Carrier 30H User Manual

Carrier Parkway • Syracuse NY 13221

Reciprocating Heat Reclaim Units

60-Hertz

CONTENTS

Page

INSTALLATION ...................................................................1

Step 1 — Inspect the Shipment

........................................

1

Step 2 — Rig and Place the Unit......................................1

RIGGING......................................................................1

PLACEMENT...............................................................1

Step 3 — Check Compressor Mounting &

Connections

......................................................................

1,2

SERVICE ACCESS

......................................................

3

Step 4 — Make Piping Connections.................................3

CONDENSER DESCRIPTION

...................................

3

TOWER CONDENSER PIPING

................................

3

HEAT RECLAIM CONDENSER PIPING .. 3

COOLER DESCRIPTION...........................................4

COOLER PIPING

........................................................

4

Step 5 — Make Electrical Connections

...........................

4

ELECTRICAL BOX, CONTROL SECTION . 5

ELECTRICAL BOX, POWER SECTION ... 5

START-UP AND SERVICE.................................................5

INITIAL CHECK..................................................................5

Check Refrigerant Charge................................................6

LIQUID CHARGING METHOD

...............................

6

Check Oil Charge

..............................................................

6

TO ADD OIL.................................................................6

TO REMOVE OIL........................................................6

START-UP AND OPERATION CHECKS

.........................

6

Check Refrigerant Feed Components

.......................

THERMOSTATIC EXPANSION VALVE

FILTER-DRIER

.....................................................

MOISTURE-LIQUID INDICATOR

....................

LIQUID-LINE SERVICE VALVE

.......................

PRESSURE RELIEF DEVICES

...........................

Page

. .7

,.7

Check Compressor Protection Devices ....

CIRCUIT BREAKER

........................................

DISCHARGE TEMPERATURE

THERMOSTAT

................................................

CRANKCASE HEATER

...................................

TIME GUARD® CONTROL

............................

FOUR FUNCTION TIMER

..............................

OIL PRESSURE SAFETY SWITCH (OPS) .8

Check Unit Safety Devices

................................................

8

SAFETY THERMOSTAT

...........................................

8

HIGH-PRESSURE SWITCH

......................................

9

LOW-PRESSURE SWITCH

.......................................

9

Check Capacity Control System

......................................

9

DESCRIPTION .............................................................9

4-STEP TEMPERATURE CONTROLLER .. 9

DESIGN SETPOINT ADJUSTMENT

......................

10

CYLINDER UNLOADING SYSTEM

......................

10

UNIT OPERATION ............................................................. 11

Control Power.................................................................. 11

Control Sequence............................................................. 11

Stoppage and Restart...................................................... 11

SERVICING THE COOLER

............................................

11,12

Tube Plugging................................................................... 12

Retubing

...........................................................................

12

Tightening Cooler Head Bolts......................................... 12

GASKET PREPARATION

........................................

12

BOLT TORQUES

.......................................................

12

BOLT TIGHTENING SEQUENCE

.........................

13

TROUBLESHOOTING GUIDE

...................................

14,15

INSTALLATION

Step 1 — Inspect the Shipment

Inspect the unit for damage or missing parts. If

damage is detected, or if shipment is incomplete,

file a claim immediately with the shipping company.

Step 2 — Rig and Place the Unit

RIGGING

On each end of the cooler, a steel loop is pro

vided for the preferred method of lifting the unit.

Use spreader bars to keep cables away from the

compressor enclosure and control box. If unit is to

be moved by fork truck, use the following methods:

1. From the front or rear, lift under the cooler rails.

Unit can be either on or off the skid.

2. When moving from the ends, leave the unit on the

skid. Lift from under the skid.

If unit is to be dragged or rolled into final posi

tion, leave it on the skid; apply force only to the skid,

not the unit. When rolling, use a minimum of 3

rollers.

