Briggs & Stratton 210000, 200000, 120000, 150000 User Manual 2

en

es

fr

Operator’s Manual Manual del Operario Manuel de l’opérateur

|

|

||

Reproduction |

|

||

|

for |

|

|

|

Model 120000 |

Snow Seriest |

|

|

|

150000 |

Professional Seriest |

Not |

|

200000 |

|

|

|

210000 |

|

Copyright E 2012 Briggs & Stratton Corporation, Milwaukee, WI, USA. All rights reserved.

Briggs & Stratton is a registered trademark of Briggs & Stratton Corporation.

English |

Español |

Français |

Form No. 279128TRI

Revision: E

en |

|

es |

|

fr |

|

|

|

|

|

1 |

|

H |

|

|

|

K |

|

|

C |

|

D |

|

|

H |

I |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

F |

|

|

|

|

M |

A |

|

E |

|

|

|

|

|

|

L |

|

|

|

|

||

|

|

|

|

|

|

|

|

B |

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

G |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

N |

|

K |

|

|

|

|

|

|

S |

|

|

|

Q |

|

|

|

|

|

|

|

|

|

|

|

|

for |

G |

F |

|

|

|

J |

|

|

|

|

P |

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

2 |

|

B |

|

|

3 |

|

A |

|

|

|

|

B |

|

|

|

|

|

Not |

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

D |

|

|

|

|

E |

Reproduction |

|

|

|||

|

|

|

|

||||

4 |

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J |

|

|

|

|

|

|

C |

|

A |

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

D |

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

BRIGGSandSTRATTON.COM |

|

5 |

|

|

|

I |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

K |

|

|

|

|

|

6 |

|

|

|

|

7 |

|

B |

A |

|

|

|

|

|

|

|

||

|

|

Reproduction |

|

|

||||

C |

A |

|

A |

|

||||

|

|

for |

|

|

|

|||

|

|

|

|

|

|

|||

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

Not |

|

|

|

|

|

8 |

|

|

|

9 |

|

D |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

A |

|

|

|

C |

|

|

|

|

|

E |

|

F |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

G |

|

|

|

J |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

H |

10 |

|

|

|

|

11 |

|

|

A |

|

|

|

|

|

|

|

|

|

A |

A |

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

General Information

This manual contains safety information to make you aware of the hazards and risks associated with engines and how to avoid them. It also contains instructions for the proper use and care of the engine. Because Briggs & Stratton Corporation does not necessarily know what equipment this engine will power, it is important that you read and understand these instructions and the instructions for the equipment. Save these original instructions for future reference.

For replacement parts or technical assistance, record below the engine model, type, and code numbers along with the date of purchase. These numbers are located on your engine (see the Features and Controls page).

Date of purchase:

MM/DD/YYYY

Engine model:

Model: Type: Code:

|

Power Rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Briggs & Stratton Engines are not designed for and are not to be used to power: |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

fun-karts; go-karts; children’s, recreational, or sport all-terrain vehicles (ATVs); |

||||||||

|

The gross power rating for individual gas engine models is labeled in accordance with |

|

|

|

motorbikes; hovercraft; aircraft products; or vehicles used in competitive events not |

|||||||||||||||||||||||||

|

|

|

|

sanctioned by Briggs & Stratton. For information about competitive racing products, |

||||||||||||||||||||||||||

|

SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

see www.briggsracing.com. For use with utility and side-by-side ATVs, please contact |

||||||||||||||||||||||||||

|

Rating Procedure), and rating performance has been obtained and corrected in |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

Briggs & Stratton Engine Application Center, 1-866-927-3349. Improper engine |

||||||||||||||||||||||||||

|

accordance with SAE J1995 (Revision 2002--05). Torque values are derived at 3060 |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

application may result in serious injury or death. |

||||||||||||||||||||||||||

|

RPM; horsepower values are derived at 3600 RPM. The gross power curves can be |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

viewed at www.BRIGGSandSTRATTON.COM. Net power values are taken with exhaust |

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||

|

and air cleaner installed whereas gross power values are collected without these |

|

|

|

|

|

|

|||||||||||||||||||||||

|

attachments. Actual gross engine power will be higher than net engine power and is |

|

|

|

NOTICE: This engine was shipped from Briggs & Stratton without oil. Before you start |

|||||||||||||||||||||||||

|

affected by, among other things, ambient operating conditions and engine--to--engine |

|

|

|

the engine, make sure you add oil according to the instructions in this manual. If you |

|||||||||||||||||||||||||

|

variability. Given the wide array of products on which engines are placed, the gas engine |

|

start the engine without oil, it will be damaged beyond repair and will not be covered |

|||||||||||||||||||||||||||

|

may not develop the rated gross power when used in a given piece of power equipment. |

|

under warranty. |

|||||||||||||||||||||||||||

|

This difference is due to a variety of factors including, but not limited to, the variety of |

|

|

|

|

|

|

|||||||||||||||||||||||

|

engine components (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), |

|

|

|

|

|||||||||||||||||||||||||

|

application limitations, ambient operating conditions (temperature, humidity, altitude), and |

|

|

|

|

|||||||||||||||||||||||||

|

engine--to--engine variability. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Due to manufacturing and capacity limitations, Briggs & Stratton may substitute an |

|

|

|

|

|

|

|||||||||||||||||||||||

|

engine of higher rated power for this Series engine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

for |

WARNING |

|||||||||||||||||||

|

Operator Safety |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Fuel and i s vapors are extremely flammable and explosive. |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fire or explosion can cause severe burns or death. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

