Alliance Laundry Systems 1336, 1305, 160 User Manual

Washer/Extractor

AC Adjustable Frequency

Drive Information

For Allen-Bradley Model Numbers:

160

1305

1336

PowerFlex 40

PowerFlex 400

U072M

PHM1396C

TMB1396C

U074M |

FAULT |

|

READY |

||

|

U071M U071

U073M

Supplement

Part No. F232120R6

January 2010

|

|

Supplement |

|

General Information........................................................................... |

3 |

Table of |

Nameplate Location.............................................................................. |

4 |

Contents |

Storage .................................................................................................. |

5 |

|

General Inspection ................................................................................ |

5 |

|

PowerFlex 40 and 400 Drive Control Logic ..................................... |

6 |

|

Installation/Wiring................................................................................ |

6 |

|

Input Power Conditioning................................................................ |

6 |

|

Electrical Interference...................................................................... |

7 |

|

Terminal Block Access .................................................................... |

8 |

|

Power Terminal Block Description ................................................. |

9 |

|

Control Terminal Blocks Description and Control Logic................ |

10 |

|

AC Drive Diagnostics/Parameter Viewing........................................... |

28 |

|

PowerFlex Integrated Keypad.......................................................... |

28 |

|

Fault Display and Troubleshooting Information .................................. |

32 |

|

Allen-Bradley Drive Fault Codes .................................................... |

33 |

|

Troubleshooting Suggestions........................................................... |

35 |

|

Allen-Bradley 160-Series AC Drives................................................. |

36 |

|

Installation/Wiring................................................................................ |

36 |

|

Input Power Conditioning................................................................ |

36 |

|

Electrical Interference...................................................................... |

37 |

|

Terminal Block Access .................................................................... |

39 |

|

Power Terminal Block Description ................................................. |

40 |

|

Control Terminal Blocks Description and Control Logic................ |

41 |

|

160 Series Drive Control Logic Chart ............................................. |

42 |

|

AC Drive Diagnostics/Parameter Viewing........................................... |

51 |

|

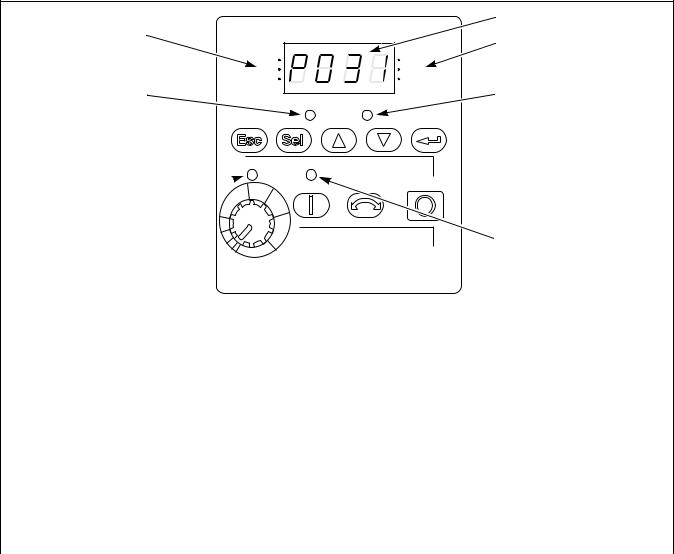

160 Program Keypad Module (PKM or Parameter Unit)................ |

51 |

|

CopyCat Keypad.............................................................................. |

54 |

|

Fault Display and Troubleshooting Information .................................. |

58 |

|

Fault Code Identification ................................................................. |

58 |

|

Allen-Bradley Drive Fault Codes .................................................... |

59 |

|

Troubleshooting Suggestions........................................................... |

61 |

|

Allen-Bradley 1305-Series AC Drives............................................... |

62 |

|

Installation/Wiring................................................................................ |

62 |

|

Input Power Conditioning................................................................ |

62 |

|

Electrical Interference...................................................................... |

63 |

|

Terminal Block Access .................................................................... |

64 |

|

Power Terminal Block Description ................................................. |

65 |

|

Control Terminal Blocks Description and Control Logic................ |

65 |

|

AC Drive Diagnostics/Parameter Viewing........................................... |

73 |

|

Human Interface Module (HIM or Parameter Unit) ........................ |

73 |

|

HIM Structure Chart – Series A 3.00, Series B 1.01 |

|

|

or Later Versions................................................................................ |

75 |

|

HIM Structure Chart – Earlier Versions............................................... |

76 |

|

Fault Display and Troubleshooting Information .................................. |

80 |

|

Fault Code Identification ................................................................. |

80 |

|

Allen-Bradley Drive Fault Codes .................................................... |

81 |

|

Troubleshooting Suggestions........................................................... |

83 |

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed written consent of the publisher.

