Carrier 50PG03-07 User Manual

50PG03---07

Single Package Rooftop Units

Electric Cooling with PURONR (R ---410A)

Refrigerant and COMFORTLinkt Controls

Installation Instructions

IMPORTANT: This installation instruction contains basic unit

installation information including installation of field control

devices. For information on unit start--up, service, and operation,

refer to the unit Controls, Start-- Up, Operation, Service, and

Troubleshooting Instructions also enclosed in the unit literature

packet.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 1.........................

INSTALLATION 4....................................

Step 1 -- Provide unit Support 4.........................

Step 2 -- Rig and Place Unit 4...........................

Step 3 -- Field Fabricate Ductwork 7......................

Step 4 -- Make Unit Duct Connections 7...................

Step 5 -- Install External Trap for Condensate Drain 7........

Step 6 -- Make Electrical Connections 8...................

Step 7 -- Install Outdoor Air Hoods (Units With

Economizer 22...............................

Step 8 -- Install All Accessories 22.......................

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should install, repair, or

service air-conditioning equipment.

Untrained personnel can perform the basic maintenance functions

of cleaning coils and filters and replacing filters. All other

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe precautions

in the literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Recognize safety information. This is the safety--alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, turn off main power switch to unit and install

lockout tag.

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

Puron (R--410a) refrigerant systems operate at higher

pressures than standard R--22 systems. Do not use R--22

service equipment or components on Puron refrigerant

equipment.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

1. Improper installation, adjustment, alteration, service,

or maintenance can cause property damage, personal

injury, or loss of life. Refer to the User’s Information

Manual provided with this unit for more details.

2. Do not store or use gasoline or other flammable

.

vapors and liquids in the vicinity of this or any other

appliance.

IMPORTANT: Units have high ambient operating limits. If limits

are exceeded, the units will automatically lock the compressor out

of operation. Manual reset will be required to restart the

compressor.

