A.O. Smith Century Pool Spa Motor User Manual

Installation

—

Maintenance

—

S e rv i c e

—

Troubleshooting

CENTURY®

POOL & SPA MOTOR

MANUAL

INTRODUCTION

elcome to A.O. Smith’s line of Century®

WMotors. This pocket manual is designed for one purpose — to make it simple for you to

install, maintain and troubleshoot Century pool and spa motors. Contrary to what you may be thinking just

now, your last name doesn’t have to be Edison in order to properly service the motors shown in the following pages. All you need are a few basic tools and some helpful hints; the kind that appear throughout this

booklet.

We’ve included all the information we think you’ll need to repair the most common pump motor problems encountered out in the field. This easy to read manual contains great illustrations and diagrams for quick

reference. Assisting your customers is your job. Helping you do that with minimum delay is our job; that’s why we’ve prepared this informative manual.

1

Replacements for every brand. Every now and then you probably come across a motor that’s beyond repair. When you do, remember that A.O. Smith manufactures replacement pool and spa motors for practically every brand you’ll ever encounter in the field. So save yourself some time and effort and just ask for Century first — at any A.O. Smith distributor or dealer. Century motors are as rugged as any you’ll find, but keep in mind that all motors need service and maintenance at one time or another.

Safety first. Remember, before you begin to work on any electrical appliance be sure to TURN OFF THE POWER. The only time you’ll need the power on is

when you check motor voltage and amperage. If you overlook this important guideline, someday you could unexpectedly get a real charge out of your work! Always play it safe — double-check to be certain that the power is off before you start to work on a pool or spa motor.

If you have any suggestions or would like more information about a particular subject, please write or call:

A.O. Smith

531 North Fourth Street

Tipp City, OH 45371

800-543-9450

2

TABLE OF CONTENTS

Century Pump Motors ...................................................... |

5 |

Design Features................................................................ |

7 |

Nameplate Information.................................................... |

9 |

Installation |

|

Heat.......................................................................... |

13 |

Moisture................................................................... |

14 |

Power Source.......................................................... |

14 |

Altitude..................................................................... |

14 |

Mounting.................................................................. |

14 |

Electrical Connections ............................................. |

15 |

Grounding................................................................ |

15 |

Wire Size.................................................................. |

15 |

Wire Selection Guide..................................................... |

16 |

Tools ................................................................................ |

17 |

Maintenance |

|

Moisture................................................................... |

17 |

Cooling..................................................................... |

18 |

Seasonal................................................................... |

18 |

Cleaning................................................................... |

18 |

Lubrication............................................................... |

18 |

3

Motor Troubleshooting |

|

Motor Fails To Start (makes no sound).................. |

19 |

Motor Fails To Start (hums, tries to start, |

|

blows fuse or trips breaker).................................... |

20 |

Motor Starts But Shuts Down |

|

(overload problem).................................................. |

21 |

Noisy Motor..................................................................... |

21 |

Motor Hot, Smoking Or Cycling .................................... |

22 |

Information Needed For Motor Replacement .............. |

23 |

Troubleshooting A Capacitor ......................................... |

23 |

Best Way To Use A Volt-Ammeter................................. |

24 |

How To Replace Bearings.............................................. |

24 |

Service ............................................................................ |

27 |

Wiring Diagrams’ Table of Contents............................. |

28 |

Wiring Diagrams....................................................... |

29-54 |

Date of Manufacture Table ............................................ |

55 |

4

CENTURY® CENTURION &

Centurion®, C-flange

Switchless “1081” Motor

•Standard Efficiency

•E-Plus, High Efficiency

•1⁄2 – 5 Hp

•No Switch, No Governor

•Single phase or three phase

•Suitable for operation at 50 Hz,

1.0service factor

•Aluminum or cast iron NEMA “C” mounting brackets

•True NEMA 56-frame

•Keyed or threaded shaft

•UL standard “1081” approvable

•Full-rated and Up-rated

•50° C Ambient

•Available as a Century two-speed motor

Centurion® SE, C-flange

Switchless “1081” Motor

•1⁄2 – 5 Hp

•Standard Efficiency

•Single phase

•Aluminum NEMA “C”

