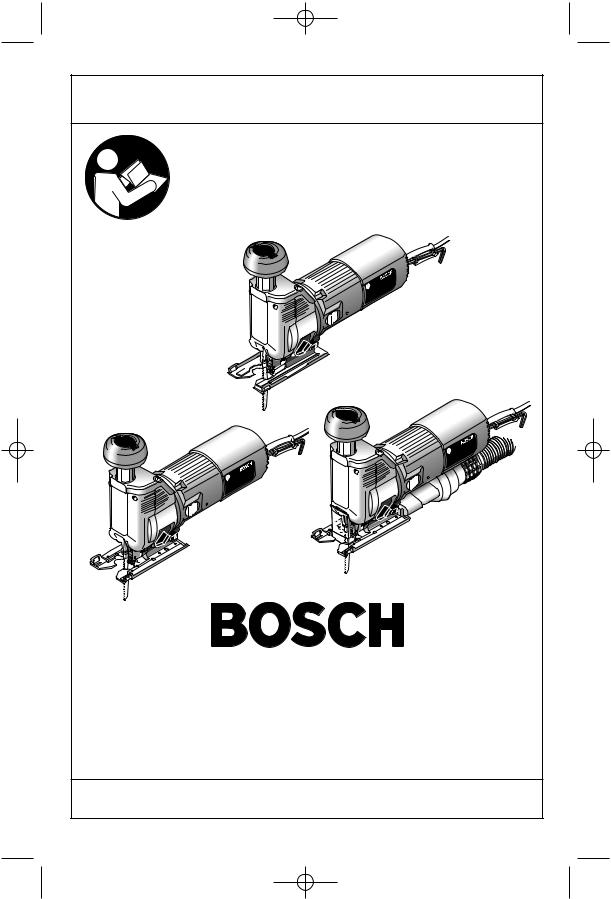

Bosch 1584DVS, 1584AVS, 1584VS User Manual

BM 2610993482 2-04 2/9/04 |

9:17 AM Page 1 |

|

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

Operating/Safety Instructions |

||

Consignes de fonctionnement/sécurité |

||

Instrucciones de funcionamiento |

||

y seguridad |

|

|

1584VS |

|

|

1584AVS |

|

|

1584DVS |

|

|

|

Consumer Information |

|

Renseignement des consommateurs |

||

|

Información para el consumidor |

|

Toll Free Number: |

Appel gratuit : |

Número de teléfono gratuito: |

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com |

||

For English |

Parlez-vous français? |

¿Habla español? |

See page 2 |

Voir page 12 |

Ver página 22 |

BM 2610993482 2-04 2/9/04 9:17 AM Page 2

Power Tool Safety Rules

! WARNING Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

Keep by-standers, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double Insulation

eliminates the need for the three wire grounded power cord and grounded power supply system. Before plugging in the tool, be certain the outlet voltage supplied is within the voltage marked on the nameplate. Do not use “AC only” rated tools with a DC power supply.

eliminates the need for the three wire grounded power cord and grounded power supply system. Before plugging in the tool, be certain the outlet voltage supplied is within the voltage marked on the nameplate. Do not use “AC only” rated tools with a DC power supply.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded. If operating the power tool in damp locations is unavoidable, a Ground Fault Circuit Interrupter must be used to supply the power to your tool. Electrician’s rubber gloves and footwear will further enhance your personal safety.

Don't expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked "W-A"

-2-

or "W." These cords are rated for outdoor use and reduce the risk of electric shock. Refer to “Recommended sizes of Extension Cords” in the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Keep handles dry, clean and free from oil and grease.

Avoid accidental starting. Be sure switch is “OFF” before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before turning the tool “ON”. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

BM 2610993482 2-04 2/9/04 9:17 AM Page 3

Do not use tool if switch does not turn it “ON” or “OFF”. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control. Any alteration or modification is a misuse and may result in a dangerous condition.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools. Develop

a periodic maintenance schedule for your tool.

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool, may become hazardous when used on another tool.

