Bosch GWH 1600 PS User Manual

Index

Index

1 |

Warning |

2 |

|

|

|

2 |

Appliance details |

3 |

2.1GWH 1600 PS specifications

|

(Technical data) |

3 |

2.2 |

Unpacking the GWH 1600 PS heater |

4 |

2.3 |

General rules to follow for safe operation |

4 |

2.4 |

Dimensions |

5 |

|

|

|

3 |

Installation instructions |

6 |

3.1 |

Introduction |

6 |

3.2 |

Proper location for installing your heater |

6 |

3.3 |

Heater placement and clearances |

6 |

3.4 |

Mounting Heater |

7 |

3.5 |

Combustion air requirements |

8 |

3.6 |

Venting |

9 |

3.7 |

Gas piping & connections |

11 |

3.8 |

Measuring gas pressure |

13 |

3.9 |

Water connections |

13 |

3.10 |

Recirculation application |

14 |

|

|

|

4 |

Operation instructions |

14 |

4.1For your safety read before operating

|

your water heater |

14 |

4.2 |

Lighting instructions |

15 |

4.3 |

To turn off appliance |

15 |

4.4 |

Calibrating the thermostat |

16 |

4.5 |

Winterizing |

16 |

|

|

|

5 |

Maintenance and service |

17 |

5.1 |

Maintenance intervals |

17 |

5.2 |

Water valve |

17 |

5.3 |

Pilot |

18 |

5.4 |

Main burners |

18 |

5.5 |

Vent assembly |

18 |

5.6 |

Mineral scale build-up |

18 |

|

|

|

6 |

Troubleshooting |

20 |

6.1 |

Introduction |

20 |

6.2 |

Pilot does not light |

20 |

6.3 |

Pilot lights, but goes out when button released |

20 |

6.4 |

Pilot goes out during or after hot water use |

20 |

6.5 |

Burners do not light with water flow |

21 |

6.6 |

Hot water temperature fluctuates at tap |

21 |

6.7 |

Water is too hot |

21 |

6.8 |

Water is not hot enough |

22 |

6.9 |

Burners ignite without hot water flow |

22 |

6.10 |

Low hot water pressure |

22 |

6.11 |

Noise when heater is running |

22 |

6.12Burners do not operate cleanly;

|

yellow flames when operating |

22 |

|

|

|

7 |

Protecting the environment |

23 |

|

|

|

8 |

Interior components and diagram parts list |

24 |

8.1 |

Interior components |

24 |

8.2 |

Components diagram |

25 |

8.3 |

Parts list |

26 |

|

|

|

9 |

Twelve Year Limited Warranty |

27 |

1Warning

Warning: The heater must be isolated from the gas supply piping system during any pressure testing of that system at test pressures equal to or more than 0.5 psig.

Caution: Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

Fig. 1

2 |

6 720 606 518 |

Appliance details

2Appliance details

2.1GWH 1600 PS specifications (Technical data)

Approved in US/Canada

Capacity

GWH 1600 PS: 4.3 GPM

Maximum output

GWH 1600 PS: 96,600 Btu/hr

Maximum input

GWH 1600 PS: 117,000 Btu/hr

Efficiency in %

Recovery efficiency 80%

Min. Output

GWH 1600 PS: 23,400 Btu/hr

Gas Requirement

Gas connection (inches) - ½” NPT

Inlet gas pressure under maximum operation*

•Propane: 10.5” - 14” water column

•Natural Gas: 5.7” - 14” water column.

* To measure Gas Pressure, see Measuring Gas Pressure, chapter 3.8.

Venting

•Natural Draft

•Vent diameter (inches) - 5”

•Minimum height (feet) - 6’ with no elbows

•Vertical termination

•Sidewall termination only with AQ1 power vent kit.

Water

•Hot water connection (inches) - ½” NPT

•Cold water connection (inches) - ½” NPT

•Water valve material: Brass

•Minimum water flow: 0.5 gallon/minute (1.9 l/m)

•Minimum recommended water pressure: 30 PSI (2.07 bar)

•Connections:

– Bottom of heater

Dimensions

•Depth (in): 8 ¾” (222 mm)

•Width (in): 18 ¼” (463 mm)

•Height (in): 29 ¾” (756 mm)

•Weight: 44 lb (20 kg).