F232120 |

© Copyright 2006, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

1 |

Supplement

Allen-Bradley 1336-Series AC Drives............................................... |

84 |

Installation/Wiring................................................................................ |

84 |

Input Power Conditioning................................................................ |

84 |

Electrical Interference...................................................................... |

85 |

Terminal Block Access .................................................................... |

86 |

Power Terminal Block Description ................................................. |

87 |

Control Terminal Blocks Description and Control Logic................ |

88 |

AC Drive Diagnostics/Parameter Viewing........................................... |

98 |

Human Interface Module (HIM or Parameter Unit) ........................ |

98 |

HIM Structure Chart – Series A 3.00, Series B 1.01 |

|

or Later Versions ............................................................................ |

100 |

HIM Structure Chart – Earlier Versions .......................................... |

101 |

Fault Display and Troubleshooting Information .................................. |

105 |

Fault Code Identification ...................................................................... |

105 |

Allen-Bradley Drive Fault Codes .................................................... |

107 |

Troubleshooting Suggestions........................................................... |

109 |

2 |

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT |

F232120 |

General Information

General Information

•This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are required when installing, testing, or servicing this assembly. Component damage may result if ESD control procedures are not followed.

•An incorrectly applied or installed drive can result in component damage or a reduction in product life. Wiring or application errors, such as incorrect or inadequate AC supply or excessive ambient temperatures, may result in malfunction of the system.

•This drive contains power storage devices that retain their charge for a time after the removal of main power. Extreme caution should be used when working in and around the drive. It is recommended that main disconnect power to the drive remain off for three minutes prior to approaching connections.

Warnings specific to a particular subject will appear in the manual with the discussion of that subject.

CAUTION

Only personnel familiar with the drive and associated machinery should plan or implement the installation, start-up, and subsequent maintenance of the system. Failure to comply may result in personal injury and/or equipment damage.