Service

Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury. For example: internal wires may be misplaced or pinched, safety guard return springs may be improperly mounted.

When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electric shock or injury. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

Safety Rules for Jigsaws

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator. Do not drill, fasten or break into existing walls or other blind areas where electrical wiring may exist. If this situation is unavoidable, disconnect all fuses or circuit breakers feeding this worksite.

Never leave the trigger locked "ON". Before plugging the tool in, check that the trigger lock is "OFF". Accidental start-ups could cause injury.

Be aware of the location and setting of the switch "Lock-ON" button. If the switch is locked "ON" during the use, be ready for emergency situations to switch it "OFF", by first pulling the trigger then immediately releasing it without pressing the "Lock-ON" button.

Keep hands away from cutting area. Do not reach under the material being cut.

The proximity of the blade to your hand is hidden from your sight.

Keep hands from between the gear housing and saw blade holder. The reciprocating blade holder can pinch your fingers.

Do not use dull or damaged blades. Bent blade can break easily or cause kickback.

Before starting to cut, turn tool "ON" and allow the blade to come to full speed.

Tool can chatter or vibrate if blade speed is too slow at beginning of cut and possibly kickback.

Always wear safety goggles or eye protection when using this tool. Use a dust mask or respirator for applications which generate dust.

Secure material before cutting. Never hold it in your hand or across legs. Small

-3-

BM 2610993482 2-04 2/9/04 9:17 AM Page 4

or thin material may flex or vibrate with the blade, causing loss of control.

Make certain all adjusting screws and the blade holder are tight before making a cut. Loose adjusting screws and holders can cause the tool or blade to slip and loss of control may result.

When removing the blade from the tool avoid contact with skin and use proper protective gloves when grasping the blade or accessory. Accessories may be hot after prolonged use.

If your tool is equipped with a dust bag, empty it frequently and after completion of sawing. Spontaneous combustion, may in time, result from mixture of oil or water with dust particles. Be extremely careful of dust disposal, materials in fine particle form may be explosive. Do not throw contents on an open fire.

-4-

Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

BM 2610993482 2-04 2/9/04 9:17 AM Page 5

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol |

Name |

Designation/Explanation |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

Volts |

Voltage (potential) |

||||

|

|

|

|

A |

Amperes |

Current |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Hz |

Hertz |

Frequency (cycles per second) |

||||||

|

|

|

W |

Watt |

Power |

|||||

|

|

|

kg |

Kilograms |

Weight |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

min |

Minutes |

Time |

|||||||

|

|

|

|

s |

Seconds |

Time |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

Size of drill bits, grinding wheels, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n0 |

No load speed |

Rotational speed, at no load |

|||||

.../min |

Revolutions or reciprocation per minute |

Revolutions, strokes, surface speed, |

||||||||

|

|

|

|

|

|

|

|

|

|

orbits etc. per minute |

0 |

|

|

|

Off position |

Zero speed, zero torque... |

|||||

|

|

|

|

|

|

|

|

|

|

|

1, 2, 3, ... |

Selector settings |

Speed, torque or position settings. |

||||||||

I, II, III, |

|

Higher number means greater speed |

||||||||

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

Infinitely variable selector with off |

Speed is increasing from 0 setting |

||

|

|

|

|

|

|

|

|

|

Arrow |

Action in the direction of arrow |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Alternating current |

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current |

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Alternating or direct current |

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Class II construction |

Designates Double Insulated |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Construction tools. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal |

Grounding terminal |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Warning symbol |

Alerts user to warning messages |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Ni-Cad RBRC seal |

Designates Ni-Cad battery recycling |

|

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed to Canadian Standards by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, and listed to Canadian Standards by Underwriters Laboratories.

This symbol designates that

this tool complies to NOM Mexican Standards.

