Cleveland Range SD-1600-K1220, SD-1200, SD-1800, KDT- 6-T, SD- 450 User Manual

...

Operators Manual

Installation, Operation & Service

Direct Steam Table Top Kettles

Table-Top Direct

Steam Kettles

MODELS: KDT- 1 - T

KDT- 3 - T

KDT- 6 - T

KDT-12 - T

KDT-20 - T

SD Stands

MODELS: SD - 450

SD - 650

SD - 760

SD -1050

SD -1200

SD -1600

SD -1800

Kettles on

SD Stands

MODELS: SD -450 - K 6

SD -650 - K12

SD -760 - K12

SD -760 - K20

SD -1050 - K 6 6

SD -1200 - K 6 12

SD -1600 - K 6 20

SD -1600 - K12 12

SD -1600 - K12 20

SD -1600 - K20 20

|

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110 |

Enodis |

Phone: (216) 481-4900 Fax: (216) 481-3782 |

|

Visit our web site at www.clevelandrange.com |

SE95008 Rev. 3

TABLE OF CONTENTS

Installation

Operating Instructions

Cleaning Instructions

Service Parts

Maintenance

Specification Drawings

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shipping Damage Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Kettles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Kettles c/w SD Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Condensate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Potable Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Final Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Recommended Piping Schematics . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Marine Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Care & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Steam Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Plumbing Assembly (for SD Stands). . . . . . . . . . . . . . . . . . . . . . 7-8

Faucet Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Valve Testing Procedure . . . . . . . . . . . . . . . . . . . 11

Steam Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Steam Flow Rating of Steam Generators . . . . . . . . . . . . . . . . . . . 12 Steam Flow Rating Requirements for Kettles. . . . . . . . . . . . . . . . 12

KDT-1-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

KDT-3-T & KDT-6-T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 KDT-12-T & KDT-20-T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 SD Stands with Kettles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INSTALLATION

GENERAL

Installation of the unit must be accomplished by qualified installation personnel working to all applicable local and national codes. Improper installation of product could cause injury or damage.

This unit is built to comply with applicable standards for manufacturers. Included among those approval agencies are: UL, NSF, ASME/Ntl.Bd., CSA, ETL, CE, and others. Many local codes exist, and it is the responsibility of the owner/installer to comply with these codes.

INSPECTION

Before uncrating, visually inspect the unit for evidence of damage during shipping. If damage is noticed, do not unpack the unit, follow shipping damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or suspected, observe the following guidelines in preparing a shipping damage claim.

1.Write down a description of the damage or the reason for suspecting damage as soon as it is discovered. This will help in filling out the claim forms later. If possible, take a polaroid picture.

2.As soon as damage is discovered or suspected, notify the carrier that delivered the shipment.

3.Arrange for the carrier's representative to examine the damage.

4.Fill out all carrier claims forms and have the examining carrier sign and date each form.

CLEARANCE REQUIREMENTS

The first installation step is to refer to the SPECIFICATION DRAWINGS at the back of this manual in order to determine the exact location of the kettle.

CLEARANCE REQUIREMENTS TO COMBUSTIBLE AND NONCOMBUSTIBLE SURFACES:

|

RIGHT |

LEFT |

BACK |

KDT-1-T |

4" |

0" |

0" |

KDT-3-T & KDT-6-T |

4" |

4" |

1" |

KDT-12-T & KDT-20-T |

4" |

4" |

1.75" |

Note: For SD Stands (with or without kettles) zero clearance is required on the sides and back.

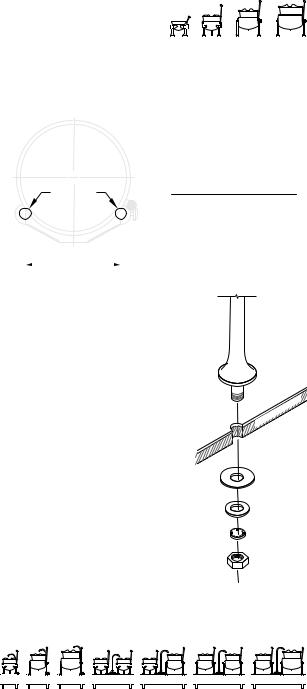

KETTLES

Table-top models must be positioned on a firm stand or existing counter top and secured in place. An optional modular cabinet base (SD Stand), with level-adjustable legs is available .

1.Make two 1" holes for the kettle legs.

|

|

|

|

|

|

|

|

A |

||||||

|

|

|

DRILL TWO |

|

||||||||||

|

|

|

1" HOLES |

KDT-1-T |

8 1/8" |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

KDT-3-T |

10" |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

KDT-6-T |

12" |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

KDT-12-T |

19 1/2" |

|

|

|

|

A |

|

|

|

|

|

|

|

KDT-20-T |

23 3/4" |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2.Remove the leg mounting locknuts and washers from the kettle's legs.

