Amana ABD2533DEW, ABD2533DEB User Manual

Bottom Freezer

Refrigerator

Use & Care Guide

Important Safety Instructions . . . . . . . . . . . . . . . 1-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Temperature Controls . . . . . . . . . . . . . . . . . . . . 10-11

Fresh Food Features . . . . . . . . . . . . . . . . . . . . . 12-14

Freezer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ice and Water . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Water Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

Food Storage Tips . . . . . . . . . . . . . . . . . . . . . . . 20-22

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . 23-26

Operating Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 28-30

Warranty & Service . . . . . . . . . . . . . . . . . . . . . . . . . 31

Guide d’utilisation et d’entretien . . . . . . . . . . . . . 32 Guía de uso y cuidado . . . . . . . . . . . . . . . . . . . . . . 64

Form No. A/01/06 |

Part No. 12828152 |

www.amana.com |

Litho U.S.A. |

Important Safety Instructions

Important Safety Instructions

Installer: Please leave this guide with this appliance.

Consumer: Please read and keep this Use and Care Guide for future reference; it provides the proper use and maintenance information.

Keep sales receipt and/or canceled check as proof of purchase.

Call: 1-800-688-9900 USA

1-800-688-2002 Canada

Have complete model and serial number identification of your refrigerator. This is located on a data plate inside the fresh food compartment, on the upper right side. Record these numbers below for easy access.

Model Number _______________________________

Serial Number ________________________________

Date of Purchase ______________________________

In our continuing effort to improve the quality and performance of our appliances, it may be necessary to make changes to the appliance without revising this guide.

What You Need to Know About Safety Instructions

Warning and Important Safety Instructions appearing in this guide are not meant to cover all possible conditions and situations that may occur. Common sense, caution and care must be exercised when installing, maintaining or operating appliance.

Always contact the manufacturer about problems or conditions you do not understand.

Recognize Safety Symbols, Words,

Labels

DANGER

DANGER

DANGER – Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING

WARNING – Hazards or unsafe practices which COULD result in severe personal injury or death.

DANGER

DANGER

To reduce risk of injury or death, follow basic precautions, including the following:

Important: Child entrapment and suffocation are not problems of the past. Junked or abandoned refrigerators are still dangerous – even if they sit out for “just a few days.” If you are getting rid of your old refrigerator, please follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so children may not easily climb inside.

• Cut off power cord plug.

This appliance is equipped with a three-prong grounded plug for your protection against possible electrical shock hazards. It must be plugged into a properly grounded wall receptacle. Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to have it replaced with a properly grounded threeprong wall receptacle. Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. Do not use an adapter plug.

Power supply cord with three-prong grounded plug

Properly grounded type wall receptacle

CAUTION

CAUTION

CAUTION – Hazards or unsafe practices which COULD result in minor personal injury or property damage.

1

Important Safety Instructions

Important Safety Instructions

WARNING

WARNING

To reduce risk of fire, electric shock, serious injury or death when using your refrigerator, follow basic precautions, including the following:

1.Read all instructions before using the refrigerator.

2.Observe all local codes and ordinances.

3.Be sure to follow grounding instructions.

4.Check with a qualified electrician if you are not sure this appliance is properly grounded.

5.Do not ground to a gas line.

6.Do not ground to a cold-water pipe.

7.Refrigerator is designed to operate on a separate 115 volt, 15 amp., 60 cycle line.

8.Do not modify plug on power cord. If plug does not fit wall receptacle, have proper receptacle installed by a qualified electrician.

9.Do not use a two-prong adapter, extension cord or power strip.

10.Do not remove warning tag from power cord.

11.Do not tamper with refrigerator controls.

12.Do not service or replace any part of refrigerator unless specifically recommended in Use and Care Guide or published user-repair instructions.

Do not attempt service if instructions are not understood or if they are beyond personal skill level.

13.Always disconnect refrigerator from electrical supply before attempting any service. Disconnect power cord by grasping the plug, not the cord.

14.Install refrigerator according to Installation Instructions. All connections for water, electrical power and grounding must comply with local codes and be made by licensed personnel when required.

15.Keep your refrigerator in good condition. Bumping or dropping refrigerator can damage refrigerator or cause refrigerator to malfunction or leak. If damage occurs, have refrigerator checked by qualified service technician.

16.Have worn power cords and/or loose plugs replaced by a qualified service technician.

17.Always read and follow manufacturer’s storage and ideal environment instructions for items being stored in refrigerator.

18.Your refrigerator should not be operated in the presence of explosive fumes.

19.Children should not climb, hang or stand on any part of the refrigerator.

20.Clean up spills or water leakage associated with water installation.

SAVE THESE INSTRUCTIONS

2

Installation

Installation

Your refrigerator was packed carefully for shipment. Remove and discard shelf packaging and tape. Do not remove the serial plate.

Location

•Do not install refrigerator near oven, radiator or other heat source. If not possible, shield refrigerator with cabinet material (contact a qualified contractor).

•Do not install where temperature falls below 55° F (12° C) or rises above 110° F (43° C). Malfunction may occur at this temperature.

•Refrigerator is designed for indoor household application only.

Measuring the Opening

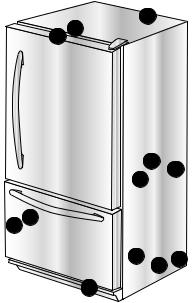

When installing your refrigerator, measure carefully. Allow 1⁄2” space at top and 1⁄2” space behind the machine compartment cover (located in the rear) for proper air circulation.

Subflooring or floor coverings (i.e. carpet, tile, wood floors, rugs) may make your opening smaller than anticipated.

Some clearance may be gained by using the leveling procedure under Leveling.

Important: If refrigerator is to be installed into a recess where the top of the refrigerator is completely covered, use distance from floor to top of hinge cap to verify proper clearance.

Transporting Your Refrigerator

•NEVER transport refrigerator on its side. If an upright position is not possible, lay refrigerator on its back. Allow refrigerator to sit upright for approximately 30 minutes before plugging it in to assure oil returns to the compressor. Plugging the refrigerator in immediately may cause damage to internal parts.

•Use an appliance dolly when moving refrigerator. ALWAYS truck refrigerator from its side or back–NEVER from its front.

•Protect outside finish of refrigerator during transport by wrapping cabinet in blankets or inserting padding between the refrigerator and dolly.

•Secure refrigerator to dolly firmly with straps or bungee cords. Thread straps through handles when possible. Do not over-tighten. Over-tightening restraints may dent or damage outside finish.

3

Leveling

To enhance the appearance and maintain performance, the refrigerator should be leveled per instructions below.

CAUTION

CAUTION

To protect property and refrigerator from damage, observe the following:

•Protect vinyl or other flooring with cardboard, rugs, or other protective material.

•Do not use power tools when performing leveling procedure.

Notes:

•Complete any required water supply connection before leveling.

•Some models only have adjustment screws (A).

Materials Needed:

•3⁄8” hex head driver

•Carpenter’s level.

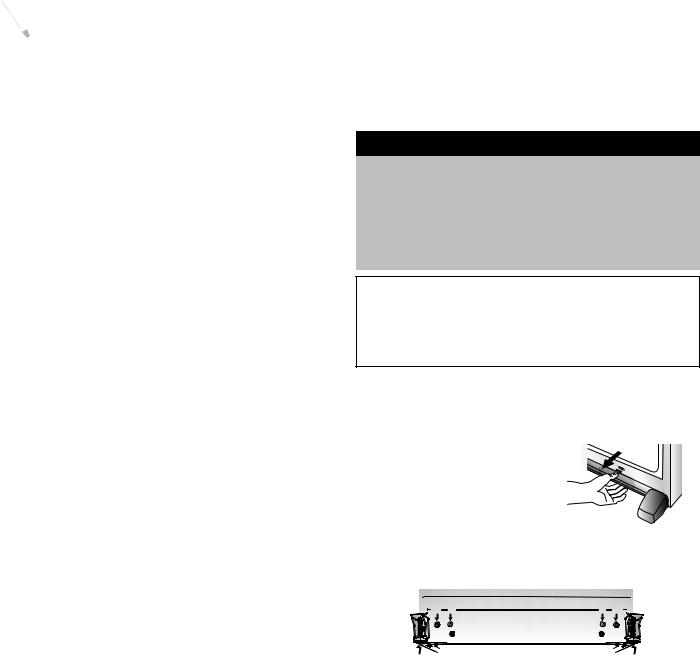

1. Remove toe grille.

• Grasp firmly and pull outward to unclip.

2.Using hex head driver, turn

the front adjustment screws (A) on each side to raise or lower the front of the refrigerator (see illustration below).

A B B A

A B B A

C C

3.Using the hex head driver, turn each of these adjustment screws (B) to raise or lower the rear of the refrigerator.

4.Using a carpenter’s level, make sure front of refrigerator is 1⁄4” (6 mm) or 1⁄2 bubble higher than back of refrigerator and that the refrigerator is level from side to side.

5.Turn stabilizing legs (C) clockwise until firmly against floor.

6.Turn adjustment screws (A) counterclockwise to allow the full weight of the refrigerator to rest on the stabilizing legs.

7.Replace the toe grille.

•Align the toe grille mounting clips with the lower cabinet slots.

•Push the toe grille firmly until it snaps into place.

Installation

Installation

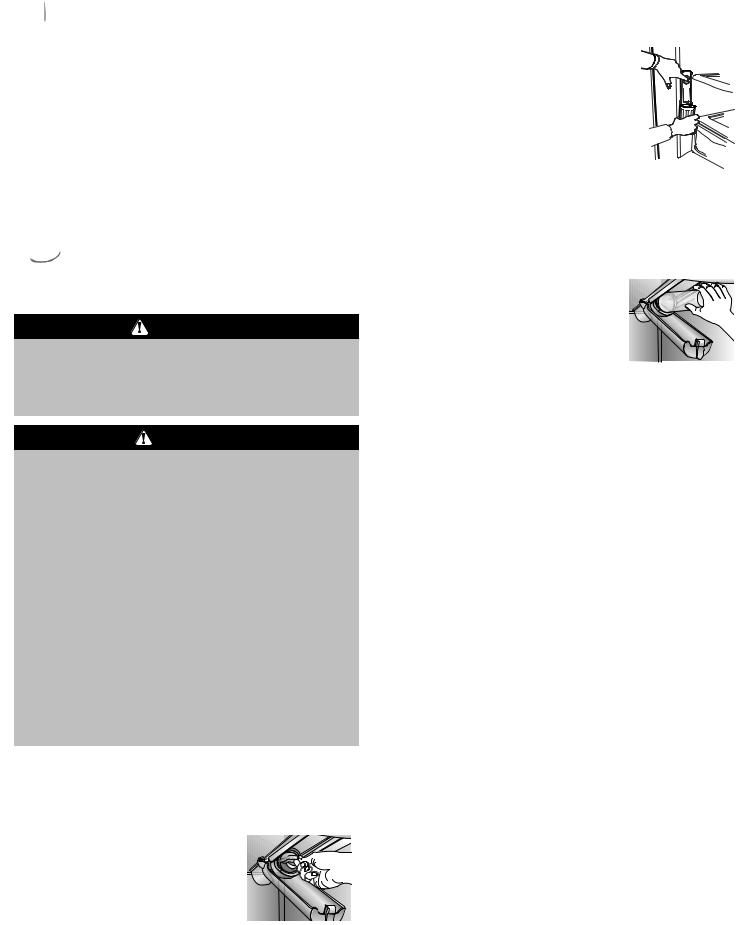

Door and Drawer Removal

Some installations require door/drawer removal to transport the refrigerator to its final location.