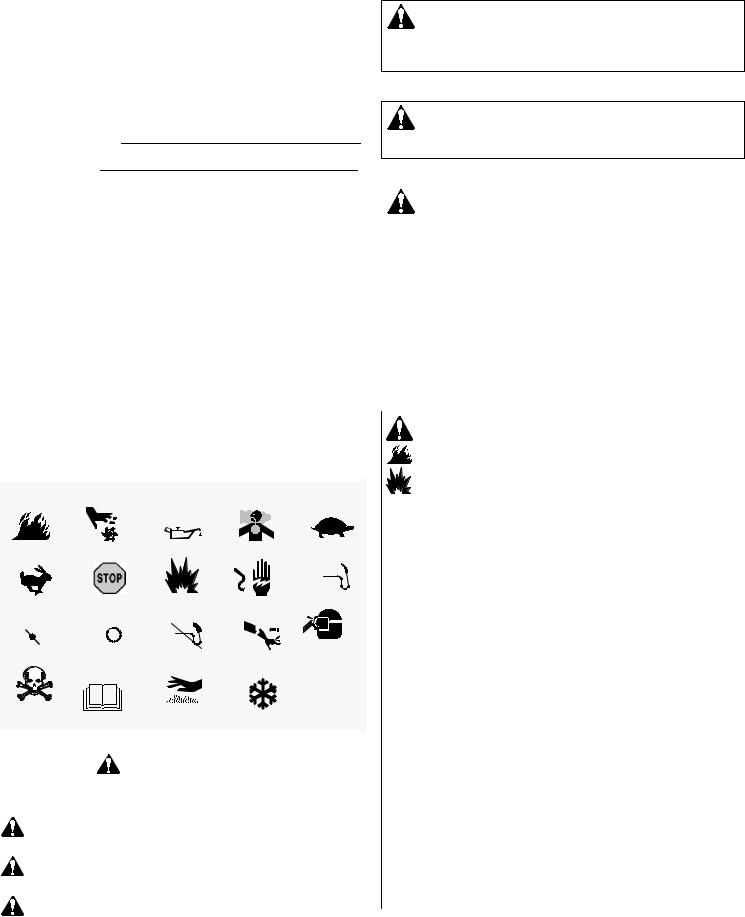

SAFETY AND CONTROL SYMBOLS |

|

|

|

|

|

|

|

|

|

When A ing F el |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T rn engine off and let engine cool at least 2 minutes before removing the fuel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cap. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fill fuel tank outdoors or n well-ventilated area. |

|

|

|

Fire |

Moving Parts |

|

|

|

Oil |

Toxic Fumes |

|

Slow |

|

|

|

Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Not |

|

|

|

|

|

|

|

|

bottom of the fuel tank neck. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sources. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. |

||

|

|

Fast |

|

|

Stop |

|

|

Explosion |

|

Shock |

|

Fu l |

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Replace if necessary |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If fuel spills, wait until it evaporates before starting engine. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When Starting Engine |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wear Eye |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Kickback |

|

|

|

Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in |

|||||||||

|

Choke |

|

On Off |

|

|

Fuel Shutoff |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

Protection |

|

|

|

|

place and secured. |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not crank engine with spark plug removed. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reproduction |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(if equipped) to FAST position and crank until engine starts. |

|

|

Hazardous |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When Operating Equipment |

||||

|

Read Manual |

Hot Surface |

|

Frostbite |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

Chemical |

|

|

|

|

|

|

|

|

|

|

Do not tip engine or equipment at angle which causes fuel to spill. |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not choke the carburetor to stop engine. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Never start or run the engine with the air cleaner assembly (if equipped) or the |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

air filter (if equipped) removed. |

|

|

The safety alert symbol |

is used to identify safety information about hazards that can |

|

When Changing Oil |

||||||||||||||||||||||||||

|

result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with the |

|

When you drain the oil from the top oil fill tube, the fuel tank must be empty or |

|||||||||||||||||||||||||||

|

alert symbol to indicate the likelihood and the potential severity of injury. In addition, a hazard |

|

||||||||||||||||||||||||||||

|

|

|

fuel can leak out and result in a fire or explosion. |

|||||||||||||||||||||||||||

|

symbol may be used to represent the type of hazard. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

When Tipping Unit for Maintenance |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

DANGER indicates a hazard which, if not avoided, will result in death or |

|

|

|

When performing maintenance that requires the unit to be tipped, the fuel tank |

||||||||||||||||||||||||

|

|

|

|

|

|

must be empty or fuel can leak out and result in a fire or explosion. |

||||||||||||||||||||||||

|

|

serious injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When Transporting Equipment |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

WARNING indicates a hazard which, if not avoided, could result in death or |

|

Transport with fuel tank EMPTY or with fuel shut-off valve OFF. |

||||||||||||||||||||||||||

|

|

|

When Storing Fuel Or Equipment With Fuel In Tank |

|||||||||||||||||||||||||||

|

|

serious injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Store away from furnaces, stoves, water heaters or other appliances that have |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

CAUTION indicates a hazard which, if not avoided, could result in minor or |

|

|

pilot lights or other ignition sources because they can ignite fuel vapors. |

|||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

moderate injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

NOTICE indicates a situation that could result in damage to the product.

4 |

BRIGGSandSTRATTON.COM |

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

If there is natural or LP gas leakage in area, do not start engine.

Do not use pressurized starting fluids because vapors are flammable.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.  Breathing carbon monoxide can cause nausea, fainting or death.

Breathing carbon monoxide can cause nausea, fainting or death.

Start and run engine outdoors.

Do not start or run engine in enclosed area, even if doors or windows are open.

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

Allow muffler, engine cylinder and fins to cool before touching.

Remove accumulated debris from muffler area and cylinder area.

It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the exhaust system is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order. Other states or federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a spark arrester designed for the exhaust system installed on this engine.

|

WARNING |

WARNING |

Unintentional sparking can result in fire or electric shock. |

Rapid retraction of starter cord (kickback) will pull hand and arm |

Unintentional start-up can result in entanglement, traumatic |

toward engine faster than you can let go. |

amputation, or laceration. |

Broken bones, fractures, bruises or sprains could result. |

Fire hazard |

When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.