W659

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

3 |

General Information

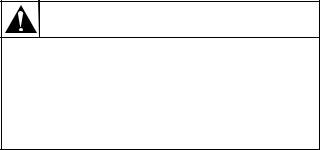

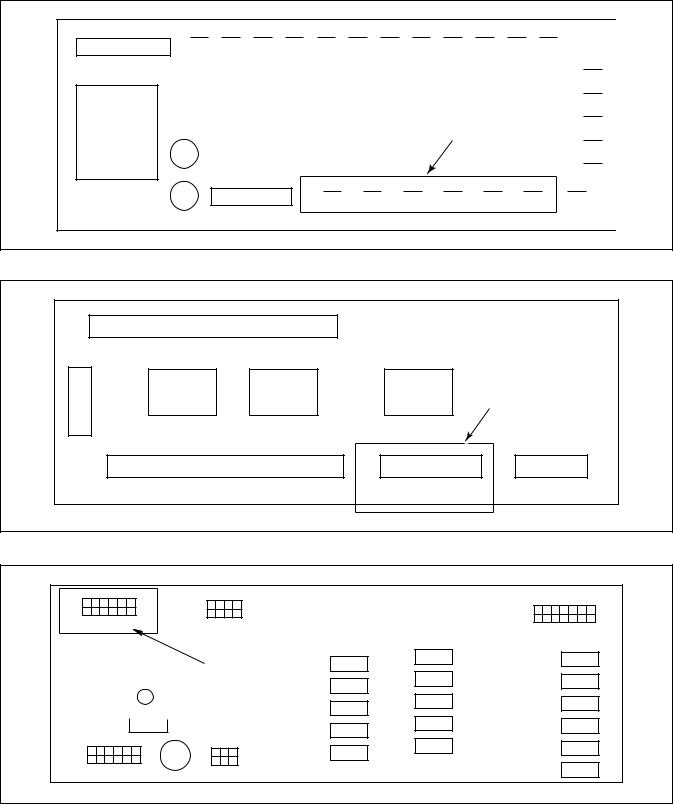

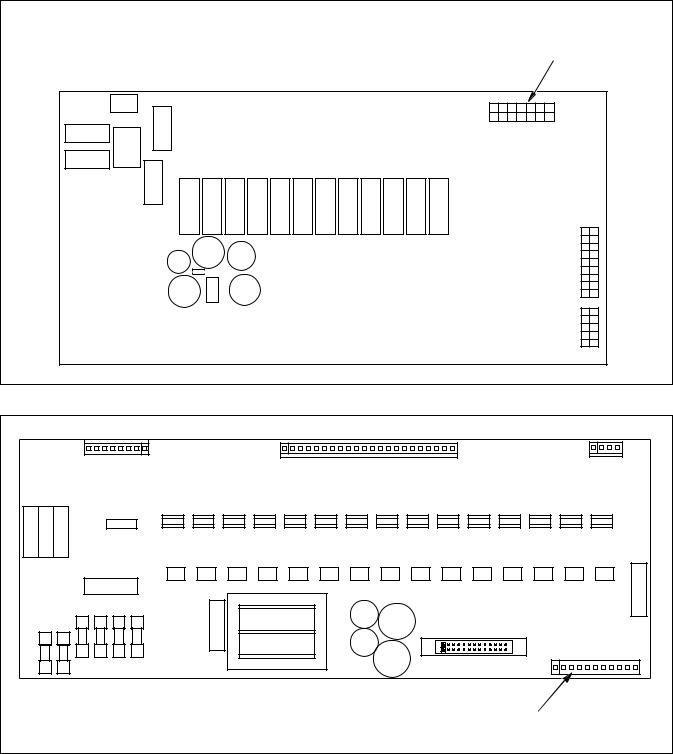

Nameplate Location

Pertinent drive information used in obtaining information on drive operation or replacement is located on the nameplate shown in Figures 1 through 4.

FAULT |

Nameplate Located on |

|

|

READY |

Exterior of Enclosure |

|

160 NAMEPLATE LOCATION

U146ME3A

Figure 1

Nameplate Located on

Exterior of Enclosure

1305 NAMEPLATE LOCATION |

U072ME3A |

|

|

|

U072ME3A |

Figure 2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

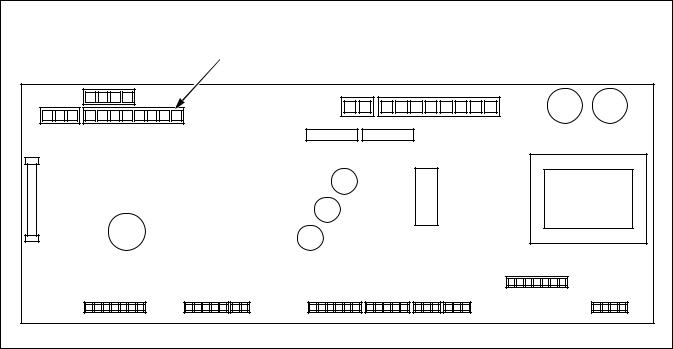

Nameplate Located |

|

|||||

on Bottom Portion of |

Nameplate Located |

|||||

Chassis Behind Cover |

||||||

on Mounting Plate of |

||||||

|

|

|

|

|

||

|

|

|

|

|

Main Control Board |

|

FRAMES A1, A2, A3, A4 |

FRAMES B-G |

|

U147ME3A |

1336 PLUS NAMEPLATE LOCATION

U147ME3A

Figure 3

Nameplate Located on

Exterior of Enclosure.

TMB1396C

POWERFLEX NAMEPLATE LOCATION

PHM1396C

Figure 4

4 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

General Inspection

Upon delivery, verify the item’s nameplate catalog number against the purchase order.

Before the installation and start-up of the drive, a general inspection of the mechanical integrity (i.e., loose parts, wires, connections, etc.) should be made.

General Information

Storage

The drive should remain in its shipping container prior to installation. If the equipment is not to be used for a period of time, it must be stored according to the following instructions in order to maintain warranty coverage:

•Store in a clean, dry location.

•Store within an ambient temperature range of -40 to 70 degrees C.

•Store within a relative humidity range of 0 to 95 percent.