WARNING

WARNING

To avoid electrical shock which can cause severe personal injury or death, observe the following:

•Disconnect power to refrigerator before removing doors or drawer. Connect power only after replacing doors or drawer.

CAUTION

CAUTION

To avoid damage to walls and flooring, protect vinyl or other flooring with cardboard, rugs or other protective material.

1. Unplug power cord from power source.

2. Remove toe grille (see page 3).

3. Remove top hinge cover from

refrigerator door by removing Phillips

refrigerator door by removing Phillips

screw and retain screw and cover for

screw and retain screw and cover for

later use.

later use.

4. Unscrew 5⁄16” hex head screws from

top hinge to remove hinge and retain  all screws for later use.

all screws for later use.

5. Lift refrigerator door from center hinge pin.

6. Remove plastic sleeve, if present. Remove center hinge pin with a 5⁄16” hex head driver. Retain hinge pin and plastic sleeve for later use.

7.Remove Phillips screws to remove center hinge and retain all screws for later use.

8. Remove bottom hinge or stabilizing bracket with 3⁄8” hex head driver and retain screws for later use. Lift out bottom hinge pin (on freezer door models).

9. See pages 4-5 for drawer removal instructions.

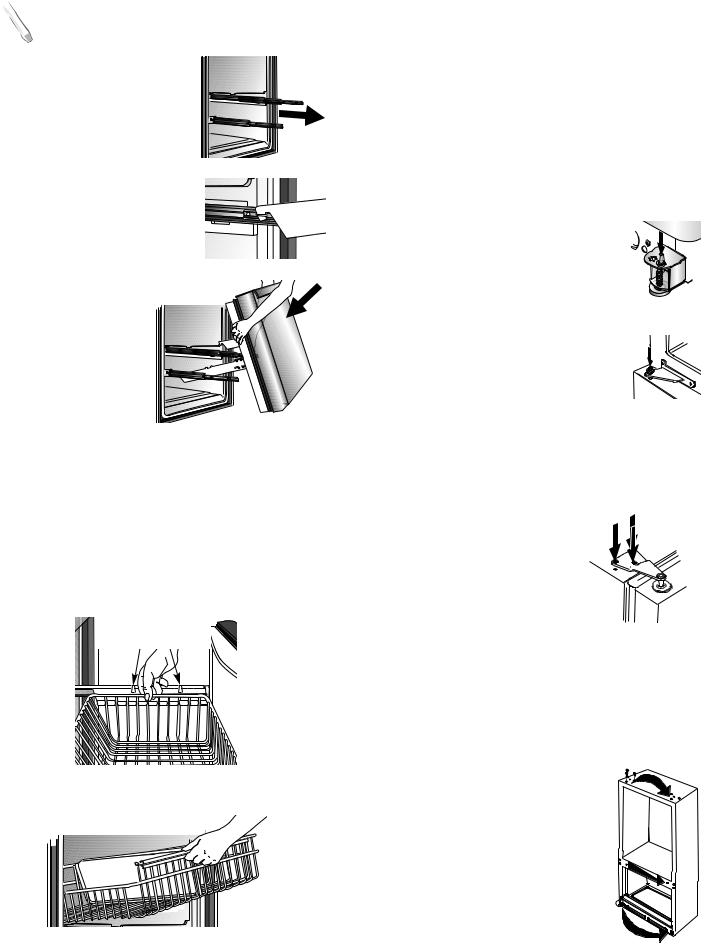

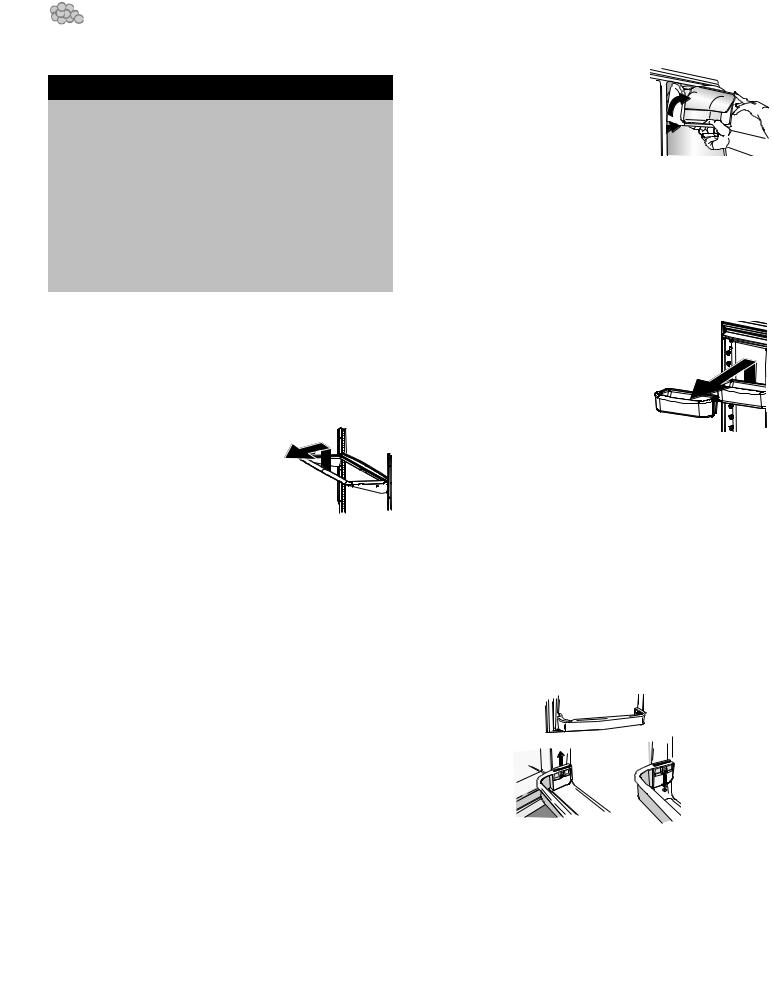

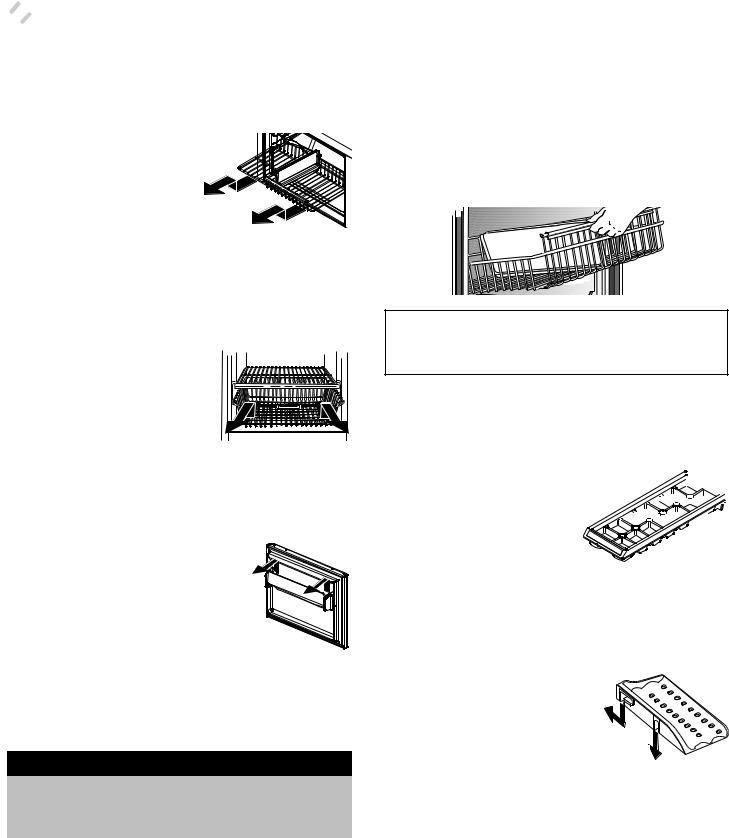

Pullout Freezer Drawer

DANGER

DANGER

To prevent accidental child entrapment or suffocation risk, do not remove the divider in the top freezer basket.

WARNING

WARNING

To avoid electrical shock, which can cause severe personal injury or death, disconnect power to refrigerator before removing doors. After replacing doors, connect power.

CAUTION

CAUTION

To avoid possible injury, product, or property damage, you will need two people to perform the following instructions.

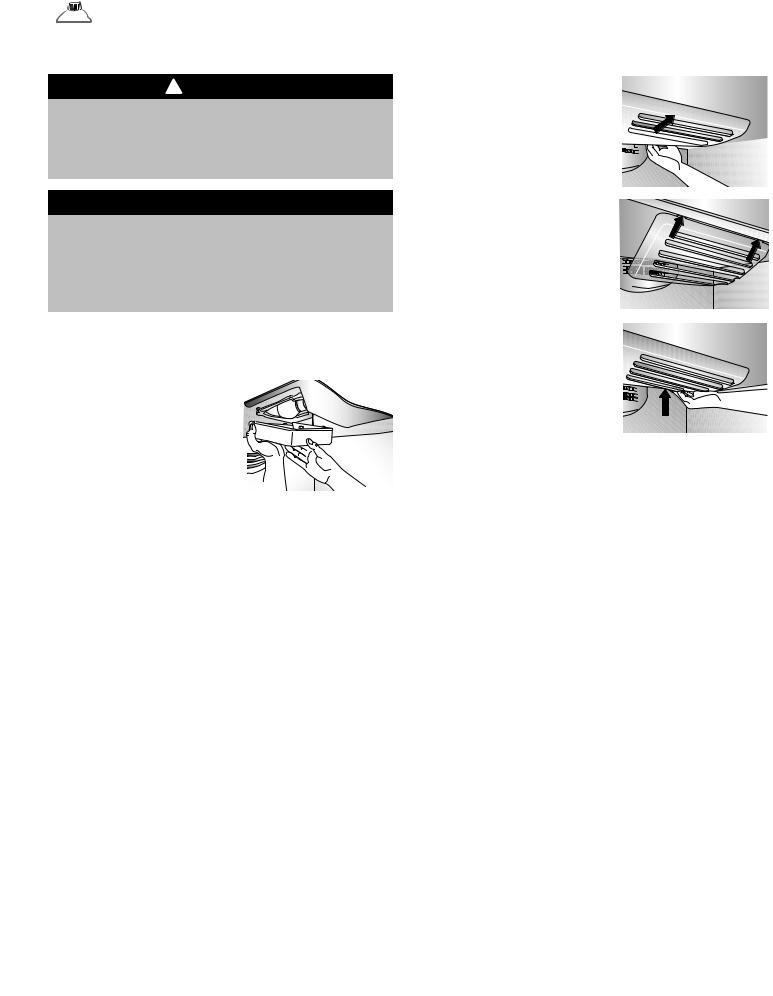

To Remove:

1.Pull drawer open to full extension.

