Carrier 38AK008, 38AKS009, 38AK012, 38AK007, 38AKS012 User Manual

...

38AK007,008,012

38AKS008,009,012 Air-Cooled Condensing Units

50/60 Hz

Installation, Start-Up and

Service Instructions

CONTENTS

Page SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Step 1 — Complete Pre-Installation Checks . . . . . . 1

•UNCRATE UNIT

•INSPECT SHIPMENT

•CONSIDER SYSTEM REQUIREMENTS

Step 2 — Rig and Mount the Unit . . . . . . . . . . . . . . . . . 4

•RIGGING

•COMPRESSOR MOUNTING

Step 3 — Complete Refrigerant Piping

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

•SIZE REFRIGERANT LINES

•FILTER DRIER AND MOISTURE INDICATOR

Step 4 — Make Electrical Connections . . . . . . . . . . . 6

•FIELD POWER SUPPLY

•FIELD CONTROL WIRING

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-11

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compressor Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Evacuate and Dehydrate . . . . . . . . . . . . . . . . . . . . . . . . . 9

Refrigerant Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compressor Overload. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cycle-LOC™ Device (CLO) . . . . . . . . . . . . . . . . . . . . . . 10

Low-Pressure/Loss-of-Charge Switch (LPS). . . . . 10

High-Pressure Switch (HPS). . . . . . . . . . . . . . . . . . . . . 10

High Flow Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigerant Service Ports . . . . . . . . . . . . . . . . . . . . . . . 10

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Oil Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11,12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Condenser-Fan Adjustment . . . . . . . . . . . . . . . . . . . . . 11

Capacity Control — Unit 38AKS012 Only . . . . . . . . 12

Compressor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Crankcase Heater (Except 38AK007) . . . . . . . . . . . . 12

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . .13,14

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . CL-1, CL-2

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should install or service air-conditioning equipment.

When working on air-conditioning equipment, observe precautions in literature and on tags and labels attached to unit.

NOTE: Ensure voltage listed on unit data plate agrees with electrical supply to unit.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for brazing operations. Have fire extinguisher available. Read these instructions thoroughly. Consult local building codes and National Electrical Code (NEC) (U.S.A. Standard) for special installation requirements.

Before installing or servicing system, always turn off main power to system and install lockout tag on disconnect. There may be more than one disconnect switch. Electrical shock can cause personal injury.

INSTALLATION

The 38AK007, 008, and 012 units use hermetic compressors. The 38AKS008, 009, and 012 units use semi-hermetic compressors. See Table 1A or 1B for physical data.