Gas types

Natural Gas.

LP Gas

Safety devices

•Flame failure device (ionization thermocouple)

•Pressure relief valve (supplied with heater)

•Over heat prevention (temperature limiter).

6 720 606 518 |

3 |

Appliance details

2.2Unpacking the GWH 1600 PS heater

This heater is packed securely.

Before installing the unit, be certain you have the correct heater for your type of Gas - Propane or Natural Gas. Identification labels are found on the shipping box, and on the rating plate sticker which is located on the right side panel of the cover.

Fig. 2 Rating plate sticker

A Serial number

BType of gas

The box includes:

•Pressure relief valve

•Mounting screws

•Product registration card

•Installation manual (additional copies can be downloaded at www.boschwaterheating.com)

•Incandescent particle tray.

Please complete and return the enclosed product registration card.

The GWH 1600 PS is not approved or designed for:

•Manufactured (mobile) homes, RV's, boats or any mobile installation

•Heating or other recirculating/pumping applications*

•Installation in a bathroom, bedroom or any other habitable room normally kept closed.

* This includes domestic hot water circulator pump loop systems that may be installed in home hot water system prior to installing this unit. An approved recirculation design can be found in chapter 3.10.

In Canada: The Installation must conform with CGA B149.(1,2) INSTALLATION CODES and /or local installation codes.

•2. You must vent your heater. See section on VENTING.

•3. Carefully plan where you install the heater. Correct combustion air supply and vent pipe installation are very important. If not installed correctly, fatal accidents can be caused by lack of air, carbon monoxide poisoning or fire.

•4. The appliance and its gas connection must be leak tested before placing the appliance in operation. The appliance must be isolated from the gas supply piping system by closing its individual manual gas shutoff valve (not supplied with heater) during any pressure testing at pressures in excess of ½ Psig (3.5 kPa).

•5. Keep water heater area clear and free from combustibles and flammable liquids. Do not locate the heater over any material which might burn.

•6. Correct gas pressure is critical for the optimum operation of this heater. Gas piping must be sized to provide the required pressure at the maximum output of the heater, while all the other gas appliances are in operation. Check with your local gas supplier, and see chapter 3.7 and 3.8 to verify proper gas line sizing.

•7. Should overheating occur or the gas supply fail to shut off, turn off the gas supply at the manual gas shut off valve, on the gas line. Note: manual gas shutoff valve is not supplied with the heater.

•8. Do not use this appliance if any part has been underwater. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been underwater.

•9. Failure to install heater correctly may lead to unsafe operation and void the warranty.

•10. The heater must not be installed in an unheated area where temperatures will reach 36°F or lower. If the heater is left in an area susceptible to such temperatures, refer to section 4.5 on Winterizing.

•11. In areas where water supply has a high mineral content, a water softener is strongly recommended. Damage to the water heater resulting from hard water/scale deposits will not be covered under warranty.

2.3General rules to follow for safe operation

•1. You must follow these instructions when you install your heater. In the United States: The installation must conform with local codes or, in the absence of local codes, the National Fuel Gas Code ANSI Z223.1/NFPA 54.

4 |

6 720 606 518 |

iBOSCH is constantly improving its

Appliance details

2.4Dimensions

Fig. 3 Dimensions in Inches and (mm)

4Heat exchanger

5Burner

11 Water valve

20 Gas connection

36Front cover

37Holes for hanging on wall

38Exhaust pipe union

39Draft diverter

40Gas valve

49Observation window

50Piezo Igniter button

51Off button

52Pilot button

53On button

6 720 606 518 |

5 |

Installation instructions

3Installation instructions

3.1Introduction

Please follow these instructions. Failure to follow instructions may result in:

B Damage or injury.

B Improper operation.

B Loss of warranty.

If you are unable to perform the tasks required to install this heater properly, please contact a locally licensed plumber or gas technician.