PLACEMENT

When the unit is in final position, remove the

skid, level the unit with a spirit level and bolt to

the floor or pad.

These units are not suitable for unprotected

outdoor use.

Carrier recommends that these units be located in

the basement or on the ground floor. However, if it

is necessary to locate the unit on an upper floor, be

sure the structure has been designed to support the

weight. If necessary, add structural support to the

floor. Also, be sure the surface for installation is

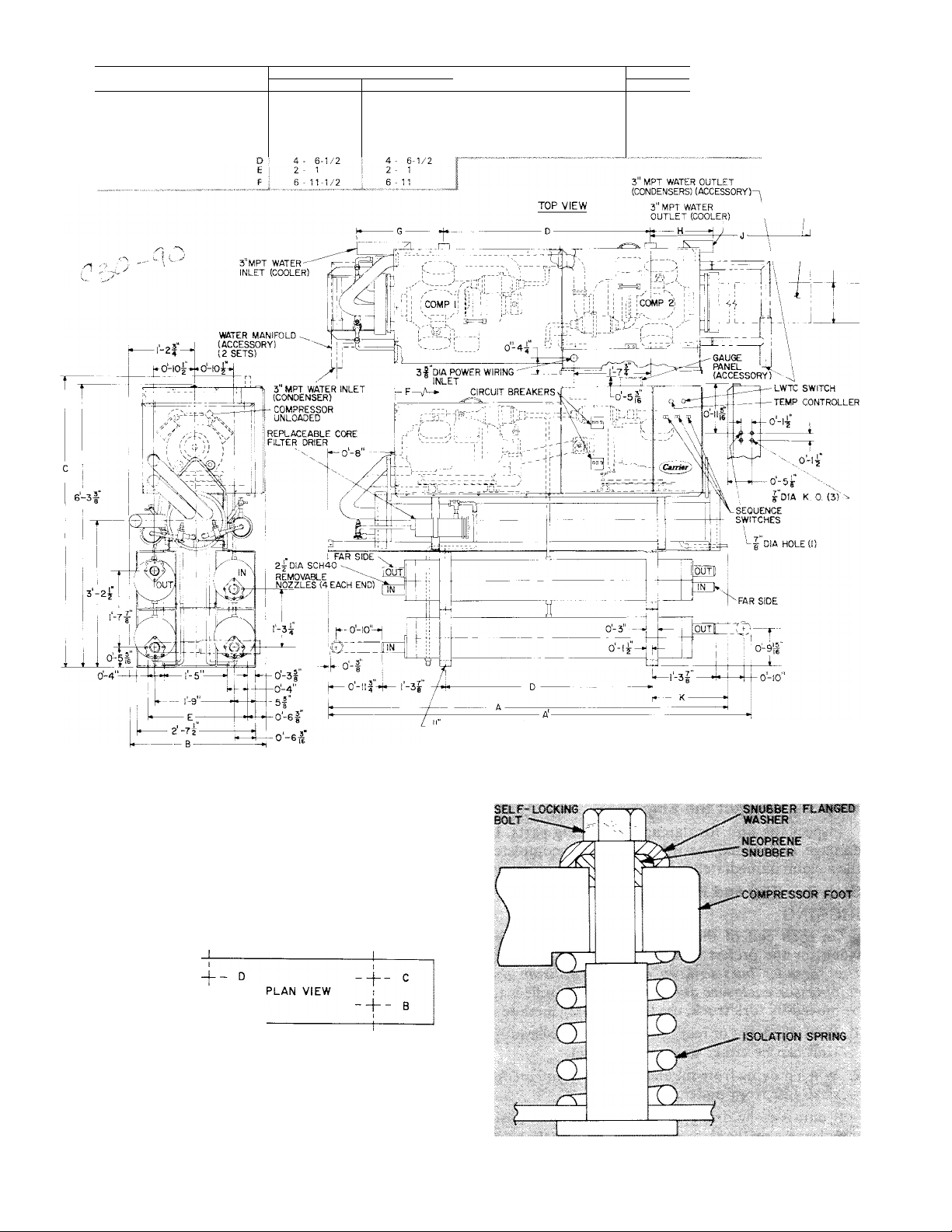

level. Refer to Fig. 1 for space requirements and

Table 1 for weight distribution.