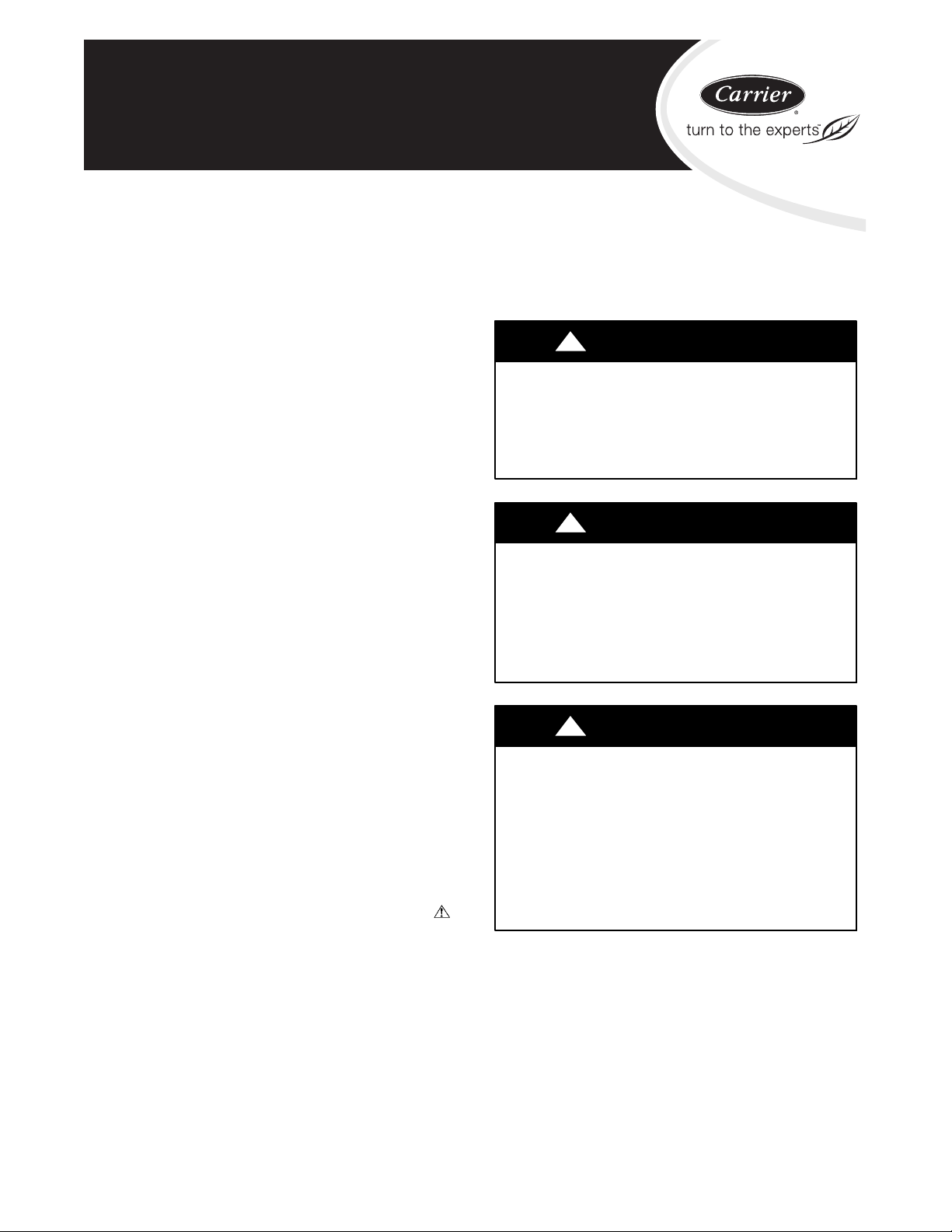

C07269

50PG03--07

Fig. 1 -- Roof Curb Details

2

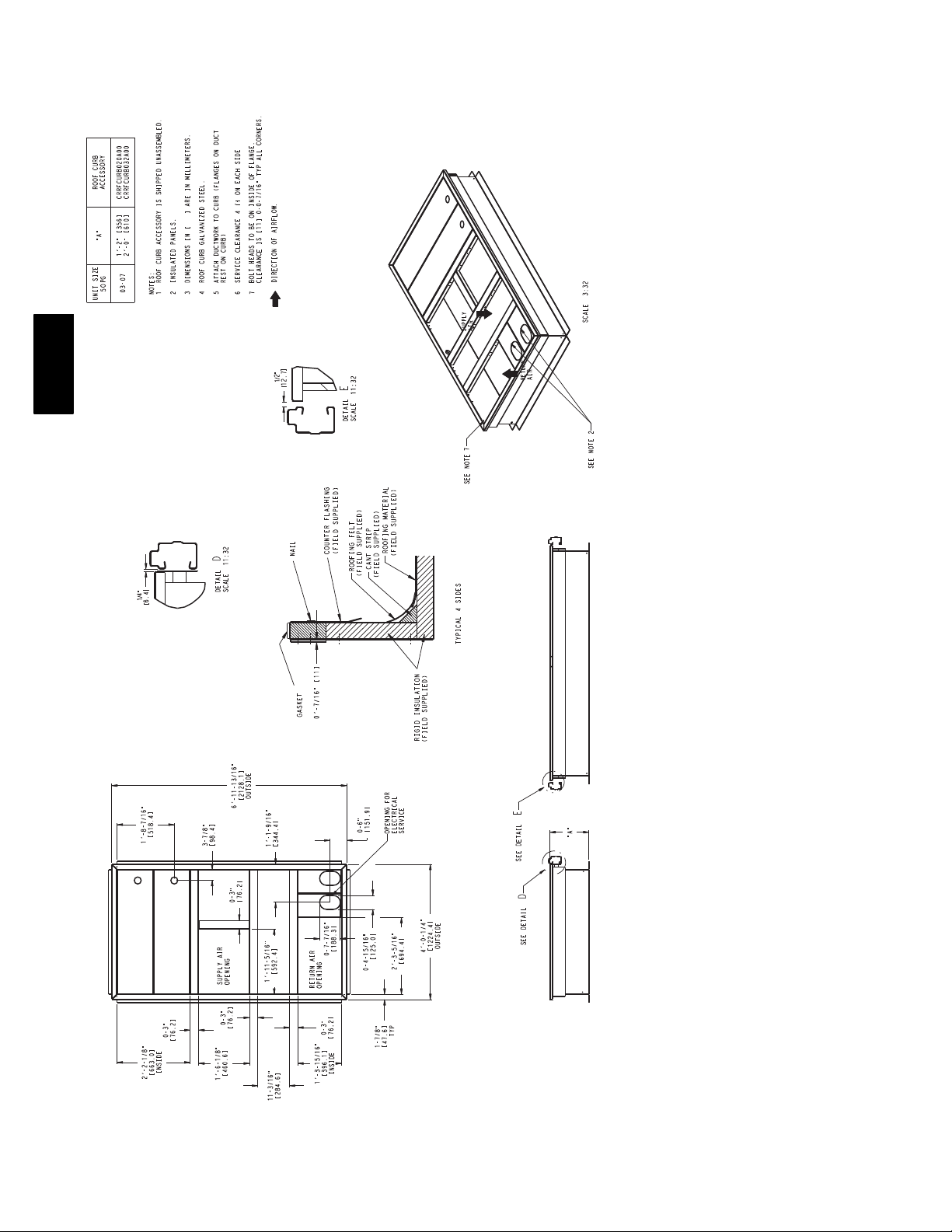

C07271

50PG03--07

Fig. 2 -- Base Unit Dimensions

3

INSTALLATION

Step 1 — Provide Unit Support

Roof Curb

Assemble or install accessory roof curb in accordance with

instructions shipped with this accessory. (See Fig. 1.) Install

insulation, cant strips, roofing, and counter flashing as shown.

Ductwork can be installed to roof curb before unit is set in place.

Ductwork must be attached to curb and not to the unit. Curb must

be level. This is necessary to permit unit drain to function properly.

Unit leveling tolerance is 1/16--in. per linear ft in any direction.

Refer to Accessory Roof Curb Installation Instructions for

additional information as required. When accessory roof curb is

used, unit may be installed on class A, B, or C roof covering

material. Carrier roof curb accessories are for flat roofs or slab

mounting.

IMPORTANT: The gasketing of theunit to the roof curb is critical

for a watertight seal. Install gasket with the roof curb as shown in

Fig. 1. Improperly applied gasket can also result in air leaks and

poor unit performance. Do not slide unit to position on roof curb.