Please contact Bosch Water Heating with any questions.

3.2Proper location for installing your heater

Carefully select the location of the water heater. For your safety and for proper heater operation, you must provide combustion air to the heater and a proper exhaust vent system.

Follow the guidelines below:

B 1. Locate the heater where venting, gas and plumbing connections are feasible and convenient.

B2. The hot water lines should be kept short to save energy. Centrally locating the water heater is best. It is always best to have hot water lines insulated.

B3. Do not install in a bathroom, bedroom or any other habitable room normally kept closed.

Warning: The water in this water heater is cold and always remains cold except for the times that hot water is being used. DO NOT INSTALL IN AN AREA WHERE IT COULD FREEZE.

Drain the heater entirely if freezing temperatures are anticipated in area where heater is installed. See chapter 4.5 for draining instructions.

To prevent any freeze damage, introduce short bursts of compressed air (20-40psi) through these connections to remove the residual water in the horizontal pipes and water valve.

Warning: Flammable materials, gasoline, pressurized containers, or any other items or articles that are potential fire hazards must NOT be placed on or adjacent to the heater. The appliance area must be kept free of all combustible materials, gasoline and other flammable vapors and liquids.

Warning: The heater must be isolated from the gas supply piping system during any pressure testing of that system at test pressures equal to or more than 0.5 psig.

Warning: Place the heater in a location where water leaks will do NO DAMAGE to adjacent areas.

3.3Heater placement and clearances

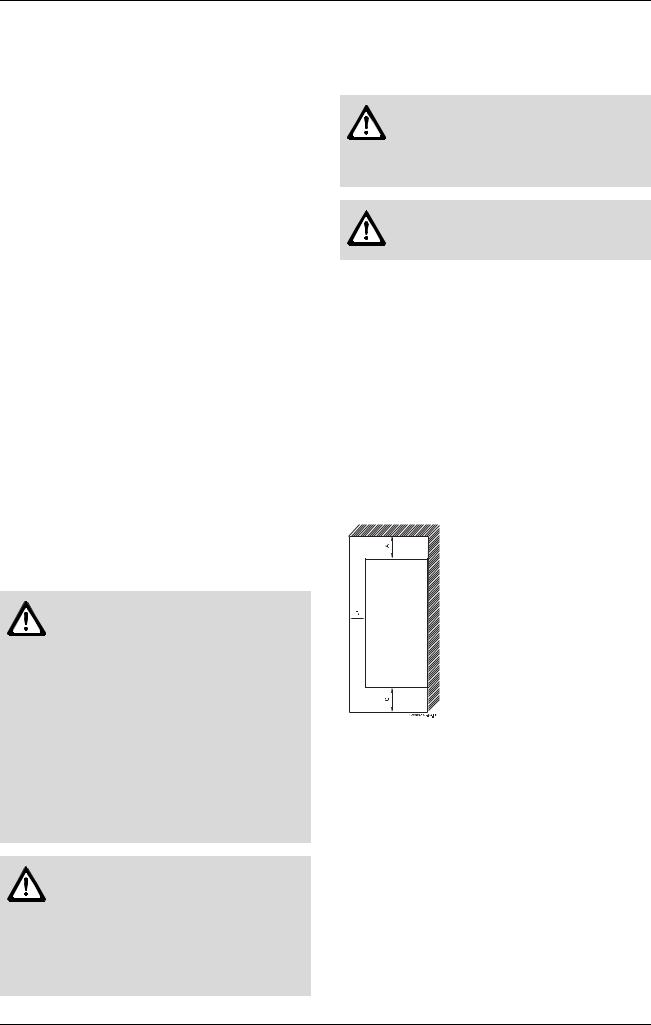

The GWH 1600 PS is design certified for installation on a combustible wall (see 3.4 Mounting installation) provided the floor covering below the heater is noncombustible. For installations in an alcove or closet, maintain the minimum clearances to combustible and non-combustible materials listed below. See also Fig. 4.