Only electrical power connections and water con-„

nections for condensers and cooler are required for

installation.

Step 3 — Check Compressor Mounting and

Connections — As shipped, compressor is held

down by special self-locking bolts and plain lock

washers. After unit is installed, remove the self-

© Carrier Corporation 1979

Form 30H-1S1

UNIT DIMENSIONS

DIMENSION

30H

1 DIMENSION

040 050,060 040

LENGTH 1 toe. CHILLED WATER CONN.

8«stc Unit

A

8 - 1-7/16 8

7

1 Inlet

G 1 - 6

With Cond. Manifolds

A’ 9 1-3/4

9 2-1/8

1 Outlet H

0-111

WIDTH B

2 - 11-3/8

2

11-3/8 SPACE FOR COOLER TUBE

HEIGHT

c

6 - 7-3/16 6 7-3/16 i REMOVAL (Either End)

J 7 - 6

BETWEEN MTG HOLES

1 LOG. COOLER DRAIN

K

1 - 2-1

050,060

1 - 11-1/2

1 - 5

Length

Width

BETWEEN LIFT ANGLES

SPACE REQUiRED

FOR REMOVABLE

OF COOLER TUBES

\ (EITHER END)

O'-iij DIA

r TUBE

I

BUNDLE

(COOLER)

LEFT SIDE VIEW

- DiA MTG HOLES (8)