Remove all external equipment/engine loads before starting engine. |

|

|

|

|

|

|

|

|

Direct-coupled equipment components such as, but not limited to, blades, |

|

|

|

|

|

|

|

|

|

Reproduction |

|||||||

impellers, pulleys, sprockets, etc., must be securely attached. |

|

|

Before performing adjustments or repairs: |

|||||

|

|

|

|

|

Disconnect the spark plug wire a d keep it away from the spark plug. |

|||

|

|

|

for |

|

|

|

||

|

|

|

|

|

Disconnect battery at |

egative termi al (only engines with electric start.) |

||

|

|

|

|

|

Use only correct |

ls. |

|

|

WARNING |

|

|

|

|

Do not tamper w th g |

ver |

r spri g, li ks or other parts to increase engine |

|

Rotating parts can contact or entangle hands, feet, hair, clothing, or |

|

|

|

speed. |

|

|

|

|

|

|

|

Replacement par s must be |

f the same design and installed in the same |

||||

accessories. |

Not |

|

|

|

position as he or g nal parts. Other parts may not perform as well, may damage |

|||

Traumatic amputation or severe laceration can result. |

|

|

|

the unit, and may result in injury. |

||||

Operate equipment with guards in place. |

|

|

|

Do not strike the flywheel with a hammer or hard object because the flywheel |

||||

Keep hands and feet away from rotating parts. |

|

|

|

|

may later shatter during operation. |

|||

Tie up long hair and remove jewelry. |

|

|

|

When testing for spark: |

|

|

||

Do not wear loose-fitting clothing, dangling drawstrings or items that could |

|

|

|

Use approved spark plug tester. |

||||

become caught. |

|

|

|

|

Do not check for spark with spark plug removed. |

|||

|

|

|

|

|

|

|

|

|

|

5 |

|

en |

||

|

||

|

|

Features and Controls |

|

|

|

|

Fuel Recommendations |

|

|

|||||

|

|

|

|

Fuel must meet these requirements: |

|

|||||||

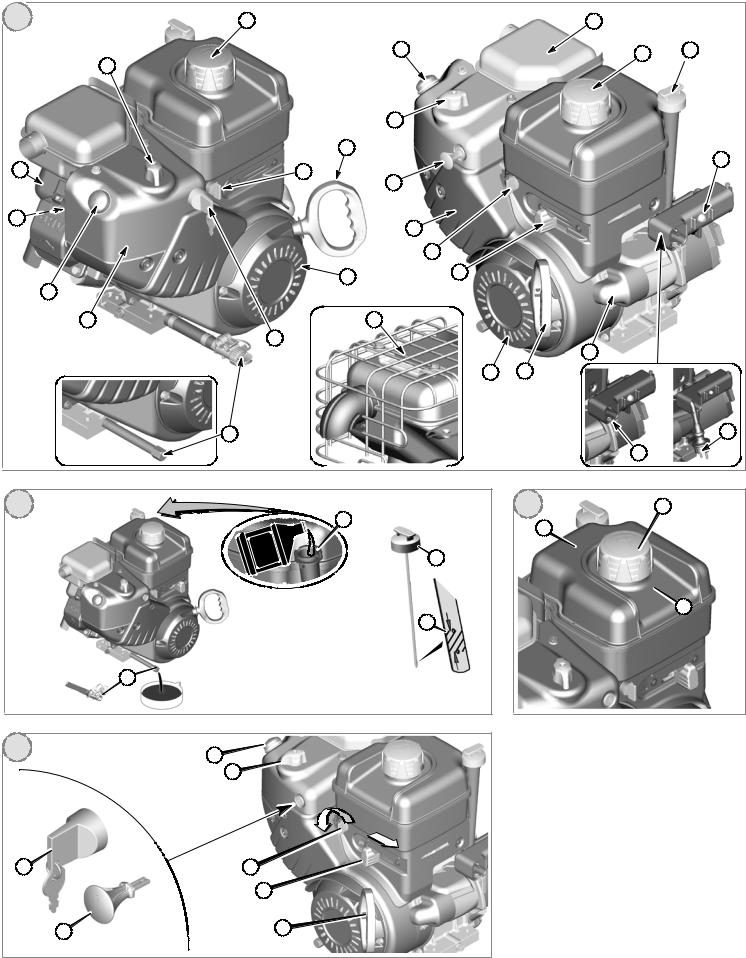

Compare the illustration 1 with your engine to familiarize yourself with the location of |

|

|||||||||||

Clean, fresh, unleaded gasoline. |

|

|||||||||||

various features and controls. |

|

|

|

|

A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below. |

|||||||

A. |

Engine Identification |

|

|

|

|

Gasoline with up to 10% ethanol (gasohol) is acceptable. |

||||||

|

|

|

|

CAUTION: Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in |

||||||||

|

Model Type Code |

|

|

|

|

|||||||

B. |

Spark Plug |

|

|

|

|

gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will |

||||||

|

|

|

|

damage the engine components and void the engine warranty. |

||||||||

C. |

Choke |

|

|

|

|

|||||||

|

|

|

|

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See |

||||||||

D. |

Primer |

|

|

|

|

|||||||

|

|

|

|

Storage. All fuel is not the same. If starting or performance problems occur, change fuel |

||||||||

E. |

Fuel Shut-off Valve |

|

|

|

|

providers or change brands. This engine is certified to operate on gasoline. The |

||||||

|

|

|

|

emissions control system for this engine is EM (Engine Modifications). |

||||||||

F. |

Starter Cord Handle |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||

G. |

Finger Guard |

|

|

|

|

High Altitude |

|

|

|

|

||

H. |

Fuel Tank and Cap |

|

|

|

|

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON) |

||||||

I. |

Dipstick/Oil Fill |

|

|

|

|

gasoline is acceptable. To remain emissions compliant, high altitude adjustment is |