A.Top 12 inches (306 mm)

B.Front 4 inches (100 mm)

C.Back 0 inches

D.Sides 4 inches (100 mm)

E.Bottom 12 inches (306 mm)

|

Model GWH 1600 |

TOP (A) |

12 inches (306 mm) |

FRONT (B) |

4 inches (100 mm) |

BACK |

0 inches |

SIDES |

4 inches (100 mm) |

BOTTOM (C) |

12 inches (306 mm) |

|

|

Fig. 4 Minimum clearances

6 |

6 720 606 518 |

|

|

|

|

|

Installation instructions |

|

3.4 |

Mounting Heater |

|

|

|

||

|

Warning: before starting installation: |

|

|

|||

|

B check that there are no loose parts |

|

||||

|

inside the appliance |

|

|

|

||

|

B ensure that gas pipe, gas valve, and |

|

||||

|

burner have no damage and are |

|

||||

|

properly fitted. |

|

|

|

||

|

B Read chapter 2.2 to verify proper gas |

|

||||

|

type and to check all parts are included |

|

||||

|

in box. |

|

|

|

|

|

i |

Front cover should be removed in order to |

|

||||

inspect |

components |

visually |

(see |

|

||

instructions below). |

|

|

|

|||

Remove cover and inspect. |

|

|

|

|||

B Loosen the fixing screw, bottom of the front cover. |

|

|||||

B Remove the outer cover by pulling it forwards and |

|

|||||

then lifting upwards, see Fig. 6. |

|

Fig. 6 Remove front cover |

||||

B Ensure that the flue terminal is clear. |

||||||

|

|

|||||

B After inspection, replace front cover. |

|

|

||||

Install incandescent particle tray. |

|

|

||||

B Install incandescent particle tray using screws |

|

|||||

provided as shown in Fig. 5. |

|

|

|

|||

|

|

|

Screws |

|

||

|

Incandescent particle tray |

|

|

|||

Fig. 5 Incandescent particle tray illustration |

Fig. 7 |

Support board |

||||

|

|

|

|

|||

Mounting heater. |

|

|

|

|

||

|

Warning: |

|

|

|

|

|

|

B Do not install this appliance on a |

|

||||

|

carpeted wall. |

|

|

|

||

The heater must be mounted on a wall using |

|

|||||

appropriate anchoring materials. If wall is sheathed with |

|

|||||

plasterboard, it is recommended that support board(s), |

|

|||||

either 1x4’s or 1/2" (minimum) plywood first be |

|

|||||

attached across a pair of studs and then the heater |

|

|||||

should be attached to the support boards, see Fig. 7. |

|

|||||

B Secure the two included L shaped hooks to wall |

|

|||||

studs or support board 13 1/4” apart. (See Fig. 7). |

|

|||||

B Hang heater on two L shaped hooks. (See Fig. 8). |

|

|||||

|

|

|

|

Fig. 8 Secure heater to wall |

||

6 720 606 518 |

|

|

|

7 |

||

Installation instructions

3.5Combustion air requirements

The AquaStar water heater holds cold water in its copper heat exchanger and water valve when not in use. Because of this, any cold air that comes down through the unit's vent pipe is capable of freezing these components. This installation manual specifies the minimum vertical vent pipe height and the amount of combustion air required for this unit. When all requirements are followed, the unit will operate properly and safely. However, there may still be a risk of freezing due to negative draft if all the combustion appliances in the building are not being supplied with a sufficient amount of make-up air. A wood stove or furnace can pull cold air down the Aquastar's vent pipe, freezing the cold water in the heat exchanger or water valve causing damage. Supplying more combustion air for all combustion appliances is the solution. A HVAC specialist should be consulted to design solutions for providing more make-up air if necessary. Observe the following guidelines concerning combustion air.

Appliances located in unconfined spaces:

a)An unconfined space is one whose volume is greater than 50 cubic feet per 1000 Btu per hour of the combined rating of all appliances installed in the space. That would be 5850 cubic feet for the AquaStar GWH 1600 PS alone.

b)Installations in structures that have been tightly constructed (air infiltration rate of 0.40 ACH or less) must be provided with combustion air per the National Fuel Gas Code. Consult a HVAC specialist if your air infiltration rate is questionable.