FRONT VIEW

Fig. 1 — Unit Dimensions {30H050,060 shown} f\

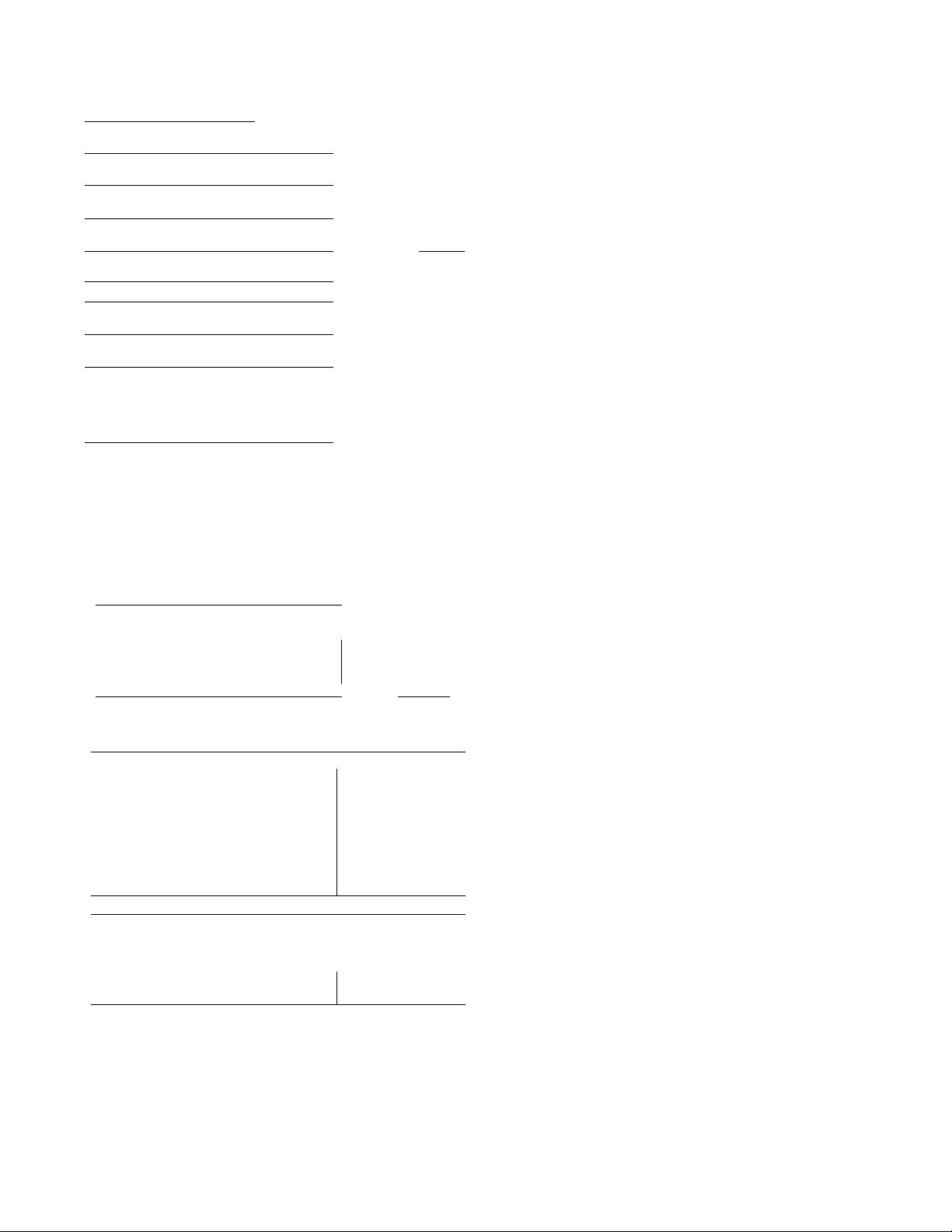

Table 1 — Weight Distribution (lb)

UNIT

30H

APPROXIMATE

OPERATING WT

APPROXIMATE LOAD

AT EACH MTG HOLE

{A, B, C, D)

040

050

060

3930

4310

983

l078“

4440 1110

LOCATION OF MOUNTING HOLES;

WATER-

INLET

END - + - A

FRONT

locking bolts one at a time and reassemble with

flanged washers and neoprene snubbers as shown in

Fig. 2. Special flanged washers and neoprene

snubbers are shipped in a cloth bag tied to one of the

compressor feet. Tighten all 4 bolts. Then loosen

each until the flanged washer can be moved sideways

with finger pressure.

Fig. 2 — Compressor Mounting

COMPLETE UNIT

Tabie 2 — Physical Data

UNIT ЗОН

040 050 060

APPROX OPER WT (lb)

:3930

4310 4440

REFRIG CHG, R-22 (lb) Ckt 1

52

■ 62 62

Ckt 2

52 : 52

62

COMPRESSOR 06E Ckt 1

B250

J275 J275

Ckt 2

B250 B250

J275

Cylinders/Compressor

Ckt 1

4

6 6

Ckt 2 : 4 4 6

Unloaders/Compressor

Ckt 1

^ 1 1 1

Ckt 2 ' 1 1 1

Oil Chg Per Compressor (pt) Ckt 1 14

19 19

Ckt 2

' 14 14 19

Capacity Control Steps

: 4 4 4

TOWER CONO, 09RP Ckt 1 022 027 027

Ckt 2 022

; 022 027

HEAT RECLAIM COND, 09RP Ckt 1 022

Ckt 2 022

MAX DESIGN WORK. PRESS, (psig)

Cooler 1

Water Side 150

Refrig Side

235

Tower Condensers j

Water Side

250

Refrig Side

385

COOLER

COOLER, 10HA400

unît зон

SHELL, Net Volume (gal.)

1^

040

13.1

154

TUBES

050, 060

..

iCopper, Internai Fins

00 X Wall Thickness (in.)

5/8 X 0.025

Number 129

129

Length (in.) 74.5 5

85.5

Effective Outside Surface Area (sq ft) i

126.6 )

146.0

REFRIG CIRCUITS

CONNECTIONS (in.)

