. For example, If component 1 is designated as REGRIND and is set for 20.0 percent, then for every 100 pounds of blend, 20 pounds will be this component.

NATURAL |

(RATIO TO EACH OTHER) |

Components designated NATURAL will be added in the proportion that you specify them to each other. Their actual percentage of the mix will depend on how much Regrind is specified and how much Additive is specified. For example, if components 2 and 3 are both designated NATURAL and are set for 10 and 40 respectively, then the RATIO of component 2 to component 3 will always be 10 to 40 or 1 to 4.

If no Regrind or Additives are specified, the mix will be: component 2, NATURAL, SET= 10, 20.0 percent of mix, component 3, NATURAL, SET= 40, 80.0 percent of mix.

The RATIO of 1 to 4 is maintained.

If component 1 is specified as REGRIND at 20 percent, The mix is then component 1, REGRIND, SET=20.0, 20 percent of mix, component 2, NATURAL, SET= 10, 16.0 percent of mix, component 3, NATURAL, SET= 40, 64.0 percent of mix.

Components 2 and 3 are still held at a 1 to 4 ratio.

Page 16

ADDITIVE |

(PERCENT OF ALL NATURALS) |

|

|

|

|||

Components designated |

ADDITIVE will be added as |

a percentage of all the |

|||||

NATURALS added together. For example: |

If |

component 5 is an ADDITIVE |

|||||

at 5 percent, Then |

the above example now looks like this: |

||||||

|

component |

1, |

REGRIND, |

SET=20.0, |

20 |

percent, |

|

|

component |

2, |

NATURAL, |

SET= |

10, |

15.2 |

percent, |

|

component |

3, |

NATURAL, |

SET= |

40, |

61.0 |

percent, |

|

component |

4, |

ADDITIVE, |

SET=05.0, |

3.8 |

percent. |

|

The REGRIND is still 20 percent of the MIX.

The NATURALS are still at a RATIO of 1 to 4, although they have been reduced to make room for the Additive.

The ADDITIVE is 5 percent of the NATURALS added together (5% of 76.2).

WHY do we do it this way? Because this is how most plastic processors think of these components. REGRIND is generally only added when available, and then as a limited percentage of the entire mix. NATURALS are generally blended at a RATIO to one another. ADDITIVES are most often only intended to be added to the entire NATURAL portion

of the mix, because regrind generally already contains these additives.

ON THE OTHER HAND:

If you prefer to think of your mix as a RATIO OF WEIGHTS, for example, components 1, 2, 3, 4, and 5 are to be mixed at 100, 50, 5, 20 and 7 pounds respectively, then you may wish to specify ALL components as NATURALS. In this way these weights may be entered just as listed here. Components will be dispensed to maintain each at the proper specified RATIO to the other components.

If you wish to think of all components as PERCENTAGES of THE MIX, percents that always add up to 100, specify ALL components as REGRIND and enter the exact percent for each. When ALL components are REGRINDS, ALL settings must add up to 99 or 100 percent. If they do not, an error message (REG >100) or (REG <100) will appear.

BUT... WE RECOMMEND that you do it this way:

REGRIND. Use this for all materials that DO NOT require the addition of the ADDITIVES. For example, your Regrind scrap.

NATURAL. Use this for all materials that are the bulk of the mix. These will be RATIOED to each other and will automatically constitute the ENTIRE mix except for the space needed for Regrind and Additives. A blend of ABS Homo-polymer and Co-polymer or a blend of Styrene Hi Impact and Crystal are examples of NATURALS ratioed together.

ADDITIVES. Use this for all materials that are added to the NATURALS only. For example; color, stabilizer, slip agent, etc.

+ |

----------------------------------------------------- |

|

|

+ |

¦ |

PROCEED TO: |

SET MATERIAL TYPES |

NEXT PAGE |

¦ |

+----------------------------------------------------- |

|

|

|

+ |

Page 17

|

|

SET MATERIAL TYPES |

||||

The Keystroke sequence to set |

TYPES |

is: |

|

|

||

Press: * |

Display will |

say: |

(PASSWORD) |

|||

Press: 22222 |

Display will |

say: |

(P |

|

x) |

|

Press: * |

Display will |

say: |

(INSTR --) |

|||

Press: 14 |

Display will |

say: |

(1TY= OFF) |

|||

|

The "1" |

is |

the component |

(device) number. |

||

|

This is |

component 1. |

It |

will control Hopper 1. |

||

Press: CE repeatedly to select one of the four options. Display will say: (1TY= REG). (Regrind)

(1TY= NAT). (Natural)

(1TY= ADD). (Additive) (1TY= OFF). (turned off)

When the selection you want is displayed, move on to NEXT component:

Press: * Display will say: (2TY= OFF)

REPEAT the "* CE" sequence for ALL components you use.