Alternate Unit Support

50PG03--07

When a curb cannot be used, install unit on a noncombustible

surface. Support unit with sleepers, using unit curb support area. If

sleepers cannot beused, support long sides of unit with a minimum

of 3 equally spaced 4--in. x 4--in. pads on each side.

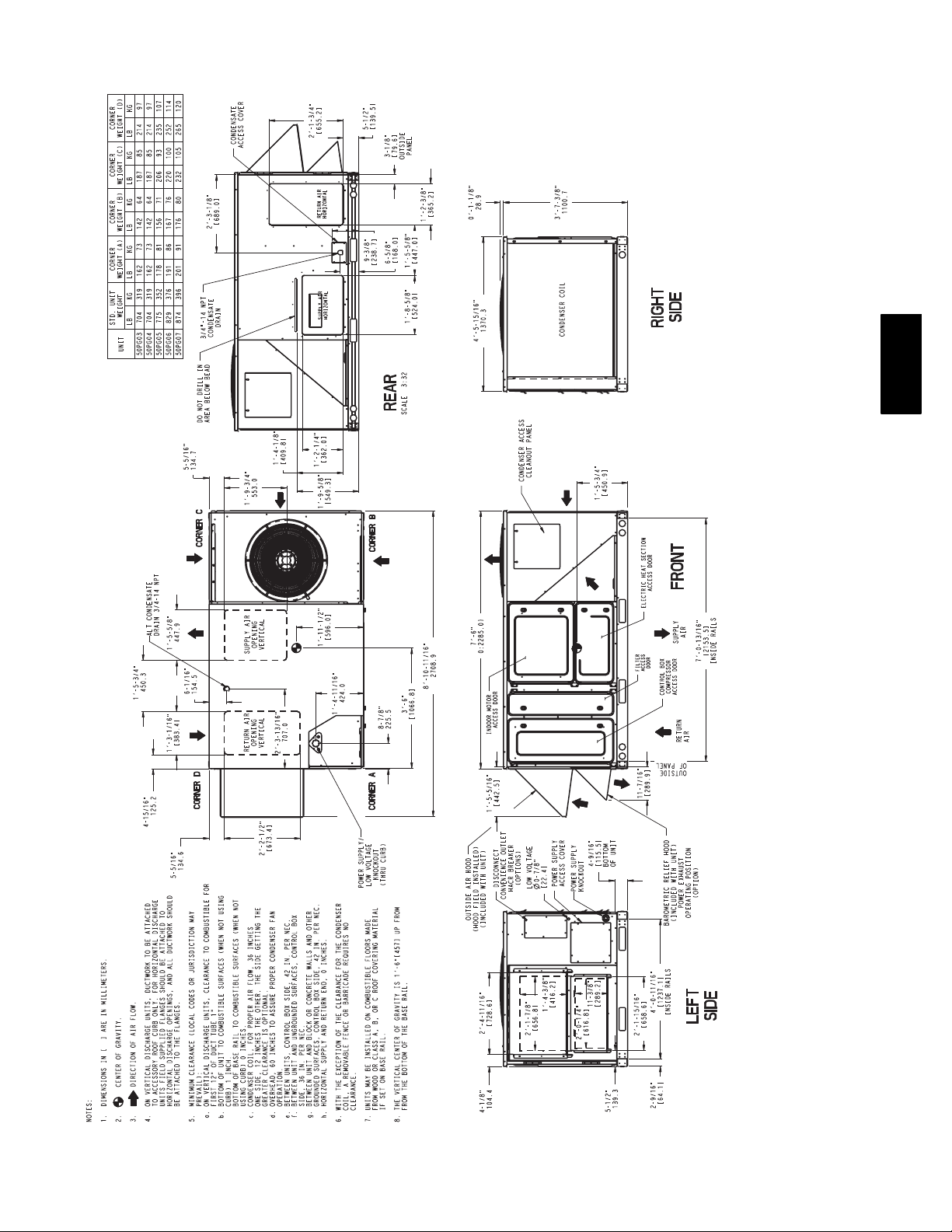

Step 2 — Rig and Place Unit

Inspect unit for transportation damage. See Table 1 for physical

data. File any claim with transportation agency.

!

CAUTION

PERSONAL INJURY AND PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in damage to roof.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck.

Do not drop unit; keep upright. Use spreader bars over unit to

prevent sling or cable damage. Rollers may be used to move unit

across a roof. Level by using unit rail as a reference; leveling

tolerance is ± 1/16--in. per linear ft in any direction. See Fig. 3 for

additional information. Unit rigging weight is shown in Fig. 3.

Rigging holes are provided in the unit base rails as shown in Fig. 3.

Refer to rigging instructions on unit.