2 2

X (In and Out

Water ir-. •

(Drain

3

3/4

3

3/4

1.125

1.125

1.625

2.125

CONDENSERS

CONDENSER 09RP (See Note)

022

027

TUBES Copper, Interna! Fins

OD (in.)

Wall Thickness (in.)

3/4

Plain End .042

Finned Section

.028

Length (in.)

70-5/32

Fins/in. 40

Number Tubes*

36 ! 44

Surface Area (sq ft)

1 Inside

iOutside

32.9 ‘ 40.2

133.6 163.4

NO. WATER PASSES

3

CONNECTIONS (in.)

I Inlet (IPS)

1 Outlet (IPS)

2-1/2

2-1/2

Relief Valve Outlett (SAE) 5/8

Liquid Outlet (OOF)

t

7/8

Hot Gas (OOF) 1-3/8

*!n Tower condensers, 5 of the tubes are n subcooling section.

tNot on Heat Reclaim Condensers.

NOTE: Heat Reclaim Condensers same as Tower Condensers

except where noted. The bottom outlet of each Heat Reclaim

Condenser is same size as Hot Gas connection.

C .'\r flON; He Mire ip-lcreunnuciiti!: pipi,ni.;ind

electrical conduits are suspended free of contact

with ar.y adiacent walls and be sure taiit capil

laries are not rubbing against anything.

SERVICE ACCESS

Remove the combination top and back cover over

each compressor. Servicing can be performed from

either top or back. For rear access, allow approxi

mately 3 ft of clear space behind unit.

Step 4 — Make Piping Connections

CONDENSER DESCRIPTION

In the 4-condenser bundle, the lower 2 are Tower

and the upper 2 are Heat Reclaim. All are shell and

tube type with removable heads for easy tube servic

ing. Each Tower condenser has an internal sub

cooler designed to provide 12 F to 15 F total

liquid subcooling at average tower water condi

tions. The Heat Reclaim condensers do not require

subcooling, therefore, the subcooler baffling is

removed. For further condenser data, refer to

Table 2 — Physical Data.

TOWER CONDENSER PIPING

Provide means for draining system in winter and

for maintenance.

iMPOR r.\N 1 ; Ci):!üc!>er wa'.ur nvj'.t a;

the bottom for proper operation of the internal .

subcooler, which is in the bottom of the con

denser (Fig. 1).

Water supply lines should be sized according to

the required flow rate for operation at design con

ditions (not necessarily connection size). Use flexi

ble connections to reduce vibration transmission.

A cooling tower bypass valve is usually used to

regulate the temperature of the water entering the

condensers. This may be controlled by sensing either

outdoor air temperature or temperature of water

leaving the Heat Reclaim condensers. For further

information on Systems Controls, refer to the Engi

neering Guide for Reciprocating Chiller Heat

Reclaim Systems.

HEAT RECLAIM CONDENSER PIPING

Normally, the piping is for series water flow thru

the condensers. Piping to and from the condensers is

connected to the heating system of the building.

Piping for parallel water flow thru the condensers is

used only when the cooling load is constant at all

times. For further piping information, refer to the

Engineering Guide for Reciprocating Chiller Heat

Reclaim Systems.

Figure 1 shows connections for series piping thru

the Heat Reclaim condensers.

CAUTION; Retìghten all condenser head bolts

before filling system with water. Torque bolts

to 150-170 Ib-ft.

Water leaving condenser is under pressure and

should not be connected directly into sewer lines.

Check local codes. A 3/8-in. drain plug is located in

the head at each end of the condenser.

Refer to Pressure Relief Devices concerning con

nections for these components.

COOLER DESCRIPTION

The cooler is a direct-expansion type with remov

able heads and is partitioned for multi-pass refrig

erant flow. The water flow across the tube bundle

is directed by baffles designed for minimum water-

pressure drop. The tubes have integral internal fins

for maximum heat transfer efficiency.