•Do not store equipment where it could be exposed to a corrosive atmosphere.

•Do not store equipment in a construction area.

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

5 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 and 400 Drive Control Logic

Installation/Wiring

CAUTION

An incorrectly installed system can result in component damage or reduction in product life. The most common causes are:

1.Wiring AC line to drive output or control terminals.

2.EXTERNAL voltage application to control terminals.

3.Incorrect or inadequate AC supply.

Contact factory for assistance with application or wiring.

W660

Input Power Conditioning

The drive is suitable for direct connection to input power within the rated voltage of the drive. Listed in

Table 1 are certain input power conditions which may cause component damage or reduction in product life. If any of the conditions exist, as described in Table 1, install one of the devices listed under the heading Corrective Action on the line side of the drive.

IMPORTANT: Only one device per branch circuit is required. It should be mounted closest to the branch and sized to handle the total current of the branch circuit.

Input Power Condition |

|

Corrective Action |

|

|

|

|

|

Low Line impedance (less than 1% line reactance) |

• |

Install Line Reactor |

|

|

• |

or Isolation Transformer |

|

Greater than 120 kVA supply transformer |

|||

• |

or Bus Inductor – 5.5 & 11kW (7.5 & 15 HP) drives |

||

|

|||

|

|

only |

|

|

|

|

|

Line has power factor correction capacitors |

• |

Install Line Reactor |

|

|

• |

or Isolation Transformer |

|

Line has frequent power interruptions |

|||

|

|

||

|

|

|

|

Line has intermittent noise spikes in excess of 6000V |

|

|

|

(lightning) |

|

|

|

|

|

|

|

Phase to ground voltage exceeds 125% of normal line to line |

• |

Remove MOV jumper to ground. |

|

voltage |

• |

or Install Isolation Transformer with grounded |

|

|

|

secondary |

|

Ungrounded distribution system |

|

||

|

if necessary |

||

|

|

||

|

|

|

|

240V open delta configuration (stinger leg) (1) |

• |

Install Line Reactor |

(1) For drives applied on an open delta with a middle phase grounded neutral system, the phase opposite the phase that is tapped in the middle to the neutral or earth is referred to as the “stinger leg,” “high leg,” “red leg,” etc. This leg should be identified throughout the system with red or orange tape on the wire at each connection point. The stinger leg should be connected to the center Phase B on the reactor.

Table 1

6 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

Electrical Interference

EMI

Careful attention must be given to the arrangement of power and ground connections to the drive to avoid interference with nearby sensitive equipment. Be sure to replace all ground connections to their appropriate locations.

RFI

Drives can be installed with an RFI filter, which controls high-frequency conducted emissions into the main supply lines.