-5-

BM 2610993482 2-04 2/9/04 9:17 AM Page 6

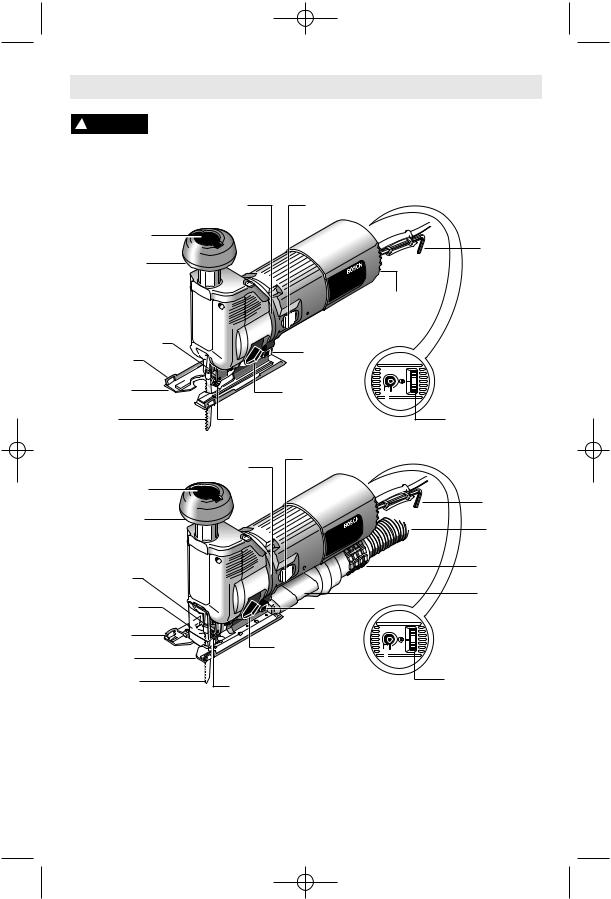

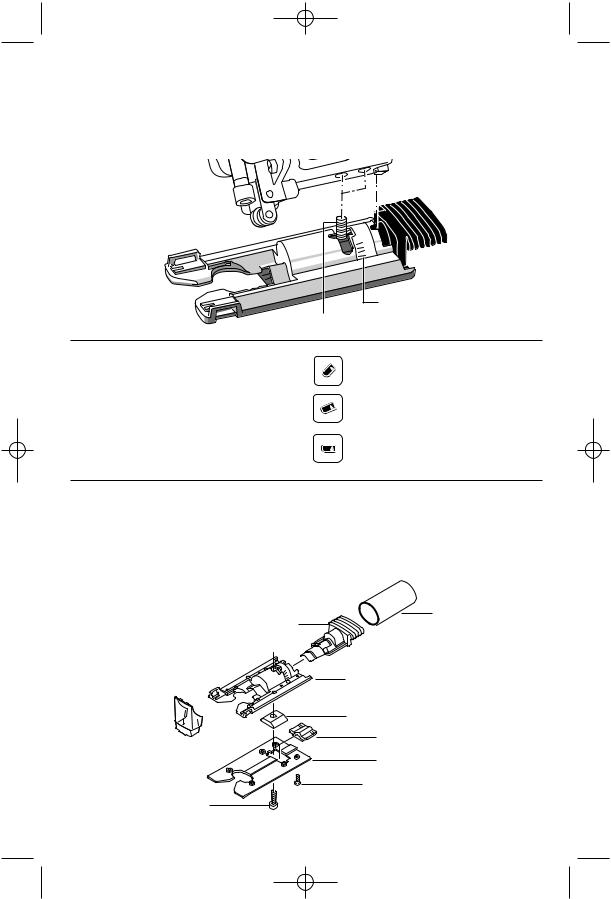

Functional Description and Specifications

Disconnect the plug from the power source before making any assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