mounting brackets

•50° C Ambient

•True NEMA 56-frame

•Keyed or threaded shaft

•UL Standard “1081” approvable

•Full-rated and Up-rated

•303 stainless steel shaft

5

E-PLUS® MOTORS

Centurion®, Square Flange

Switchless “1081” Motor

•Standard Efficiency

•E-Plus, High Efficiency

•1⁄2 – 5 Hp

•No Switch, No Governor

•303 stainless steel threaded shaft

•Suitable for operation

at 50 Hz, 1.0 service factor

•Single or three phase

•True NEMA 56-frame

•UL standard “1081” approvable

•Full-rated and Up-rated

•50° C Ambient

•Available as a

Century two-speed motor

Neptune®, C & Square Flange

•Standard Efficiency

•High Efficiency

•1⁄2 – 3 Hp

•Advanced Switch Technology

•48 frame shell diameter

•303 stainless steel threaded shaft

•UL standard “1081” approvable

•Full-rated and Up-rated

•50° C Ambient

6

FLEX-48™

POOL AND SPA MOTORS

Flex-48™ Single-Speed Motors, Thru-Bolt Mount

Suitable for jetted tubs and above-ground pools and spas.

•1⁄2 - 3 Hp

•56-frame conversion base

•3-1⁄2” shaft height

•3⁄8” threaded shaft

•Auto-reset overload

protection

• 1.0 service factor

Flex-48™ Two-Speed Low Amp Start & Run Motors

For Spas and above-ground pools, thru-bolt mount.

•3⁄4 - 3 Hp

•56-frame conversion base

•3-1⁄2” shaft height

•3⁄8” threaded shaft

•Auto-reset overload

protection

• 1.0 service factor

CENTURION®

DESIGN FEATURES

entury pool and spa pump motors are tailored for

Cdemanding pool loads and environments. Check these outstanding features:

1.Full-rated 56-Frame diameter gives greater thermal capacity, better durability with industrial quality construction.

7

CENTURION®

DESIGN FEATURES

2.All Threaded shafts are 303 stainless steel for superior corrosion resistance. Keyed shaft of carbon steel is iron phosphate treated to prevent rust. Stainless steel shafts provided on cast iron C-flange, keyed shaft product.

3.Double-sealed high thrust bearings protect against dirt and moisture. Factory lubricated, never need regreasing.

4. Special aluminum alloy brackets or cast iron NEMA “C”

brackets resist corrosion from pool chemicals.

5.Drive-end bearing locked to limit shaft endplay.

6.Continuous rated run capacitor provides high running efficiency and better starting performance in low voltage situations.

7.Easy connect terminal board is designed with screw post line terminals. All you need is a screwdriver for fast and easy installation wiring.

8.Moisture resistant, Class B insulated windings for extra protection against moisture, high ambient temperatures, salt spray, chemicals, diatomaceous earth, sand, dirt, insects, etc.

9.Motors designed to meet UL Standard #1081, protects internal components from rain, dirt and chemicals.

10.Class B automatic reset overload protector suitable for high ambient temperatures. Prevents nuisance tripping in hot areas.

8

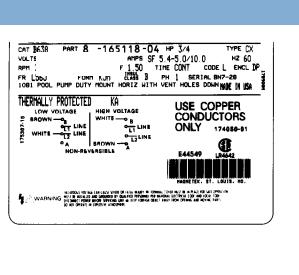

NAMEPLATE INFORMATION

hen you need information about the motor

Wyou’re servicing, you’ll always be able to find it printed on the motor nameplate. On A.O. Smith motors the nameplate is usually found on the side of the

motor, below the capacitor. Shown below is a sample pool motor identification nameplate. As you read the nameplate, refer to the guide so that you understand the meaning of each item that the manufacturer provides about its motor. Remember also that your dealer or distributor can give you valuable information that can help you to make the correct selection of a replacement motor.

9

1.CAT NO (Catalog Number): This number indicates

that the motor is a stock rating, readily available

from standard inventory as a replacement pool

motor.

2.PART: This identifies the motor’s specific design by part number.

3.FR (Frame): The frame identifies the mounting and shaft configuration. It doesn’t indicate the diameter of the shell. A.O. Smith’s line of Centurion and Centurion SE motors have a “56 frame” shell and are 6.5 inches in diameter. Neptune and Flex-48 products are designed in a 48 frame shell

and are 5.6 inches in diameter. Common terms you’ll see on the nameplate are “56J,” “56C” and “56Y.” The 56J is always a C-flange, threaded-shaft motor; the 56C is always a C-flange, keyed-shaft motor. Motor-frame mountings with the “Y” identification

10

NAMEPLATE INFORMATION

identify motors not specified by NEMA mounting and shaft standards.