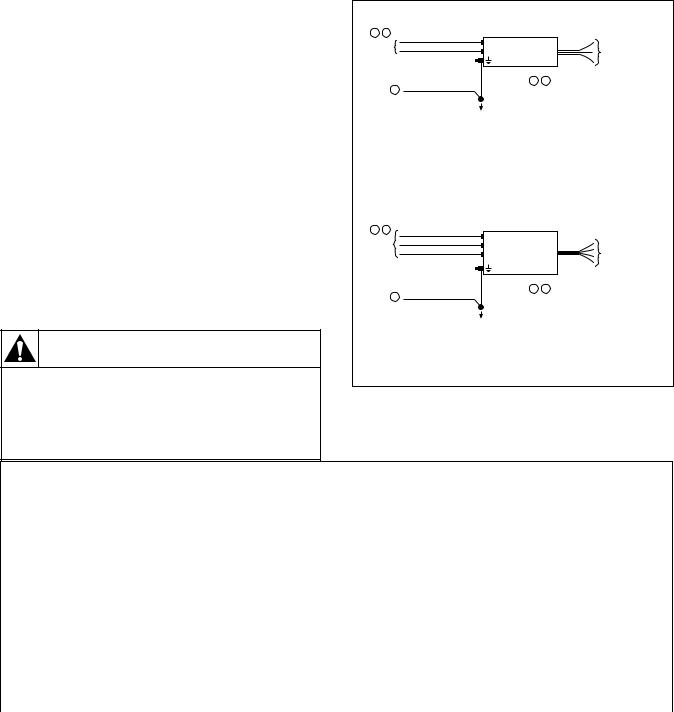

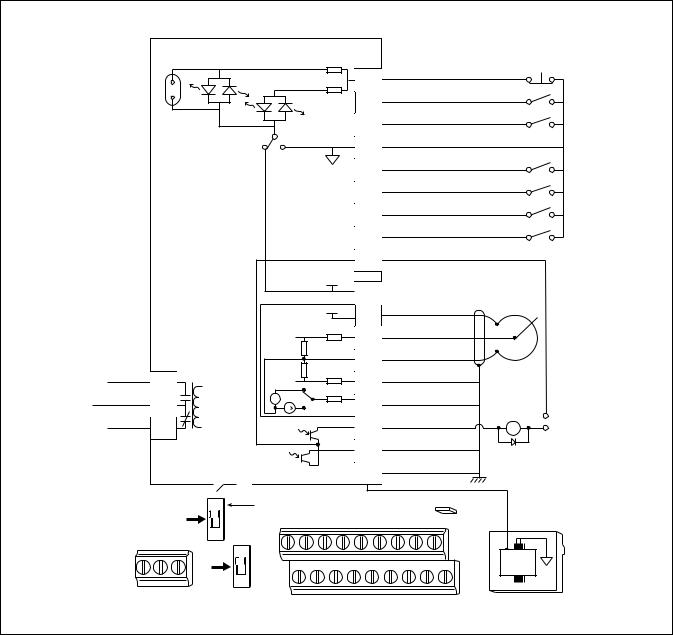

Where it is essential that very low emission levels must be achieved or if conformity with standards is required, the optional RFI filter may be present. Figure 5 displays an electrical schematic for various RFI configurations. Table 2 shows associated RFI filter part numbers.

CAUTION

ELECTRIC SHOCK HAZARD! Service and

maintenance to be performed only by an authorized technician. Disconnect power before opening any access panels.