2.Pull upper basket out to full extension and lift out to remove.

3.Lift lower basket straight up and out to remove.

4.On each side rail is a

basket cradle with two snap attachments. To release each cradle, unlatch the snaps by pushing them inward, away from the side rail system. Lift the cradles off of the rails.

5. Remove Phillips screw from each side of rail system (select models).

6. Lift top of drawer front to unhook supports from rail system. Lift door front out to remove.

4

Installation

Installation

To Install:

1. Pull both rails out to full extension.

2. While supporting door front, hook supports into tabs located on inside of rail.

3. Lower door front into final position.

4.Replace and tighten Phillips screws that were removed from each side of rail system (select models).

5.Place the basket cradles back onto the side rails. Align snaps with the slots on the side rails and press each snap towards the rail until it clicks.

6.With rails pulled out to full extension, set the basket straight down into the basket cradles.

Basket cradle snap attachments

7.Slide upper basket into freezer. Make sure that rear of basket hooks behind rail catch.

Reinstallation of the Doors

1.Install hinge assemblies:

•Install top hinge loosely with 5⁄16” hex head screws.

•Install center hinge with Phillips screws.

•Freezer door models: Install bottom hinge with 3⁄8” hex head screws.

2.Freezer door models: Insert bottom

hinge pin.

• Locate bottom hinge hole closest to outside edge of cabinet, and insert bottom hinge pin. Replace any door shims, if present.

3. Freezer door models: Place hinge side of freezer door on bottom hinge pin and hold freezer door upright while installing center hinge pin with 5⁄16” hex head driver.

•Replace plastic sleeve.

•Replace any applicable door shims.

•Make sure the hinge pin is installed tightly.

4.Place hinge side of refrigerator

door on center hinge pin.

5. While holding refrigerator door upright, tighten down top hinge with 5⁄16” hex head driver and replace hinge cover.

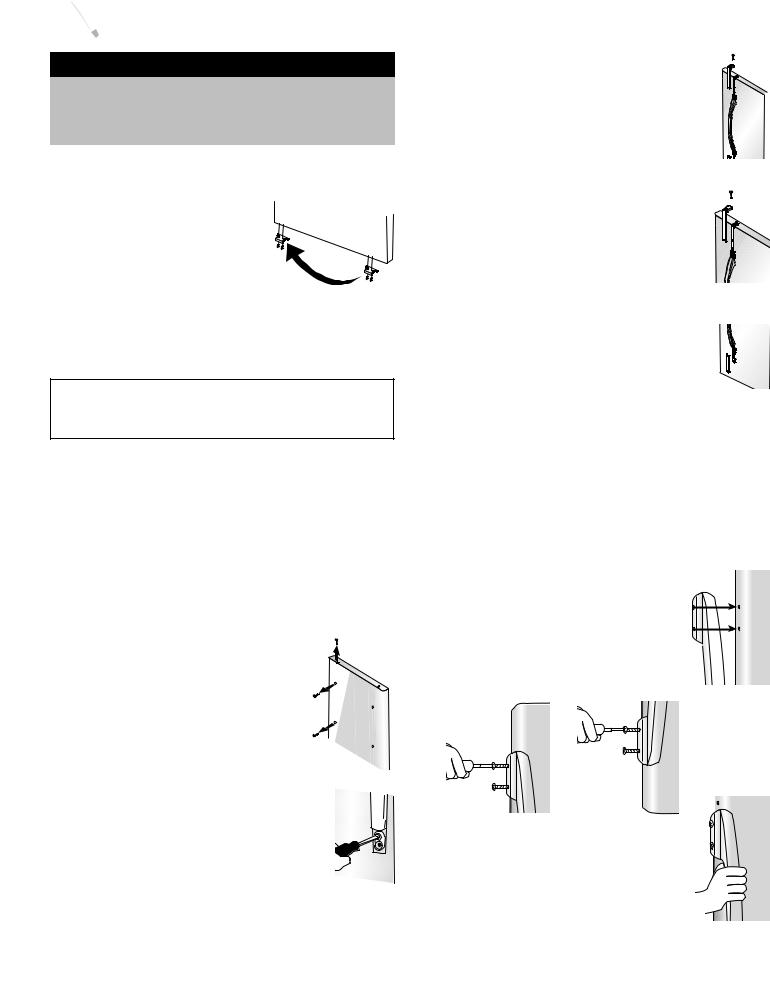

Door Reversal

In some installations, reversing the door swing allows for more convenient access to stored items. Both doors can be reversed on freezer door models and the fresh food door is reversible on freezer drawer models.

1. Remove door(s) (see page 4).

2. Transfer cabinet plugs and cabinet screws to opposite side of cabinet.

• Remove cabinet plugs with flat blade of screwdriver tip wrapped in masking tape.

• Remove center mullion screws with 5⁄16” hex head screwdriver.

•Freezer door models: Remove

bottom mullion screws with 3⁄8” hex head driver.

5

Installation

Installation

CAUTION

CAUTION

To avoid possible injury and damage to property:

•Place doors on a nonabrasive surface protected by towels or rugs while working directly on doors.

3.Transfer door stops from bottom edge of fresh food door and freezer door, if applicable, to opposite side of door edge.

• Use a Phillips screwdriver for removal and installation.

4. Install handles (see below and page 7).

5. Reinstall the door(s).

Handles

Note: If not installed, the handle is located in the interior of the fresh food section or attached to the back of your refrigerator.

Remove and discard handle packaging and tape.

Handle design varies from refrigerator to refrigerator. Please reference the appropriate instructions for your model below.

Fresh Food Handles

Standard Front Mount Handle

Materials Needed:

• Phillips screwdriver

• 5⁄16” hex head driver

To Install:

1. Remove 1⁄4” hex head screws from door face with hex head driver, and Phillips screw from top of door.

•If reversing door, remove door

plugs from opposite side of door and insert in screw holes.

2. Align handle holes with screw holes on door face and secure with two door face screws from step 1.

3. Locate handle trim in literature pack and install over top and bottom of handle, as illustrated.

• Secure top handle trim with remaining screw removed in step 1.

• Snap bottom trim over bottom portion of handle.

To Remove:

1. Remove top handle trim by removing top handle screw.

• Retain trim and screw for later replacement.

2. Pry bottom handle trim from handle with screwdriver flat blade wrapped in masking tape.

•Retain trim for later replacement.

3.Remove two hex head screws.

•Retain screws for later replacement.

Side Mount Handle

Materials Needed:

• Phillips screwdriver

To Install:

1.Remove screws from the side of the door.

2. Align the side mount handle with the predrilled holes in the door panel.

3.Insert the screws in the sequence as shown.

Upper |

2 |

|

Handle |

||

|

|

1 |

4 |

|

Lower |

|

3 |

|

|

|

Handle |

|

|

|

4.Ensure the door handle is snug to the door panel.

To Remove:

Reverse installation procedure.

6

Installation

Installation

Freezer Handles

Partial-Width Handle

Materials Needed:

• Phillips screwdriver

To Install:

1. Install handle by fastening with screws removed from edge of door.

• If reversing freezer door, remove door plugs from top edge of door and insert into screw holes.

To Remove:

1. Remove handle screws with Phillips screwdriver and retain screws for later use.

Front Mount Plastic Freezer Handle

Notes:

•There is a slight curve to this style of freezer handle.

•For proper installation, be sure handle is oriented as shown.

To Install:

1.Align door handle clips to the studs attached to the freezer door.

2.Ensure the large hole in the mounting clip is positioned to the right on both ends of the handle.

Handle Door Stud

Clip  Handle

Handle

Base

Base

3.Rotate the handle so that the handle is flat against the door.

4.Grasp the handle firmly and slide handle to the right.

To Remove:

1.With both hands, firmly grasp the handle toward the right side.

2.Slide toward the left, lift and remove from the surface.

7

Installation

Installation

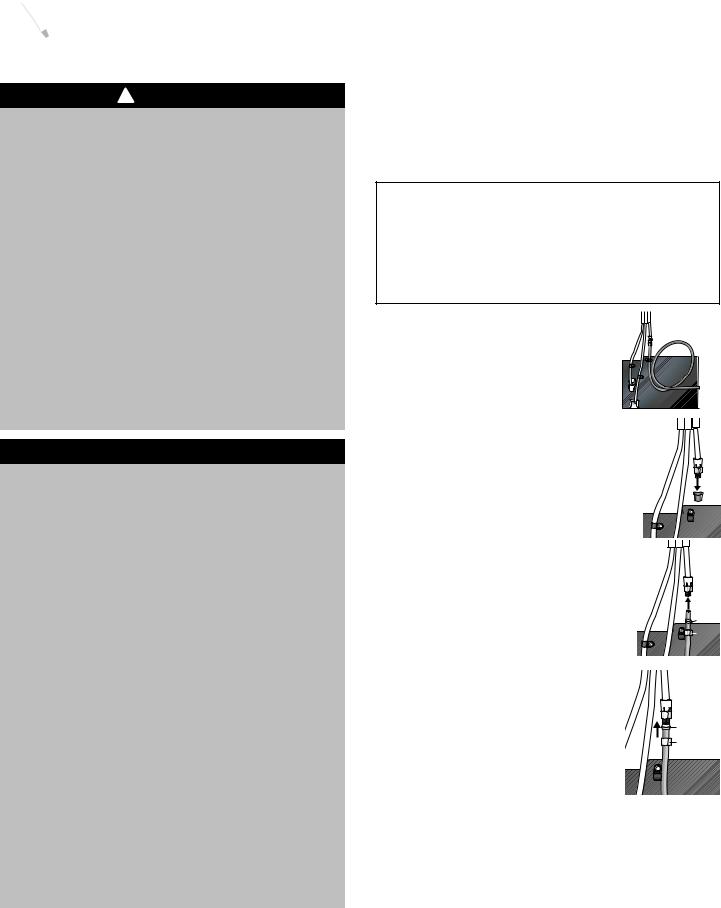

Connecting the Water Supply

WARNING

WARNING

To reduce the risk of injury or death, follow basic precautions, including the following:

•Read all instructions before installing ice maker.

•Do not attempt installation if instructions are not understood or if they are beyond personal skill level.

•Observe all local codes and ordinances.