||||||

|

|

|

|

required. Operation without this adjustment will cause decreased performance, |

||||||||

J. |

Oil Drain Plug |

|

|

|

|

|||||||

|

|

|

|

increased fuel consumption, and increased emissions. See an authorized Briggs & |

||||||||

K. |

Muffler |

|

|

|

|

Stratton Dealer for high altitude adjustment information. |

||||||

|

Muffler Guard (optional) |

|

|

|

|

Operation of the engine at altitudes below 2,500 feet (762 meters) with the high altitude |

||||||

|

Muffler Deflector |

|

|

|

|

kit is not recommended. |

|

|

|

|

||

L. |

Safety Key (optional) * |

|

|

|

|

|

|

|

|

|

|

|

M. |

Push Button Electric Start |

|

|

|

|

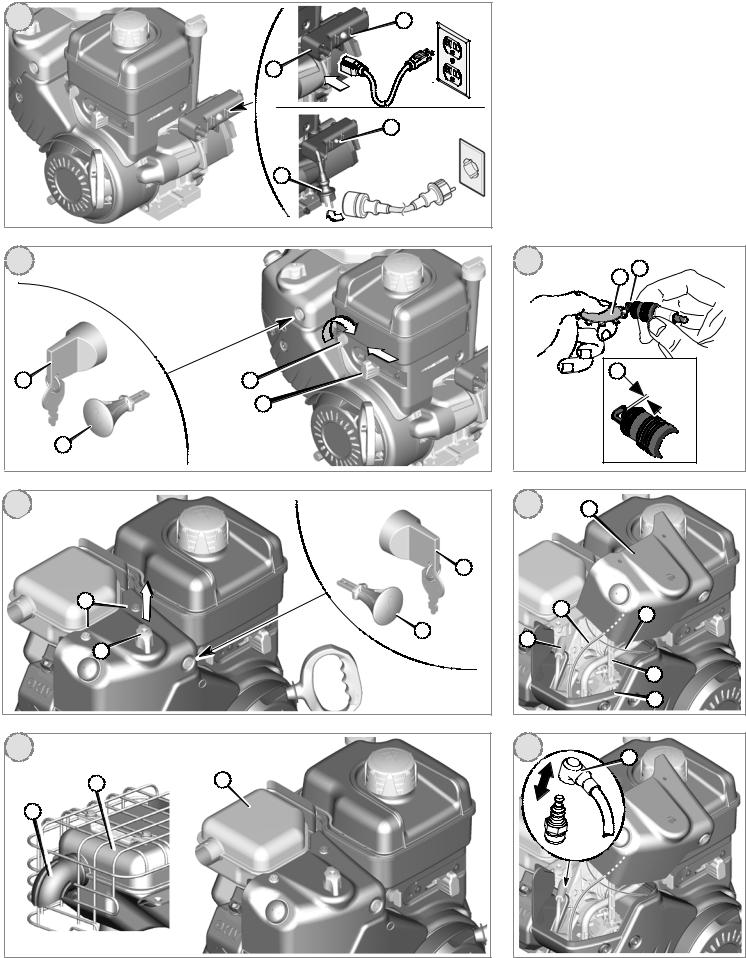

How To Add Fuel - Figure |

3 |

|

||||

N. |

Snow Hood |

|

|

|

|

|

||||||

O. |

Power Cord Receptacle -- 120 Volt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

P. |

Power Cord Receptacle -- 230 Volt |

|

|

|

|

|

|

WARNING |

|

|

|

|

Q. |

Electric Starter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

R. |

Throttle Control (optional) * |

|

|

|

|

|

|

Fuel and its vapors are extremely flammable and explosive. |

||||

S. |

Key (optional) * |

|

|

|

|

|

|

Fire or explosion can cause severe burns or death. |

||||

|

|

|

|

|

|

|

|

|

|

|

||

* Some engines and equipment have remote controls. See the equipment manual for |

|

|

|

|

|

|

|

|

|

|||

location and operation of remote controls. |

|

|

|

|

When Adding Fuel |

|

|

|

|

|||

Operation |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Tu n engine off and let e |