W661

PowerFlex 40 and 400 Drive Control Logic

SINGLE PHASE MACHINES

1 |

2 |

|

|

|

|

|

INPUT |

L1 |

LINE |

ALLEN-BRADLEY |

LOAD |

||

POWER |

L2 |

RFI |

||||

|

|

|||||

|

|

|

|

FILTER |

|

|

|

|

|

|

2 |

3 |

|

|

3 |

PROVEN EARTH GROUND |

|

TO AC DRIVE UNIT Ð |

||

|

|

|

|

GREEN-YELLOW WIRE MUST CONNECT TO |

||

|

|

|

|

AC DRIVE GROUND TERMINAL. |

||

WASHING |

BLACK WIRES WILL CONNECT TO AC DRIVE |

|

INPUT TERMINALS "R", "S" & "T". |

||

MACHINE |

||

BLACK WIRES ARE NOT LABELED AND THEIR |

||

GROUNDING |

||

RESPECTIVE TERMINATION IN AC DRIVE IS |

||

TERMINAL |

||

NOT OF IMPORTANCE. |

||

|

THREE PHASE MACHINES

1 |

2 |

|

|

|

|

INPUT |

L1 |

LINE |

ALLEN-BRADLEY |

|

|

L2 |

|

LOAD |

|||

POWER |

RFI |

||||

|

|

L3 |

|

|

|

|

|

|

FILTER |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

3 |

|

3 |

PROVEN EARTH GROUND |

|

TO AC DRIVE UNIT Ð |

|

|

|

|

|

GREEN-YELLOW WIRE MUST CONNECT TO |

|

|

|

|

|

AC DRIVE GROUND TERMINAL. |

|

WASHING |

BLACK WIRES WILL CONNECT TO AC DRIVE |

|

INPUT TERMINALS "R", "S" & "T". |

||

MACHINE |

||

BLACK WIRES ARE NOT LABELED AND THEIR |

||

GROUNDING |

||

RESPECTIVE TERMINATION IN AC DRIVE IS |

||

TERMINAL |

||

NOT OF IMPORTANCE. |

||

|

||

|

U166ME3A |

U166ME3A

Figure 5

RFI Filter Part Number Information

Drive P/N |

Drive Catalog |

|

Machine Voltage |

Filter P/N |

F8044301 and F8168603 |

22B-B017N104xx |

|

200-240V 50-60Hz 3 phase |

F8053901 |

F8044401 and F8168604 |

22B-D010N104xx |

|

380-480V 50-60Hz 3 phase |

F8053902 |

|

|

|

|

|

F8044701 and F8168601 |

22B-B012N104xx |

|

200-240V 50-60 Hz 3 Phase |

F8053901 |

|

|

|

|

|

F8044901 and F8168602 |

22B-D6P0N104xx |

|

380-480V 50-60 Hz 3 Phase |

F8053902 |

C002501 and F8168701 |

22B-B024N104xx |

|

200-240V 50-60 Hz 3 Phase |

F8054001 |

|

|

|

|

|

C002502 and F8168702 |

22B-D012N104xx |

|

380-480V 50-60 Hz 3 Phase |

F8054002 |

|

|

|

|

|

C002507 and F8168705 |

22B-D024N104xx |

|

380-480V 50-60 Hz 3 Phase |

C002569 |

C002502, F200309300 |

22B-B033N104Axx |

|

200-240V 50-60Hz 3 phase |

F8054001 |

and F8168703 |

|

|

|

|

C002506, F200309400 |

22B-D017N104Axx |

|

380-480V 50-60Hz 3 phase |

F8054002 |

and F8168704 |

|

|

|

|

|

|

Table 2 |

|

|

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

7 |

PowerFlex 40 and 400 Drive Control Logic

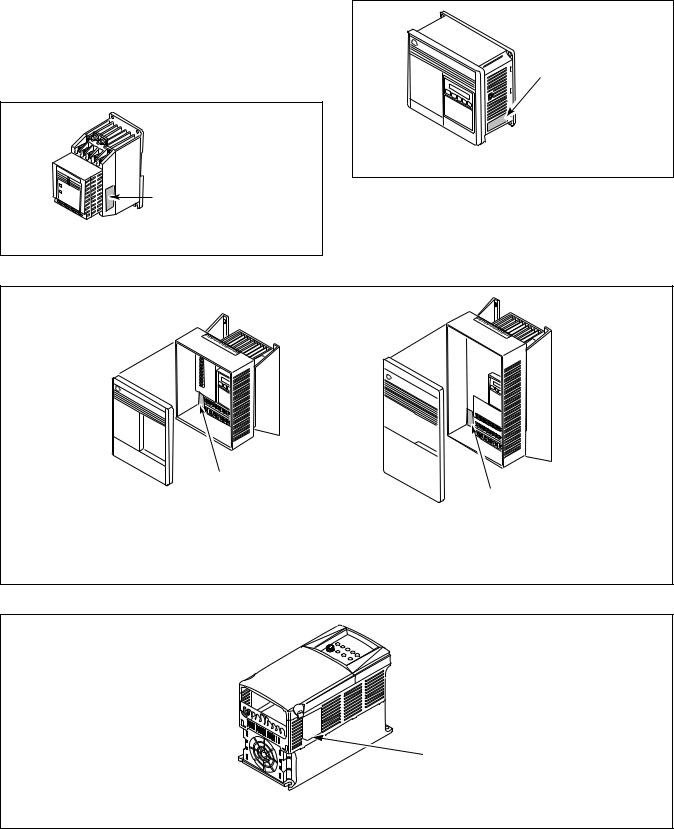

Terminal Block Access

WARNING

To reduce risk of electric shock, severe injury or death, allow machine power to remain off for three minutes minimum prior to working in and around AC drive. Proceed with caution.