The * key will walk you through all components.

The CE key will change the TYPE for a component.

Components NOT CONNECTED, or NEVER USED, set to OFF.

When done: |

|

|

|

|

|

|

Press: |

EXIT |

Display |

will |

say: |

(P |

x) |

Press: |

EXIT |

Display |

will |

say: |

( |

x) |

After EXIT, if display says (NEED NAT) then you have specified an ADDITIVE without specifying a NATURAL. This is unacceptable.

NOTE: FOUR dispense valve systems use components 1 through 4. TWO dispense valve systems use 1 and 2.

SIX dispense valve systems use 1 through 4, then 7 and 8. Panel front OUTLETS are always components 5 and 6. Additional outlets are generally components 7 and 8.

+ |

----------------------------------------------------- |

|

|

+ |

¦ |

|

|

|

¦ |

¦ |

PROCEED TO: |

RATE CALIBRATION |

NEXT PAGE |

¦ |

¦ |

|

|

|

¦ |

+----------------------------------------------------- |

|

|

|

+ |

Page 18

RATE CALIBRATION

YOU DON'T HAVE TO DO THIS.

Software is set to expect STANDARD hardware. If a device meters at a much lower feed rate then expected, the software will take 10 to 20 cycles to fully adjust. During this time cycles will take longer.

An example of this is a system using a 1/2" auger instead of 1".

If you don't mind letting the system SELF ADJUST, or |

|

||

your hardware is STANDARD, |

|

|

|

then: |

|

|

|

+--------------------------------------------------- |

|

|

+ |

¦ |

|

|

¦ |

¦ PROCEED TO: |

ENTERING SETTINGS |

NEXT PAGE |

¦ |

¦ |

|

|

¦ |

+--------------------------------------------------- |

|

|

+ |

To perform a RATE CALIBRATION:

Have the HOPPER LOADED with enough material to run for several cycles without running out.

Have the "OFF AT END OF CYCLE" and "PAUSE" switches DOWN.

Press: |

* |

Display |

will |

say: |

(PASSWORD) |

|

Press: |

22222 |

Display |

will |

say: |

(P |

x) |

If you are calibrating an auger feeder, operate it briefly to ensure it is fully primed. To do so:

Press: |

OPER |

Display will say: |

(OPERATE ) |

||

Press: |

5 (or 6) Run until |

auger |

is dispensing. |

||

Press: |

DUMP |

This will |

empty |

the |

weigh bin. |

Now you can CALIBRATE the material.

To do so:

Press: |

CAL |

Display will |

say: |

(CALIBRATE) |

Press: |

5 |

Component #5 |

will calibrate itself. |

|

|

(or whatever component |

you are calibrating) |

||

Repeat this two key calibration routine for EACH material that you wish to calibrate. Only components that have a TYPE selected (not "OFF") will operate.

Each time a dispense will occur, followed by weighing, followed by a dump to empty the weigh bin.

Press: |

EXIT |

when |

all calibrations are |

done. |

|

YOU ARE NOW |

READY FOR ACCURATE PRODUCTION BLENDING. |

||||

|

+--------------------------------------------------- |

|

|

|

+ |

|

¦ |

PROCEED TO: |

ENTERING SETTINGS |

NEXT PAGE ¦ |

|

|

+--------------------------------------------------- |

|

|

|

+ |

Page 19

|

|

ENTERING |

SETTINGS |

|

||

Press: |

SET |

Display will say |

(1 R |

xx.x) |

(Regrind) |

|

|

|

or |

(1 |

N |

xxx) |

(Natural) |

|

|

or |

(1 |

A |

xx.x) |

(Additive) |

1 is Component number. R,N,A is Type.

xx.x is Setting.

Enter a 3 digit setting: |

|

|

|

||

|

|

Regrind settings |

= PERCENTAGE of the |

ENTIRE MIX |

|

|

|

Natural settings |

= RATIO to |

OTHER NATURAL SETTINGS |

|

|

|

Additive settings = PERCENTAGE of ALL |

the NATURALS |

||

Press: |

SET |

for the NEXT setting. |

|

|

|

|

|

Repeat this sequence for all |

components. |

||

Press: |

EXIT |

when finished. |

|

|

|

When entering settings, remember: |

|

|

|

||

Panel front OUTLETS are always components 5 and |

6; (left |

and right). |

|||

If only one natural is present, any number will |

do for a |

setting. |

|||

Any component set to zero will not dispense. |

|

|

|||

THUMBWHEEL ASSIGNMENTS - THIS IS OPTIONAL

You may assign a component to one of the three thumbwheel switches. You might do this for components that you wish to change settings frequently. This is ENTIRELY OPTIONAL.