gi e c |

ol at least 2 minutes before removing the fuel |

|||||

|

|

|

|

|

cap. |

|

|

|

|

|

||

Oil capacity (see the Specifications section) |

|

|

|

|

|

Fill fuel tank ou d |

rs r |

n well-ventilated area. |

||||

|

|

|

|

|

|

|

Do not overf ll fuel |

ank. To all |

w for expansion of the fuel, do not fill above the |

|||

Oil Recommendations |

|

|

|

|

|

bottom of he fuel ank neck. |

|

|

||||

|

|

|

|

Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition |

||||||||

We recommend the use of Briggs & Stratton Warranty Certified oils f best |

|

|

|

|

so r |

es. |

|

|

|

|

||

|

for |

|

|

|

|

|

||||||

performance. Other high-quality detergent oils are acceptable if classified f |

r service SF, |

|

Che |

k f el lines, tank, cap, and fittings frequently for cracks or leaks. |

||||||||

SG, SH, SJ or higher. Do not use special additives. |

|

|

|

|

|

Replace if necessary |

|

|

|

|||

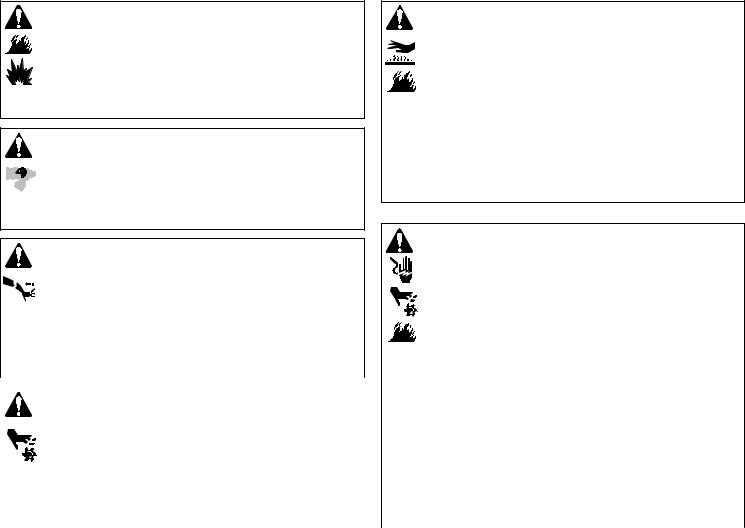

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to |

|

If f el spills, wait until it evaporates before starting engine. |

||||||||||

|

|

|

|

|

|

|

||||||

select the best viscosity for the outdoor temperature range expected. |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap (A) (Figure 3). |

||||||

|

|

Not |

|

|

2. Fill the fuel tank (B) with fuel. To allow for expansion of the fuel, do not fill above the |

|||||||

|

|

|

|

b |

ttom of the fuel tank neck (C). |

|

|

|||||

|

|

|

|

3. Reinstall the fuel cap. |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

How To Start The Engine - Figure 4 |

5 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|

|

Rapid retraction of starter cord (kickback) will pull hand and arm |

||||

|

|

|

|

|

|

|

|

toward engine faster than you can let go. |

|

|||

|

|

|

|

|

|

|

|

Broken bones, fractures, bruises or sprains could result. |

||||

|

|

Reproduction |

|

|||||||||

|

|

|

|

|

|

When starting engine, pull the starter cord slowly until resistance is felt and then |

||||||

|

|

|

|

|

|

|

pull rapidly to avoid kickback. |

|

|

|||

|

|

|

|

|

|

Remove all external equipment/engine loads before starting engine. |

||||||

* Below 40°F (4°C) the use of SAE 30 will result in hard starting. |

|

|

|

Direct-coupled equipment components such as, but not limited to, blades, |

||||||||

|

|

|

|

impellers, pulleys, sprockets, etc., must be securely attached. |

||||||||

|

|

|

|

|

|

|

||||||

**Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check oil level more frequently.

How To Check/Add Oil - Figure |

2 |

WARNING |

|

Fuel and its vapors are extremely flammable and explosive. |

|||

|

|

||

Before adding or checking the oil |

|

Fire or explosion can cause severe burns or death. |

Place engine level.

Clean the oil fill area of any debris.

1. |

Remove the dipstick (C) and wipe with a clean cloth. |

When Starting Engine |

||

2. |

Insert and tighten the dipstick. |

Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in |

||

|

place and secured. |

|||

3. |

Remove the dipstick and check the oil level. It should be at the top of the full indicator |

|

||

|

Do not crank engine with spark plug removed. |

|||

|

(D) on the dipstick. |

|||

|

|

If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle |

||

4. |

To add oil, pour the oil slowly into the engine oil fill (B). Do not overfill. After adding |

|||

|

(if equipped) to FAST position and crank until engine starts. |

|||

|

oil, wait one minute and then recheck the oil level. |

|

|

|

5. |

Replace and tighten the dipstick. |

|

|

|

6 |

BRIGGSandSTRATTON.COM |

|

|

|

|

|

|

|

|

|

|

|

Note: If the engine does not start after repeated attempts, go to |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA). |

||||||||

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Engines give off carbon monoxide, an odorless, colorless, poison gas. |

|

|

|

WARNING: Rapid retraction of the starter cord (kickback) will pull your |

||||||||||||

|

|

|

|

|

|

||||||||||||||

|

|

|

Breathing carbon monoxide can cause nausea, fainting or death. |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

hand and arm toward the engine faster than you can let go. Broken bones, fractures, |

|||||||||

|

Start and run engine outdoors. |

|

|

|

|

|

|

bruises or sprains could result. When starting engine, pull the starter cord slowly until |

|||||||||||

|

Do not start or run engine in enclosed area, even if doors or windows are open. |

|

|

resistance is felt and then pull rapidly to avoid kickback. |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

9. Electric Start: First connect the extension cord to the power cord receptacle (H, 120 |

|||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

Volt) or (K, 230 Volt) and then into a wall receptacle. See Figure 5. If an additional |

||||||||

|

|

|

WARNING |

|

|

|

|

|

|

|

extension cord is required, make sure to use a 3-wire grounded extension cord. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Unintentional sparking can result in fire or electric shock. |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

Unintentional start-up can result in entanglement, traumatic |

|

|

|

|

WARNING: If the extension cord is damaged, it must be replaced by the |

|||||||||||

|

|

|

amputation, or laceration. |

|

|

|

|

|

|

manufacturer or its service agent or a similarly qualified person in order to avoid a |

|||||||||

|

|

|

Fire hazard |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

hazard. |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

10. Electric Start: Depress the push button (I). After you start the engine, first |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

disconnect the extension cord from the wall receptacle and then from the power cord |

||||||||

|

Use a 3-wire extension cord. |

|

|

|

|

|

|

|

receptacle (H, K). |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

Note: If the engine does not start after repeated attempts, go to |

|||||||||||

|

First attach extension cord to electric starter connector and then into a wall |

|

|

|

|||||||||||||||

|

|

|

|

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA). |

|||||||||||||||

|

|

receptacle. If additional extension cord is required, use a 3-wire. |

|

|

|

||||||||||||||

|

|

|

|

|

NOTICE: To extend the life of the starter, use short starting cycles (five seconds |

||||||||||||||

|

If the supply cord is damaged, it must be replaced by the manufacturer or its |

|

|

|

|||||||||||||||

|

|

|

|

maximum). Wait one minute between starting cycles. |

|

||||||||||||||

|

|

service agent or a similarly qualified person in order to avoid a hazard. |

|

|

|

|

|||||||||||||

|

|

|

|

11. Allow the engine to warm up for several minutes. Then, slowly move the choke |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

position. |

|

|

||||

NOTICE: This engine was shipped from Briggs & Stratton without oil. Before you start |

|

|

|

control knob to the run |

|

|

|

|

|||||||||||

the engine, make sure you add oil according to the instructions in this manual. If you |

|

|

|

|

|

|

|

|

|

|

|

||||||||

start the engine without oil, it will be damaged beyond repair and will not be covered |

|

|

|

|

|

|

|

|

|

|

|

||||||||

under warranty. |

|

|

|

|

|

|

How To Stop The E gi e - Figure |

6 |

|

||||||||||

Note: Some engines and equipment have remote controls. See the equipment manual |