|

Jigsaws |

VENTILATION |

SLIDE |

OPENINGS |

SWITCH |

BLADE CHANGE |

ALLEN |

BUTTON |

WRENCH |

TOP HANDLE |

5MM |

|

|

|

VENTILATION |

|

OPENINGS |

BLADE PLUNGER |

CHIP |

|

CUTTING |

BLOWER |

|

LEVER |

|

|

GUIDE SLOTS |

|

|

BLADE ORBIT |

|

|

|

1 |

|

|

|

|

FOOTPLATE |

SELECTOR |

|

|

LEVER |

VARIABLE |

|

|

|

BLADE |

BLADE ROLLER |

SPEED |

|

GUIDE |

DIAL |

|

VENTILATION |

|

SLIDE |

|

|

|

SWITCH |

|

|

|

OPENINGS |

|

|

|

|

|

|

|

|

BLADE CHANGE |

|

|

|

ALLEN |

BUTTON |

|

|

|

WRENCH |

TOP HANDLE |

|

|

|

5MM |

|

|

|

VACUUM |

|

|

|

|

|

|

|

|

|

|

HOSE |

|

|

|

|

DUST PORT |

|

|

|

|

CONNECTOR |

BLADE |

|

|

|

(1584DVS) |

PLUNGER |

|

|

|

DUST PORT |

DUST COVER |

|

|

CHIP |

(1584DVS) |

(1584DVS) |

|

|

BLOWER |

|

CUTTING |

|

|

LEVER |

|

GUIDE SLOTS |

|

|

|

1 |

|

BLADE ORBIT |

|||

|

|

|||

FOOTPLATE |

|

SELECTOR |

|

|

|

|

|

LEVER |

VARIABLE |

BLADE |

BLADE ROLLER |

SPEED |

||

|

DIAL |

|||

|

GUIDE |

|

||

|

|

|

||

|

Maximum capacities: |

|||

|

Material |

|

Size |

|

|

Wood |

|

2-3/8" (60mm) |

|

|

Plastic |

|

1-1/4" (32mm) |

|

|

Aluminum |

|

3/4" (20mm) |

|

|

Non-ferrous metal |

3/4" |

(20mm) |

|

|

Mild steel |

|

3/8" |

(10mm) |

|

Stainless steel |

|

1/8" |

(3mm) |

|

Alloy steel |

|

1/8" |

(3mm) |

-6-

BM 2610993482 2-04 2/9/04 9:17 AM Page 7

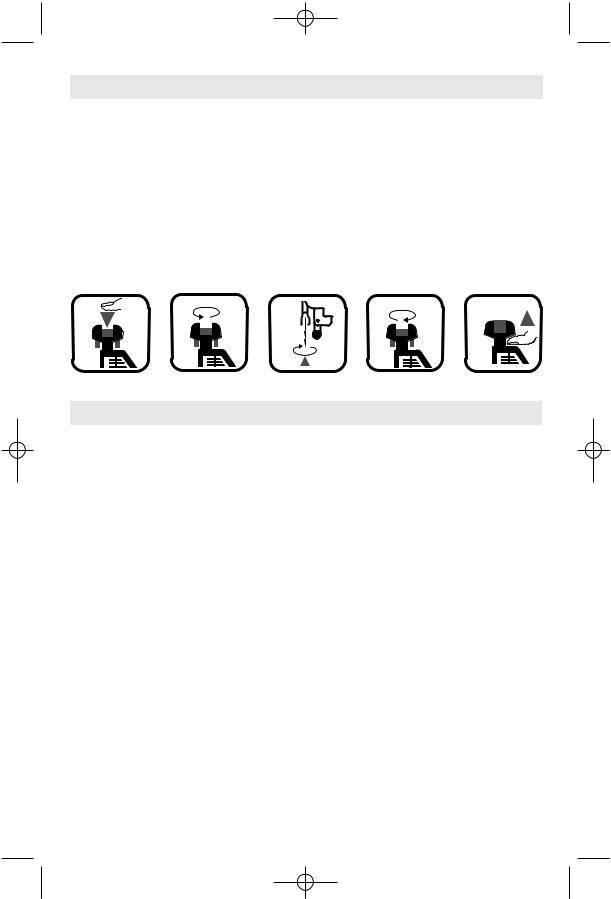

Assembly

BLADE INSTALLATION

Set the blade orbit selector lever to position III.

Push blade change button downward as far as it will go and turn the top handle three turns counterclockwise (viewed from the top of the tool).