TO DO SO: |

|

|

|

|

|

Press: |

SET |

Display |

will say (1 R xx.x) |

|

|

Press: |

A |

Display |

will say (1 R TW 1) |

(Thumbwheel 1) |

|

or |

B |

Display |

will say (1 R TW 2) |

(Thumbwheel 2) |

|

or |

C |

Display |

will say (1 R TW 3) |

(Thumbwheel 3) |

|

|

|

1 |

= TOP |

switches, |

|

|

|

2 |

= MIDDLE switches, |

|

|

|

|

3 |

= BOTTOM switches. |

|

|

To RETURN component to KEYPAD entry of the setting:

Press: |

CE |

Display will return to (1 R 00.0) |

Press: |

EXIT |

when finished. |

Page 20

SELECTED MODELS - SPECIAL INSTRUCTIONS

This section relates SPECIAL information about a few selected models.

|

MICRO PULSE |

Micro Pulse valves are |

available on models: |

GB/WSB GBM |

(MICRO Blender) with micro pulse valves. |

GB/WSB 122 |

with optional MICRO PULSE valves. |

GB/WSB 131 |

with optional MICRO PULSE valves. |

GB/WSB 140 |

with optional MICRO PULSE valves. |

GB/WSB 240R |

with optional MICRO PULSE valves. |

GB/WSB 440R |

with optional MICRO PULSE valves. |

These models may use our "MICRO PULSE" metering system for Color and Additive components.

PULSED OUTPUT parameters control the on/off timing, or pulsing, of the valves. The controlling parameters are the "_PO" component parameters.

When set to 00000, normal slide gate operation occurs.

When set to a value, such as 03030, power will pulse ON then OFF, at 30 interrupt time intervals each way. This ON/OFF cycling will repeat for the entire dispense time.

When using a MICRO PULSE valve, you must set the related _PO parameter to 03030.

If overall blender throughput is too low, you may increase the metering rate of each Micro Pulse device by adjusting the cylinder air flow control valves for higher flow rate. This causes more rapid movement of the cylinder, ejecting more pellets per pulse. The drawback is noisy operation.

We recommend air flow be adjusted for quiet operation, but assuring full valve movement per on/off cycle. We have already done this. No further adjustment should be necessary.

The approximate correct air flow adjustments are:

At nose of cylinder, 1.5 full turns out from full closed. At rear of cylinder, 2.5 full turns out from full closed. MICRO BLENDER slant valves, adjust by sound.

On fixed hoppers with horizontal micro pulse valves, CLEAN OUT of the hopper can be accomplished by opening the "clean out" port provided under the valve. Turn to one side to allow material to drain.

MICRO PULSE - ACCURACY

All MICRO PULSE valves are more accurate if the associated PT parameter is set to 00090. Read PT parameter in the PARAMETER section.

+--------------------------------------------------- |

|

+ |

¦ |

|

¦ |

¦ PROCEED TO: |

NORMAL OPERATION |

NEXT PAGE ¦ |

¦ |

|

¦ |

+--------------------------------------------------- |

|

+ |

|

Page 21 |

|

INSTRUCTIONS FOR NORMAL OPERATION

OPERATION: ....very simple.

1.Fill HOPPERS.

2.Turn POWER ON. Verify correct settings.

3.On Controller, set STOP and PAUSE switches UP.

Turn MIXER motor switch DOWN to run for a timed period.

Unit will now operate automatically to maintain a level of material high enough to cover the sensor.

Use the STOP or PAUSE switches to stop the blender. Turn POWER off only on final shutdown.

----------------------------------------------------------------------

AFTER SEVERAL DAYS OF PROPER OPERATION:

Save all parameter information to the EEPROM for future retrieval just in case software problems develop later.

To SAVE all parameter information to the EEPROM:

+--------------------------------------------------- |

|

|

|

+ |

¦ Press: |

* |

Display will say: |

(PASSWORD) ¦ |

|

¦ Press: |

22222 |

Display will say: |

(P |

x) ¦ |

¦ Press: |

* |

Display will say: |

(INSTR --) ¦ |

|

¦ Press: |

23 |

Display will say: |

(SAVING |

) ¦ |

¦ Wait: |

when done, |

Display will say: |

(P |

x) ¦ |

¦ Press: |

EXIT |

Display will say: |

( |

x) ¦ |

+--------------------------------------------------- |

|

|

|

+ |

If software related problems develop later, RETRIEVE this correct copy of the parameters from the EEPROM. This clears corrupted data from RAM and corrects most software problems.