3.Install the legs into the two 1" holes.

4. Position washers as illustrated and secure the kettle to its' base by refastening the locknut from underneath the cabinet or countertop.

5. Once the kettle is secure, screw the tilt handle into the mounting block welded to the side of the kettle.

6. Install service requirements as required.

|

|

|

|

|

RTO |

P |

|

|

N |

T |

E |

|

|

|

U |

|

|

|||

CO |

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

KETTLES c/w SD STAND

1.Place unit in desired location.

2.Place a carpenter's level on the kettle rim and level the stand using the level adjustable feet.

3.Install service requirements as required.

1

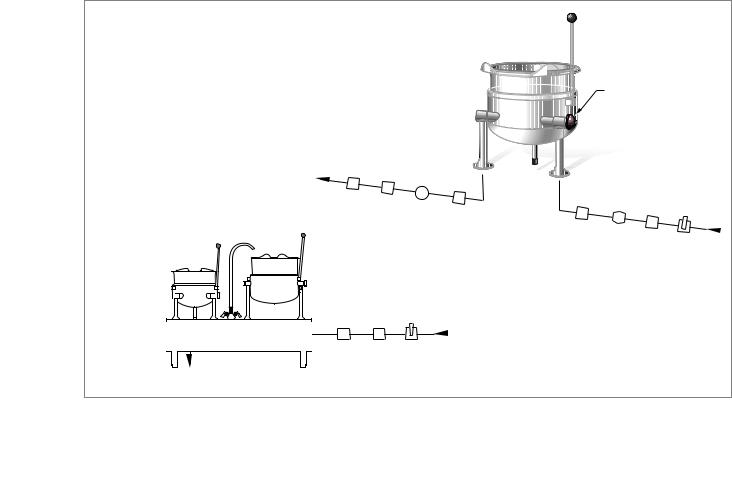

STEAM |

CONDENSATE (Kettles c/w SD Stands) |

All steam plumbing to and from the kettle and steam boiler should be thoroughly cleaned and inspected for dirt and debris before final connection to the kettle are made.

Generally, kettles require 1/2" i.p.s. pipe, 10-45 psi steam pressure. If the steam supply pressure exceeds 45 psi, a pressure reducing valve is required. The steam inlet is at the right side of the kettle, as seen from the front.

CONDENSATE (Kettles without SD Stands)

Maximum pressure rating on table-top kettles is 50psi. It is highly recommended that a pressure relief valve equal to or less than this pressure be installed on the incoming steam line close to the kettle.

A steam condensate trap must be plumbed to a drain, using minimum 1/2" NPT plumbing. The condensate line is limited to a maximum rise of 10 feet in order for the steam pressure to adequately force the condensate through the plumbing. Any higher rise requires a pump.

If the steam boiler to which this kettle is installed has a condensate return (closed loop system), a 1/2" steam strainer, a 1/2" steam trap, and a 1/2" check valve must be installed on the output (condensate) side of the kettle.

The stand comes factory plumbed so the condensate is connected to the stands drain manifold.

POTABLE WATER

The water faucet (optional on kettles purchased without SD stands) with swing spout, requires 1/2 inch O.D. copper tube plumbing for hot or cold water supplies to the faucet (SPK - cold water connection only, DPK - hot and cold water connection).

FINAL INSTALLATION CHECK

1.Partially fill the kettle with water.

2.Slowly turn the steam supply valve's knob to the open position.

3.Release the safety valve, ensuring that the steam escapes freely. Stay clear of steam exhaust when releasing the safety valve.

4.Observe that the water in the kettle comes to a boil.

5.Close the steam supply valve.

6.Drain off the water by tilting the kettle.

