Bradford-White EF-100T-199 User Manual

800-B-1006-A

Commercial Gas

Ultra High Efficiency Water Heater

The Ultra High Efficiency Water Heater Models Feature:

■Thermal Efficiency Up To 99.1%.

■60 Gallon Tank Capacity in 125,000, 150,000 and 199,999 BTU/hr Inputs.

■100 Gallon Tank Capacity in 150,000, 199,999, 250,000, 300,000 and 399,999 BTU/hr Inputs.

■Flexible Venting—Conventional, Through-the-Wall or Direct Vent.

■Three Pass Flue System.

■Low NOx Premix Power Burner.

■Ultra Quiet Operation.

■Submerged Combustion Chamber.

■1" NPT Side Connection For Hydronic Applications.

■Electronic Controls.

■Zero Inch Clearance To Combustibles.

■Vitraglas® Lined Tank.

■Four Protective Magnesium Anode Rods (except EF-100T-399).

■Powered Anode Rods (only EF-100T-399).

■Hand Hole Cleanout—Allows inspection of tank interior.

■Factory Installed Hydrojet® Sediment Reduction System.

■Factory Installed Dielectric Fittings.

■Non-CFC Foam Insulation.

■3" Optional Concentric Vent Kit.

■ASME Construction Available.

■NSF Construction Available With Optional Kit.

■Brass Drain Valve.

■T&P Relief Valve Factory Installed.

■Three Year Limited Warranty On Steel Tank.

■One Year Limited Warranty On Parts.

Photo is of

EF-100T-199

3 or 5-Year Limited Tank Warranties / 1-Year Limited Warranty on Component Parts.

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada and Puerto Rico. Some states do not allow limitations on warranties. See complete copy of the warranty included with the heater.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 7,063,133 B2; 5,954,492; 5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185; 5,485,879; 5,277,171; (B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448; 4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968; 4,672,919; Re. 34,534. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105.

Vitraglas® and Hydrojet® are registered trademarks of Bradford White® Corporation. ©2006, Bradford White Corporation. All rights reserved. Printed in U.S.A.

Ultra High Efficiency Water Heaters

eF Series® Standard Equipment Features:

Thermal Efficiency up to 99.1%—Fully condensing design.

Three Pass Flue System—The three pass flue system keeps the hot combustion gases moving at a high velocity. The combination of high turbulence and velocity causes an enormous rate of heat transfer into the water.

Low NOx Premix Power Burner—Developed for the eFSeries®, a turbulent flame shoots down the submerged combustion chamber. This turbulence causes a thorough mixing of the gas and air for optimum combustion and high heat transfer efficiencies. — Far exceeds California emission requirements.

Submerged Combustion Chamber—Submerging the combustion chamber in the center of the water storage tank minimizes radiant heat loss and improves efficiency.

Non-CFC Foam Insulation—Surrounds the tank surface, saving energy by retarding loss of heat.

Electronic Controls—Adjustable electronic thermostat for control between 80°F and 180°F. The recycling Energy Cut Off (ECO) shuts off all gas flow in an event of an overheat condition.

Zero Inch Clearance—The eFSeries® jacket is cool to the touch and is approved for zero inch clearance to combustibles for unsurpassed installation flexibility.

Vitraglas® Lined Tank—Bradford White’s water heater tanks are protected from the corrosive effects of hot water by an exclusive ceramic porcelain-like coating. Our high silica Vitraglas® lining provides a tough interior surface for Bradford White’s water heater tanks.

Protective Magnesium Anode Rods—Employed to provide an extra measure of corrosion protection for longer life. Each eF heater has 4 anodes, except the EF-100T-399 which has 2 powered anode rods and one non-powered anode rod.

Factory Installed Hydrojet® Sediment Reduction System—Cold inlet sediment reduction device made of stainless steel for increased durability. Helps prevent sediment build up in tank.

Factory Installed Dielectric Fittings—All heaters equipped with special water heater nipples for longer heater life. No special dielectric fittings to buy.

Flexible Venting—The eF Series® can vent vertically or horizontally with either 3" or 4" PVC, CPVC or ABS vent pipe, and is approved for direct vent closed combustion applications, or those applications that require inside air for combustion. Foam Core pipe is permitted on the entire venting system. The eF Series® is also approved for unbalanced venting, which means the air intake pipe doesn't have to be vented the same distance as the exhaust.

(NOTE: Air intake cannot exceed exhaust by more than 30 feet.)

Model |

Max. 3" PVC, |

Max. 4" PVC, |

Number |

ABS & CPVC |

ABS & CPVC |

|

|

|

EF-60T-125 |

120 ft. |

170 ft. |

EF-60T-150 |

100 ft. |

150 ft. |

EF-60T-199 |

80 ft. |

130 ft. |

EF-100T-150 |

120 ft. |

170 ft. |

EF-100T-199 |

100 ft. |

150 ft. |

EF-100T-250 |

80 ft. |

130 ft. |

EF-100T-300 |

60 ft. |

110 ft. |

EF-100T-399 |

50 ft. |

100 ft. |

Determining required vent length

1.Determine the total length of straight vent pipe (in feet) required for both the intake and the exhaust.

2.Add 5 feet of venting for every 90˚ elbow.

3.Add 2 1⁄2 feet of venting for every 45˚ elbow.

4.Total vent length cannot exceed "Max Length" in the above venting table.

5.Air intake cannot exceed exhaust by more than 30 feet in any venting situation.

NOTICE: Do not include the 3" exhaust elbow or vent terminals in determining maximum vent length.

Three year limited warranty on steel tank — Heavy gauge steel automatically formed, rolled and welded to assure a continuous seam for glass lining.

One year limited warranty on parts

eF Series® Optional Equipment Features:

Maxitrol Gas Pressure Regulating valve—Ensures proper supply pressure to eF unit of 7" to 11" W.C. (provided incoming pressure is between 1/2 and 2 psi). This can be ordered as a separate part, or as part of the heater. For the separate part, please use

p/n 243-45517-00 (not available for use with the EF-100T-399).

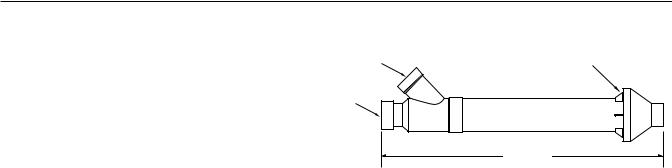

Concentric Vent Terminal Kit—3" termination fitting provides for only one exit opening through wall or roof (p/n 239-44069-01).

Intake/ |

|

Combustion |

|

Air |

Rain Cap |

Vent

Exhaust

46 3/4"

NSF Compliance Kit—p/n 265-44542-04. |

p/n 239-44069-01 |

|

|

|

|

|

|

Loading...

Loading...