To Retrieve:

+---------------------------------------- |

|

|

+ |

¦ Switch: |

POWER OFF. |

¦ |

|

¦ Hold: |

|

the "CE" key down. |

¦ |

¦ Switch: |

POWER ON. |

¦ |

|

¦ Release: |

the "CE" key. |

¦ |

|

¦ |

|

Display will say ( CLEAR |

) ¦ |

¦ |

If you do not see ( CLEAR ) |

¦ |

|

¦ |

on the display, do it again. |

¦ |

|

+---------------------------------------- |

|

|

+ |

Page 22

NORMAL OPERATING SEQUENCE - EACH CYCLE

As the sensor is uncovered, the cycle begins. The target weight of a complete batch is 18000, 9000, 4000, 2000, 1000, or 400 grams.

REGRINDS are dispensed first, in their order of size, largest dispense first. After all the Regrind dispenses, the space remaining in the weigh bin is determined.

NATURALS are dispensed second, in their order of size, each at the correct ratio to the others. These dispenses are calculated to fill the bin leaving just enough space for the Additive dispenses. After all Natural dispense are complete the exact weight of all of the NATURALS is determined and, based on this actual dispense weight, the Additive dispenses are now calculated.

ADDITIVES are dispensed last. These dispenses are calculated as a percentage of all the NATURAL components only.

If any dispense fails to reach the requested weight, the process does NOT CONTINUE. The ALARM Strobe light flashes, the Beeper sounds, and the system continues to retry the dispense until the problem is remedied.

The total batch is then dropped into the mixing chamber for blending before entering the throat of the process machine.

SPECIAL FEATURES

To use one of these SPECIAL FEATURES, read about it first. The KEYSTROKE sequence required is given at the end of this section.

To TAG all material usage data with Work Order or Employee numbers for better tracking of material used, read:

KEYPAD, TAG key, and set 2nd digit in the FLG parameter to 1.

To store RECIPES using the RECIPE storage feature, read:

KEYPAD, RECIPE key, and set 3rd digit in the FLG parameter to 1.

To increase throughput, using the FAST key, read:

KEYPAD, FAST key, and set 4th digit in the FLG parameter to 1.

To blend a preset BATCH amount of material and then stop, read: KEYPAD, BATCH key, and set 5th digit in the FLG parameter to 1.

BATCH, RECIPE, FAST, and TAG keys REQUIRE that you read: PARAMETERS, FLG parameter.

To use a lower percentage then 00.1 percent, read:

PARAMETERS, _XT parameter.

To change the MIXER RUN TIME, read:

PARAMETERS, MIX Parameter.

To place UPPER LIMITS on settings, read:

PARAMETERS, _SE Parameter.

Page 23

To LOCK OUT others from changing the settings, read: PARAMETERS, (*78) - Changing the Password.

To VERIFY ACCURACY of the entire system, read:

PRINTER OUTPUT and TROUBLESHOOTING sections.

To TRACK MATERIAL usage, read:

KEYPAD, VIEW DATA, and PARAMETERS, PRT Parameter.

To configure TWELVE software to look and act like FOUR software, See: KEYPAD, STAR FUNCTIONS (*04) - Configuration to FOUR software.

READ the rest of the manual at your leisure to learn more about how your AUTOWEIGH BLENDER works and what else it can do.

KEYSTROKE SEQUENCE for these or other SPECIAL FEATURES

With STOP END OF CYCLE |

switch DOWN, |

|

|

|

||

Turn |

POWER ON. |

|

Wait 5 seconds, until display says ( |

x) |

||

Press: |

* |

|

Display will say: |

(PASSWORD) |

|

|

Press: |

22222 |

|

Display will say: |

(P |

x) |

|

|

|

|

This is the PROGRAM MODE |

|

|

|

To alter a PARAMETER; |

|

press: PARA key |

|

|

|

|

Press repeatedly until the parameter you want is displayed. |

|

|||||

If you accidentally pass it, use the * key to back up. |

|

|||||

With the proper parameter displayed, enter the NEW number. |

|

|||||

Enter 5 digits; use leading zeros if necessary. |

|

|||||

For correct entries, follow specific directions given in the |

|

|||||

PARAMETER section. |

|

|

|

|||

Press: |

EXIT |

|

when correct parameter has been entered. |

|

||

To make a (*XX) entry: |

|

|

|

|

||

Be in the PROGRAM |

mode, the same as above. |

|

|

|||

|

|

Display will say (P |

x) |

|

|

|

Press: |

* |

Display will say (INSTR --) |

|

|

||

Enter the 2 digit |

code. |

|

|

|

||

For correct entries, follow specific directions given in the |

|

|||||

KEYPAD section, STAR FUNCTIONS. |

|

|

|

|||

Press: |

EXIT |

when correct information has been entered. |

|

|||

When finished, press EXIT again to exit the PROGRAM MODE.