Step 1 — Complete Pre-Installation Checks

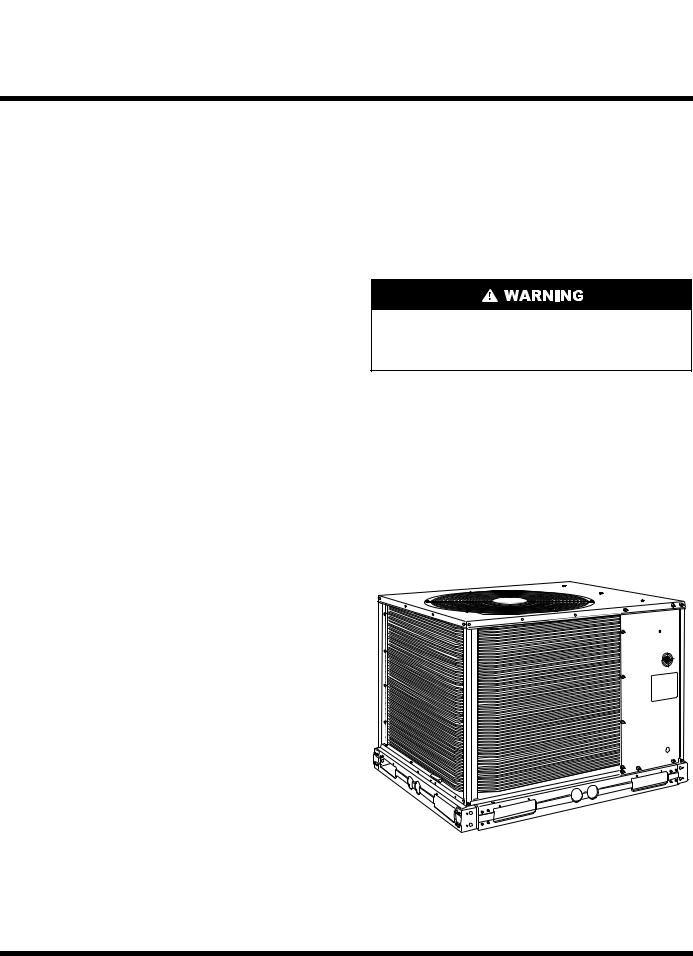

UNCRATE UNIT (See Fig. 1) — Remove unit packaging except for the top skid assembly and wood bumpers, which should be left in place until after unit is rigged into place.

INSPECT SHIPMENT — File claim with shipping company if shipment is damaged or incomplete.

Fig. 1 — Model 38AK (Size 007 Shown)

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book |

1 |

4 |

PC 111 |

Catalog No. 533-80003 |

Printed in U.S.A. |

Form 38A-9SI |

Pg 1 |

5-01 |

Replaces: 38A-8SI |

Tab |

3a |

2a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1A — Physical Data — 50/60 Hz (English)

|

UNIT 38 |

AK007 |

|

AK008 |

|

AK012 |

|

|

|

AKS008 |

|

AKS009 |

|

|

|

AKS012 |

OPERATING WEIGHT (lb) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aluminum Coils (Standard) |

340 |

|

392 |

|

426 |

|

|

|

510 |

|

564 |

|

|

|

564 |

|

Copper Coils (Optional) |

386 |

|

460 |

|

503 |

|

|

|

578 |

|

632 |

|

|

|

632 |

|

RIGGING WEIGHT (lb) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aluminum Coils (Standard) |

390 |

|

442 |

|

476 |

|

|

|

560 |

|

614 |

|

|

|

614 |

|

Copper Coils (Optional) |

436 |

|

510 |

|

553 |

|

|

|

628 |

|

682 |

|

|

|

682 |

|

REFRIGERANT* |

|

|

|

|

R-22 |

|

|

|

|

|

|

|

|

|

|

|

COMPRESSOR |

Bristol, Reciprocating |

|

Copeland, Scroll |

|

Copeland, Scroll |

|

|

Reciprocating, Semi-Hermetic |

||||||||

Quantity...Type |

1...H26A72Q |

|

1...ZR94KC |

|

1...ZR125KC |

|

|

1...06DA818 |

|

1...06DA824 |

|

|

1...06DH824 |

|||

|

|

|

|

|

|

|

(See Note) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quantity Cylinders |