W662

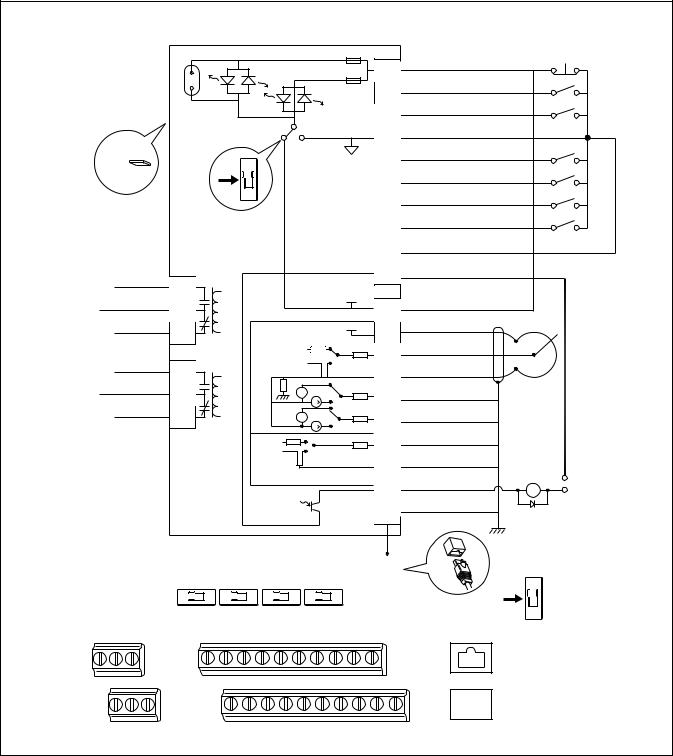

The following information illustrates the terminal block designations for each of the drive models.

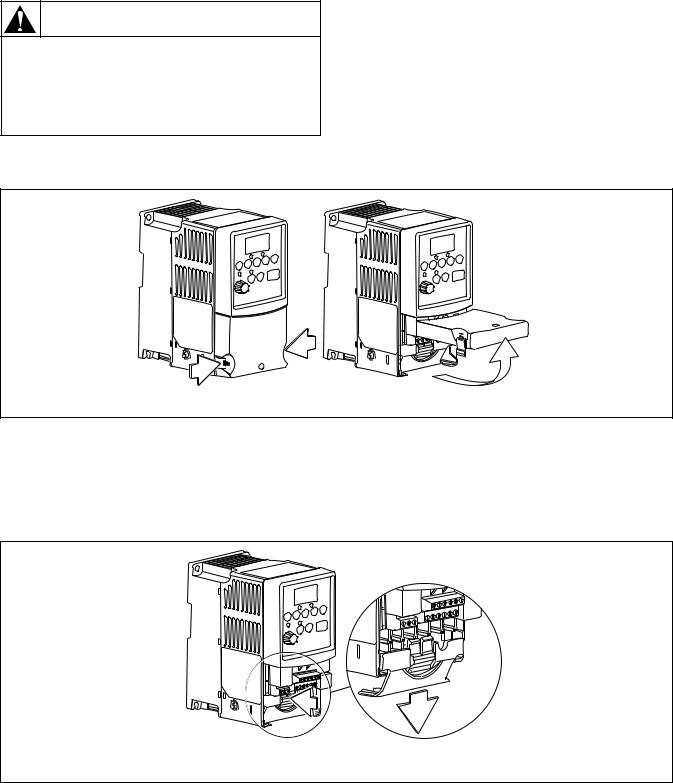

Opening the Cover

1.Press and hold in the tabs on each side of the cover. Refer to Figure 6.

2.Pull the cover out and up to release.

COVER

PHM636N

Figure 6

Power Terminal Block

The drive utilizes a finger guard over the power wiring terminals. To remove:

1. Press in and hold the locking tab.

2.Slide finger guard down and out. Refer to

Figure 7.

3.Replace the finger guard when wiring is complete.

POWER TERMINAL BLOCK (TYPICAL)

PHM637N

Figure 7

8 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

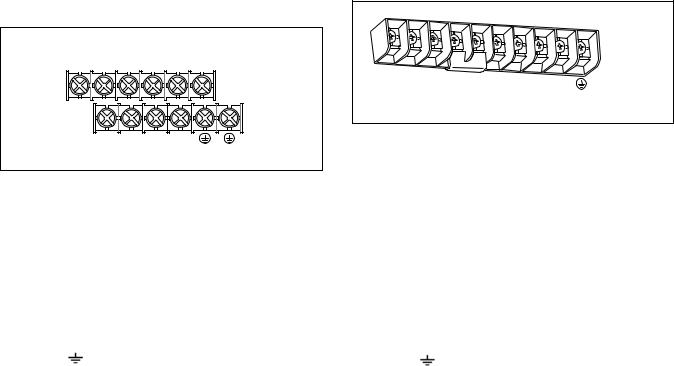

Power Terminal Block Description

PowerFlex 40

Input and Output Power Terminals (TB1)

B Frame

R/L 1 S/L 2 T/L 3 U/T 1 V/T 2 W/T 3

DC- |

DC+ |

BR+ |

BR- |

PHM741N

Figure 8

PowerFlex 40

Power Block Terminal (TB1)