Insert the blade into blade plunger at a 90˚ angle to the cutting direction. With a slight upward pressure, turn the blade teeth forward (direction of cut) and guide the back of the blade into the groove in the center of blade roller guide. Pull gently down on the blade to seat the blade tabs in the plunger.

With the blade in the proper position, turn top handle clockwise until a noticable “Clic” sound is heard, indicating that the blade is locked in place.

Push blade change button upward to its original position (flush with the top of the top handle), and the saw is ready for use.

Removing the blade is essentially the reverse of the installation procedure, however, take note that once the blade change button is loosened, gently push the blade upward to release the blade tabs from the plunger.

1. |

2. |

3x |

3. |

4. clic |

5. |

Operating Instructions

SLIDE "ON-OFF" SWITCH

The Tool is switched "ON" by the slide switch located at the side of the motor housing.

TO TURN TOOL "ON": slide the switch forward.

TO TURN TOOL "OFF": slide the switch backward.

VARIABLE SPEED DIAL

This tool is equipped with a Variable Speed Dial. The stroke rate of the Blade Plunger may be controlled by presetting the dial in any one of six positions.

Setting |

SPM rating (strokes per minute) |

1-2 |

Low stroke (1 = 500 SPM) |

3-4 |

Medium stroke |

5-6 |

High stroke (6 = 3100SPM) |

PLUNGER SPEED

The jigsaw cutting speed or stroke rate required depends on the material being cut, the type of blade used, and the feed rate preferred by the operator. The best speed for a particular application is largely determined by experience, though as a general rule, slower speeds are for denser materials and faster speeds for soft materials. Note that when the jigsaw is used at low speed settings for any

length of time, the motor temperature will rise due to the slower speed of the internal cooling fan. In such cases, it is necessary to occasionally run the tool at full speed for a few minutes to keep the motor operating at high efficiency.

BLADE ORBIT

Maximum cutting efficiency can be obtained by adjusting the blade orbit selector lever to suit the material being cut. The following chart will help you determine which setting to use for your application. This chart is intended as a guideline only, and test cuts in scrap material should be performed first to determine the best setting.

Setting O hard materials such as metals or thin sheet metals and used with knife blades, grit edge blades or rasp work

Setting I soft materials where cleaner cutting or delicate scrolling work is performed

Setting II medium density materials such as harder woods or particle board

Setting III soft materials such as wood, plastics, etc.

-7-

BM 2610993482 2-04 2/9/04 9:17 AM Page 8

The following types of blades should only be used with orbital Setting O:

1. Blades with teeth that point downward (reverse-tooth blades).

2.Blades with teeth that point straight out rather than up or down.

3.Carbide-tipped blades.

4.Grit-edge blades.