Page 24

CONTROLS and OUTPUTS

1.POWER ON switch.

Controls all power to the controller and all outputs. When power is switched off, battery backed-up RAM preserves all internal totals and parameters. All other functions are reset for normal start-up when power is restored.

2.STOP END OF CYCLE / CONTINUE switch

This is the switch that you should use to STOP the system. This switch is wired in series with the level sensor. Turning it off breaks the signal to the computer the same as covering the level sensor with material. This stops the process at the end of a full cycle.

3.IMMEDIATE PAUSE / CONTINUE switch

Causes a computer-controlled immediate pause during a cycle. Dispenses will stop in mid-dispense if necessary. When switched back to CONTINUE, the process continues without any error in amounts dispensed.

4.ALL AIR SOLENOID outputs

There is a single 8 pin or 14 pin (or 17 pin) Amphanol plug located on the front of the control panel. this provides output of all 120 volt (or 24 volt) signals to drive the air solenoids. These power sources are transistor driven and are protected by the 1/2 amp panel fuse. See the wiring diagram section for the correct wiring to each pin.

If more then 7 outputs are to be driven, a 14 pin connector is provided with outputs for components 8, 9, A, B, and C.

If 24 volt solenoids are used, a 17 pin connector is provided.

5.POWER OUTPUTS (receptacles on panel front)

Each outlet puts out 120 volts (240 outside USA) through internal plugin solid state relays rated and fused at 3 amps. These relay outputs are designed to drive motors or other devices requiring power up to 3 amps each. The LEFT outlet is for component number 5, and the RIGHT outlet is for component number 6.

6.EIGHT CHARACTER DISPLAY

Displays the accumulated total bin weight, in grams, after each dispense. The display flashes when an inadequate dispense has occurred and the dispense is going to be retried. Other information displayed here includes material usage totals, internal parameters, component types and settings and various information prompts to assist the operator.

###### |

Numbers displayed |

are the |

total |

weight |

of material, in |

grams, |

||||||||

|

in |

the |

bin at |

any |

time. The |

weight |

in |

the |

bin |

is |

updated only |

|||

|

after an individual dispense |

is |

complete. |

During |

the dispense |

|||||||||

|

the displayed |

weight does |

not change. |

|

|

|

|

|

||||||

P |

in |

the |

left most position |

indicates |

unit is in |

PROGRAM |

mode. |

|||||||

M indicates unit is in MANUAL mode.

1 R 20.0 indicates: Component 1, REGRIND, SETTING of 20 percent. Page 25

INVALID indicates:

1.you pressed an incorrect key,

2.you pressed a key for a function that is not active, or

3.you are not in the right mode for this key to operate.

PASSWORD |

is displayed when you press the |

"*" key from the normal mode. |

|

|

Enter "11111" for MANUAL mode or |

"22222" for PROGRAM mode or |

|

|

enter your |

own password number if you have established one. |

|

INSTR -- |

is displayed when you press the "*" key from the PROGRAM mode. |

||

|

Enter a 2 digit instruction number for special tasks. |

||

SETTING, |

OPERATE, TIMED, and CALIBRATE are displayed when the |

||

|

respective |

keys are pressed from |

the manual or program modes. |

|

These displays are followed by pressing a device key; 1 |

||

|

through 9, |

A, B, C, DUMP, ALARM, |

MIX, or HOLD. |

FLASHING |

means that |

retries are occurring |

because the first dispense |

|

was not enough. Other error conditions also cause flashing. |

||

ROM OK |

or ROM BAD |

indicates condition of ROM chip. |

|

|

See KEYPAD, *25, for explanation. |

|

|

7.LED LIGHTS

The LED lights in two rows of eight located above the 8 character display indicate the following:

LEFT COLUMN from top:

1 through 8. Component 1 through 8 is operating. RIGHT COLUMN from top:

1 through 4. Component 9, A, B, or C is operating.