•Do not service ice maker unless specifically recommended in Use & Care Guide or published user-repair instructions.

•Disconnect power to refrigerator before installing ice maker.

•Water damage due to an improper water connection may cause mold/mildew growth. Clean up spills or leakage immediately!

CAUTION

CAUTION

To avoid property damage or possible injury, follow basic precautions, including the following:

•Consult a plumber to connect 1⁄4” O.D. copper tubing to household plumbing to assure compliance with local codes and ordinances.

•Confirm water pressure to water valve is between 35 and 100 pounds per square inch, 20 pounds per square inch without filter.

•Do not use a self-piercing or 3⁄16” saddle valve. Both reduce water flow and can become clogged over time, and may cause leaks if repair is attempted.

•Tighten nuts by hand to prevent cross threading. Finish tightening nuts with pliers and wrenches. Do not over-tighten.

•Wait two to three hours before placing refrigerator into final position to check and correct any water leaks. Recheck for leaks after 24 hours.

•Verify the copper tubing under the sleeve is smooth and free from defects. Do not reuse an old sleeve.

Materials Needed:

•1⁄4” outer diameter flexible copper tubing

•Shut-off valve (requires a 1⁄4” hole to be drilled into

water supply line before valve attachment)

•Adjustable wrench (2)

•1⁄4” hex nut driver

Notes:

•Use copper tubing only for installation. Plastic is less durable and can cause damage.

•Add 8’ to tubing length needed to reach water supply for creation of service loop.

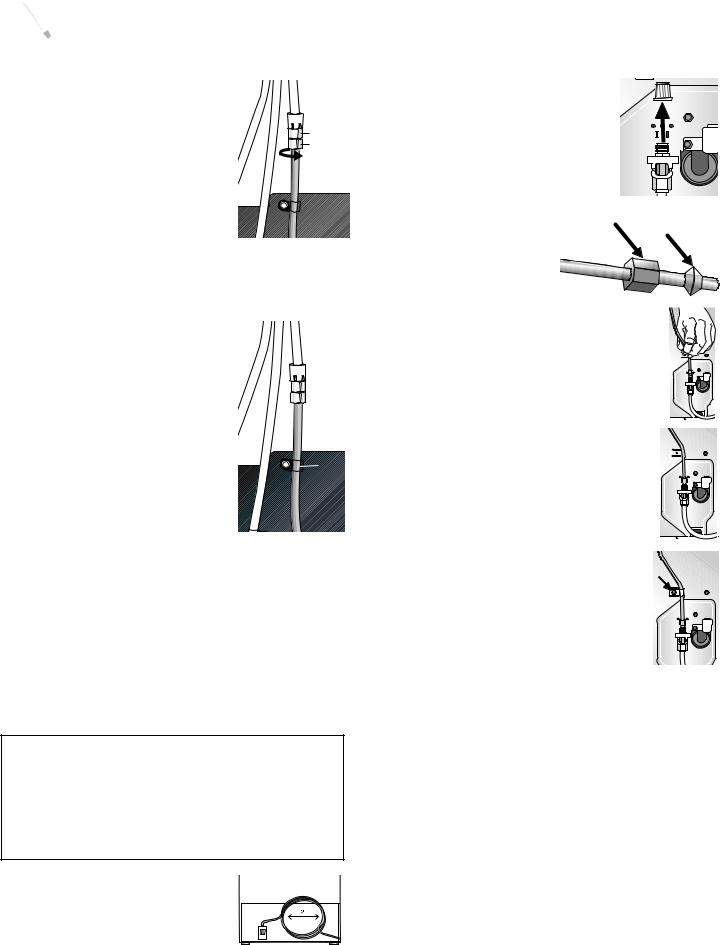

1. Create service loop with copper |

2’ diameter |

tubing (minimum 2’ diameter). |

minimum |

|

|

Avoid kinks in the copper tubing |

|

when bending the service loop. |

|

Do not use plastic tubing. |

|

2.Remove plastic cap from water valve inlet port.

3.Place brass nut (A) and sleeve (B)

on copper tube end as illustrated. |

|

|

Reminder: Do not use an old |

|

|

sleeve. The nut and sleeve are |

B |

|

provided in the Use and Care |

||

A |

||

packet. |

|

|

4. Place end of copper tubing into |

|

|

water valve inlet port. Shape |

B |

|

tubing slightly. Do not kink – so |

||

that tubing feeds straight into inlet |

A |

|

|

||

port. |

|

8

Installation

Installation

5.Slide brass nut over sleeve and screw nut into inlet port.

Place adjustable wrench on nut |

1 |

|

(1) attached to plastic waterline |

||

2 |

and maintain position.

Using second adjustable wrench turn the lower nut (2) counterclockwise and fully tighten while holding the upper nut in place.

Important: Do not over-tighten. Crossthreading may occur.

6. Pull on tubing to confirm |

|

connection is secure. Connect |

|

tubing to frame with water |

|

tubing clamp (C) and turn on |

|

water supply. Check for leaks |

|

and correct if necessary. |

|

Continue to observe the water |

|

supply connection for two to |

C |

three hours prior to moving the |

|

refrigerator to its permanent |

|

location. |

|

7. Monitor water connection for 24 hours. Correct leaks, if necessary.

Alternate connection (select models)

Materials Needed:

•1⁄4” outer diameter flexible copper tubing

•Shut-off valve (requires a 1⁄4” hole to be drilled into

water supply line before valve attachment)

•Adjustable wrench

•1⁄4” hex nut driver

Notes:

•Use copper tubing only for installation. Plastic is less durable and can cause damage.

•Add 8’ to tubing length needed to reach water supply for creation of service loop.

1. Create service loop with copper |

2’ diameter |

|

minimum |

||

tubing (minimum 2’ diameter). |

||

|

||

Avoid kinks in the copper tubing |

|

|

when bending the service loop. |

|

|

Do not use plastic tubing. |

|

2. Remove plastic cap from water valve inlet port.

3. Place brass nut (A) and sleeve (B) on copper tube end as illustrated.

Reminder: Do not use old sleeve. The nut and the sleeve are provided in the use and care

packet. A

B

4. Place end of copper tubing into water valve inlet port. Shape tubing slightly. Do not kink – so that tubing feeds straight into inlet port.

5. Slide brass nut over sleeve and screw nut into inlet port. Tighten nut with wrench.

Important: Do not over-tighten.

Crossthreading may occur.

6. Pull on tubing to confirm connection is secure. Connect tubing to frame with water tubing clamp (C) and turn on water supply. Check for leaks and correct if necessary. Continue to observe the water supply connection for two to three hours prior to moving the

refrigerator to its permanent location.

C

7. Monitor water connection for 24 hours. Correct leaks, if necessary.

9

Temperature Controls

Temperature Controls

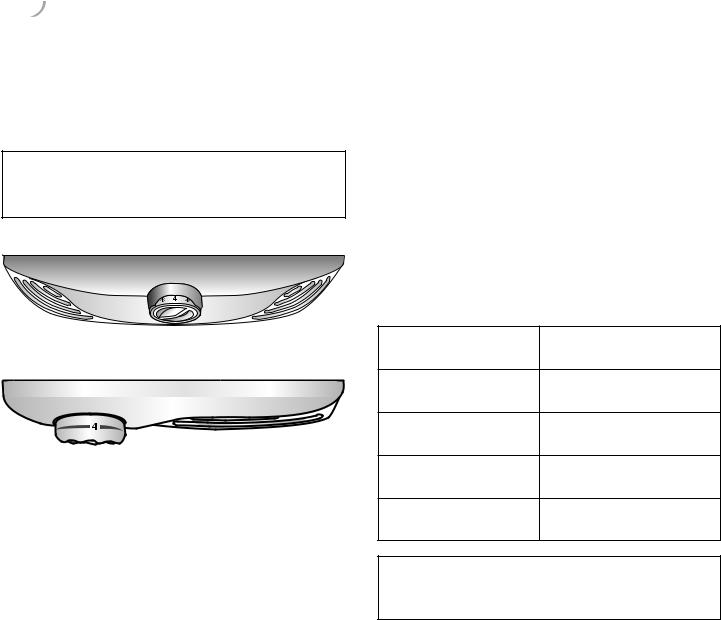

Dial Temperature Controls

(select models)

The controls are located at the top front of the refrigerator and freezer compartments.

Note: The freezer control turns the cooling system on. Neither section will cool if freezer control is set to OFF.

Refrigerator Control

Freezer Control

Initial Control Settings

After plugging the refrigerator in, set the controls.

•To adjust the controls, turn the control knob to the left or right as desired.

•The temperature control range for both compartments is 1 through 7 (coldest).

•Set the Freezer control on 4.

•Set the Refrigerator control on 4.

•Let the refrigerator run at least 8 to 12 hours before adding food.

Warm Cabinet Surfaces

At times, the front of the refrigerator cabinet may be warm to the touch. This is a normal occurrence that helps prevent moisture from condensing on the cabinet. This condition will be more noticeable when you first start the refrigerator, during hot weather and after excessive or lengthy door openings.

Adjusting the Controls

•24 hours after adding food, you may decide that one or both compartments should be colder or warmer. If so, adjust the control(s) as indicated in the

Temperature Control Guide table below. See page 20 for instructions on checking compartment temperature.

•Except when starting the refrigerator, do not change either control more than one number at a time.

•Allow 24 hours for temperatures to stabilize.

•Changing either control will have some effect on the temperature of the other compartment.

Temperature Control Guide

Refrigerator too warm Turn the Refrigerator control to next higher number.

Refrigerator too cold Turn the Refrigerator control to next lower number.

Freezer too warm Turn the Freezer control to next higher number.

Freezer too cold Turn the Freezer control to next lower number.

Turn refrigerator OFF Turn the Freezer control to OFF.

Note: Turning freezer control to OFF stops cooling in both compartments. It does not shut off power to the refrigerator.