Viewed from the front of the unit, the chilled

water enters (returns) at the left end of the cooler and

leaves at the right end. The sensing bulb for the

factory-set water temperature controller is located

in the return-water nozzle; the return-water tem

perature being the control point. The sensor for the

low water-temperature cutout is located in the

leaving water nozzle.

The cooler is insulated with a flexible, closed

cell plastic foam insulation of suitable thickness.

Water vapor cannot penetrate the cellular structure

to condense either within the cells or on the cooler

shell. Thus, the insulation itself is a vapor barrier.

Because of the toughness of the insulation, a pro

tective sheet metal covering is not necessary.

The standard cooler can be used for all glycol

brines down to -20 F. However, for calcium or

sodium chloride brines, it is important that the

proper inhibitors be carefully selected for protection

of the copper tubes. Refer to publications of the

Calcium Institute or the Mutual Chemical Division

of Allied Chemical Corporation for information

on corrosion control in calcium or sodium chloride

systems.

COOLER PIPING

Plan piping for minimum number of changes in

elevation. Install manual or automatic vent valve at

high points in line. Maintain system pressure by

using a pressure tank or combination relief and

reducing valve.

See Carrier System Design Manual, Part 3,

Piping Design, for chilled water piping detials.

Install thermometers in entering and leaving

water lines. Provide drain connections at all low

points to permit complete drainage of system.

Connect shutoff valve to drain line before operating

unit. Install shutoff valves near entering and

leaving water connections. Use flexible connections

to reduce vibration transmission.

Insulate piping after leak testing to prevent heat

transfer and sweating. Cover insulation with mois

ture seal.