5.Weigh bin dump valve operating.

6.Mixer motor drive relay operating.

7.Mixer flow control valve is open.

8.Alarm output operating.

NOTE: The silk screening on the panel front next to the leds is correct for FOUR software but not for TWELVE software.

8.STROBE LIGHT AND BEEPER ALARMS

The Strobe light flashes and the Beeper sounds when a component fails to meter properly. Alarms begin after a number of retries have occurred, this number determined by the parameter table (see Parameters, _AL). These alarms can also indicate an out-of-range TARE weight. This range is set by the TL and TH parameters; above 100 or below -50 grams.

9.ALARM SILENCE

This button stops the STROBE and BEEPER ALARMS. The continuation of the cycle to its proper completion will also stop the alarm. When in the BATCH mode, this button also serves to start the next batch.

10.LEVEL SENSOR input

The high level sensor in the mixing chamber plugs into this outlet and signals the controller to start a dispense cycle when it is uncovered. The sensor must be uncovered for at least 2 seconds before a cycle will start (see DLY 00488 Parameter). Once a dispense cycle is started, covering the sensor does not stop it. Operation continues until the cycle is complete.

Page 26

11.MIXER MOTOR OUTLET

This outlet is energized by the software for a time period following the dump of the weigh bin. You may adjust this time in the parameter table (MIX 00010). This time should be just long enough to provide adequate mixing. Mixing for a longer period may contribute to a static problem. Also, excessive mixing sometimes causes separation of pellets of different size and weight. (MIX 00099) will cause the motor to run for 360 seconds (6 minutes).

12.MIXER MOTOR ON/OFF/TIMED SWITCH

The Mixer ON/OFF/TIMED switch has been removed. To have the mixer operate continuously, the MIX parameter may be set to 00099. 99 will instruct the software to run the mixer for 6 minutes after the weigh bin has emptied at the end of each cycle. This is more then enough time. This limitation prevents accidentally running the mix motor for hours on end when the blender is not actually operating.

13.MIXER MOTOR FUSE - 3 amp

This fuse is rated at 3 amps and protects the mixer motor circuit separately from all other fuses. On 100, 200, and 400 series models, this fuse protects the mix motor directly. On 900 and 1800 series models, this circuit operates a 25 amp solid state relay in a separate box. The mix motor is protected by a "motor starter" switch with a "heater". This switch must be on for the motor to operate.

14.LOAD CELL input port

The system's two load cells are joined by a common connector that is plugged into this port.

15.PRINTER output

This is a parallel printer port. A printer plugged in here allows four types of information to be ported directly to a printer giving the benefit of a permanent printed record. They are:

1.The totals of the material usage data.

(press VIEW and "*" keys or use the PRT parameter to AUTOMATICALLY and periodically print these totals.)

2.A listing of the internal parameter table. (press *77 in the PROGRAM mode.)

3.A printout of information after each cycle including actual dispensed weights and percentages for every cycle. (press *54 in the PROGRAM mode, use "*" to set printer flag ON.)

4.A printout of information after the TIME or CALIBRATE routines. (*54 flag must be on)

Any common parallel printer that you would use with a small PC computer may be used. Connect using a standard parallel printer cable, (34 pin parallel Centronix connector to a DB25 IBM compatible connector), available from us or at any computer store. See: PRINTED OUTPUTS for a

Page 27

detailed explanation of these printouts.

16.COMPUTER input / output

If you choose to gather material usage data automatically and continuously by computer, then this connector allows for connection to any IBM PC type computer operating under MS-DOS or WINDOWS.

The COMPUTER port is a DB9 (9 pin) male port. You will need a specially wired cable from us to connect to the serial port on your standard PC computer. Your computer operating system must be MS-DOS or WINDOWS. You will need software from us for communicating with your Autoweigh Blender. This software allows downloading settings and retrieval of information and produces reports for those customers who wish to take advantage of this feature. Either one or many Weigh Scale Blenders can be connected to one computer. For multiple Weigh Scale Blender systems, or communication over long distances, an additional piece of hardware is required. All GB/WSB controllers are fully programmed to communicate with your computer now or at a later date.

17.PANEL FUSE for duplex receptacle - 3 amp

Fuses the common power wire of the duplex receptacle (the color and additive outputs). Since these outlets are only turned on one at a time, each is protected to the full 3 amp rating of the fuse.

18.PANEL FUSE for processor - 1/2 amp

Fuses power to the circuit board power supply which includes all solenoid outputs and solid state relay outputs.

