A.O. Smith 500, 750, GB-GW-300, 650 User Manual

GAS-FIRED COMMERCIAL |

|

|

COPPER BOILERS FOR HYDRONIC |

USER'S INFORMATION MANUAL |

|

HEATING AND HOT WATER SUPPLY |

||

|

||

|

GB/GW-300, 400, 500, 650, 750 |

|

|

SERIES 400, 401, 402, 403, 404, 405, |

|

|

2-STAGE UNITS |

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

—Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING

WARNING

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical supply to the pump. Instead, shut off the gas supply at a location external to the appliance.

WARNING

WARNING

Do not use this boiler if any part has been under water. Immediately call a qualified service technician to inspect the boiler and to replace any part of the control system and any gas control which has been under water.

INDEX |

PAGE |

LIGHTING INSTRUCTIONS ....................................... |

2-3 |

MAINTENANCE .......................................................... |

3-4 |

OPERATING SEQUENCE, EMC5000 ......................... |

8-14 |

CONNECTION DIAGRAM ............................................ |

13 |

EMC5000 INSTRUCTIONS ...................................... |

14-18 |

WARRANTY................................................................. |

19 |

CAUTION

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ THOROUGHLY BEFORE INSTALLING AND USING THIS APPLIANCE.

A DIVISION OFA. O. SMITH CORPORATION

MC BEE, SC., RENTON, WA.,

STRATFORD-ONTARIO, VELDHOVEN-THE NETHERLANDS www.hotwater.com

|

PLEASE KEEP THESE INSTRUCTIONS ADJACENT TO BOILER AND |

|

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE. |

PRINTED IN U.S.A. 0306 |

PART NO. 212132-001 |

1

THE UNIT SHOULD NOT BE INSTALLED DIRECTLY ON A CARPETED FLOOR. A FIRE HAZARD MAY RESULT. Instead, the boiler must be installed on the A. O. Smith Combustible Floor Kit Base or concrete blocks extending beyond the full width and depth of the boiler by at least 3 (76.2mm) inches. If the boiler is installed in a carpeted alcove, the entire floor must be covered with concrete blocks, or use the A. O. Smith Combustible Floor Kit Base.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER BE PLACED ON ORADJACENT TO THE BOILER. OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT BE STORED OR USED IN THE SAME ROOM WITH THE BOILER.

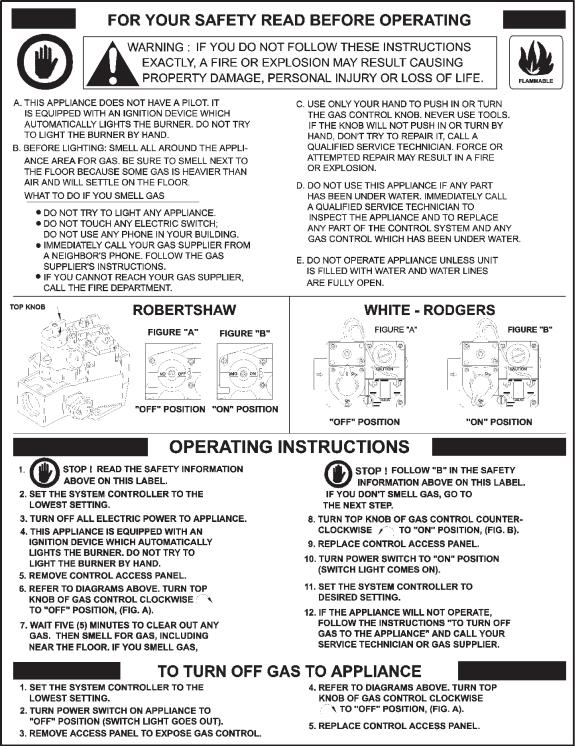

Light the unit in accordance with the instructions on the lighting and operating label attached to the boiler. These instructions are repeated on the following two pages.

Lighting Instructions for the G(B/W) 300 through 750 models

2

LIGHTING INSTRUCTIONS

These models have an automatic hot surface ignition system mounted on the combustion chamber panel inside the front jacket. This hot surface igniter ignites the main burner gas whenever the system control calls for heat.

Before proceeding with operation of the unit, make sure the boiler and system are filled with water and all air is expelled from the boiler, radiator tank(s) and piping.

WARNING

WARNING

THE MAIN MANUAL GAS SHUT-OFF VALVE MUST HAVE BEEN CLOSED FOR AT LEAST FIVE (5) MINUTES BEFORE LIGHTING. This waiting period is an important safety step. Its purpose is to permit gas that might have accumulated in the combustion chamber to clear. IF YOU DETECT GAS AT THE END OF THE PERIOD DO NOT PROCEED WITH LIGHTING. RECOGNIZE THAT GASODOR,EVENIFITSEEMSWEAK,MAYINDICATEPRESENCE OFACCUMULATEDGASSOMEPLACEINTHEAREAWITHARISK OF FIRE OR EXPLOSION.