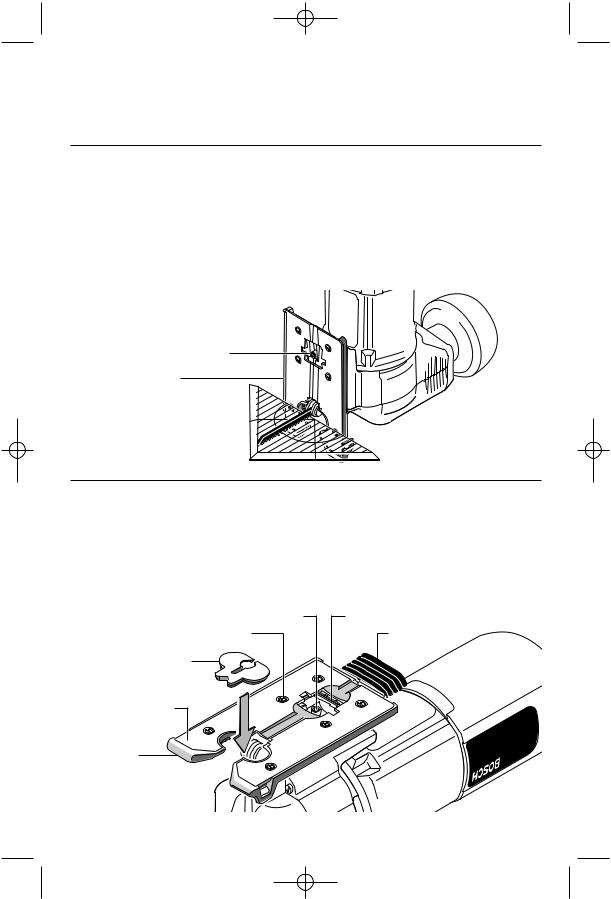

FOOTPLATE ANGLE ADJUSTMENT

The footplate may be tilted to allow angle cuts up to 45˚ in either direction. To adjust footplate, loosen screw (A) with allen wrench, slide the footplate towards the front of the tool, and rotate to the desired angle, as marked on the angle scale. Detent slots will hold the footplate firmly at 0˚, and there are additional position marks for 15˚ and 45˚ angles.

Intermediate angles may be set with a protractor. After positioning the footplate, securely tighten screw (A).

On model 1584DVS, screw (A) is covered by sliding cover, which should be closed after making the footplate adjustment. Note that when the footplate is used on an angle, dust cover must be removed, and chip collection efficiency will be reduced.

SCREW (A)

FOOTPLATE

PROTRACTOR (Not included)

(Not included)

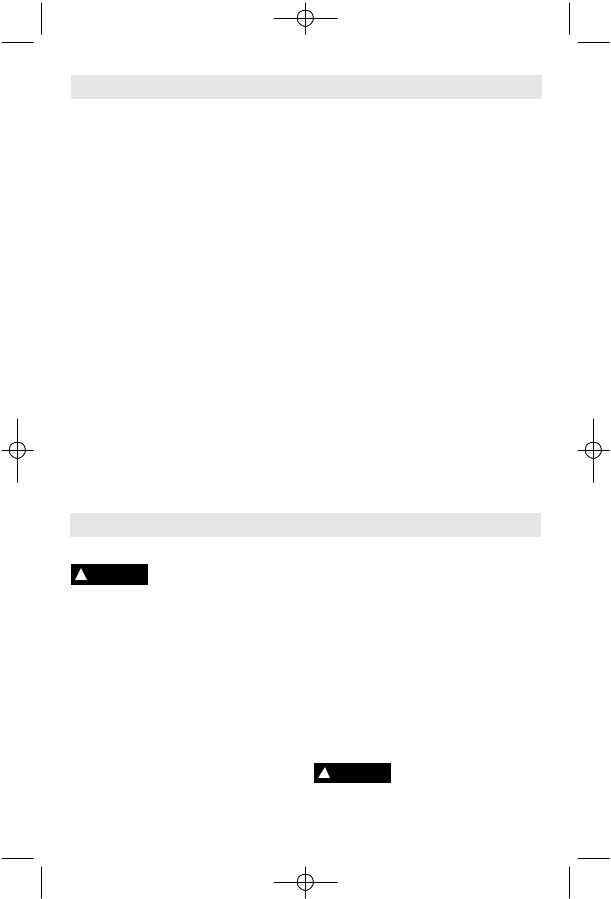

FOOTPLATE INSERTS (1584AVS & 1584DVS)

Model 1584AVS & 1584DVS will accept two footplate inserts which may be changed by removing the six screws (B). The steel insert is used for most general cutting operations, and the smooth plastic insert may be used to minimize scratches on fine surfaces.

ANTI-SPLINTER INSERT

To minimize splintering of the top surface of the material being cut, place the anti-splinter insert in the blade opening of the footplate. Note: This insert will only work with blades that have ground sides such as T301CD, T101B, T101D, and T101DP.

SCREW (A) |

COVER (1584DVS) |

SCREW (B) |

DUST PORT |

(1584AVS & 1584DVS) |

(1584DVS) |

ANTI-SPLINTER

INSERT

FOOTPLATE INSERT |

(1584AVS & 1584DVS) |

FOOTPLATE

-8-

BM 2610993482 2-04 2/9/04 9:17 AM Page 9

FLUSH CUTTING

To allow the saw to make a perpendicular cut close to a vertical surface, the footplate may be repositioned as follows. Remove screw (A), move footplate to the front mounting slot, and be sure the detent notch is aligned with the

detent slot in the footplate. Re-insert screw (A) into the threaded hole closest to the detent notch, and securely tighten. Note that when the footplate is retracted in this manner, only 90˚cuts are possible, and dust cover or optional cutting guide may not be used.