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||

for location and operation of remote controls. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

1. Check the oil level. See the How To Check/Add Oil section. |

|

|

|

|

WARNING |

|

|

|

|

||||||||||

2. Make sure equipment drive controls, if equipped, are disengaged. |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

Fuel and s vap |

rs are extremely flammable and explosive. |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

3. |

Move the throttle control lever (B), if equipped, to the fast |

position (Figure 4). |

|

|

Fire or expl |

s n can cause severe burns or death. |

|||||||||||||

|

|

Operate the engine with the throttle control lever in the fast position. |

|

|

|

|

|

|

|

|

|

|

|

||||||

4. Turn the fuel shut-off valve (A), if equipped, to the on position (Figure 4). |

|

|

|

Do not hoke the |

arburetor to stop engine. |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

5. |

Insert the key (C), if equipped, and turn to the on/start |

|

positi n |

for |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

or |

|

|

|

|

|

|

1. |

T rn the key (C), if equipped, to the off |

position (Figure 6). |

|||||||

|

|

Push in the safety key (D), if equipped. |

|

|

|

|

|

|

|

|

|

|

|

|

or |

|

|

||

6. |

Turn the choke control knob (J) to the choke |

|

position. |

|

|

|

|

Remove the safety key (D), if equipped. |

|

|

|||||||||

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

or |

|

|

|||||||

|

|

Note: Choke is usually unnecessary when restarting a warm engine. |

|

|

|

M ve the throttle control lever (B), if equipped, to slow |

and then to the stop |

||||||||||||

|

|

|

|

|

|

|

Not |

|

|

|

|||||||||

7. Push the primer (F) two times. See Figure 4. |

|

|

|

|

|

|

|

position. |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Note: Priming is usually unnecessary when restarting a warm engine. |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

2. Remove the key (C, D). Keep the key out of reach of children. |

|||||||||||||||

8. |

Rewind Start: Firmly hold the starter cord handle (G, Figure 4). Pull the start cord |

||||||||||||||||||

3. After the engine stops, turn the fuel shut-off valve (A) to the closed position. |

|||||||||||||||||||

|

|

handle slowly until resistance is felt, then pull rapidly. |

|

|

|

|

|||||||||||||

|

|

|

Reproduction |

|

|

||||||||||||||

Maintenance |

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|||||||

We recommend that you see any Briggs & Stratton Authorized Dealer for all |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

Unintentional sparking can result in fire or electric shock. |

|||||||||||||||

maintenance and service of the engine and engine parts. |

|

|

|

|

|

|

|||||||||||||

NOTICE: All the components used to build this engine must remain in place for proper |

|

|

Unintentional start-up can result in entanglement, traumatic |

||||||||||||||||

|

|

amputation, or laceration. |

|

|

|||||||||||||||

operation. |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

Fire hazard |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

WARNING: When performing maintenance that requires the unit to be |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

tipped, the fuel tank must be empty or fuel can leak out and result in a fire or |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

explosion. |

|

|

|

|

|

|

Before performing adjustments or repairs: |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

Disconnect the spark plug wire and keep it away from the spark plug. |

|||||||||

|

|

|

|

|

|

|

|

|

|

Use only correct tools. |

|

|

|

|

|||||

Emissions Control |

|

|

|

|

|

|

Do not tamper with governor spring, links or other parts to increase engine |

||||||||||||

|

|

|

|

|

|

|

speed. |

|

|

|

|

|

|

||||||

Maintenance, replacement, or repair of the emissions control devices and systems |

Replacement parts must be of the same design and installed in the same |

||||||||||||||||||

|

position as the original parts. Other parts may not perform as well, may damage |

||||||||||||||||||

may be performed by any non-road engine repair establishment or individual. |

|

|

|

||||||||||||||||

|

|

|

the unit, and may result in injury. |

|

|

||||||||||||||

However, to obtain “no charge” emissions control service, the work must be performed |

|

|

|

||||||||||||||||

Do not strike the flywheel with a hammer or hard object because the flywheel |

|||||||||||||||||||

by a factory authorized dealer. See the Emissions Warranty. |

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

may later shatter during operation. |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

When testing for spark: |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Use approved spark plug tester. |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Do not check for spark with spark plug removed. |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