10

Temperature Controls

Temperature Controls

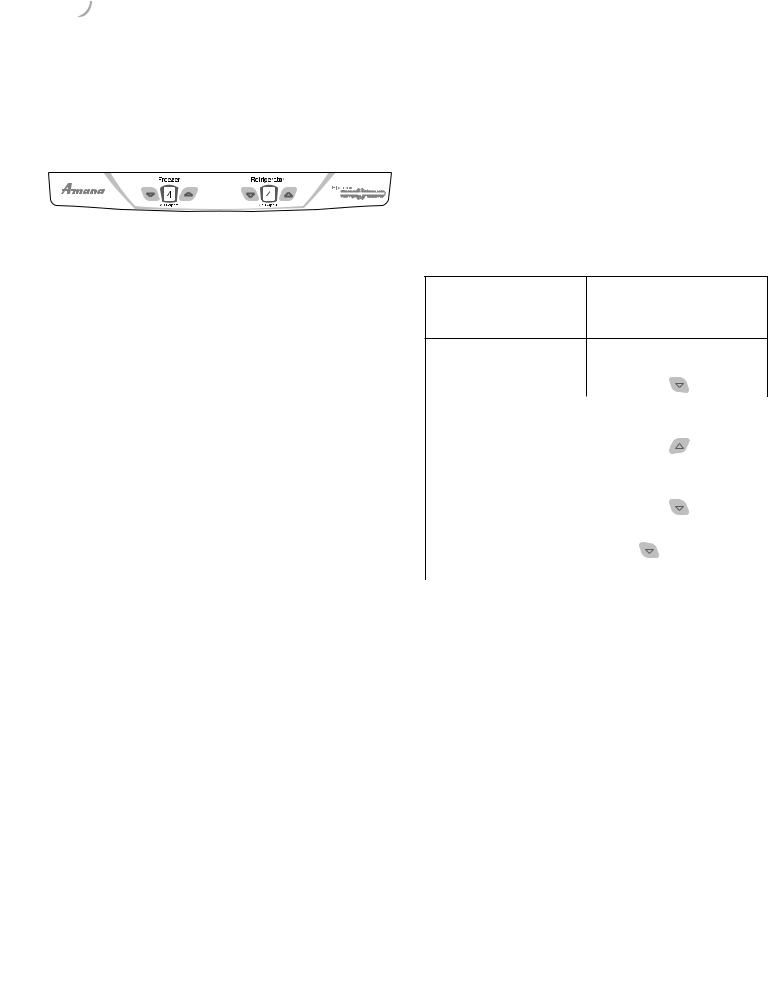

Touch Temperature Controls

(select models)

The controls are located at the top front of the refrigerator compartment.

Control

Adjusting the Controls

•24 hours after adding food, you may decide that one or both compartments should be colder or warmer. If so, adjust the control(s) as indicated in the

Temperature Control Guide table below. See page 20 for instructions on checking compartment temperature.

•Except when starting the refrigerator, do not change either control more than one number at a time.

•Allow 24 hours for temperatures to stabilize.

Initial Control Settings

After plugging the refrigerator in, set the controls.

•Pressing the  or

or  pads adjusts the controls to the desired setting.

pads adjusts the controls to the desired setting.

•The temperature control range for both compartments is 1 through 7 (coldest).

•Set the Freezer control on 4.

•Set the Refrigerator control on 4.

•Let the refrigerator run at least 8 to 12 hours before adding food.

Warm Cabinet Surfaces

At times, the front of the refrigerator cabinet may be warm to the touch. This is a normal occurrence that helps prevent moisture from condensing on the cabinet. This condition will be more noticeable when you first start the refrigerator, during hot weather and after excessive or lengthy door openings.

Temperature Control Guide

Refrigerator too warm Set the Refrigerator control to next higher number by pressing the

pad.

pad.

Refrigerator too cold |

|

Set the Refrigerator control |

|

|||

|

|

|

to next lower number by |

|

||

|

|

|

pressing the |

pad. |

|

|

|

|

|

|

|

||

Freezer too warm |

|

|

|

|||

|

Set the Freezer control to |

|

||||

|

|

|

next higher number by |

|

||

|

|

|

pressing the |

pad. |

|

|

|

|

|

|

|

||

Freezer too cold |

|

Set the Freezer control to |

|

|||

|

|

|

next lower number by |

|

||

|

|

|

pressing the |

pad. |

|

|

|

|

|

|

|||

Turn refrigerator OFF |

|

|

|

|

||

|

|

Press the Refrigerator or |

|

|||

|

|

|

Freezer |

pad until a dash |

|

|

|

|

|

(–) appears in the display. |

|

||

|

|

|

|

|||

|

|

|

|

|

|

|

11

Fresh Food Features

Fresh Food Features

Shelves

CAUTION

CAUTION

To avoid personal injury or property damage, observe the following:

•Never attempt to adjust a shelf that is loaded with food.

•Confirm shelf is secure before placing items on shelf.

•Handle tempered glass shelves carefully. Shelves may break suddenly if nicked, scratched, or exposed to sudden temperature change.

Your refrigerator has either Spillsaver™ or non-sealed shelves. The Spillsaver™ shelves have a spill retainer edge which allows for easier clean up and some are equipped with the EasyGlide™ slide out feature. To slide out (select models), grasp the front of the shelf and pull forward. Push in the shelf to return to the original position.

To Remove a Shelf:

• Slightly tilt up the front and lift up the rear of the shelf, then pull the shelf straight out.

To Lock the Shelf Into Another Position:

•Tilt up the front edge of the shelf.

•Insert the hooks into the desired frame openings and let the shelf settle into place.

•Be sure the shelf is securely locked at the rear.

The Crisper Top serves as the lower fresh food shelf.

To Remove the Crisper Top:

•Remove drawers as indicated on pages 13 and 14.

•Place hand under the frame to push up the glass. Lift glass out.

•Lift frame from refrigerator liner rails.

•To install, repeat above instructions in reverse order.

Door Storage

Dairy Center

The Dairy Center provides convenient door storage for spreadable items such as butter

and margarine. This compartment can be moved to different locations to accommodate storage needs. To use the dairy center, raise the cover.

To Remove:

• Raise the cover, pull upward and tilt out.

To Install:

• Reverse above procedure.

Door Buckets

Door Buckets can be moved to meet storage needs.

To Remove:

• Slide bucket up and pull straight out.

To Install:

•Slide bucket in and down until firmly seated in the door liner.

Full-Width Door Shelf

Full-Width Door Shelf removes for easy cleaning.

To Remove:

• Slide shelf up and pull straight out.

To Install:

• Reverse above procedure.

12

Fresh Food Features

Fresh Food Features

Beverage Chiller™

(select models)

The Beverage Chiller™ keeps

beverages and other items cooler

than the rest of the fresh food  section. A cold air inlet allows air from the freezer section to pass into the beverage chiller.

section. A cold air inlet allows air from the freezer section to pass into the beverage chiller.  The Beverage Chiller™ control is located

The Beverage Chiller™ control is located  on the left wall of the fresh food

on the left wall of the fresh food

compartment. The control adjusts the

compartment. The control adjusts the  amount of cold air allowed in to the

amount of cold air allowed in to the  beverage chiller. For a cooler temperature

beverage chiller. For a cooler temperature

in the Beverage Chiller™, slide the control down.

To Remove:

• First remove the pick off shelf to the left of the Beverage Chiller™.

• Firmly hold each side of beverage chiller, lift up and away from door liner.

To Install:

• Reverse above procedure.

Note: Cold air diverted into the Beverage Chiller™ can decrease the main refrigerator temperature. Refrigerator control may need to be adjusted.

Storage Drawers

Snack Drawer (select models)

The Snack Drawer can be used for storage of miscellaneous items or extra produce.

To Remove:

•Pull drawer out to full extension. Tilt up front of drawer and pull straight out.

To Install:

•Insert drawer into frame rails and push back into place.

Crisper Drawers

The Crisper Drawers provide a higher humidity environment for fresh fruit and vegetable storage.

Controls

The Crisper Controls regulate the amount of humidity in the crisper drawer. Slide the control toward the low setting for produce with outer skins. Slide the control toward the high setting for leafy produce.

To Remove:

•Pull drawer out to full extension. Tilt up front of drawer and pull straight out.

To Install:

•Insert drawer into frame rails and push back into place.

Note: For best results, keep the crispers tightly closed.

13

Fresh Food Features

Fresh Food Features

Temperature-Controlled Drawer

(select models)

The Chef’s Pantry™ drawer is a full-width drawer with adjustable temperature control. This drawer can be used for large party trays, deli items, beverages or miscellaneous items.

There is a temperature control which adjusts the amount of cold air allowed into the Chef’s Pantry™. The control is located on the right side of the drawer. Depending on your model, it is either on the front of the drawer or under the lid.

Set the control to cold or  to provide a normal refrigerator temperature. Set the drawer on the coldest or

to provide a normal refrigerator temperature. Set the drawer on the coldest or  setting when a temperature colder than the main refrigerator compartment is desired. Use the coldest setting when storing meats.

setting when a temperature colder than the main refrigerator compartment is desired. Use the coldest setting when storing meats.

Notes:

•Cold air directed to the Chef’s Pantry™ can decrease refrigerator temperature. Refrigerator control may need to be adjusted.

•Do not place leafy vegetables in the Chef’s Pantry™ drawer. Colder temperatures could damage leafy produce.

To Remove:

•Lift lid (select models). Pull drawer out to full extension. Tilt up front of pantry and pull straight out.

To Install:

•Push metal glide rails to the back of the refrigerator (select models). Place drawer onto rails and slide drawer back until it falls into place.

Some models feature a divider to organize the Chef’s Pantry™ into sections.

To Remove:

•Pull drawer completely out and raise the front of the divider to unhook it from the rear wall of the pantry and lift it out.

To Install:

•Hook back of divider over rear wall of pantry and lower into place.

Beverage Organizer™ (select models)

The Beverage Organizer™ slides out from underneath the Spillsaver™ shelf. The Beverage Organizer™ holds up to twelve 12-ounce beverage cans.

To Remove:

•Pull out to full extension. Tilt up the front of the Beverage Organizer™ and pull straight out.

To Install:

•Insert Beverage Organizer™ into frame rails and push back into place.

Accessories

Wine Trivet/Can Rack (select models)

The Wine Trivet/Can Rack accessory fits in the Chef’s Pantry™ or on a shelf.

Bottles or cans can be laid crosswise, or a single bottle may be laid in the center depression.

Grip Pads (select models)

The Grip Pads prevent objects from sliding in the door buckets. Grip Pads are removable

and are top-rack dishwasher safe for easy cleaning.

14

Freezer Features

Freezer Features

Shelves and Baskets

Models with swing freezer door:

Freezer Shelf (select models)

Select models have a shelf

To Remove:

• Pull shelf out to full extension. Tilt up front of shelf and pull straight out.

To Install:

•Insert shelf into freezer liner rails and push to back of compartment.

Wire Basket (select models)

To Remove:

• Pull basket out to full extension. Tilt up front of basket and pull straight out.

To Install:

•Insert basket into freezer liner rails and push back into place.

Freezer Door Shelf (select models)

The Freezer Door Shelf provides convenient storage for frozen food items in freezer door.

To Remove:

• Lift shelf from side liner tabs and pull out.

To Install:

• Fit ends of shelf on liner tabs and slide down.

Models with pullout freezer drawer:

DANGER

DANGER

To prevent accidental child entrapment or suffocation risk, do not remove the divider in the top freezer basket

Upper Wire Basket

To Remove:

•Pull upper basket out to full extension and lift out to remove.

To Install:

•Slide upper basket into freezer. Make sure that rear of basket hooks behind rail catch.

Note: Freezer Drawer Models: See page 5 for lower basket and complete pullout drawer instructions.

Accessories

Ice Cube Tray (select models)

The Ice Cube Tray provides an area to

freeze cubes for manual

freeze cubes for manual

dispensing of ice.

dispensing of ice.