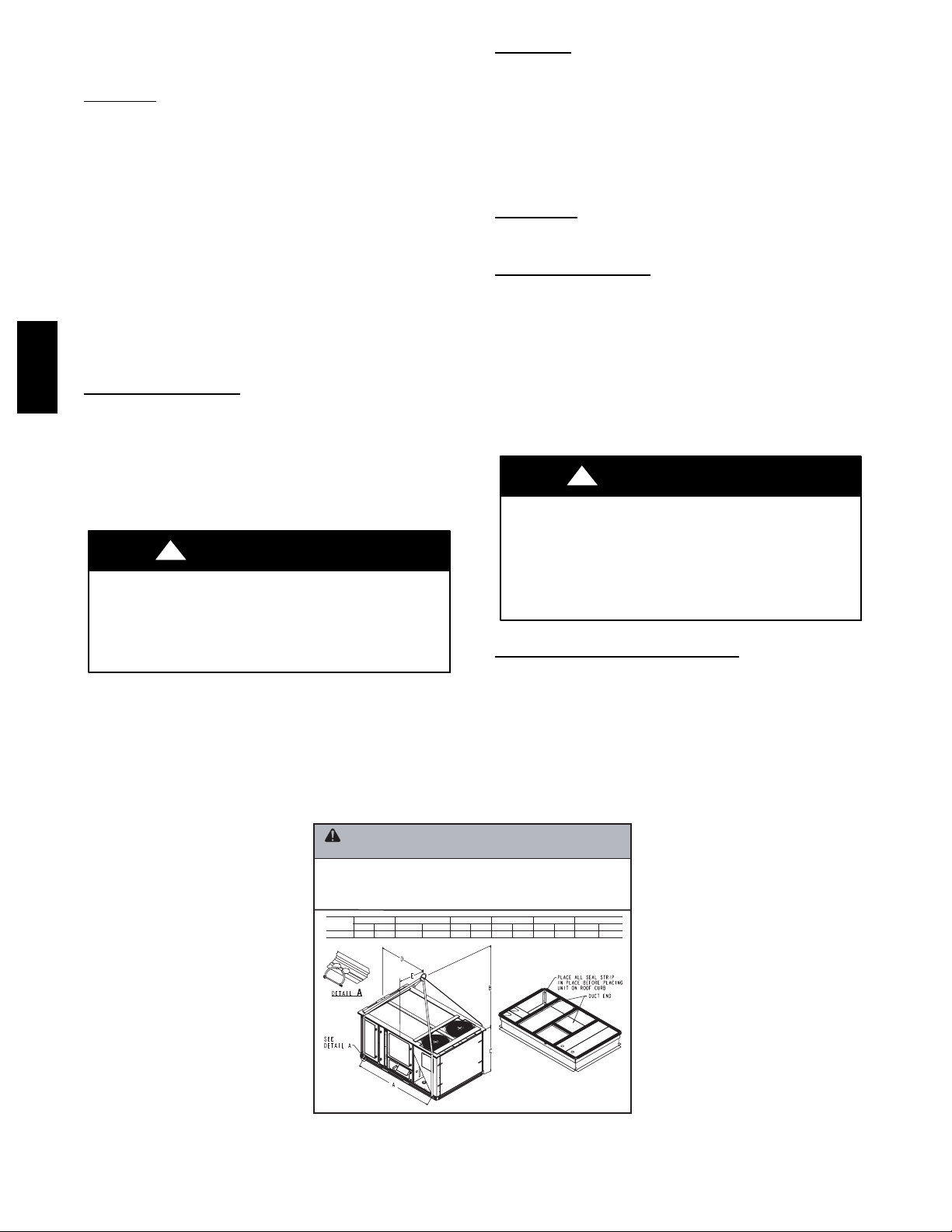

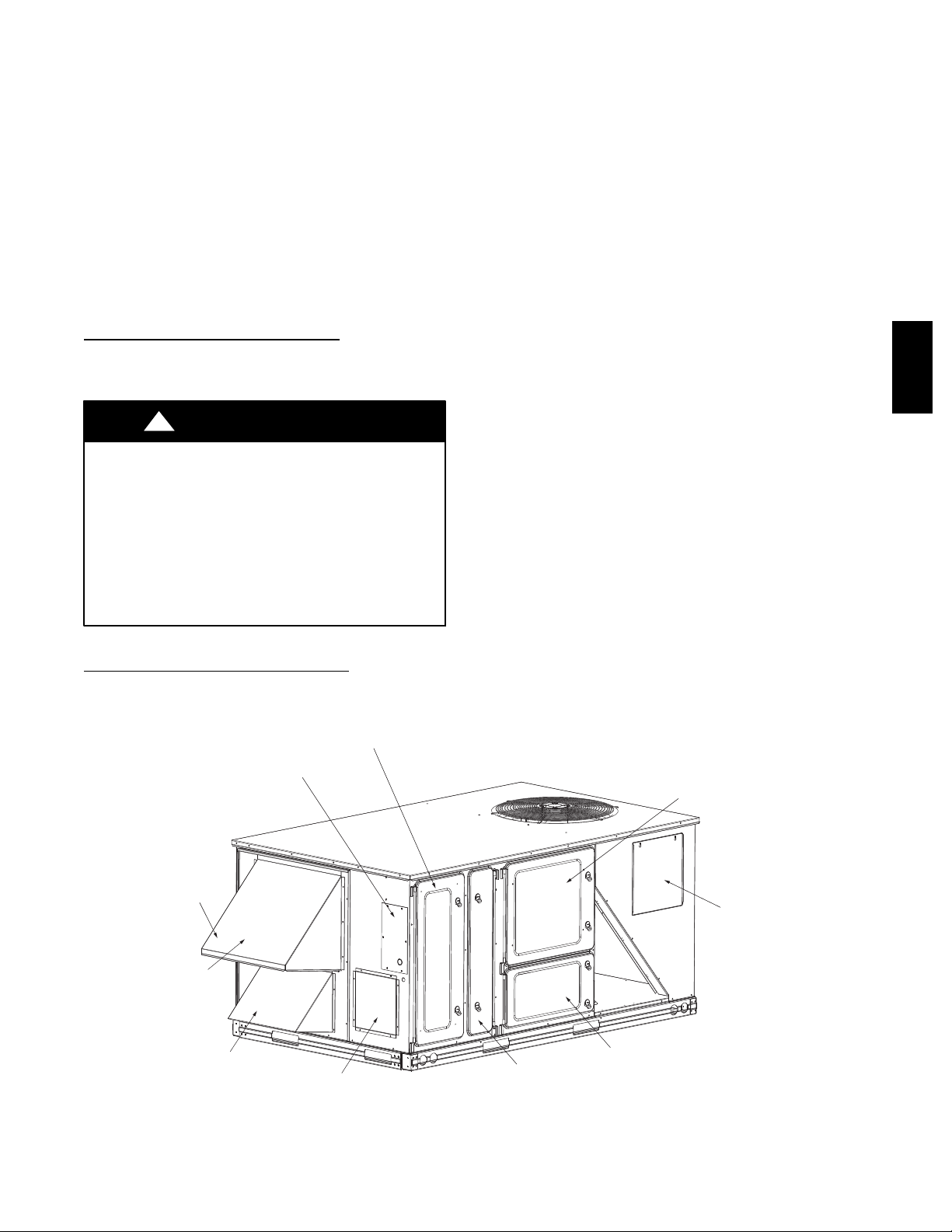

Positioning

Maintain clearance, per Fig. 2, around and above unit to provide

minimum distance from combustible materials, proper airflow, and

service access. See Fig. 4 for location of access panels.

Do not install unit in an indoor location. Do not locate air inlets

near exhaust vents or other sources of contaminated air.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

After unit is in position, remove crating and polyethylene sheet.

Roof Mount

Check building codes for weight distribution requirements. Unit

operating weight is shown in Table 1.

Installation Onto Curb

The 50PG units are designed to fit on the accessory full perimeter

curb. In either case, correct placement of the unit onto the curb is

critical to operating performance. To aid in correct positioning,

place unit on roof curb to maintain 1/4--in. gap between the inside

of rail and roof curb on long sides and a 1/2--in. gap between the

inside of rail and roof curb on both duct and condenser ends. Refer

to Fig. 1 and 3, to assure proper duct opening alignment.

NOTE: Before positioning unit onto curb, refer to Step 5 -- Install

External Trap for Condensate Drain section concerning bottom

drain connection plug.

!

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Do not slide unit to position when it is sitting on the curb.

Curb gasketing material may be damaged and leaks may

result.

Slab Mount (Horizontal Units Only)

Provide a level concrete slab that extends a minimum of 6--in.

beyond unit cabinet. Install a gravel apron in front of

condenser--coil air inlet to prevent grass and foliage from

obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

CAU OTI

ACCESS PANEL MUST BE IN PLACE WHEN RIGGING.

Hook rigging shackles through holes in base rail, as shown in

Detail A. Holes in base rails are centered around the unit

center of gravity. Use wooden top skid, when rigging, to

prevent rigging straps from damaging unit.