19.INTERNAL FUSES

An in-line fuse is provided internally to protect the main 120 volt power cord supply (10) amps. If this fuses blow, an internal short circuit is indicated and we don't recommend that you try to fix it.

Remember, this unit carries a three year warranty; just send it back.

The MIX MOTOR timed power source and the AUGER FEEDER OUTLETS are driven by internal solid state plug-in relays. These relays are located on the circuit board mounted on the inside back surface of the controller enclosure. A small 5 amp glass fuse is located to the right of each relay. A spare fuse is also located on the board if replacement is necessary.

20.THUMBWHEEL SWITCHES

The three sets of THUMBWHEEL switches have no effect unless they are assigned to a particular output device. Entry of all SETTINGS is done by using the KEYPAD. However, if you prefer, you may assign up to three components to the Thumbwheel switches and then use these switches to set and alter their settings.

Since only three switch sets are available, only 3 components can be controlled in this manner. All others must use the keypad.

See ENTERING SETTINGS for more information on how to do this.

21.KEYPAD: Explained in next section, next page.

Page 28

KEYPAD - SUMMARY DESCRIPTION

Detailed explanations are given on the pages that follow.

AUTOMATIC OPERATION MODE: (normal operation on power up)

VIEW: View Data: date, time, cycles, and each component weight. Press VIEW,* to print data.

RCP: Enter and retrieve stored RECIPES.

BTCH: View BATCH data: Target Weight, Current Portion, Accumulated Total, and Batch Count. CE = clear displayed field.

FAST: Run rapid FAST cycles after a normal weighed cycle. TAG: Tag Work Order and Operator numbers to all reports. EXIT: Press to EXIT all sequences from ALL MODES.

SET: Press to review or change settings.

CE: Press to display "raw signal" weight readout for 3 seconds.

MANUAL MODE: Press: "*"; then (11111) or your own 5 digit password.

OPER: Operate all devices manually; open and close valves. TIME: Operate devices for a selected time period.

CAL: Operate devices to learn rate.

Above keys use 1 through 9, A, B, C, DUMP, MIX, HOLD, ALARM. ZERO: Zero the tare weight with the bin empty.

FULL: Using known weights, enter gram weight to calibrate load cells.

*00 Clear DATA fields.

*99 Set flag to enable weight calibration of load cells.

PROGRAM MODE: Press: "*"; then (22222) or your own password.

SET: Enter settings if access in Automatic mode has been locked out. PARA: View or change system parameters. Press PARA for next in list,

"*" for previous, SET for next table, VIEW for previous table.

STAR FUNCTIONS: Press * and two numbers for the following functions:

*02 |

Extrusion and Yield Control. |

*52 |

Double dump weigh bin. |

*03 |

Four digit (xx.xx) settings. |

*54 |

Print cycle information. |

*04 |

Simulate FOUR software. |

*66 |

GB/WSB I.D. number (1-255). |

*05 |

Inhibit table clearing. |

*69 |

Regrind as second natural. |

*11 |

DATE - TIME, real-time clock. |

*71 |

Color percent of blend. |

*12 |

Move table from ROM to RAM. |

*72 |

Additive percent of blend. |

*23 |

Move from RAM to EEPROM. |

*74 |

Stop, alarm MAX wt exceeded. |

*32 |

Move from EEPROM to RAM. |

*75 |

Alarm on weight drop. |

*14 |

Set types: REG, NAT, ADD, OFF. |

*77 |

Print parameters. |

*25 |

ROM OK flag, "CE" to clear. |

*78 |

Change program mode PASSWORD. |

*33 |

Special Alarms. |

*82 |

Precision Ratioing. |

*44 |

End cycle - bin full. |

*87 |

VOLUMETRIC operation. |

*45 |

Change MANUAL mode password. |

*88 |

Print display readout. |

*47 |

Totalizer flag. |

*89 |

Select pounds, kilos. |

*48 |

Dispense range xx.x to xxx. |

*98 |

Display raw weight number. |

Use "*" key to select readout or toggle flags ON or OFF.

Page 29

KEYPAD - DESCRIPTION OF FUNCTIONS

Three (3) operation Modes are available; AUTOMATIC, MANUAL, PROGRAM.

KEYPAD - AUTOMATIC OPERATION MODE

This is the NORMAL operating mode. When power is turned on, the unit is in this mode. Automatic dispensing occurs ONLY in this mode. The AUTOMATIC mode is indicated by the ABSENCE of the letter "P" or "M" at the left end of the display.

Only the VIEW, RECIPE, BATCH, FAST, TAG, CE and EXIT keys are available in this mode:

These keys operate only BETWEEN cycles or when the PAUSE switch is on. To stop between cycles, use the "STOP END OF CYCLE" switch.