4.TYPE: The electrical design of the motor is shown by its type. A.O. Smith uses “CX” to identify its switchless design. Other codes include “CS” for capacitor-start, “S P” for split-phase and “CP” for capacitor start / capacitor run. Be sure to check with the dealer or distributor, because motor type codes may vary among manufacturers.

5.HP (Horsepower): Conventional unit of measurement for power. One horsepower equals 746 watts.

6.RPM (Revolutions Per Minute): RPM states the rotational speed of the shaft at rated load.

7.HZ (Hertz): Measurement of frequency, equaling cycles per second of alternating current.

8.PH (Phase): Denotes a singleor three-phase motor.

9.SF (Service Factor): Service factor is the measure of the reserve margin built into a motor. Motors rated over 1.0 SF allow the motor to operate at a higher margin than designated by the horsepower rating. Maximum horsepower capability equals horsepower multiplied by the SF.

(continuous operation).

10.VOLTS: Voltage is the required electrical potential applied to the motor, the force that produces current in an electrical conductor.

11.AMPS: Electrical current flowing through the conductors. On pool motors, the amperage is maximum or service factor amps that result at

11

maximum horsepower (Hp x SF).

12.TIME: Time indicates the duty cycle of the motor. Pool and spa motors are generally rated for continuous duty.

13.AMB (Ambient Temperature): The maximum ambient (surrounding) temperature in which the motor is designed to operate. This temperature is shown in Celsius rather than Fahrenheit.

14.INSUL CLASS (Insulation Classification):

The temperature rating of insulation used in the construction of the motor. Most pool and spa motors use a Class “B” insulation.

15.ENCL (Enclosure): Common enclosures used include DP (dripproof) and TEFC (totally enclosed fan cooled). Most pool and spa motors feature a dripproof design, with “1081” features.

16.CODE: The NEMA code letter specifies locked rotor kVA per Hp (volts multiplied by locked rotor amps, divided by 1000 times rated HP).

17.SERIAL: The serial indicates the date of manufacture, which often appears as year/month combinations. Serial code information for each pool and spa motor can be found in guides and bulletins provided by the manufacturer (See p.55).

18.VOLTAGE DIAGRAM: This diagram provides information on the correct electrical connections to ensure proper operation of the motor.

19.WARNING: The warning at the bottom of the label re-emphasizes that voltage can be hazardous. Always TURN THE POWER OFF before working on a pool or spa motor.

12

INSTALLATION

The number one enemy of a motor is heat. Overheating always results

whenever there is a lack of clean, continually-circulating air for a motor. Heat can damage a motor’s windings, insulation, bearing lubricant and run capacitor. In short, heat can quickly decrease the service life of a motor. Remember, proper ventilation is always a crucial consideration when installing a motor.

If at all possible, install a motor in a location that is free of dirt, dust or airborne debris, such as leaves. Indoors is best, but not in areas with high humidity, such as a laundry room or shower area. If the motor is installed outdoors, try to choose a shady spot that’s protected from leaves and grass clippings. If you cover the motor to protect it from possible debris or water, be sure to leave enough space between the cover and the motor for adequate ventilation.

A.O. Smith single phase pool and spa motors feature a thermal overload protector that will shut down the motor if it overheats. As the windings begin to cool down, the overload protector will automatically re-start the motor. Blocked ventilation or an overload condition can cause the motor to shutdown on a repeated basis. If a problem cannot be located or if tripping continues after a noted problem is corrected, contact the original equipment contractor for a recommendation on matching motor horsepower to the pump.

TIP: In situations where the ambient temperature is exceptionally hot, utilizing an E-Plus (High Efficiency) motor in place of a standard efficient motor can prevent the overload protector from nuisance tripping.

13

Century and Neptune motors have superior resistance to moisture, but you should avoid placing

the motor where it can be splashed. Avoid installing the motor in low spots where it could collect water and be flooded. In fact, it’s probably a good idea to elevate the motor at least two inches off the ground.

Before you turn the motor on,

check to see that the line voltage, phase and frequency match the specifications shown on the motor nameplate. Current capacity must be adequate enough to maintain rated voltage at the motor terminals under all conditions. If it’s too high, contact the local utility. If it’s too low check for overloaded circuits, loose connections or wire of the wrong gauge (see wire selection guide).