A B C D E MAX. WEIGHT

UNIT

SIZE

in. mm in. mm in. mm in. mm in. mm lb kg

03-07 77.9 1978 36-54 914-1371 44.8 1139 42.0 1067 23.5 597 1156 52

N- NOTICE TO R GGERS:I

Fig. 3 -- 50PG Rigging Label

4

5

C07270

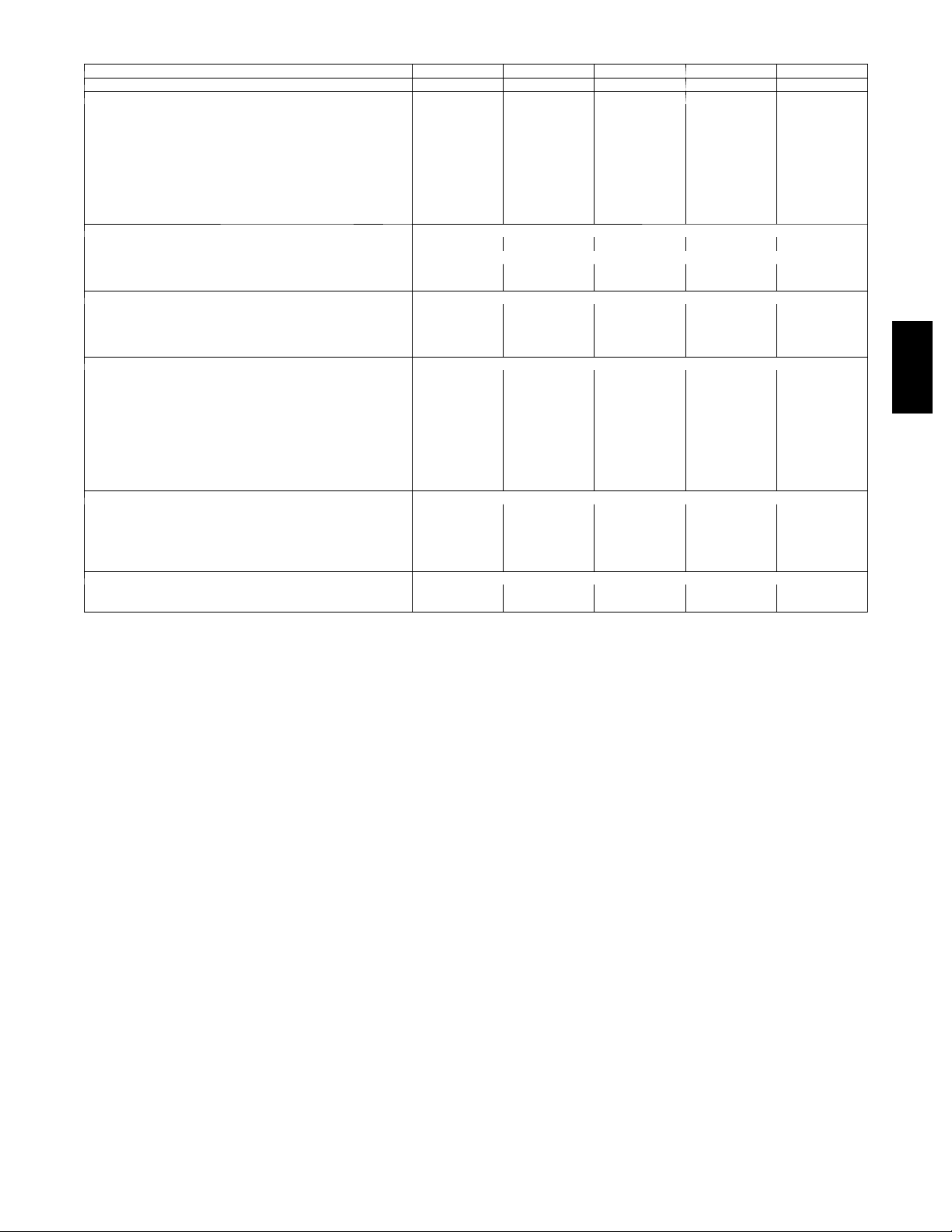

Table 1 – Physical Data

BASE UNIT 50PG 03 04 05 06 07

NOMINAL CAPACITY (Tons)

OPERATING WEIGHT (lb)

Unit*

Economizer

Vert ical

Horizontal

Humidi-MiZer™ Adaptive Dehumidification

System

Roof Curb

14-in.

24-in.

COMPRESSOR

Quantity

Oil Type

Number of Refrigerant Circuits

Oil (o z )

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb) — Standard Unit

Operating Charge (lb) — Unit with

Humidi-MiZer System

CONDENSER COIL

Condenser A (Outer)

Rows...Fins/in.

Face A rea (s q ft)

Condenser B (Inner)

Rows...Fins/in.

Face A rea (s q ft)

Humidi-MiZer Coil

Rows...Fins/in.

Face A rea (s q ft)

CONDENSER FAN

Quantity…Diameter (in.)

Nominal Cfm (Total, all fans)

Motor Hp

Nominal Rpm — High Speed

Nominal Rpm — Low Speed

EVAPORATOR COIL

Rows…Fins/in.

Face A rea (s q ft)

* See Legend on next page.

2 3 4 5 6

704 704 775 829 874

40 40 40 40 40

50 50 50 50 50

22

22 31 27 26

122 122 122 122 122

184 184 184 184 184

Fully Hermetic Scroll

1 1 1 1 1

Copeland 3MA

1 1 1 1 1

38 42 42 66 56

R-410A (Puron® Refrigerant)