2 |

|

— |

|

— |

|

|

|

4 |

|

|

|

6 |

|||

Speed (rpm) — 60 Hz |

3500 |

|

3500 |

|

3500 |

|

|

|

1750 |

|

|

1750 |

||||

|

— 50 Hz |

|

|

|

|

|

|

|

|

1460 |

|

|

1460 |

|||

Oil Charge (oz) |

65 |

|

85 |

|

110 |

|

|

|

88 |

|

|

128 |

||||

CONDENSER FAN — 60 Hz |

|

|

|

Propeller; Direct Drive |

|

|

|

|

|

|

||||||

Quantity...Rpm |

1...850 |

|

|

|

|

|

1...1100 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||||

Diameter (in.) |

26 |

|

|

|

|

|

26 |

|

|

|

|

|

|

|||

Motor Hp (NEMA) |

1/ |

|

|

|

|

|

3/ |

|

|

|

|

|

|

|||

Nominal Airflow (cfm) |

3 |

|

|

|

|

|

4 |

|

|

|

|

|

|

|||

3800 |

|

6500 |

|

7000 |

|

|

|

6500 |

|

6500 |

|

|

|

6500 |

||

CONDENSER FAN — 50 Hz |

|

|

|

Propeller; Direct Drive |

|

|

|

|

|

|

||||||

Quantity...Rpm |

|

|

|

1...960 |

|

|

|

|

|

|

|

|

|

|||

Diameter (in.) |

|

|

|

26 |

|

|

|

|

|

|

|

|

|

|

||

Motor Hp (NEMA) |

|

|

|

1/ |

|

|

|

|

|

|

|

|

|

|

||

Nominal Airflow (cfm) |

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

||

3150 |

|

5400 |

|

5800 |

|

|

|

5400 |

|

5400 |

|

|

|

5400 |

||

CONDENSER COIL |

|

|

Enhanced Copper Tubes, Aluminum Lanced Fins |

|

|

|

|

|

|

|||||||

Face Area (sq ft) |

12.24 |

|

15.75 |

|

20.5 |

|

|

|

18.0 |

|

18.0 |

|

|

|

18.0 |

|

|

|

|

|

|

|

|

||||||||||

Storage Capacity (lb)† |

11.26 |

|

14.88 |

|

18.87 |

|

|

|

16.56 |

|

16.56 |

|

|

|

16.56 |

|

CONNECTIONS (sweat) |

11/8 |

|

11/8 |

|

11/8 |

|

|

|

11/8 |

|

11/8 |

|

|

|

11/8 |

|

Suction (in.) |

|

|

|

|

|

|

|

|

|

|||||||

Liquid (in.) |

1/ |

|

1/ |

|

5/ |

|

|

|

1/ |

|

5/ |

|

|

|

5/ |

|

|

|

2 |

|

2 |

|

8 |

|

|

|

2 |

|

8 |

|

|

|

8 |

CONTROLS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressurestat Settings (psig) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High |

Cutout |

|

|

|

426 ± |

7 |

|

|

|

|

|

|

|

|

|

|

|

Cut-in |

|

|

|

320 ± 20 |

|

|

|

|

|

|

|

|

|

||

Low |

Cutout |

|

|

|

7 ± |

3 |

|

|

|

|

|

|

|

|

|

|

|

Cut-in |

|

|

|

22 ± |

5 |

|

|

|

|

|

|

|

|

|

|

LEGEND

NEMA — National Electrical Manufacturing Association

*Unit is factory supplied with holding charge only.

†Storage capacity of condenser coil with coil 80% full of liquid R-22 at 124 F.

NOTE: Unit 38AKS012 has one step of unloading. Full load is 100% capacity, and one step of unloading is 67% capacity. Unit 38AKS012 has the following unloader settings: load is 70 ± 1 psig and unload is 60 ± 2 psig.

2

Table 1B — Physical Data — 50/60 Hz (SI)

|

UNIT 38 |

AK007 |

|

AK008 |

|

AK012 |

|

AKS008 |

|

AKS009 |

|

|

AKS012 |

OPERATING WEIGHT (kg) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Aluminum Coils (Standard) |

154 |

|

177 |

|

192 |

|

231 |

|

256 |

|

|

256 |

|

Copper Coils (Optional) |

175 |

|

208 |

|

215 |

|

262 |

|

287 |

|

|

287 |

|

RIGGING WEIGHT (kg) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Aluminum Coils (Standard) |

176 |

|

200 |

|

215 |

|

254 |

|

279 |

|

|

279 |

|

Copper Coils (Optional) |

198 |

|

231 |

|

250 |

|

285 |

|

309 |

|

|

309 |

|

REFRIGERANT* |

|

|

|

|

R-22 |

|

|

|

|

|

|

|

|

COMPRESSOR |

Bristol, Reciprocating |

|

Copeland, Scroll |

|

Copeland, Scroll |

Reciprocating, Semi-Hermetic |

|||||||

Quantity...Type |

1...H26A72Q |

|

1...ZR94KC |

|

1...ZR125KC |

|

1...06DA818 |

|

1...06DA824 |

|

|

1...06DH824 |

|

|

|

|

|

|

|

(See Note 1) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quantity Cylinders |