To release ice cubes from tray, hold tray upside down over a storage container and twist

both ends of tray until cubes release.

Ice Service Rack (select models)

The Ice Service Rack holds the ice cube tray.

To Install: |

|

• Slide L-shaped groove of shelf |

1 |

down over back wall screw. |

|

Push rack back until screw is |

2 |

stopped in L-shaped groove

(1). Slide front portion of shelf over front wall screw (2).

To Remove:

• Perform above steps in reverse order.

15

Ice and Water

Ice and Water

Automatic Ice Maker

(select models)

Note: Energy rating guides that are posted on the refrigerator at the time of purchase do not include optional ice maker energy usage.

Some models are automatic ice maker ready. The number of the appropriate ice maker kit is IC11B. The kit contains installation instructions and water connection instructions.

Other models have a factory installed ice maker. Connect the ice maker to the water supply as instructed on page 9. Proper water flow and a level refrigerator are essential for optimal ice maker performance.

Operating Instructions

•Confirm ice bin is in place and ice maker arm is down.

• After freezer section reaches approximately 0° F (-18° C), ice maker fills with water and begins operating. You will have a complete harvest of ice approximately every three hours.

•Allow approximately 24 hours after installation to receive first harvest of ice.

•Discard ice created within first 12 hours of operation to assure system is flushed of impurities.

•Stop ice production by raising ice maker arm until click is heard.

•Ice maker will remain in the off position until arm is pushed down.

•The first one or two batches will probably contain undersized and irregular cubes because of air in the supply line.

•When the ice cubes are ejected it is normal for several cubes to be joined together at the ends. They can easily be broken apart. The ice maker will continue to make ice until the supply of ice cubes raises the sensor arm, shutting the ice maker off.

•Certain sounds may accompany the various cycles of the ice maker. The motor may have a slight hum, the

cubes will rattle as they fall into an empty storage bin and the water valve may click or “buzz” occasionally.

•If the ice is not used frequently, the ice cubes will become cloudy, shrink, stick together and taste stale. Empty the ice storage bin periodically and wash it in lukewarm water. Be sure to dry the bin thoroughly before replacing it.

•Beverages and foods should not be placed in the ice storage bin for quick chilling. These items can block the sensor arm, causing the ice maker to malfunction.

•Turn off (arm up) the ice maker when the water supply is to be shut off for several hours.

To Remove the Ice Bin:

•Pull it forward, away from the ice maker. To avoid the ice maker dumping ice while the bin is removed, turn the ice maker off by raising the sensor arm.

To Install the Ice Bin:

•Reverse the above procedure. Turn the ice maker on by lowering the sensor arm.

WARNING

WARNING

To avoid personal injury or property damage, observe the following:

•Do not place fingers or hands on the automatic ice making mechanism while the refrigerator is plugged in. This will help protect you from possible injury. It will also prevent interference with moving parts of the ejector mechanism and the heating element that releases the cubes.

•Under certain rare circumstances, ice cubes may be discolored, usually appearing with a greenbluish hue. The cause of this unusual discoloration can be a combination of factors such as certain characteristics of local waters, household plumbing and the accumulation of copper salts in an inactive water supply line which feeds the ice maker. Continued consumption of such discolored ice cubes may be injurious to health. If such discoloration is observed, discard the ice cubes and contact your dealer to purchase and install a water line filter.

•Water damage due to improper water connection may cause mold/mildew growth.

•Clean up water and ice spills to avoid personal injury and to prevent mold/mildew growth.

16

Ice and Water

Ice and Water

Water Dispenser (select models)

The Water Dispenser is located on the left side wall of the fresh food section. This design is for cold water dispensing only.

To Dispense Water:

•Hold container under spout and press dispenser pad.

Water Filter (select models)

Water Filter (select models)

Removal and Installation |

3. Rotate gently clockwise until |

||

|

WARNING |

filter stops. Snap filter cover |

|

|

closed. |

||

To avoid serious illness or death, do not use |

4. Reduce water spurts by flushing |

||

refrigerator where water is unsafe or of unknown |

|||

air from system. Run water |

|||

quality without adequate disinfection before or after |

|||

continuously for two minutes through dispenser |

|||

use of filter. |

|||

until water runs steady. During initial use, allow |

|||

|

|

||

|

CAUTION |

about a oneto two-minute delay in water |

|

|

dispersal to allow internal water tank to fill. |

||

After installing a new water filter, always |

|||

• Additional flushing may be required in some |

|||

dispense water for two minutes before |

|||

households where water is of poor quality. |

|||

removing the filter for any reason. |

|||

|

|||

• The bypass cap does not filter water. Be sure to |

Replacing Water Filter |

||

|

have replacement cartridge available when filter |

Important: Air trapped in system may cause |

|

|

change is required. |

||

|

water and cartridge to eject. Always dispense |

||

• |

If water filtration system has been allowed to |

||

water for two minutes before removing the filter |

|||

|

freeze, replace filter cartridge. |

for any reason. Use caution when removing. |

|

• |

If system has not been used for a short period of |

1. Turn filter counterclockwise until it releases from |

|

|

time, and water has an unpleasant taste or odor, |

filter head. |

|

|

flush system by dispensing two to three glasses of |

2. Drain water from filter into sink, and dispose in |

|

|

water. If unpleasant taste or odor persists, change |

||

|

normal household trash. |

||

|

filter cartridge. If system has not been used for |

||

|

|

||

|

three months or more, replace water filter |

3. Wipe up excess water in filter cover and continue |

|

|

cartridge (see page 26). |

with Initial Installation, steps 2 and 4. |

|

Initial Installation |

The filter should be changed at least every 12 months. |

||

The water filter is located in the upper right hand |

Important: Condition of water and amount used |

||

determines life span of water filter cartridge. If water |

|||

corner of the fresh food compartment. |

|||

use is high, or if water is of poor quality, replacement |

|||

|

|

||

1. Remove blue bypass cap and |

may need to take place more often. |

||

|

retain for later use. |

To purchase a replacement water filter cartridge, |

|

2. Remove sealing label from end |

contact your dealer or call 1-877-232-6771 USA or |

||

|

of filter and insert into filter |

1-800-688-8408 Canada. |

|

|

head. |

The dispenser feature may be used without a water |

|

|

|

filter cartridge. If you choose this option, replace filter |

|

|

|

with blue bypass cap. |

|

17

Water Filter (select models)

System Specification and Performance Data Sheet

TM Refrigerator Water Filter Cartridge Model UKF8001AXX

Specifications

Service Flow Rate (Maximum)............................................. |

0.78 GPM (2.9 L/min) |

Rated Service Life UKF8001AXX-750 (Maximum)...... |

750 gallons/2838 liters |

Maximum Operating Temperature ..................................... |

100° F / 38° C |

Minimum Pressure Requirement........................................ |

35 psi /241 kPA |

Minimum Operating Temperature...................................... |

33° F/1° C |

Maximum Operating Pressure............................................. |

120 psi /827 kPA |

Performance Data |

|

1000 Apollo Road

Eagan, Minnesota 55121-2240

651.450.4913

EPA EST #35917-MN-1

100834/B

Standard No. 42: Aesthetic Effects

|

USEPA |

Influent |

Influent |

Effluent |

% Reduction |

Min. Required |

||

Parameter |

MCL |

Challenge Concentration |

Average |

Average |

Maximum |

Average |

Minimum |

Reduction |

Chlorine |

— |

2.0 mg/L ± 10% |

1.88 mg/L |

<0.05136364 mg/L |

0.06 mg/L |

>97.26% |

96.84% |

50% |

T & O |

— |

— |

— |

— |

— |

— |

— |

— |

Particulate** |

— |

at least 10,000 particles/ml |

5,700,000 #/ml |

30,583 #/ml |

69,000 #/ml |

99.52% |

98.94% |

85% |

|

|

|

|

|

|

|

|

|

|

|

Standard No. 53: Health Effects |

|

|

|

|

|

|

|

USEPA |

Influent |

Influent |

Effluent |

% Reduction |

Min. Required |

||

Parameter |

MCL |

Challenge Concentration |

Average |

Average |

Maximum |

Average |

Minimum |

Reduction |

Turbidity |

1 NTU** |

11 ± 1 NTU*** |

10.7 NTU |

0.31 NTU |

.049 NTU |

97.09% |

95.20% |

0.5 NTU |

Cysts |

99.5% Reduction |

Minimum 50,000/L |

166,500 #/L |

<1 #/L |

<1 #/L |

>99.99% |

>99.99% |

>99.95% |

Asbestos |

99% Reduction |

107 108 fibers/L; fibers >10 micrometers in length |

155 MF/L |

<1 MF/L |

<1 MF/L |

>99.99% |

>99.99% |

99% |

Lead at pH 6.5 |

0.015 mg/L |

0.15 mg/L + 10% |

0.153 mg/L |

<.001 mg/L |

<.001 mg/L |

>99.35% |

>99.29% |

0.10 mg/L |

Lead at pH 8.5 |

0.015 mg/L |

0.15 mg/L + 10% |

0.150 mg/L |

<.001 mg/L |

<.001 mg/L |

>99.33% |

>99.29% |

0.10 mg/L |

Mercury at pH 6.5 |

0.002 mg/L |

.006 mg/L ± 10% |

0.006 mg/L |

0.0003 mg/L |

0.0005 mg/L |

95.70% |

90.91% |

0.002 mg/L |

Mercury at pH 8.5 |

0.002 mg/L |

.006 mg/L ± 10% |

0.006 mg/L |

0.0008 mg/L |

0.0015 mg/L |

86.22% |

75.93% |

0.002 mg/L |

Atrazine |

0.003 mg/L |

0.009 mg/L + 10% |

0.009 mg/L |

<0.002 mg/L |

0.002 mg/L |

76.99% |

75.31% |

0.003 mg/L |

Benzene |

0.005 mg/L |

0.015 mg/L ± 10% |

0.014 mg/L |

0.0006 mg/L |

0.0011 mg/L |

95.71% |

92.14% |

0.005 mg/L |

Carbofuran |

0.04 mg/L |

0.08 mg/L ± 10% |

0.081 mg/L |

<0.001 mg/L |

<0.001 mg/L |

98.74% |

98.46% |

0.04 mg/L |

1,4-Dichlorobenzene |

0.075 mg/L |

.225 mg/L ± 10% |

0.208 mg/L |

<0.0005 mg/L |

<0.0005 mg/L |

99.76% |

99.74% |

0.075 mg/L |

Lindane |

0.0002 mg/L |

0.002 mg/L + 10% |

0.002 mg/L |

0.000 mg/L |

<0.0001 mg/L |

98.72% |

96.50% |

0.0002 mg/L |

Toxaphene |

0.003 mg/L |

0.015 ± 10% |

0.015 mg/L |

<0.001 mg/L |

<0.001 mg/L |

92.97% |

91.67% |

0.003 mg/L |

|

|

|

|

|

|

|

|

|

*Tested using a flow rate of 0.78 gpm; pressure of 60 psig; pH of 7.5 + 0.5; temp. of 68° + 5° F (20° + 3° C)

**Measurement in Particles /ml. Particles used were 0.5 - 1 microns

***NTU - Nephelometric Turbidity Units

Tested and certified by NSF International against ANSI/NSF Standards 42 & 53 in models UKF8001AXX-750 for the reduction of:

Standard No. 42: Aesthetic Effects |

Standard No. 53: Health Effects |

Taste and Odor Reduction |

Chemical Reduction Unit |

Chlorine Taste & Odor |

Lead, Atrazine, Lindane, Benzene, |

Mechanical Filtration Unit |

Carbofuran, 1,4-Dichlorobenzene, |

Particulate Reduction Class 1 |

Mercury & Toxaphene Reduction |

|

Mechanical Filtration Unit |

|

Cyst, Turbidity and Asbestos Reduction |

General Use Conditions

Read this Performance Data Sheet and compare the capabilities of this unit with your actual water treatment needs.