Appliances located in confined spaces:

The confined space must be provided with two permanent openings, one commencing within 12 inches of the top and one commencing within 12 inches of the bottom of the enclosure. Each opening must have a minimum free area of one square inch per:

•1000 Btu/hr if all air is taken from inside the building.

•2000 Btu/hr if all air is taken from the outside by horizontal ducts.

•4000 Btu/hr if all air is taken from the outside by direct openings or vertical ducts.

Or the confined space must be provided with one permanent opening or duct that is within 12 inches of the ceiling of the enclosure. This opening must have a minimum free area of one square inch per:

•3000 Btu/hr if all air is taken from the outside by a direct opening or vertical duct.

Louvers, grills and screens have a blocking effect. If the effective free area is not known, increase the sizes of your openings by 400% if your louvers are wood and by 135% if your louvers are metal. Refer to the National Fuel Gas Code for complete information. In buildings of tight construction all air should be taken from outside.

8 |

6 720 606 518 |

3.6Venting

Danger: Do not reduce the vent pipe size. Do not put an elbow directly on top of heater. Failure to follow venting requirements may cause deadly exhaust gases to enter living space.

B Minimum vent pipe diameter: 5 inches

B Minimum vertical vent height: 6 feet, with no elbows

B Establish 12 inch rise before any elbow

The heater must be vented to the outside following all local ordinances and specifications for installing a gas appliance vent or chimney. The heater must be located as close as practicable to a vertically rising chimney or vent that has a listed vent cap at its termination point. The venting system must be designed and constructed so as to develop a positive flow adequate to remove flue gasses to the outdoors. Consult the National Fuel Gas Code if the vent will have elbows or share venting with another natural draft appliance.

Warning: Do not combination vent with a mechanically vented appliance.

3.6.1Horizontal venting

Warning: Horizontally venting to a vertically constructed vent stack along an outside wall of a building is not permissible.

Warning: Horizontally venting to a sidewall vent terminator (without power vent) is not permissible.

A power vent (model AQ1), with a proof-of-draft safety interlock device, is required and is available for sidewall venting. Contact your dealer. In the Commonwealth of Massachusetts power vented applications must utilize proof-of-draft safety interlock device.

3.6.2Vertical venting

B A 5 inch diameter gas vent constructed of double wall Type B gas vent is required. A 6 inch vent is required in elevations greater than 2000 feet, see Fig. 10. Under no circumstances should the vent pipe be reduced in size.

B An approved gas vent connector must be attached to the top of the water heater and rise vertically at least 12" before entering into an approved gas vent connector elbow.

B The minimum vertical gas vent height allowed is 6 feet; horizontal vent connectors and elbows are not to be considered in the total gas vent height.

Installation instructions

B All gas vent sections must be secured to each other with sheet metal screws and be properly supported.

Horizontal runs:

Any gas vent section that is greater than 45 degrees from the vertical is considered horizontal. Horizontal sections must slope upwards at least ¼ inch for every foot of its horizontal length and be properly supported. Keep the horizontal section short and avoid too many elbows. The maximum horizontal run allowed is half of the total vertical vent height; horizontal vent connectors and elbows are not to be considered in the total gas vent height.

Vent termination:

The gas vent constructed of double wall Type B gas vent must terminate above the roof surface with a listed vent cap at a height that's in accordance with Fig. 11 and table 2, provided they are at least 10 feet (2.4 m) from a vertical wall or similar obstruction. All other gas vents that are not able to terminate within the minimum specified height allowed must terminate not less than 2 feet (0.6 m) above the highest point where it passes through the roof and at least 2 feet (0.6 m) higher than any vertical wall or similar obstruction within 10 feet (3.1 m).

Fig. 9 Flat roof

Fig. 10 Vent Adaptor for High Altitude Installations

6 720 606 518 |

9 |

L I S T E D

5” X 6” ADAPTOR

V

Loading...

Loading...