2 |

|

— |

|

— |

|

4 |

|

|

6 |

|||

Speed (r/s) — 60 Hz |

58.4 |

|

58.4 |

|

58.4 |

|

29.2 |

|

|

29.2 |

|||

|

— 50 Hz |

48.4 |

|

48.4 |

|

48.4 |

|

24.2 |

|

|

24.2 |

||

Oil Charge (L) |

1.92 |

|

2.51 |

|

3.25 |

|

2.60 |

|

|

3.78 |

|||

CONDENSER FAN — 60 Hz |

|

|

|

|

Propeller; Direct Drive |

|

|

|

|

|

|||

Quantity...R/s |

1...14.2 |

|

|

|

|

|

1...18.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Diameter (mm) |

660 |

|

|

|

|

|

660 |

|

|

|

|

|

|

Motor Hp (NEMA) |

1/ |

|

|

|

|

|

3/ |

|

|

|

|

|

|

Nominal Airflow (L/s) |

3 |

|

|

|

|

|

4 |

|

|

|

|

|

|

1800 |

|

3050 |

|

3300 |

|

3050 |

|

3050 |

|

|

3050 |

||

CONDENSER FAN — 50 Hz |

|

|

|

|

Propeller; Direct Drive |

|

|

|

|

|

|||

Quantity...R/s |

|

|

|

1...16.0 |

|

|

|

|

|

|

|||

Diameter (mm) |

|

|

|

660 |

|

|

|

|

|

|

|

||

Motor Hp (NEMA) |

|

|

|

1/ |

|

|

|

|

|

|

|

||

Nominal Airflow (L/s) |

|

|

|

3 |

|

|

|

|

|

|

|

||

1490 |

|

2550 |

|

2750 |

|

2550 |

|

2550 |

|

|

2550 |

||

CONDENSER COIL |

|

|

Enhanced Copper Tubes, Aluminum Lanced Fins |

|

|

|

|||||||

Face Area (sq m) |

1.14 |

|

1.46 |

|

1.90 |

|

1.67 |

|

1.67 |

|

|

1.67 |

|

|

|

|

|

|

|||||||||

Storage Capacity (kg)† |

5.1 |

|

6.75 |

|

8.6 |

|

7.5 |

|

7.5 |

|

|

7.5 |

|

CONNECTIONS (sweat) |

11/8 |

|

11/8 |

|

11/8 |

|

11/8 |

|

11/8 |

|

|

11/8 |

|

Suction (in.) |

|

|

|

|

|

|

|||||||

Liquid (in.) |

1/ |

|

1/ |

|

5/ |

|

1/ |

|

5/ |

|

|

5/ |

|

|

|

2 |

|

2 |

|

8 |

|

2 |

|

8 |

|

|

8 |

CONTROLS |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressurestat Settings (kPa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

High |

Cutout |

|

|

|

2937 ± |

48 |

|

|

|

|

|

|

|

|

Cut-in |

|

|

|

2206 ± 138 |

|

|

|

|

|

|

||

Low |

Cutout |

|

|

|

48 ± |

20 |

|

|

|

|

|

|

|

|

Cut-in |

|

|

|

151 ± |

34 |

|

|

|

|

|

|

|

LEGEND

NEMA — National Electrical Manufacturing Association

*Unit is factory supplied with holding charge only.

†Storage capacity of condenser coil with coil 80% full of liquid R-22 at 51 C. NOTES:

1.Unit 38AKS012 has one step of unloading. Full load is 100% capacity, and one step of unloading is 67% capacity. Unit 38AKS012 has the following unloader settings: load is 483 ± 6.9 kPa and unload is 414 ± 13.8 kPa.

2.Equivalent mm values for connectors are as follows:

in. mm

1/ |

|

12.7 |

2 |

|

15.9 |

5/ |

|

|

8 |

|

28.6 |

11/ |

8 |

3

CONSIDER SYSTEM REQUIREMENTS

•Consult local building codes and NEC for special installation requirements.

•Allow sufficient space for airflow clearance, wiring, refrigerant piping, and unit servicing. See Fig. 2.

•Locate unit so that condenser airflow is unrestricted on all sides and above. Refer to Fig. 2.

•Unit may be mounted on a level pad directly on base rails or mounted on raised pads at support points. See Table 2 for weight distribution based on recommended support points.

NOTE: If vibration isolators are required for a particular installation, use corner weight information in Table 2 to make proper selection.