Generally, motors will run hotter with increasing

altitudes. For installations more than 3,300 feet above sea level, it’s advisable to use a motor with the next

larger horsepower rating than the one recommended

for that application at sea level or use a A.O. Smith E-Plus (High Efficiency) motor of the same rating when available.

Fastening the pump and motor assembly securely

to a foundation or base will prevent vibration, loosening, and future misalignment. Make sure that the motor and pump assembly rotate freely before starting the motor.

14

The task of wiring your motor is fairly simple. The wiring

diagrams shown on the following pages are color-coded for easy reading. The appropriate part number is listed in each illustration, just in case you need to order the complete wiring diagram or connection label sticker

for your motor. Make sure the connections are tight to prevent failure or overheating. If you do find loose connections, check for excessive vibration.

Without proper grounding of a motor, serious elec-

tric shock is possible. A grounding conductor should always be connected under the green grounding screw, which is located within the terminal compartment of the motor. National and local electrical codes are important, and should be adhered to when working

on a motor.

Incorrect voltage at the motor terminals can cause

the motor to overheat. It’s a good idea to check the electrical supply wires to confirm that they are sufficient to handle the motor load. For example, if you’re using

a 1-1⁄2 Hp motor at 115 volts over a distance of 150 feet, use #8 wire. If the motor can be installed to

operate on 230 volts, #12 wire should be sufficient for a 150 foot distance.

15

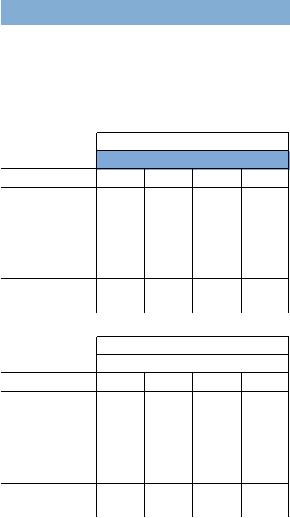

WIRE SELECTION GUIDE

THE SIZES SHOWN IN THE FOLLOWING WIRE SELECTION CHARTS ARE RECOMMENDATIONS ONLY. ALWAYS FOLLOW LOCAL AND NATIONAL ELECTRIC CODES.

115V Power Line

Maximum Distance from Fuse Box to Motor

Motor Hp |

50’ |

100’ |

150’ |

200’ |

1⁄3 |

14 |

14 |

12 |

12 |

1⁄2 |

14 |

12 |

10 |

10 |

3⁄ |

12 |

12 |

10 |

8 |

4 |

|

|

|

|

1 |

12 |

10 |

8 |

8 |

1-1⁄ |

10 |

10 |

8 |

6 |

2 |

|

|

|

|

2 |

10 |

8 |

6 |

6 |

3 |

— |

— |

— |

— |

|

|

230V Power Line |

|

|

|

Maximum Distance from Fuse Box to Motor |

|||

|

|

|

|

|

Motor Hp |

50’ |

100’ |

150’ |

200’ |

1⁄ |

14 |

14 |

14 |

14 |

3 |

|

|

|

|

1⁄ |

14 |

14 |

14 |

14 |

2 |

|

|

|

|

3⁄ |

14 |

14 |

14 |

14 |

4 |

|

|

|

|

1 |

14 |

14 |

14 |

12 |

1-1⁄ |

14 |

14 |

12 |

12 |

2 |

|

|

|

|

2 |

14 |

14 |

12 |

10 |

3 |

12 |

12 |

10 |

10 |

|

|

Guides for copper conductors only. |

||

16

TOOLS

ith a few simple tools, you’ll be ready for just

Wabout any kind of basic motor service. To make your job easier when installing or servicing a

pool or spa motor, make sure that you have these tools

in your toolbox before you begin working...

•Standard screwdriver

•Wide blade screwdriver

•1⁄2” open end wrench

•Rubber mallet

•Clamp-on ammeter/voltmeter

•Ammeter

•5⁄16” nut driver

•Needle-nose pliers

•Tape for marking

MAINTENANCE

.O. Smith pool and spa pump motors are built

Atough, to run day after day without being serviced. When service is necessary, serviceable parts usu-

ally can be accessed quite easily. For example, capacitors are externally mounted, and single-phase motors have screw-type connectors for quick reconnection in the field.

Water leaks from pump seals or pipe joints should

be repaired to prevent failure of bearings and insulation. DO NOT splash or spray the motor. Mount the motor away from low spots and damp areas, and take measures to protect it from windblown rain.

17

Loading...

Loading...