WARNING

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH AS GAS WATER BOILERS IN ROOMS, GARAGES OR OTHER AREAS WHERE GASOLINE AND OTHER FLAMMABLE LIQUIDS ARE USED OR STORED, OR ENGINE-DRIVEN EQUIPMENT OR VEHICLES ARE STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS ARE HEAVYAND TRAVEL ALONG THE FLOORAND MAY BE IGNITED BYTHE BOILER'S MAIN BURNER FLAMES CAUSING FIRE OR EXPLOSION. Some local codes permit operation of gas appliances if installed 18 inches or more above the floor. This may reduce the risk if location in such an area cannot be avoided.

TEMPERATURE REGULATION

DANGER

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/ OR DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS VARIES WITH THE PERSON'S AGE AND TIME OF EXPOSURE. THE SLOWER RESPONSE TIME OF CHILDREN, AGED OR DISABLED PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW THEIR OWN BATH WATER. NEVER LEAVE A CHILD OR DISABLED PERSON UNATTENDED IN A BATHTUB OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA WHERE THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET TEMPERATURES.

It is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the water temperature be set for the lowest temperature which satisfies the user's hot water needs. This will also provide the most energy efficient operation of the water heater and minimize scale formation.

SETTING THE WATER HEATER TEMPERATURE AT 120°F WILL REDUCE THE RISK OF SCALDS. Some states require settings at specific lower temperatures. Table 1 below shows the approximate time-to-burn relationship for normal adult skin.

Table 1: Risk of Scalds

Temperature |

Time to Produce 2nd & 3rd |

Setting |

Degree Burns on Adult Skin |

|

|

Over 170°F |

Nearly instantaneous |

160°F |

About 1/2 second |

150°F |

About 1-1/2 seconds |

140°F |

Less than 5 seconds |

130°F |

About 30 seconds |

120°F or less |

More than 5 minutes |

|

|

BOILER LOCATION

Water heater life depends upon water quality, water pressure and the environment in which the water heater is installed. Water heaters are sometimes installed in locations where leakage may result in property damage, even with the use of a drain pan piped to a drain. However, unanticipated damage can be reduced or prevented by a leak detector or water shutoff device used in conjunction with a piped drain pan. These devices are available from some plumbing supply wholesalers and retailers, and detect and react to leakage in various ways:

•Sensors mounted in the drain pan that trigger an alarm or turn off the incoming water to the water heater when leakage is detected.

•Sensors mounted in the drain pan that turn off the water supply to the entire home when water is detected in the drain pan.

•Water supply shutoff devices that activate based on the water pressure differential between the cold water and hot water pipes connected to the water heater.

•Devices that will turn off the gas supply to a gas water heater while at the same time shutting off its water supply.

BLOCKED VENT SHUT-OFF SYSTEM

The Boiler is equipped with a blocked vent shut-off system which will close the gas valve and shut off the main burner gas when there is excessive pressure in the vent system due to a partially or completely blocked vent system.

DO NOT ATTEMPT TO OPERATE THE BOILER if this situation occurs. Shut the boiler off before performing all the steps shown in "TO TURN OFF GAS TO APPLIANCE" section of the Lighting and Operating Instructions.

Contact a qualified service agent to inspect the unit and vent system and correct the problem.

VENT SYSTEM

The flue products are corrosive in nature and if the boiler is vented horizontally the flue gases are at a higher pressure than

3

the surrounding air pressure. Inspection of the boiler and vent system is necessary to insure that flue gas leakage to the surrounding area does not occur.

Inspect the external surfaces of the vent system every 3 months for corrosion and leakage. Inspect the vent terminations for corrosion and foreign matter which may be blocking the exhausting flue products. Call a qualified service agent to replace or repair any corroded or leaking parts.

A qualified service agent must inspect the internal surfaces of the vent system and the boiler at least once a year.

BURNER SYSTEM

To maintain safe operation and the greatest efficiency for the boiler, observe the burner flame through the observation port on the jacket panel, once a month for proper flame characteristics.

•The burners should display the following characteristics:

•Provide complete combustion of gas.

•Cause rapid ignition and carry over across all burners and across the entire burner.

•Give quiet operation during ignition, burning and extinction.

•Cause no excessive lifting of flames from the burner ports.