DETENT NOTCH

DETENT NOTCH

0

15 30 45

ANGLE SCALE

SCREW (A)

CHIP BLOWER

The jigsaw is equipped with a three-position chip blower to help keep the cutting line clear of chips. By adjusting the chip blower lever, the force of the discharged air may be altered as follows;

Strongest blowing action for working in woods and similar materials.

Medium blowing action.

No blowing action

DUST EXTRACTION (1584AVS & 1584DVS)

Model 1584DVS is equipped with a dust port for chip extraction. To use this feature, attach vacuum hose (optional accessory) to the dust port connector, than attach the dust port connector to the dust port. Connect the other end of hose to a shop vacuum cleaner with

*Included in "Dust Collection Adapter Kit"

*DUST PORT

adapter (optional accessories). For maximum efficiency, dust covermust be in place.

Model 1584AVS can be converted to dustless by adding the "Dust Collection Adapter Kit" which is available from Bosch Service Centers or Distributors.

* DUST PORT CONNECTOR

0 15

30 45

* COVER

SCREW (A)

FOOTPLATE

PLATE

* COVER

FOOTPLATE INSERT

SCREW (B)

-9-

BM 2610993482 2-04 2/9/04 9:17 AM Page 10

Tool Tips

Always be certain that smaller workpieces are securely fastened to a bench or other support. Larger panels may be held in place by clamps on a bench or sawhorses.

To begin a cut, clearly mark the cutting line, and rest the front of the footplate on the work. Engage the switch, and move the blade into the work using only enough forward pressure to keep the blade cutting steadily. DO NOT FORCE, as this will not make the saw cut faster; let the blade do the work.

When cutting metal, it is often advisable to use a lubricant to cool the blade and extend its life.

Choose blades carefully, as the ability of the jigsaw to follow curves, provides smoother finishes, or faster cutting is directly related to the type of blade used.

BLADE SELECTION

•Choose blades carefully, as the ability of the jigsaw to make the fastest cuts, to follow tight curves, to achieve the smoothest finish and/or to maximize the life of the blade are directly related to the type of blade used.

•Always use a blade that is appropriate for the cutting task.

•Always make a test cut in a piece of scrap material.

•Most jigsaw blades have upward-pointing teeth, which helps to pull the jigsaw against the workpiece and minimizes vibration. Blades with upward-pointing teeth produce a clean cut on the bottom of the workpiece.

•Blades with downward-pointing teeth (reverse-tooth blade) can be used to produce a clean cut on the top of the workpiece (that side that faces the jigsaw's footplate), such as when cutting an already-installed countertop from the top. When using reverse-tooth blades, downward force must be applied to the jigsaw.

•Blades with teeth that point straight out (rather than up or down) allow splinter-free cutting on both sides of the workpiece. When using such blades, downward force must be applied to the jigsaw.

•The following types of blades should only be used with orbital Setting O:

1.Blades with teeth that point downward (reverse-tooth blades).

2.Blades with teeth that point straight out rather than up or down.

3.Carbide-tipped blades.

4.Grit-edge blades.

Maintenance

Service

Preventive maintenance performed by unauthorized personnel may result in misplacing of

internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Authorized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Bosch replacement brushes specially designed for your tool should be used.

BEARINGS

After about 300-400 hours of operation, or at every second brush change, the bearings should be replaced at Bosch Factory Service Center or Authorized Bosch Service Station. Bearings which become noisy (due to heavy load or very abrasive material cutting) should be replaced at once to avoid overheating or motor failure.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak

Cleaning

! WARNING To avoid accidents always disconnect the tool from

the power supply before cleaning or

-10-

Loading...

Loading...