VIEW DATA: Press to display the CURRENT Date and Time, LAST CLEARED (VIEW) date and time, and stored material usage data. Total

CYCLES and Material totals are available: (in Pounds, Kilos, Grams, or Ounces)

Number of CYCLES that have occurred: |

(D = #####) |

||||||

TOTAL |

weight |

of |

each component |

(X): |

(X |

= |

#####) |

(only active components are displayed) |

|

|

|

||||

Total |

weight |

of |

ALL materials: |

|

(T |

= |

#####) |

Each successive press of the VIEW key displays the next total. The last displayed line will say (00=CLEAR) for 5 seconds. During this time, you may press 0,0 to clear the data. Waiting 5 seconds or pressing any other key will exit the sequence. When the sequence is exited, normal automatic operation resumes. These totals may be displayed as pounds, grams, kilograms, or ounces by a selection procedure explained later (*89).

Press the VIEW key once followed by the "*" key to cause all information to be sent to the printer (if available). To then clear the data, press 00 within 5 seconds. Press any other key or, wait 5 seconds, to continue the process without clearing the totals.

RECIPE: |

This |

key |

allows you to |

GET, |

LOAD, and SAVE RECIPES. To |

|||

(RCP) |

SAVE |

a recipe you |

must |

be in |

the PROGRAM mode. |

Recipes are |

||

|

thumbwheel switch |

settings. |

|

50 recipes may be |

stored, |

|||

|

numbered |

00 to 50. |

|

|

|

|

|

|

This key is NOT FUNCTIONAL unless the third digit in the "FLG" parameter is set to 1 (FLG xx1xx). To do this, see the MAINTENANCE section, PARAMETER TABLE, "FLG".

Assuming a proper FLG parameter is set:

In normal Automatic mode: Press RCP key. If a RECIPE is currently in use then display will flash through the current stored data:

(RCP --), (1R= xx ), (2N= xx.x), etc., (CE=CLEAR)

Press CE to CLEAR CURRENT RECIPE and return settings to those previously set. Then press RCP to look at another

Page 30

recipe. Display = (GET --).

If no RECIPE is currently in use, display says (GET --). Enter 2 digits to retrieve one of 50 recipes.

Display will flash through this recipe data:

(RCP 01), (1R= xx ), (2N= xx.x), etc., (* = LOAD)

Press "*" to LOAD this recipe into memory. Routine will exit automatically. Press RCP or EXIT to return to the display (GET --). Press RCP or EXIT again to exit.

To SAVE a RECIPE you must be in the PROGRAM mode.

If you press RCP key again after display of (GET --), display says (SAVE --). Enter 2 digits, display will say (SAVING ). The current settings are saved into memory under the recipe number you have entered.

Routine will EXIT automatically.

EXIT will exit at any time.

To clear a recipe, set all component settings to zero and save these settings into the recipe location.

BATCH: |

This key allows you to blend a PRE-SELECTED WEIGHT of |

|

|

|

(BTCH) |

material, |

and then STOP running and sound the ALARM. |

The |

|

|

process may also be programmed to sound the alarm but |

|

|

|

|

continue running. Since each cycle will always blend a |

full |

||

|

weigh bin |

amount, the total amount blended may exceed the |

||

|

target batch weight by up to one cycle's blend weight. |

|

||

|

This key is NOT FUNCTIONAL unless the last digit in the |

|

||

|

"FLG" parameter is set to 1 or 2. (xxxx1 or xxxx2). |

To |

do |

|

|

this, see |

the MAINTENANCE section, PARAMETER TABLE, "FLG". |

||

|

The ALARM |

SILENCE button on the side of the controller, |

is |

|

|

the ONLY way to CONTINUE OPERATION after a BATCH amount |

has |

||

|

been run. |

|

|

|

Assuming a proper "FLG" parameter is set:

Press the BTCH key once to view the desired BATCH WEIGHT. Display will say (BW #####).

BATCH WEIGHT is the amount you wish to dispense before stopping and/or sounding the alarm.

Press again to view the CURRENT PORTION, of the batch, that has been dispensed.

Display will say (CP #####).

CURRENT PORTION shows how much of the Batch Weight you have blended so far.

Press again to view the ACCUMULATED TOTAL weight of all batches dispensed.

Display will say (AT #####).

ACCUMULATED TOTAL is the sum weight of all batches that have been blended. This number will continue to grow until it is manually cleared to zero, or it exceeds its maximum possible value.