If the preceding characteristics are not evident, check for accumulation of lint or other foreign material that restricts the inlet air or burner ports. Ensure there is the proper amount of air to the burner. Flame lifting from the burner is caused by too much air to the burner.

The burners must be inspected by a qualified service technician at least once a year.

DO NOT STORE COMBUSTIBLE MATERIALS, GASOLINE, OR OTHER FLAMMABLE VAPORS, LIQUIDS IN THE AREA OF THE APPLIANCE. NONCOMPLIANCE MAY RESULT IN FIRE OR EXPLOSION. DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR VENTILATION AIR TO THE APPLIANCE.

CHEMICAL VAPOR CORROSION

Boiler corrosion and component failure can be caused by airborne chemical vapors. Spray can propellants, cleaning solvents, refrigerants, calcium or sodium chloride (water softener salts), waxes, and process chemicals are typical compounds that are potentially corrosive. These materials are corrosive at very low concentration levels with little or no odor to reveal their presence. Products of this sort should not be stored near the boiler. Air which is brought in contact with the boiler should not contain any of these chemicals. The boiler should be provided with air from outdoors when installed in environments having corrosive atmospheres.

CIRCULATION PUMP

Refer to the pump manufacturer's schedule of maintenance for frequency and method of lubricating the pump and motor. Inspect the pump once a month for leaky mechanical seals and/or O-rings and loose or damaged components. Contact a qualified service agent to replace or repair parts as required.

ELECTRONIC HOT SURFACE

IGNITION CONTROL BOARD

The EMC5000 control system is a fully integrated, state of the art electronic control system. It consists of sensors, output devices, a power switch, a 24vac transformer, wiring, and the following printed circuit boards:

Central Control Board (CCB). |

See Figure 1A. |

Flame Control Board (FCB). |

See Figure 1B. |

User Interface Board (UIB). |

This part of the User Interface |

|

Module (UIM). See Figure 3. |

Power Distribution Board (PDB). See Figure 1C. |

|

Touch Sensor Board (TSB). |

This is part of the User |

|

Interface Module (UIM). See |

|

Figure 3. |

The CCB contains circuitry for both master control and flame control for the first stage. The FCB contains circuitry for flame control on up to one additional stage. Dip switches on the CCB and FCB are used to configure the system. The UIB and TSB are included in the User Interface Module (UIM) along with a 4 line by 20-character LCD display. The PDB provides connection points for input power, the water pump, and the transformer. It also distributes power to the system and contains the system fuses.

Dual stage control is accomplished by means of an internal communication network and the FCB's. One FCB is required for each stage beyond initial first stage. The CCB also contains an external communications system to allow for connection to a PC, a modem, or an EMS system. Through this connection multiple boilers can also be linked together.

CAUTION

CAUTION

The internal communications cables should never be connected to the external communications connectors and vice-versa.

There are several microcontrollers used on the board. Three on the CCB, two on the FCB, and one on the UIB. These micros control the temperature and ignition control functions for the boiler. Inherent in the design are the normal operating sequences and safety features associated with a gas ignition control system. The system continuously performs various diagnostic tests to verify proper appliance and control operation. Should an unsafe condition occur, the control will shut down the burner and display a red fault light as well as indicate the cause of the fault on the display. The operating programs for the system are stored in permanent memory inside the micros. User-selectable operating parameters and a history of detected faults are stored in re-writable memory in the micros. A loss of power does not affect either of the memories.

Inputs To CCB and FCB:

•Temperature Sensors:

•Temperature probes (CCB - outlet and either inlet or tank is required): The CCB accepts analog temperature inputs from up to three sensors (inlet, outlet and tank).

•ECO input (CCB - required):

The ECO (Energy Cut-Off) is a Hi-Limit switch, which is located inside the output probe. It is a normally closed switch that opens if the probe is exposed to a temperature higher than the trip point.

•Thermostat input (CCB - optional):

This input is set up to work with an externally connected thermostat that provides a contact closure. If this input is

4

Figure 1A. CCB (Drawing #211758)

5

Figure 1B. FCB (Drawing #211759)

6

Figure 1C. PDB (Drawing #211760)

7

closed and everything else is in the proper state, a "call for heat" condition will be initiated. These leads should be shorted together, when a thermostat is not being used. If it is desired that the thermostat control the temperature of the boiler, the operating setpoint of the system should be set higher than the temperature that the thermostat is controlling to. This will allow the thermostat to control the boiler. When the thermostat closes, a call for heat will be generated until the thermostat determines that the control temperature has been reached.

•Air Pressure Sensors (open condition indicates fault):

•Blocked Flue (CCB - required)

•Normally closed switch that opens if the flue becomes blocked during operation.