TXV TXV TXV TXV TXV

7.3 9.0 15.7 16.6 19.0

11.75 13.50 25.00 22.00 22.70

Enhanced Copper Tubes, Aluminum Lanced Fins

1…17 1…17 2…17 2…17 2…17

12.6 12.6 12.6 12.6 12.6

— 1…17 2…17 2…17 2…17

— 12.6 12.6 12.6 12.6

1...17 1...17 1...17 1...17 1...17

6.4 6.4 9.3 9.3 9.3

Propeller

1…24 1…24 1…24 1…24 1…24

3500 3500 3500 4500 4500

1

/

8

825 825 825 1100 1100

1

/

8

1

/

8

1

/

4

300 300 300 300 300

Enhanced Copper Tubes, Aluminum Double-Wavy Fins, Face Split

2…15 2…15 2…15 3…15 4…15

9.3 9.3 9.3 9.3 9.3

50PG03--07

1

/

4

5

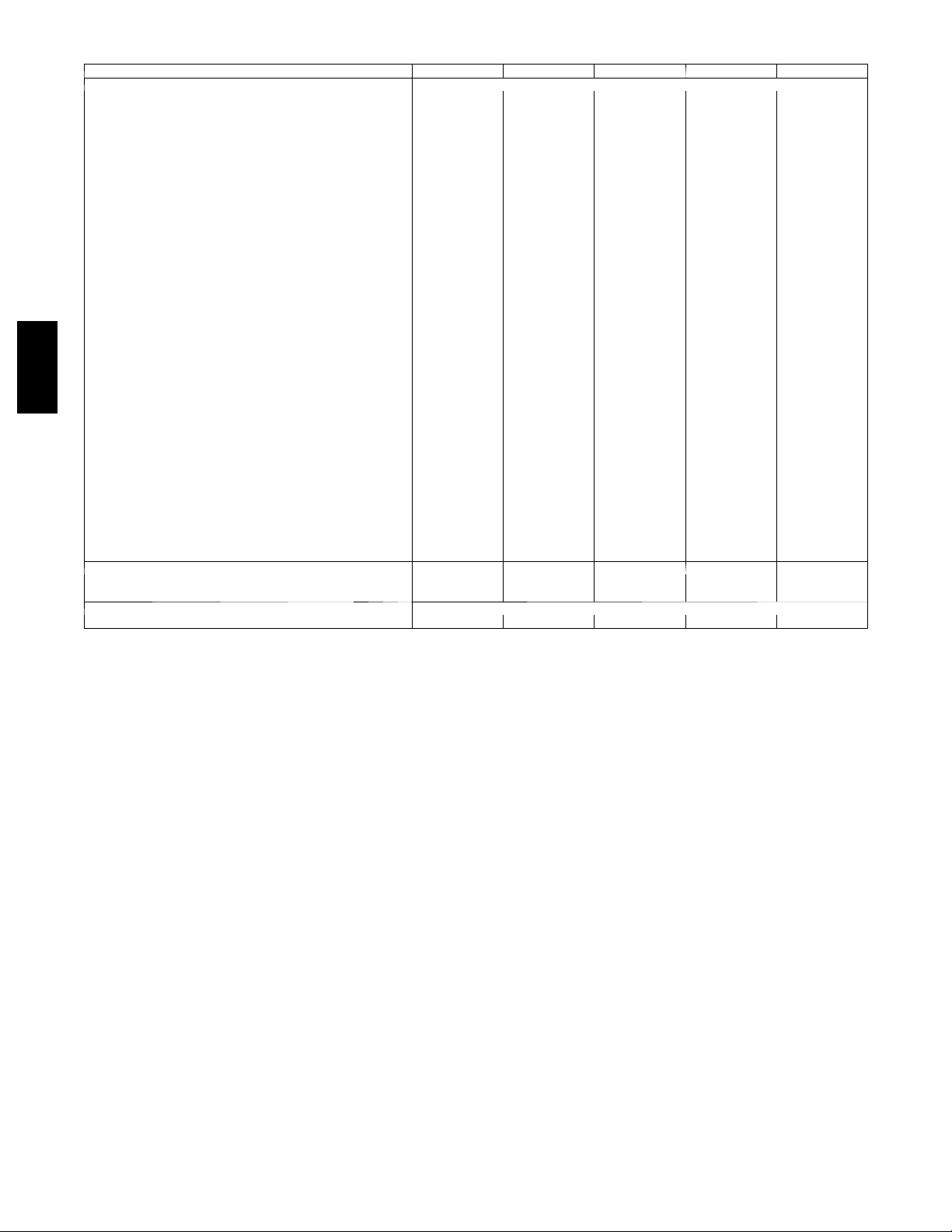

BASE UNIT 50PG (co nt) 03 04 05 06 07

EVAPORATOR FAN

Quantity…Size (in.) Low

Ty pe D ri ve Low

Nominal Cfm

Maximum Continuous Bhp Low

Motor Nominal Rpm

Motor Frame Size Low

Fan Rp m Range Low

Motor Bearing Type

Maximum Fan Rpm

Motor Pulley Pitch Diameter Range (in.) Low

Fan Pulley Pitch Diameter (in.) Low

Nominal Motor Shaft Diameter (in.) Low

Belt...PitchLength(in.)

Belt…Ty pe Low

50PG03--07

Pulley Center L ine Distance Min. (in.) Low

Pulley Center Line Distance Max. (in.) Low

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full

Turns from Closed Position

FactoryPulleySetting(rpm) Low

Fan Shaft Diameter at Pulley (in.)

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS

Quantity…Size (in.)

LEGEND

TXV --- Thermostatic Expansion Valve

* Aluminum evaporator coil/aluminum condenser coil.

{ Single phase/three phase.

Table 1 — Physical Data (cont)