Table 2 — Weight Distribution

UNIT |

STD UNIT |

CORNER |

CORNER |

CORNER |

CORNER |

|||||||||

W |

|

|

X |

|

Y |

|

Z |

|||||||

38AK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lb |

Kg |

Lb |

|

Kg |

Lb |

|

Kg |

Lb |

|

Kg |

Lb |

|

Kg |

|

|

|

|

|

|

||||||||||

|

|

|

With Aluminum Coil |

|

|

|

|

|

|

|||||

007 |

340 |

154 |

86 |

|

39 |

53 |

|

24 |

77 |

|

35 |

124 |

|

56 |

008 |

392 |

177 |

86 |

|

39 |

78 |

|

35 |

99 |

|

45 |

107 |

|

49 |

012 |

426 |

192 |

89 |

|

40 |

92 |

|

42 |

109 |

|

49 |

105 |

|

48 |

S008 |

510 |

231 |

115 |

|

52 |

89 |

|

40 |

133 |

|

60 |

173 |

|

87 |

S009,S012 |

564 |

256 |

133 |

|

60 |

97 |

|

44 |

141 |

|

64 |

193 |

|

88 |

|

|

|

With Copper Coil |

|

|

|

|

|

|

|||||

007 |

386 |

175 |

106 |

|

48 |

65 |

|

30 |

82 |

|

37 |

133 |

|

60 |

008 |

460 |

208 |

114 |

|

52 |

95 |

|

43 |

108 |

|

49 |

121 |

|

55 |

012 |

503 |

215 |

118 |

|

53 |

116 |

|

53 |

119 |

|

54 |

119 |

|

54 |

S008 |

578 |

262 |

143 |

|

65 |

106 |

|

48 |

142 |

|

64 |

187 |

|

85 |

S009,S012 |

632 |

287 |

161 |

|

73 |

114 |

|

52 |

150 |

|

68 |

207 |

|

94 |

NOTES:

1. Dimensions in [ ] are in millimeters.

2. See Fig. 3 for additional information.

Step 2 — Rig and Mount the Unit

Be sure unit panels are securely in place prior to rigging.

RIGGING — These units are designed for overhead rigging. Refer to rigging label for preferred rigging method. Spreader bars are not required if top crating is left on unit. All panels must be in place when rigging. (See Fig. 3.) As further protection for coil faces, plywood sheets may be placed against sides of unit, behind cables. Run cables to a central suspension point so that angle from the horizontal is not less than 45 degrees. Raise and set unit down carefully.

If it is necessary to roll unit into position, mount unit on rails, using a minimum of 3 rollers. Apply force to rails, not unit. If unit is to be skidded into position, place it on a large pad and drag it by the pad. Do not apply any force to unit.

Raise from above to lift unit from rails or pad when unit is in final position.

After unit is in position, remove all shipping materials and top crating.

COMPRESSOR MOUNTING — Compressors are shipped from the factory held down by 4 bolts. After unit is installed, loosen each bolt until the snubber washer can be moved with finger pressure. See Fig. 4.

Step 3 — Complete Refrigerant Piping Connections — Suction connection is sweat with plastic cap; liquid connection is sweat with plastic cap. Refer to Table 3A or 3B for the proper line sizes. Follow standard piping practices.

SIZE REFRIGERANT LINES — Consider length of piping required between condensing unit and air handler, amount of liquid lift, and compressor oil return. See Table 4A and 4B and also refer to Part 3 of Carrier System Design Manual for design details and line sizing. Refer to air handler installation instructions for additional information.