•Powered Vent (CCB - optional):

Normally open switch that closes when the powered vent is operating properly. This input is enabled-disabled by a dipswitch on the CCB.

•Blower Prover High (FCB - required on stages that have blowers):

Normally open switch that closes when the air pressures produced by the high-speed blower is above the trip level.

•Gas Pressure Sensors (open condition indicates fault):

•Low Gas (CCB - optional):

Normally open switch that closes when the gas pressure rises above the trip level. This input is enabled/disabled by a dipswitch on the CCB.

•Hi Gas (FCB - optional):

Normally closed switch that opens in the gas pressure exceeds a set value. This input is enabled/disabled by a dipswitch on the CCB and FCB's.

•Water Level Sensor (open conditions indicates fault):

•Low Water Cut Off (CCB - optional):

Normally closed switch opens if a low water condition occurs. This input is enabled/disabled by a dipswitch on the CCB.

•Water Flow Sensor:

•Flow (CCB - required):

Normally open switch that closes when flow exceeds a set value.

•IRI Gas Valve Sensor:

•IRI Gas Valve (CCB - optional):

Normally open switch that closes when the IRI Gas Valve is operating correctly. This input is enabled/disabled by a dipswitch on the CCB.

•Flame Sensor:

•Flame (FCB - required on stage 1 and on stage 2 of a 4 stage system - optional on others):

Returns a signal to the microprocessor if flame is detected in the burner. This input is enabled/disabled by a dipswitch on the FCB.

Outputs from CCB and FCB's :

•Relay Contact Outputs:

•IRI Gas Valve (CCB - 120vacoptional):

Provides electrical power to operate an IRI Gas Valve device.

•Alarm (CCB - 24vacoptional):

Provides electrical power to operate on external alarm. This can be an audio device (i.e. Sonalert), a visual device (lamp), or any other device that will operate with the voltage and current level provided.

•Pump (CCB - 120vac - required on systems that do not have an external pump):

Provides electrical power to directly operate a pump or the coil of an externally connected contactor.

•Powered Vent (CCB - 24vac - optional):

Provides electrical power to operate a powered vent.

•Low and High Speed Blowers (FCB - 120vac - required on

stage 1 and on stage 2 of a 4-stage system and optional on others.):

Independent outputs that provide power to operate low and high speed blower output. Dip switches on the FCB's enable/ disable the use of blowers on stages 2, 3 and 4.

•Igniter (FCB - 120vac - required on stage 1 and on stage 2 of a 4-stage system and optional on others.):

Provides power to operate the Silicon Carbide igniter. Dip switches on the FCB's enables/disables the use of an igniter on stages 2, 3 and 4.

•Gas Valve (FCB - 24vac - required):

Provides power to activate the gas valve. The gas valve cannot be activated when the ECO contacts are open.

•Direct Connection Output:

•Low Water Cut Off (CCB - 24vac - optional):

Directly connected to the 24 vac line to provide power to operate an external LWCO device.

Line Polarity Indicator & Fuse Protection

CCB/FCB Indicator Lamps & Fuses

A green LED is mounted on the PDB to indicate when line voltage is applied. (The PDB also contains a yellow LED, a red LED, and a test-run jumper, that are used during installation to verify proper power connections.) A red LED on the CCB is used to indicate when the 24 vac input fuse has blown. The FCB's also have fuses on their 24vac power line. (Recommended replacement fuses are: Littlefuse p/n 29707.5 for the 7.5 amp CCB fuse, and Littlefuse p/n 297003 for the 3 amp FCB fuses.)

Repeated failure of fuse is an indication of failure to some part of the system.

Yellow LED's are located near the micros on the CCB and FCB's. These LED's are "heartbeat indicators" and blink approximately twice per second to indicate that the micros are running.

Igniters

The Genesis 400 Series Boilers use a Silicon Carbide Igniter.

Appliance Operating Sequence

NOTE: The following sequence is based on a four-stage system with all options and two-speed blowers. It is characteristic of most system configurations.

1.The EMC5000 controller has four modes of operation: Initialization, Standby, Running and Service. The internal CCB and FCB micros control these modes through a sequence of steps (or States) which are further described in the "UIM Operating Procedures" section.

2.When power is applied to the system, it enters the Initialization mode and the following automatic functions are performed:

•A. O. Smith opening screen is displayed on the UIM.

•The system goes through a self-calibration indicated by the green running LED blinking and then staying on: next the red service LED and yellow standby LEDS come on; next the stage 1 service and running LEDS blink on and off followed by stage 2, stage 3, stage 4 and then back to stage 1,2,3,4 LEDS.

8

Loading...

Loading...