DO NOT use this product where water is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. System certified for cyst reduction may be used on disinfected water that may contain filterable cysts.

USE ONLY WITH COLD WATER SUPPLY. CHECK FOR COMPLIANCE WITH THE STATE AND LOCAL LAWS AND REGULATIONS.

The PuriClean® II retractable water filtration system uses a UKF8001AXX replacement cartridge. Timely replacement of filter cartridge is essential for performance satisfaction from this filtration system. Please refer to the applicable section of your Use & Care Guide for general operation, maintenance requirements and troubleshooting.

This system has been tested according to ANSI/NSF 42 and 53 for reduction of the substance listed above. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving

the system, as specified in ANSI/NSF 42 and 53.

18

|

|

Water Filter |

03 - 1583 |

|

|

|

(select models) |

|

|

|

State of California |

|

|

|

Department of Health Services |

|

|

|

Water Treatment Device |

|

|

|

Certificate Number |

|

|

|

Date Issued: September 16, 2003 |

|

|

|

|

|

|

|

|

|

Trademark /Model Designation |

Replacement Elements |

|

|

|

PuriClean® II UKF8001AXX750 |

UKF8001AXX |

Manufacturer: PentaPure Inc.

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section 116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity |

Inorganic/Radiological Contaminants |

||

|

|

|

|

Cysts |

Asbestos |

||

Turbidity |

Lead |

||

|

|

Mercury |

|

Organic Contaminants |

|

|

|

|

|

|

|

Atrazine |

|

|

|

Lindane |

|

|

|

Toxaphene |

|

|

|

Rated Service Capacity: 750 gal. |

Rated Service Flow: 0.78 gpm |

|

|

Conditions of Certification:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

19

Food Storage Tips

Food Storage Tips

Fresh Food Storage

•The fresh food compartment of a refrigerator should be kept between 34° and 40° F (1° and 4° C) with an optimum temperature of 37° F (3° C). To check the temperature, place an appliance thermometer in a glass of water and place in the center of the refrigerator. Check after 24 hours. If the temperature is above 40° F (4° C) adjust the controls as explained on pages 10 and 11.

•Avoid overcrowding the refrigerator shelves. This reduces the circulation of air around the food and results in uneven cooling.

Fruits and Vegetables

•Storage in the crisper drawers traps humidity to help preserve the fruit and vegetable quality for longer time periods (see page 13).

•Sort fruits and vegetables before storage and use bruised or soft items first. Discard those showing signs of decay.

•Always wrap odorous foods such as onions and cabbage so the odor does not transfer to other foods.

•While vegetables need a certain amount of humidity to remain fresh, too much humidity can shorten storage times (especially leafy vegetables). Drain vegetables well before storing.

•Wait to wash fresh produce until right before use.

Meat and Cheese

•Raw meat and poultry should be wrapped securely so leakage and contamination of other foods or surfaces does not occur.

•Occasionally mold will develop on the surface of hard cheeses (Swiss, Cheddar, Parmesan). Cut off at least an inch around and below the moldy area. Keep your knife or instrument out of the mold itself. Do not try to save individual cheese slices, soft cheese, cottage cheese, cream, sour cream or yogurt when mold appears.

Dairy Food

•Most dairy foods such as milk, yogurt, sour cream and cottage cheese have freshness dates on their cartons for appropriate length of storage. Store these foods in the original carton and refrigerate immediately after purchasing and after each use.

Frozen Food Storage

•The freezer compartment of a refrigerator should be kept at approximately 0° F (-18° C). To check the temperature, place an appliance thermometer between the frozen packages and check after 24 hours. If the temperature is above 0° F (-18° C), adjust the control as described on pages 10 and 11.

•A freezer operates more efficiently when it is at least two-thirds full.

Packaging Foods for Freezing

•To minimize dehydration and quality deterioration use aluminum foil, freezer wrap, freezer bags or airtight containers. Force as much air out of the packages as possible and be sure they are tightly sealed. Trapped air can cause the food to dry out, change color and develop an off-flavor (freezer burn).

•Overwrap fresh meats and poultry with suitable freezer wrap prior to freezing.

•Do not refreeze meat that has completely thawed.

Loading the Freezer

•Avoid adding too much warm food to the freezer at one time. This overloads the freezer, slows the rate of freezing and can raise the temperature of frozen foods.

•Leave space between the packages so cold air can circulate freely, allowing food to freeze as quickly as possible.

•Avoid storing hard-to-freeze foods such as ice cream and orange juice on the freezer door shelves. These foods are best stored in the freezer interior where the temperature varies less with door openings.

Refer to the Food Storage Chart on pages 21 and 22 for approximate storage times.

20

Food Storage Tips

Food Storage Tips

Food Storage Chart

Storage times are approximate and may vary depending on type of packaging, storage temperature, and the quality of the food when purchased.

FOODS |

REFRIGERATOR |

FREEZER |

|

|

STORAGE TIPS |

|||

DAIRY PRODUCTS |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Butter |

1 month |

6 to 9 months |

Wrap tightly or cover. |

|||||

|

|

|

|

|

|

|

|

|

Milk and cream |

1 week |

Not recommended |

Check carton date. Close tightly. Do |

|||||

|

|

|

|

|

|

not return unused portions to |

||

|

|

|

|

|

|

original container. Do not freeze |

||

|

|

|

|

|

|

cream unless whipped. |

||

|

|

|

|

|

|

|

|

|

Cream cheese, cheese |

1 to 2 weeks |

Not recommended |

Wrap tightly. |

|||||

spread and cheese food |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Cottage cheese |

3 to 5 days |

Not recommended |

Store in original carton. |

|||||

|

|

|

|

|

|

Check carton date. |

||

|

|

|

|

|

|

|

|

|

Sour cream |

10 days |

Not recommended |

Store in original carton. |

|||||

|

|

|

|

|

|

Check carton date. |

||

|

|

|

|

|

|

|

|

|

Hard cheese |

1 to 2 months |

4 to 6 months |

Wrap tightly. |

|||||

(Swiss, Cheddar and Parmesan) |

|

May become |

Cut off any mold. |

|||||

|

|

|

|

|

crumbly |

|

|

|

|

|

|

|

|

|

|

|

|

EGGS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Eggs in the shell |

3 weeks |

Not recommended |

Refrigerate small ends down. |

|||||

|

|

|

|

|

|

|

|

|

Leftover yolks or whites |

2 to 4 days |

9 to 12 months |

For each cup of yolks to be frozen, |

|||||

|

|

|

|

|

|

add 1 tsp. sugar for use in sweet, or |

||

|

|

|

|

|

|

1 tsp. salt for non-sweet dishes. |

||

|

|

|

|

|

|

|

|

|

FRUITS |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Apples |

1 month |

8 months (cooked) |

May also store unripe or hard apples |

|||||

|

|

|

|

|

|

at 60° to 70° F (16° to 21° C). |

||

|

|

|

|

|

|

|

|

|

Bananas |

2 to 4 days |

6 months |

Ripen at room temperature before |

|||||

|

|

|

|

|

(whole/peeled) |

refrigerating. Note: Bananas darken |

||

|

|

|

|

|

|

when refrigerated. |

||

|

|

|

|

|

|

|

|

|

Pears, plums, avocados |

3 to 4 days |

Not recommended |

Ripen at room temperature before |

|||||

|

|

|

|

|

|

refrigerating. Note: Avocados darken |

||

|

|

|

|

|

|

when refrigerated. |

||

|

|

|

|

|

|

|

|

|

Berries, cherries, apricots |

2 to 3 days |

6 months |

Ripen at room temperature before |

|||||

|

|

|

|

|

|

refrigerating. |

||

|

|

|

|

|

|

|

|

|

Grapes |

3 to 5 days |

1 month (whole) |

Ripen at room temperature before |

|||||

|

|

|

|

|

|

refrigerating. |

||

|

|

|

|

|

|

|

|

|

Citrus fruits |

1 to 2 weeks |

Not recommended |

May also store at 60° to 70° F |

|||||

|

|

|

|

|

|

(16° to 21° C). |

||

|

|

|

|

|

|

If refrigerated, store uncovered. |

||

|

|

|

|

|

|

|

|

|

Pineapples, cut |

2 to 3 days |

6 to 12 months |

Will not ripen after purchase. |

|||||

|

|

|

|

|

|

Use quickly. |

||

|

|

|

|

|

|

|

|

|

21

Food Storage Tips

Food Storage Tips

FOODS |

REFRIGERATOR |

FREEZER |

|

STORAGE TIPS |

||||

VEGETABLES |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Asparagus |

1 to 2 days |

8 to 10 months |

Do not wash before refrigerating. |

|||||

|

|

|

|

|

|

Store in crisper. |

||

|

|

|

|

|

|

|

|

|

Brussels sprouts, broccoli, |

3 to 5 days |

8 to 10 months |

Wrap odorous foods. |

|||||

cauliflower, green peas, |

|

|

Leave peas in pods. |

|||||

lima beans, onions, peppers |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Cabbage, celery |

1 to 2 weeks |

Not recommended |

Wrap odorous foods and refrigerate in |

|||||

|

|

|

|

|

|

crisper. |

||

|

|

|

|

|

|

|

|

|

Carrots, parsnips, beets and |

7 to 10 days |

8 to 10 months |

Remove tops. Wrap odorous foods and |

|||||

turnips |

|

|

refrigerate in the crisper. |

|||||

|

|

|

|

|

|

|

|

|

Lettuce |

7 to 10 days |

Not recommended |

|

|

||||

|

|

|

|

|

|

|

|

|

POULTRY and FISH |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Chicken and turkey, whole |