en |

||

|

||

|

|

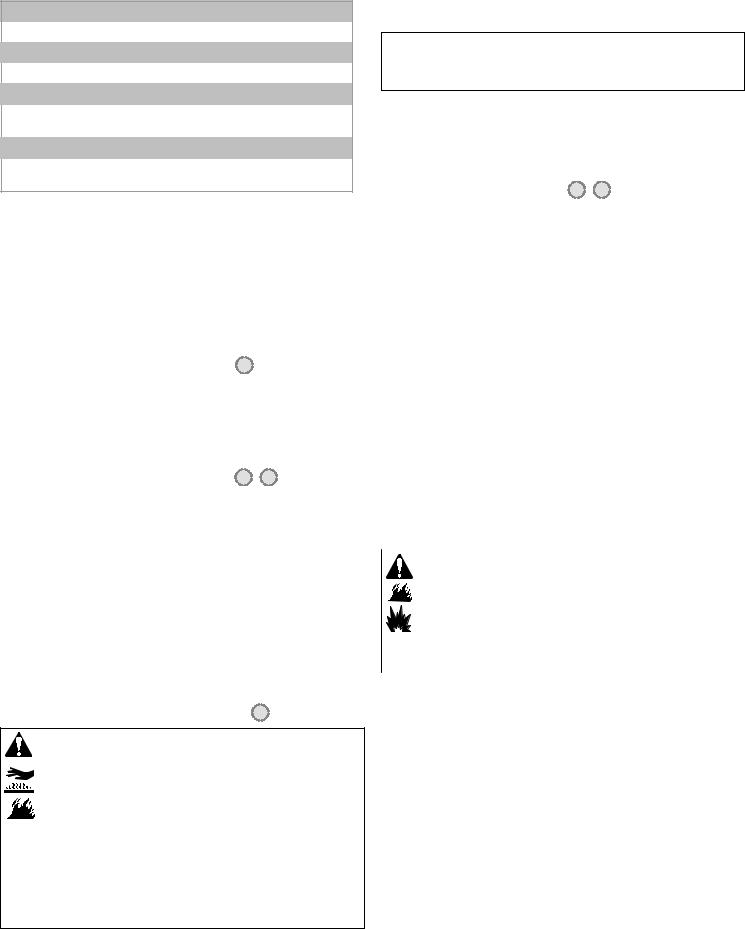

Maintenance Chart

First 5 Hours

Change oil

Every 8 Hours or Daily

Check engine oil level

Every 50 Hours or Annually

Change engine oil

Check muffler and muffler guard

Annually

Replace spark plug

Check valve clearance *

*Not required unless engine performance problems are noted.

Remove accumulated debris from muffler area and cylinder area. Inspect the muffler (A, Figure 10) for cracks, corrosion, or other damage. Remove the spark arrester (B), if equipped, and inspect for damage or carbon blockage. If damage is found, install replacement parts before operating.

WARNING: Replacement parts must be of the same design and installed

WARNING: Replacement parts must be of the same design and installed

in the same position as the original parts. Other parts may not perform as well, may damage the unit, and may result in injury.

Air Filter

This engine is not equipped with an air filter. DO NOT use this engine for anything other than snow removal.

How To Change The Oil - Figure 2 11

Used oil is a hazardous waste product and must be disposed of properly. Do not discard with household waste. Check with your local authorities, service center, or dealer for safe disposal/recycling facilities.

Carburetor Adjustment

Never make adjustments to the carburetor. The carburetor was set at the factory to operate efficiently under most conditions. However, if adjustments are required, see any Briggs & Stratton Authorized Dealer for service.

NOTICE: The manufacturer of the equipment on which this engine is installed specifies the top speed at which the engine will be operated. Do not exceed this speed.

Remove Oil

1.With engine off but still warm, disconnect the spark plug wire (A) and keep it away from the spark plug (Figure 11).

Note: To access the spark plug wire, you must first remove the snow hood from the engine. See How To Access The Spark Plug.

2.Remove the oil drain cap (E, Figure 2). Drain the oil into an approved receptacle.

3.After the oil has drained, install and tighten the oil drain cap.

How To Replace The Spark Plug - Figure |

7 |

|

|

|

|

Add oil |

|

|||

|

|

|

|

|

Place engine level. |

|

||||

Check the gap (A, Figure 7) with a wire gauge (B). If necessary, reset the gap. Install |

|

|

||||||||

|

|

Clean the oil f ll area |

f a y debris. |

|||||||

and tighten the spark plug to the recommended torque. For gap setting or torque, see the |

||||||||||

|

See the Spec f ca |

ns secti n f r oil capacity. |

||||||||

Specifications section. |

|

|

|

|

|

|

||||

Note: In some areas, local law requires using a resistor spark plug to suppress igni i n |

1. |

Rem ve the d ps ck (C, F gure 2) and wipe with a clean cloth. |

||||||||

signals. If this engine was originally equipped with a resistor spark plug, use |

he same |

2. |

Pour the oil slowly in o he engine oil fill (B). Do not overfill. After adding oil, wait |

|||||||

type for replacement. |

|

|

|

|

|

|

one minute and then recheck the oil level. |

|||

|

|

|

|

|

|

for |

|

|||

|

|

|

|

|

|

|

3. Install and tighten the dipstick. |

|||

How To Access The Spark Plug - Figure |

8 |

|

9 |

|

|

4. |

Remove the dipstick and check the oil level. It should be at the top of the full indicator |

|||

To access the spark plug, the snow hood must be removed as follows: |

|

|

|

(D) on the dipstick. |

|

|||||

|

|

5. Install and tighten the dipstick. |

||||||||

1. |

Remove the key (A, B Figure 8). Keep the key out of reach of children. |

|

|

|||||||

|

|

|

|

|

||||||

2. |

Grasp the choke control knob (J) and pull up to remove. |

|

|

|

|

|

|

|||

3. |

Remove the mounting screws (C). |

|

Not |

St |

rage |

|

||||

|

|

|

|

|

|

|||||

4. |

Carefully remove the top part of the snow hood (D, Figure 9). Do not disconnect the |

|

|

|

||||||

|

|

|

||||||||

|

primer hose (E), if equipped, or the key switch wire (F). |

|

|

|

|

|

WARNING |

|

||

5. |

The spark plug (G) can now be accessed. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Fuel and its vapors are extremely flammable and explosive. |

||||

6. |

Before installation of the snow hood, make sure that the prim hos , if |

quipped, |

|

|

||||||

|

|

Fire or explosion can cause severe burns or death. |

||||||||

|

and the key switch wire are connected. |

|

|

|

|

|

|

|||

7. |

Mount the top part of the snow hood to the snow hood base (H). Make sure the top |