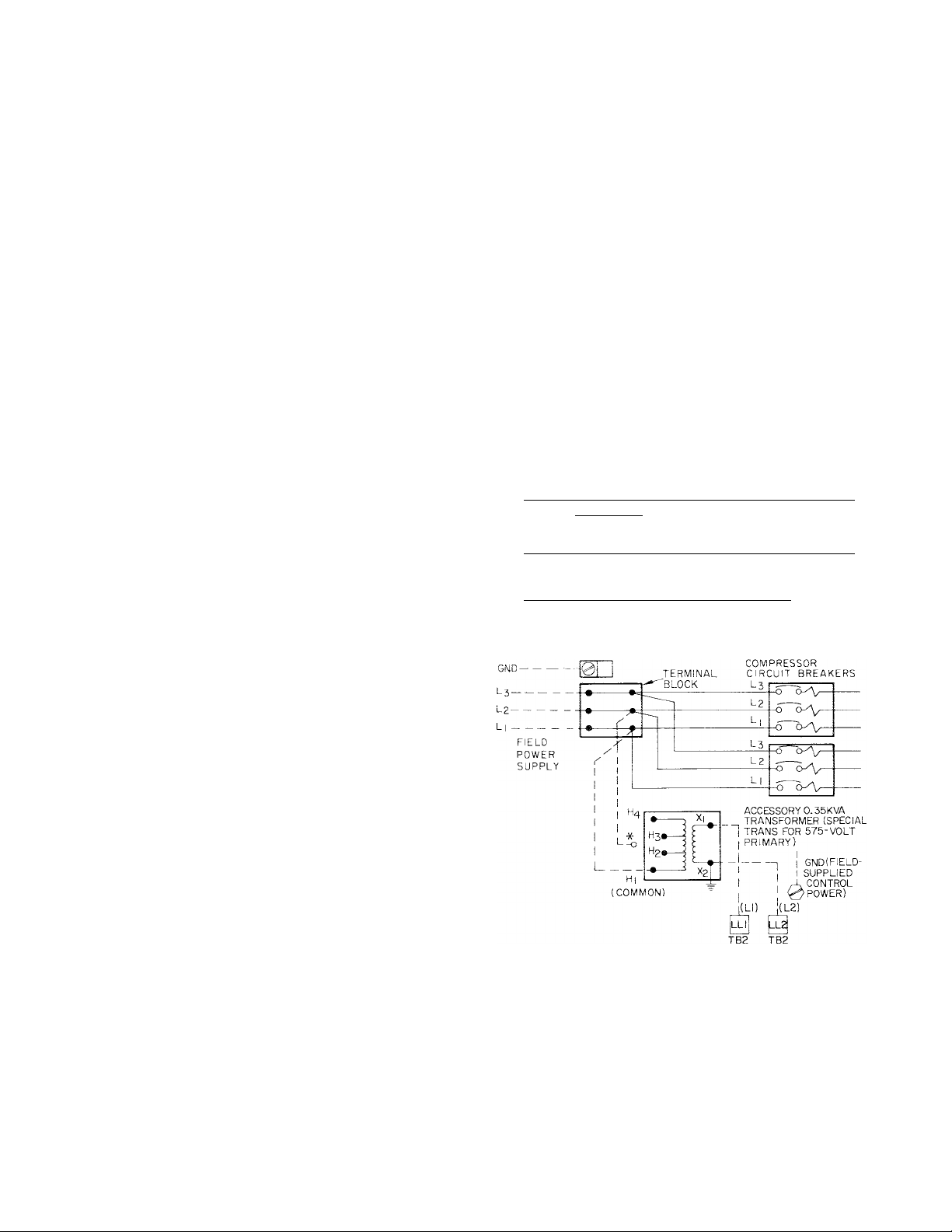

All field wiring must conform with local code

requirements. Control circuit is 115 volts on all

60-Hertz units. Accessory transformer package is

available to allow 115 volts to be taken directly from

unit terminal block (see Fig. 3). Installation instruc

tions are furnished with the accessory package. Con

trol power may also be supplied from a separate

source thru a 15-amp fused disconnect.

Inside the control box, provision is made to

connect the ground wire which must be installed

with each field power supply.

All units are factory supplied with across-the-line

start at all voltages.

Refer to Table 4 for electrical data on individual

compressors and complete units and compressor

usage.

LABEL DIAGRAMS

The applicable Label Diagrams for the 30H040,

050,060 Heat Reclaim units are the same as for the

standard 30HK040,050,060 units.

Table 3 — Unit Voltage and Model Number

Step 5 — Make Electrical Connections

UNIT

30H

VOLTS

230 i

Model*

460

575

200

.....

040 ! 420

: 520 1

620 120

050 i 420

520 ‘

620 > 120

060 420 520 I 620 120

*Last 3 digits of complete mode! number.

EQUIP GND

WHEN CONTROL CIRCUIT POWER IS FROM SEPARATE SOURCE

INCOMING WIRES ARE CONNECTED DIRECTLY TO

TERMINALS

LL! AND

LL2

ON TB2.

±2 MUST BE

CONNECTED TO NEUTRAL (GROUND) POTENTIAL.

CB — Circuit Breaker

EQUIP GIMD — Equipment Ground

TB — Terminal Board

*Appropriate transformer terminal depends on unit voltage,

instructions with accessory transformer package. H2 = 200 v;

H3 = 230 v; H4 = 460 v.

NOTE: For grounding 1 1 5-voit control circuit when transformer is

used, see instructions with accessory transformer package.

Fig. 3 — Wiring Schematic — Unitand Control

Power Supply

COMPLETE UNIT

Table 4 — Electrical Data; 3-Phase, 60-Hertz

Nameplate

VOLTS

200 230 460

575

06E COMPR

Supply Range"

180-229

207-264 414-528

518-660

USAGEt

Max

Max Max

Max

UNIT 30 MKW

MCA

Fuse

MCA

Fuse MCA

Fuse MCA Fuse

Cl rcuit

Amps

Amps Amps

Amps

l' (l(^''' 2'{R) /^

040 50.4

194

250

167 225

84

110 68 90 B250 B250

H 050

61.1 230

300

207 300

104

150

84

125

I

J275 B250

060 71.8 259 350

239

300 120 150 97

125

J275 ; J275

INDIVIDUAL COMPRESSORS

COMPR

200 V

230 V

460 V

...