1 to 2 days |

12 months |

Keep in original packaging for |

|||||

|

|

|

|

|

|

refrigeration. Place in the meat and |

||

Chicken and turkey, pieces |

1 to 2 days |

9 months |

||||||

cheese drawer. When freezing longer |

||||||||

|

|

|

|

|

|

|||

Fish |

1 to 2 days |

2 to 6 months |

||||||

than two weeks, overwrap with freezer |

||||||||

|

|

|

|

|

|

wrap. |

||

|

|

|

|

|

|

|

|

|

MEATS |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Bacon |

7 days |

1 month |

|

|

||||

|

|

|

|

|

|

|

|

|

Beef or lamb, ground |

1 to 2 days |

3 to 4 months |

Fresh meats can be kept in original |

|||||

|

|

|

|

|

|

packaging for refrigeration. |

||

|

|

|

|

|

|

|

|

|

Beef or lamb, roast and steak |

3 to 5 days |

6 to 9 months |

Place in the meat and cheese drawer. |

|||||

|

|

|

|

|

|

When freezing longer than two weeks, |

||

|

|

|

|

|

|

overwrap with freezer wrap. |

||

|

|

|

|

|

|

|

|

|

Ham, fully cooked, whole |

7 days |

1 to 2 months |

|

|

||||

|

|

|

|

|

|

|

|

|

half |

5 days |

1 to 2 months |

|

|

||||

|

|

|

|

|

|

|

|

|

slices |

3 days |

1 to 2 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Luncheon meat |

3 to 5 days |

1 to 2 months |

Unopened, vacuum-packed luncheon |

|||||

|

|

|

|

|

|

meat may be kept up to two weeks in |

||

|

|

|

|

|

|

the meat and cheese drawer. |

||

|

|

|

|

|

|

|

|

|

Pork, roast |

3 to 5 days |

4 to 6 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Pork, chops |

3 to 5 days |

4 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Sausage, ground |

1 to 2 days |

1 to 2 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Sausage, smoked |

7 days |

1 to 2 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Veal |

3 to 5 days |

4 to 6 months |

|

|

||||

|

|

|

|

|

|

|

|

|

Frankfurters |

7 days |

1 month |

Processed meats should be tightly |

|||||

|

|

|

|

|

|

wrapped and stored in the meat and |

||

|

|

|

|

|

|

cheese drawer. |

||

|

|

|

|

|

|

|

|

|

Sources: United States Department of Agriculture; Food Marketing Institute; Cooperative Extension Service, Iowa State University

22

Care and Cleaning

Care and Cleaning

CAUTION

CAUTION

To avoid personal injury or property damage, observe the following:

•Read and follow manufacturer’s directions for all cleaning products.

•Do not place buckets, shelves or accessories in dishwasher. Cracking or warping of accessories may result.

Refrigerator Cleaning Chart

WARNING

WARNING

To avoid electrical shock which can cause severe personal injury or death, disconnect power to refrigerator before cleaning. After cleaning, reconnect power.

PART |

DO NOT USE |

DO |

|

Textured Doors |

Abrasive or harsh cleaners |

Use 4 tablespoons of baking soda dissolved in |

|

and Exterior |

Ammonia |

1 quart (1 liter) warm, soapy water. |

|

|

Chlorine bleach |

Rinse surfaces with clean, warm water and dry |

|

Cabinet Interior |

|||

Concentrated detergents |

immediately to avoid water spots. |

||

|

|||

|

or solvents |

|

|

|

Metal or plastic-textured |

|

|

|

scouring pads |

|

|

|

|

|

|

Stainless Steel Doors and |

Abrasive or harsh cleaners |

Use warm, soapy water and a soft, clean cloth |

|

Exterior (select models) |

Ammonia |

or sponge. |

|

Important: |

Chlorine bleach |

Rinse surfaces with clean, warm water and dry |

|

Damage to stainless steel |

Concentrated detergents |

immediately to avoid water spots. |

|

finish due to improper use |

or solvents |

To polish and help prevent fingerprints, follow |

|

of cleaning products or |

Metal or plastic-textured |

with Stainless Steel Magic Spray (part no. |

|

non-recommended products |

scouring pads |

20000008*). |

|

is not covered under this |

Vinegar-based products |

|

|

product’s warranty. |

Citrus-based cleaners |

|

|

|

|

|

|

Door Gaskets |

Abrasive or harsh cleaners |

|

|

|

Metal or plastic-textured |

|

|

|

scouring pads |

|

|

|

|

|

|

Condenser Coil |

|

Use a vacuum cleaner hose nozzle. |

|

Remove base grille to access. |

|

|

|

|

|

|

|

Condenser Fan Outlet Grille |

|

Use a vacuum cleaner hose nozzle with brush |

|

See back of refrigerator. |

|

attachment. |

|

|

|

|

|

Accessories |

A dishwasher |

Follow removal and installation instructions |

|

Shelves, buckets, |

|

from appropriate feature section. |

|

drawers, etc. |

|

Allow items to adjust to room temperature. |

|

|

|

Dilute mild detergent and use a soft, clean |

|

|

|

cloth or sponge for cleaning. |

|

|

|

Use a plastic bristle brush to get into crevices. |

|

|

|

Rinse surfaces with clean, warm water. |

|

|

|

Dry glass and clear items immediately to avoid |

|

|

|

spots. |

|

|

|

|

|

* To order, call 1-877-232-6771 USA or 1-800-688-8408 Canada. |

|

||

23

Care and Cleaning

Care and Cleaning

Removing Odors From

Refrigerator

WARNING

WARNING

To avoid electrical shock which can cause severe personal injury or death, disconnect power to refrigerator before cleaning. After cleaning, reconnect power.

1.Remove all food and turn the refrigerator OFF.

2.Disconnect power to the refrigerator.

3.Clean the walls, floor, ceiling of cabinet interior, drawers, shelves and gaskets according to the instructions on page 23.

4.Dilute mild detergent and brush solution into crevices using a plastic bristle brush. Let stand for 5 minutes. Rinse surfaces with warm water. Dry surfaces with a soft, clean cloth.

5.Wash and dry all bottles, containers and jars. Discard spoiled or expired items.

6.Wrap or store odor-causing foods in tightly sealed containers to prevent recurring odors.

7.Reconnect power to refrigerator and return food to refrigerator.

8.Allow the refrigerator to cool.

9.After 24 hours, check if odor has been eliminated.

If odor is still present:

1.Remove drawers and place on top shelf of refrigerator.

2.Pack refrigerator and freezer sections – including doors – with crumpled sheets of black and white newspaper.

3.Place charcoal briquettes randomly on crumpled newspaper in both freezer and refrigerator compartments.

4.Close doors and let stand 24 to 48 hours.

Energy Saving Tips

•Avoid overcrowding refrigerator shelves. This reduces air circulation around food and causes refrigerator to run longer.

•Avoid adding too much warm food to refrigerator at one time. This overloads compartments and slows rate of cooling.

•Do not use aluminum foil, wax paper, or paper toweling as shelf liners. This decreases air flow and causes refrigerator to run less efficiently.

•A freezer that is two-thirds full runs most efficiently.

•Locate refrigerator in coolest part of room. Avoid areas of direct sunlight, or near heating ducts, registers or other heat producing appliances. If this is not possible, isolate exterior by using a section of cabinet.

•Clean door gaskets every three months according to cleaning instructions. This will assure that door seals properly and refrigerator runs efficiently.

•Take time to organize items in refrigerator to reduce time that door is open.

•Be sure your doors are closing securely by leveling refrigerator as instructed in your installation instructions.

•Clean condenser coils as indicated in the cleaning instructions every three months. This will increase energy efficiency and cooling performance.

24

Care and Cleaning

Care and Cleaning

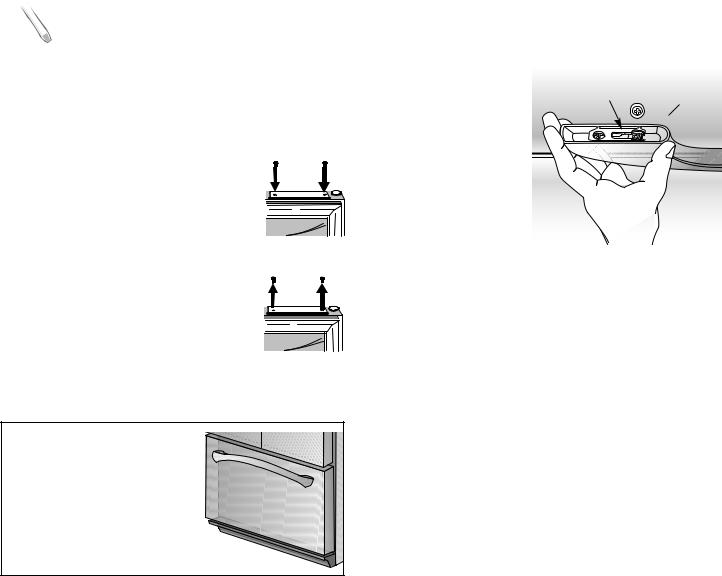

Replacing Light Bulbs

WARNING

WARNING

To avoid electrical shock which can cause severe personal injury or death, disconnect power to refrigerator before replacing light bulb. After replacing light bulb, reconnect power.

CAUTION

CAUTION

To avoid personal injury or property damage, observe the following:

•Allow light bulb to cool.

•Wear gloves when replacing light bulb.

Fresh Food Section

(style of light shield varies)

1. Slide clear light shield toward back of compartment to release from light assembly.

2. Remove light bulbs.

3.Replace with appliance

bulbs no greater than 40 watts.

4.Replace light bulb cover by inserting tabs on light shield into liner holes on each side of light assembly. Slide shield toward front of refrigerator until it locks into place. Do not force shield beyond locking point. Doing so may damage light shield.

Freezer (style of light shield varies)

1.Reach behind the light cover.

2. With firm pressure, press

forward on the notches at

the back of the cover and

the back of the cover and

pull down. The cover will open from the back.

3. Remove the cover.

4. Remove light bulb.

5. Replace bulb with appliance bulb no greater than 40 watts.

6. Insert front tabs of light cover into slots in freezer liner and snap rear portion over light assembly until rear tab engages.

25

Care and Cleaning

Care and Cleaning

Preparing for Vacation

CAUTION

CAUTION

If your refrigerator has a dispenser and there is any possibility that the temperature can drop below freezing where the refrigerator is located, the water supply system (including the water tank and the water valve) must be drained by a qualified servicer.

For short vacations or absences (three months or less):

1.Remove all perishables.

2.If no one will be checking in on the refrigerator during your absence, remove all frozen items also.

3.If your refrigerator has an automatic ice maker:

•Shut off the water supply to the ice maker at least one day ahead of time.

•After the last load of ice drops, raise the wire shut off arm to the OFF position.

•Empty the ice bin.

4.If the room temperature will drop below 55° F

(12° C), follow the instructions for longer absences.

For long vacations, absences (more than three months) OR if the room temperature will drop below 55º F (12° C):

1.Remove food.