Table 3A — Refrigerant Piping Sizes — 60 Hz

LINEAR LENGTH OF PIPING — FT (M)

|

|

0-25 |

|

25-50 |

50-75 |

|

75-100 |

|

||||

UNIT |

(0-7.6) |

|

(7.6-15.2) |

(15.2-22.9) |

(22.9-30.5) |

|||||||

38 |

|

|

|

|

Line Size (in. OD) |

|

|

|

|

|||

|

L |

S |

|

L |

S |

L |

S |

|

L |

S |

|

|

AK007 |

1/ |

11/ |

8 |

1/ |

11/ |

1/ |

11/ |

8 |

1/ |

11/ |

8 |

|

|

|

2 |

|

2 |

8 |

2 |

|

2 |

|

|||

AK008 |

1/ |

2 |

11/ |

8 |

1/ |

11/ |

5/ |

11/ |

8 |

5/ |

13/ |

8 |

|

|

|

2 |

8 |

8 |

|

8 |

|

||||

AK012 |

5/ |

11/ |

8 |

5/ |

13/ |

5/ |

13/ |

8 |

5/ |

13/ |

8 |

|

|

|

8 |

|

8 |

8 |

8 |

|

8 |

|

|||

AKS008 |

1/ |

11/ |

8 |

1/ |

11/ |

5/ |

11/ |

8 |

5/ |

13/ |

8 |

|

|

|

2 |

|

2 |

8 |

8 |

|

8 |

|

|||

AKS009 |

5/ |

11/ |

8 |

5/ |

11/ |

5/ |

13/ |

8 |

5/ |

13/ |

8 |

|

|

|

8 |

|

8 |

8 |

8 |

|

8 |

|

|||

AKS012 |

5/ |

11/ |

8 |

5/ |

11/ |

5/ |

13/ |

8 |

5/ |

13/ |

8 |

|

|

|

8 |

|

8 |

8 |

8 |

|

8 |

|

|||

LEGEND

L — Liquid LIne

S — Suction Line

Table 3B — Refrigerant Piping Sizes — 50 Hz

LINEAR LENGTH OF PIPING — FT (M)

|

0-25 |

25-50 |

50-75 |

75-100 |

||||

UNIT |

(0-7.6) |

(7.6-15.2) |

(15.2-22.9) |

(22.9-30.5) |

||||

38 |

|

|

Line Size (in. OD) |

|

|

|||

|

L |

S |

L |

S |

L |

S |

L |

S |

AK007 |

1/2 |

11/8 |

1/2 |

11/8 |

1/2 |

11/8 |

1/2 |

11/8 |

AK008 |

1/2 |

11/8 |

1/2 |

11/8 |

5/8 |

13/8 |

5/8 |

13/8 |

AK012 |

5/8 |

11/8 |

5/8 |

13/8 |

5/8 |

13/8 |

5/8 |

13/8 |

AKS008 |

1/2 |

11/8 |

1/2 |

11/8 |

5/8 |

13/8 |

5/8 |

13/8 |

AKS009 |

5/8 |

11/8 |

5/8 |

11/8 |

5/8 |

13/8 |

5/8 |

13/8 |

AKS012 |

5/8 |

11/8 |

5/8 |

11/8 |

5/8 |

13/8 |

5/8 |

13/8 |

LEGEND

L — Liquid LIne

S — Suction Line

NOTES FOR TABLES 3A AND 3B:

1.Pipe sizes are based on a 2 F (1 C) loss for liquid and suction lines.

2.Pipe sizes are based on the maximum linear length shown for each column, plus a 50% allowance for fittings.

3.Charge units with R-22 in accordance with unit installation instructions.

4.Line size conversion to mm is:

in. |

mm |

1/2 |

12.7 |

5/8 |

15.9 |

11/8 |

28.6 |

13/8 |

34.9 |

4

UNIT 38 |

DIM. A |

DIM. B |

DIM. C |

DIM. D |

DIM. E |

DIM. F |

|

AK007 |

1′-61/2″ |

1′-23/4″ |

— |

1′-21/4″ |

1′-45/16″ |

2′-95/16″ |

|

[470.0] |

[375.0] |

— |

[362] |

[415] |

[846.5] |

||

|

|||||||

AK008 |

1′-8″ |

1′-61/2″ |

— |

1′-3″ |

2′-5/16″ |

3′-57/16″ |

|

[508.0] |

[470.0] |

— |

[381] |

[613] |

[1052.5] |

||

|

|||||||

AK012 |

1′-9″ |

1′-8″ |

2′-0″ |

1′-3″ |

2′-5/16″ |

3′-57/16″ |

|

[533.4] |

[508.0] |

[609.6] |

[381] |

[613] |

[1052.5] |

||

|

|||||||

AKS008 |

1′-6″ |

1′-43/4″ |

2′-913/16″ |

1′-3″ |

2′-5/16″ |

3′-57/16″ |

|

[457.2] |

[425.5] |

[858.8] |

[381] |

[613] |

[1052.5] |

||

|

|||||||

AKS009 |

1′-7″ |

1′-5″ |

2′-913/16″ |

1′-3″ |

2′-5/16″ |

3′-57/16″ |

|

[482.6] |

[431.8] |

[858.8] |

[381] |

[613] |

[1052.5] |

||

|

|||||||

AKS012 |

1′-7″ |

1′-5″ |

2′-913/16″ |

1′-3″ |

2′-5/16″ |

3′-57/16″ |

|

[482.6] |

[431.8] |

[858.8] |

[381] |

[613] |

[1052.5] |

||

|

|||||||

NOTES: |

|

|

|

|

|

|

|

1. Dimensions in [ |

] are in millimeters. |

|

|

|

|

||

2. Center of Gravity. See chart for dimensions.

3.Direction of Airflow.

4.Minimum clearance (local codes or jurisdiction may prevail):

a.Condenser coil, for proper airflow, 36 in. [914] one side, 12 in. [305] the other. The left or rear side getting the greater clearance is optional.

b.Overhead, 60 in. [1524] to assure proper condenser fan operation.

c.Between units, control box side, 42 in. [1067] per NEC (National Electrical Code) (U.S.A. Standard).

d.Between unit and ungrounded surfaces, control box side, 36 in. [914] per NEC.

e.Between unit and block or concrete walls and

other grounded surfaces, control box side, 42 in. [1067] per NEC.

5.With the exception of the clearance for the condenser coil as stated in Note 4b, a removable fence or barricade requires no clearance.

6.Units may be installed on combustible floors made from wood or Class A, B, or C roof covering material.

ELECTRICAL CONNECTIONS

CONNECTION SIZES

AA13/8″ Dia [35] Field Power Supply Hole

BB2″ Dia [51] Power Supply Knockout

CC21/2″ Dia [64] Power Supply Knockout

DD7/8″ Dia [22] Field Control Wiring Hole

SERVICE VALVE CONNECTIONS — 50/60 Hz

UNIT 38 |

SUCTION |

LIQUID |

|

|

|

AK007 |

11/8″ [28.6] |

11/2″ [12.7] |

AK008 |

11/8″ [28.6] |

11/2″ [12.7] |

AK012 |

11/8″ [28.6] |

15/8″ [15.9] |

AKS008 |

11/8″ [28.6] |

11/2″ [12.7] |

AKS009 |

11/8″ [28.6] |

15/8″ [15.9] |

AKS012 |

11/8″ [28.6] |

15/8″ [15.9] |

Fig. 2 — Dimensions (ft-in.)

UNIT |

RIGGING |

|

A |

|

B |

|

C |

||||

WEIGHT* |

|

|

|

||||||||

38 |

|

|

|

|

|

|

|

|

|

|

|

lb |

kg |

in. |

|

mm |

in. |

|

mm |

in. |

|

mm |

|

|

|

|

|

||||||||

AK007 |

390 |

176 |

45.0 |

|

1143 |

38.5 |

|

978 |

35.5 |

|

904 |

AK008 |

442 |

200 |

45.0 |

|

1143 |

38.5 |

|

978 |

43.5 |

|

1105 |

AK012 |

476 |

215 |

45.0 |

|

1143 |

38.5 |

|

978 |

43.5 |

|

1105 |

AKS008 |

560 |

254 |

45.0 |

|

1143 |

38.5 |

|

978 |

43.5 |

|

1105 |

AKS009 |

614 |

279 |

45.0 |

|

1143 |

38.5 |

|

978 |

43.5 |

|

1105 |

AKS012 |

614 |

279 |

45.0 |

|

1143 |

38.5 |

|

978 |

43.5 |

|

1105 |

*Weights are for aluminum coils.

Fig. 3 — Rigging Label

5

Loading...

Loading...