High

High

High

High

High

High

High

High

Low

High

High

High

High

Low

High

Low

High

High

1...12 x 9

1...12 x 9

Belt

Belt

800 1200 1600 2000 2400

0.85

0.85

1620 1620 1620 1725 1725

48Y

48Y

482-736

656-1001

Ball Ball Ball Ball Ball

2000 2000 2000 2000 2000

1.9-2.9

1.9-2.9

6.8

5.0

1

/

2

1

/

2

49.3 49.3 49.3 49.3 49.3

49.3

AX

AX

16.2

16.2

20.2

20.2

48

65

5

5

482

656

3

/

4

660 ± 10 660 ± 10 660 ± 10 660 ± 10 660 ± 10

505 ± 20 505 ± 20 505 ± 20 505 ± 20 505 ± 20

4…16 x 20 x 2 4…16 x 20 x 2 4…16 x 20 x 2 4…16 x 20 x 2 4…16 x 20 x 2

1...12 x 9 1...12 x 9 1...12 x 9 1...12 x 9

Centrifugal Type, Belt Drive

1...12 x 9 1...12 x 9 1...12 x 9 1...12 x 9

Belt Belt Belt Belt

Belt Belt Belt Belt

0.85 0.85 0.85/2.40† 2.40

0.85 1.60/2.40† 1.60/2.40† 3.10

48Y 48Y 56Y 56Y

48Y 56Y 56Y 56Y

482-736 596-910 690-978 796-1128

796-1128 828-1173 929-1261 1150-1438

1.9-2.9 1.9-2.9 2.4-3.4 2.4-3.4

2.4-3.4 2.4-3.4 2.8-3.8 4.0-5.0

6.8 5.5 6.0 5.2

5.2 5.0 5.2 6.0

1

/

2

1

/

2

1

/

2

5

/

8

5

/

8

5

/

8

5

/

8

7

/

8

49.3 49.3 49.3 52.3

AX AX AX AX

AX AX AX AX

16.2 16.2 16.2 16.2

16.2 16.2 16.2 16.2

20.2 20.2 20.2 20.2

20.2 20.2 20.2 20.2

48 59 58 66

62 69 66 58

5 5 5 5

5 5 5 5

482 596 690 796

796 828 929 1150

3

/

4

3

/

4

3

/

4

3

/

4

Throwaway

6

Step 3 — Field Fabricate Ductwork

On vertical units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. For horizontal

applications, field--supplied flanges should be attached to

horizontal discharge openings and all ductwork secured to the

flanges. Insulate and weatherproof all external ductwork, joints,

and roof openings with counter flashing and mastic in accordance

with applicable codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet

return--air static pressure (a negative condition) shall not exceed

0.35--in. wg with economizer or 0.45--in. wg without economizer.

Step 4 — Make Unit Duct Connections

Vertical Supply/Return Configuration

Unit is shipped in vertical supply/return configuration. Ductwork

openings are shown in Fig. 1 and 3. Attach the ductwork to the

roof curb. Do not attach duct directly to the unit.

!

WARNING

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

injury.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a

90--degree turn in the return ductwork between the unit

and the conditioned space. If a 90--degree elbow cannot

be installed, then a grille of sufficient strength and

density should be installed to prevent objects from

falling into the conditioned space.

Horizontal Supply/Return Applications

Unit can be field--converted from vertical supply/return to

horizontal supply/return. Remove all screws securing horizontal

CONTROL BOX

AND

COMPRESSOR

ELECTRICAL

OPTIONS PANEL

duct covers to duct panel. Save panels. Install duct covers in the

vertical duct openings in the basepan with the insulation side up.

Covers will drop into openings and can be secured using

field--supplied self--tapping screws. Ductwork can be attached to

duct flanges provided on unit. When securing ductwork to unit, do

not drill in area below bead or above top edge of duct opening.

Step 5 — Install External Trap for Condensate

Drain

The unit’s 3/4--in. condensate drain connections are located on the

bottom and side of the unit. If the down drain is used, drill a

minimum of a 5/8-in. diameter hole but not larger than a

diameter hole through the drain pan. A dimple of 2 mm in

diameter and 1.5 mm deep will be provided in the drain pan to help

locate the drill bit and to start the hole. Do not cut through the

PVC pipe threads. Unit discharge connections do not determine

the use of drain connections; either drain connection can be used

with vertical or horizontal applications. See Fig. 2 for locations.

When using the standard side drain connection, make sure the plug

(red) in the alternate bottom connection is tight before installing the

unit. (See Fig. 5.)

To use the bottom drain connection for a roof curb installation,

relocate the factory--installed plug (red) from the bottom

connection to the side connection. A 1/2--in. socket extension can

be used to remove the plug. (See Fig. 5.) The piping for the

condensate drain and external trap can be completed after the unit

is in place.

All units must have an external trap for condensate drainage. Install

a trap at least 4--in. deep and protect against freezeup. If drain line

is installed downstream from the external trap, pitch the line away

from the unit at 1--in. per 10 ft of run. Do not use a pipe size

smaller than the unit connection (3/4--in.). (See Fig. 6 and 7.)

The 50PG units are provided with a removable condensate pan for

ease of cleaning. It is recommended that a union be placed between

the unit and condensate drainage to ease the removal of the pan

during servicing. Adequate clearance should be allowed if removal

of condensate pan is required. Allow 54--in. between condensate

pan access panel and any obstruction for complete removal.

INDOOR MOTOR

ACCESS DOOR

3

/4-in.

50PG03--07

OUTDOOR AIR

SCREEN

(HIDDEN)

ECONOMIZER

HOOD

BAROMETRIC

RELIEF DAMPER

HOOD

BASEPAN CONNECTIONS

ACCESS PANEL

Fig. 4 -- Panel and Filter Locations

FILTER ACCESS DOOR

7

ELECTRIC HEAT

ACCESS DOOR

CONDENSER COIL

ACCESS PANEL

C07272

Loading...

Loading...