RECOMMENDED PIPING |

|

|

|

KETTLES |

|

SCHEMATICS |

|

|

|

|

|

(all service connections shown supplied by others) |

|

|

|

|

|

|

|

|

MANUAL |

|

|

|

|

|

STEAM |

|

|

|

|

|

VALVE |

|

|

CONDENSATE RETURN |

|

|

|

||

TO DRAIN OR BOILER |

|

|

|

|

|

CONDENSATE LINE |

|

|

|

|

|

UNION |

CHECK |

|

|

|

STEAM |

KETTLES c/w |

STEAM |

STRAINER |

|

||

VALVE |

TRAP |

|

IN |

||

|

|

STRAINER |

|

|

|

SD STANDS |

|

|

|

|

|

|

|

PRESSURE |

UNION |

|

|

|

|

REDUCING |

BALL |

||

|

|

|

VALVE |

|

|

|

|

|

|

VALVE |

|

|

|

|

|

|

|

|

|

STEAM |

|

|

|

|

|

|

IN |

|

|

STRAINER |

UNION |

BALL |

|

|

|

|

|

VALVE |

|

|

|

TO DRAIN (CONDENSATE RETURN PLUMBED TO 1 1/2" DRAIN MANIFOLD) |

|

|

|||

|

|

2 |

|

|

|

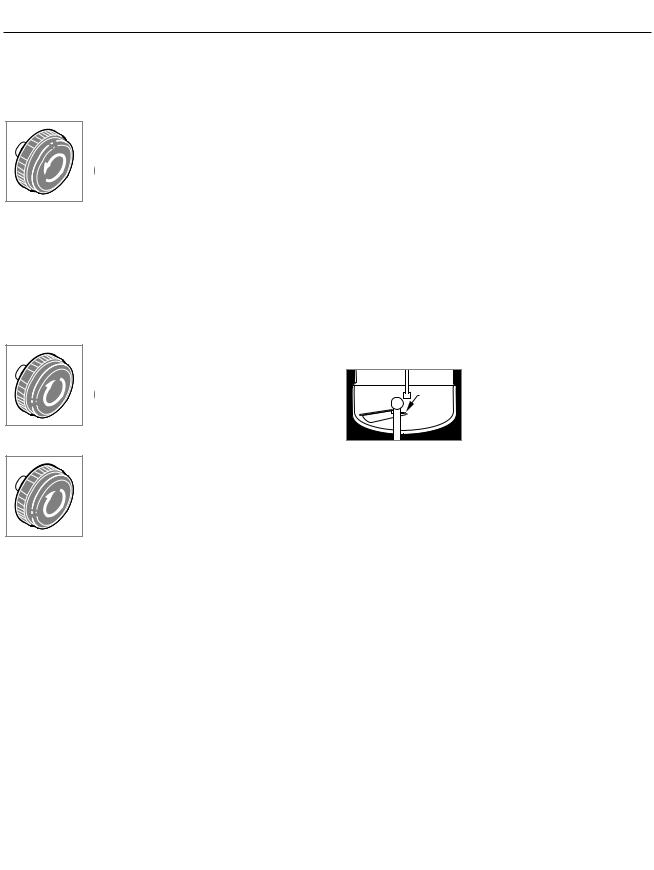

OPERATING INSTRUCTIONS

CLEVELAND STEAM COOKING EQUIPMENT IS INTENDED FOR COMMERCIAL USE ONLY BY PROFESSIONALLY TRAINED PERSONNEL.

FOR KETTLE/STEAMER COMBINATIONS:

If the boiler in a steamer is supplying steam to a kettle, always heat the kettle first. After the kettle contents are heated, and the boiler's steam pressure returns to normal, the steamer may be used. Pressure steamer compartments should be sequentially started, and preheated before cooking.

NOTE: As with cleaning food soil from any cookware, art important part of kettle cleaning is to prevent food from drying on. For this reason, cleaning should be completed immediately after cooked foods are removed. . Please read the "Care and Cleaning" instructions for detailed kettle washing procedures

(12 & 20 gal. models only)

If your unit is equipped with a marine lock to prevent

accidental tilting, it must be

inspected daily to insure it moves freely and

automatically locks into place when kettle is returned to upright position.

Use the following procedure to tilt the kettle.

1. Securely grasp the tilt handle.

3

CLEANING INSTRUCTIONS

CARE AND CLEANING

Your kettle must be cleaned regularly to maintain its fast, efficient cooking performance, and to ensure its continued safe, reliable operation.

WARNING: Do not use chloride base detergents.

1.Prepare a warm water and mild detergent solution in the kettle.

2.Remove food soil inside the kettle using a nylon brush. Do not use a metal bristle brush, as this may permanently damage the kettle's stainless steel surface.

3.Loosen food which is stuck to the kettle by allowing it to soak at a low temperature setting.

4.Tilt kettle forward to drain wash water.

5.Rinse kettle interior thoroughly, then drain the rinse water.

6.Using mild soapy water and a damp sponge, wash the exterior of the kettle, rinse, and dry.

7.Leave the cover off when the kettle is not in use..

8.If your unit is equipped with a marine lock, clean any food deposits that may have spilled onto the mechanism.

NOTE: For more difficult cleaning applications one of the following can be used: alcohol, baking soda, vinegar, or a solution of ammonia in water. Avoid the use of chloride cleansers, which may damage the kettle's or stands stainless steel surface.

WARNING: Steel wool should never be used for cleaning the cooking chamber of the kettle. Particles of steel wool become embedded in the cooking surface and rust, which may corrode the stainless steel.

4

Loading...

Loading...