575

........................

UNIT 30

nctr KW

06 E

RLA LRA ; MTA

RLA LRA MTA RLA

LRA

MTA RLA LRA MTA

; 040 250 (2) 25 2 86 345

; eo..; 74 300

102

37 150 50 30 120 42

275 (L) 35.9 11 5 506

' 80 "

106 440

"i 72

..........

''

53 220 73 43 176 58

П L/OU

250 (R) 25.2 86 345

74 300 ; 102 37 150 50 30

; 120 42

060 275 (2) 35.9 115 506

Í" 80" 106 440

1

......

72 ' 1 53 220 73 43 176 : 58

6-Pole Breakers: values shown are for each 3-poie

section.

KW — Maximum Power Input (compressor)

LRA — Locked Rotor Amps

MCA — M inimum Circuit Amps. Complies with National Elec

trical Code (NEC), Section 430-24.

MKW — Unit Power Input at operating conditions of 50 F Leaving

Chilled Water Temperature (44 F Saturated Suction

Temperature) and 145 F Saturated Discharge

Temperature.

MTA — Must Trip Amps (Factory-installed circuit breaker)

RLA — Rated Load Amps

*Untts are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the range

limits shown.

fPrefix: B, J = 1 electric unloader.

ELECTRICAL BOX CONTROL SECTION

Inside this section are: relays, high- and low-

pressure cut-outs, low water-temperature cut-out,

timer, terminal strips and a 4-step temperature

controller. On the outside (control panel) are: con

trol circuit ON-OFE switch, partial load switch,

compressor transfer switch, compressor run light,

safety trip lights and control circuit fuse. The control

panel is hinged to provide easy access to the controls

inside.

ELECTRICAL BOX, POWER SECTION

The main electrical power supply is brought in

thru the top of the electrical box, on the left-hand

side (see Fig. 1). The hole is suitable for accommo

dating 3-in. conduit. Pressure-lug connections on

the terminal block are suitable for copper, copper-

clad aluminum or aluminum wire.

In this section are: main power terminal block,

compressor circuit breakers with calibrated mag

netic trip (for compressor motor overload and

locked rotor protection) and compressor motor con

tactors. The panel over this section is secured with

screws as a safety measure against casual entry for

purposes other than service.

START-UP AND SERVICE

WARNING: Shut off all power to the unit

before proceeding with any service work.

INITIAL CHECK

Do not start the liquid chiller even momentarily

until the following steps have been completed.

1. Check all auxiliary components such as chilled

liquid circulating pump, cooling tower if used,

air handling equipment, or other equipment to

which the chiller supplies liquid. Consult the

manufacturer’s instructions.

2. Check safety thermostat. See Safety

Thermostat.

3. Determine if there is a refrigerant charge in the

system. See Check Refrigerant Charge.

4. Backseat (open) compressor suction and dis

charge shutoff valves.

5. Open liquid line shutoff valves.

6. Fill chilled liquid circuit completely with clean

water or other noncorrosive fluid to be cooled.

Bleed all air out of high points of system.

7. Fill cooling tower for condenser cooling water.

8. Set temperature controller.

9. Check tightness of all electrical connections..

10. Check compressor oil (should be visible in

bull’s-eye). Refer to Check Oil Charge.

11. Be sure crankcase of each compressor is warm

(heaters should be on for 24 hours before

starting compressors).

12. Be sure compressors are floating freely. See

INSTALLATION, Step 3.

Loading...

Loading...