|

|

|

||||||

|

interlocks with the base. Secure with the mounting screws. |

|

|

|

When Storing Fuel Or Equipment With Fuel In Tank |

|||||

8. |

Align the slots in the choke control knob with the tabs on the choke shaft (I) and then |

|||||||||

|

Store away from furnaces, stoves, water heaters or other appliances that have |

|||||||||

|

push down to install. If the knob is not installed correctly, the choke will not operate. |

|||||||||

|

|

pilot lights or other ignition sources because they can ignite fuel vapors. |

||||||||

|

|

|

|

|

|

|

|

|||

9. |

Reproduction |

|||||||||

Do not install the key until you are ready to start the engine. |

|

|||||||||

Inspect Muffler And Spark Arrester - Figure 10

WARNING

Running engines produce heat. Engine parts, especially muffler, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

Allow muffler, engine cylinder and fins to cool before touching.

Remove accumulated debris from muffler area and cylinder area.

It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the exhaust system is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order. Other states or federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a spark arrester designed for the exhaust system installed on this engine.

Fuel System

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum deposits to form in the fuel system or on essential carburetor parts. To keep fuel fresh, use Briggs & Stratton Advanced Formula Fuel Treatment & Stabilizer, available wherever Briggs & Stratton genuine service parts are sold.

For engines equipped with a FRESH START® fuel cap, use Briggs & Stratton FRESH START® available in a drip concentrate cartridge.

There is no need to drain gasoline from the engine if a fuel stabilizer is added according to instructions. Run the engine for 2 minutes to circulate the stabilizer throughout the fuel system before storage.

If gasoline in the engine has not been treated with a fuel stabilizer, it must be drained into an approved container. Run the engine until it stops from lack of fuel. The use of a fuel stabilizer in the storage container is recommended to maintain freshness.

Engine Oil

While the engine is still warm, change the engine oil.

Troubleshooting

Need Assistance? Go to BRIGGSandSTRATTON.COM or call 1-800-233-3723.

8 |

BRIGGSandSTRATTON.COM |

Specifications

Engine Specifications

Model |

120000 |

|

|

Displacement |

12.48 ci (205 cc) |

|

|

Bore |

2.688 in (68.28 mm) |

|

|

Stroke |

2.200 in (55.88 mm) |

|

|

Oil Capacity |

18 -- 20 oz (0.54 -- 0.59 L) |

Engine Specifications

Model |

150000 |

|

|

Displacement |

15.24 ci (250 cc) |

|

|

Bore |

2.970 in (75.44 mm) |

|

|

Stroke |

2.200 in (55.88 mm) |

|

|

Oil Capacity |

18 -- 20 oz (0.54 -- 0.59 L) |

Engine Specifications

Model |

200000 |

|

|

Displacement |

18.63 ci (305 cc) |

|

|

Bore |

3.120 in (79.24 mm) |

|

|

Stroke |

2.438 in (61.93 mm) |

|

|

Oil Capacity |

26 -- 28 oz (0.77 -- 0.83 L) |

Engine Specifications

Model |

210000 |

|

|

Displacement |

20.85 ci (342 cc) |

|

|

Bore |

3.300 in (83.81 mm) |

|

|

Stroke |

2.438 in (61.93 mm) |

|

|

Oil Capacity |

26 -- 28 oz (0.77 -- 0.83 L) |

Tune-up Specifications * |

|

|

|

Tune-up Specifications * |

|

|

|

|

|

|

|

|

|

Reproduction |

|

||

Model |

120000, 150000 |

|

Model |

200000, 210000 |

|

|

|

|

for |

|

|

Spark Plug Gap |

0.030 in (0.76 mm) |

|

Spa k Plug Gap |

0.030 in (0.76 mm) |

|

Spark Plug Torque |

180 lb-in (20 Nm) |

|

Spa k Plug Torque |

180 lb-in (20 Nm) |

|

Armature Air Gap |

0.010 |

- 0.014 in (0.25 - 0.36 mm) |

|

Armature Air Gap |

0.010 - 0.014 in (0.25 - 0.36 mm) |

Intake Valve Clearance |

0.004 |

- 0.006 in (0.10 - 0.15 mm) |

|

Intake Valve Clearan e |

0.004 - 0.006 in (0.10 - 0.15 mm) |

Exhaust Valve Clearance |

0.009 |

- 0.011 in (0.23 - 0.28 mm) |

|

Exha st Valve Clearan e |

0.004 - 0.006 in (0.10 - 0.15 mm) |

|

Not |

|

|

|

|

|

Comm |

Se vice Parts |

|

||

Service Part |

Part Number |

|

|

Service Part |

Part Number |

Fuel Additive |

5041, 5058 |

|

|

Spark Plug Wrench |

89838, 5023 |

|

|

|

|

|

|

Resistor Spark Plug (Models 120000, 150000, |

491055 |

|

|

Spark Tester |

19368 |

200000, 210000) |

|

|

|

|

|

|

|

|

|

|

|

Long Life Platinum Spark Plug (Models |

696202, 5066 |

|

|

|

|

120000, 150000) |

|

|

|

|

|

Long Life Platinum Spark Plug (Models |

793541 |

|

|

|

|

200000, 210000) |

|

|

|

|

|

|

|

|

|

|

|

* Engine power will decrease 3.5% for each 1,000 feet (300 meters) ab ve sea level and 1% for each 10 F (5.6 C) above 77 F (25 C). The engine will operate satisfactorily at an angle up to 15 . Refer to the equipment operator’s manual for safe all wable perating limits on slopes.

n We recommend that you see any Briggs & Stratton Authorized Dealer for all maintenance and service of the engine and engine parts.

|

9 |

|

en |

||

|

||

|

|

Loading...

Loading...