Terminal |

Description |

R/L1, S/L2, T/L3 |

Single-phase or |

|

3-phase Power Input |

U/T1, V/T2, W/T3 |

3-phase Motor Output |

DC-1, DC+, -DC |

DC Bus Connection |

|

|

|

Ground Connection (PE) |

|

|

Table 3

PowerFlex 40

Power Terminal Block

Torque |

|

1.7-2.2 N-m (16-19 lb-in) |

|

|

|

Max Wire Size |

|

5.3 mm2 (10 AWG) |

Min Wire Size |

|

1.3 mm2 (16 AWG) |

|

Table 4 |

|

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 400

Input and Output Power Terminals (TB1)

Frame D

R/L 1 |

S/L 2 |

T/L 3 |

P 1 |

P 2 |

DC- |

|

|

|

|

U/T 1 |

V/T 2 W/T 3 |

||||

|

|

|

|

||||

|

|

|

|

|

|

PHM742N

Figure 9

PowerFlex 400

PowerFlex Power Block Terminal (TBI)

Terminal |

|

Description |

R/L1, S/L2, T/L3 |

|

3-phase Power Input |

|

|

|

U/T1, V/T2, W/T3 |

|

3-phase Motor Output |

|

|

|

P1, P3 |

|

DC Bus inductor connection |

|

|

jumper or Bus inductor must |

|

|

be present for drive to power- |

|

|

up. |

P2, DC- |

|

DC Bus Connection |

|

|

Ground Connection (PE) |

|

|

|

|

Table 5 |

|

PowerFlex 400 |

|

|

Power Terminal Block

Torque |

|

5.1N-m (45 lb-in) |

Max Wire Size |

|

33.6 mm2 (2 AWG) |

Min Wire Size |

|

8.4 mm2 (8 AWG) |

|

Table 6 |

|

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

9 |

PowerFlex 40 and 400 Drive Control Logic

Control Terminal Blocks Description and

Control Logic

WARNING

To reduce risk of electric shock, severe injury or death, allow machine power to remain off for three minutes minimum prior to working in and around AC drive. Proceed with caution.

W662

NOTE: Do not connect AC drive digital common, analog common, or common terminals to chassis ground.

Input Mode Parameter

The control terminal functions are determined in part by the “Start Source” parameter #36. Changing this parameter affects the function of some terminals.

Speed Selection

Motor speeds on digitally-controlled AC drives are controlled by solid state or mechanical switch closure inputs to Digital In 1, Digital In 2, and Digital In 3 terminals. Similarly, motor rotation direction is controlled by inputs to Start/Run FWD and Direction/ Run REV terminals. Refer to Figure 10.

An inactive control input terminal (H) will measure approximately 24v DC while an active control input terminal (L) will measure less than 1v DC. When a control input (i.e., Digital In 1, 2, 3, 4, Fwd, Rev, or Stop) is connected to a common terminal (terminal 4), the voltage on the control input terminal is reduced to near zero and the input is activated.

Tables 8 – 14 designate the speed and rotation direction based on inputs to the control terminals. The AC drive’s input status parameters display of 1s and 0s at various machine actions can be viewed while monitoring parameter #13 and/or #14. When the control input terminal voltage is high (inactive) the status display will read “0” (logic 0). When the control input terminal voltage is low (active) the status will read “1” (logic 1).

Balance Output

The AC drive balance output signal is transmitted to the machine controller by the operation of an on-board normally open relay or transistor. Refer to Figure 10. The AC drive will analyze the wash load distribution during certain drain steps and communicate the severity of load imbalance to the machine controller. The machine controller then determines if the load is suitably distributed for the programmed spin speed. The severity of load imbalance is communicated digitally by the on-board relay or transistor using a series of pulses or continuous open or closed state.

CAUTION

Never permanently jumper the AC drive balance output terminals or short the wires in these terminals together. This will override the balance detection routine and cause the wash cycle to abort, potentially causing machine damage or personal injury in the process.

W671

Stop/Enable Input

The Stop Input function is machine dependent. The input is typically used to disable the drive either when the frame vibration safety limit switch has been tripped or when the loading door has been opened. Refer to the applicable machine electrical schematic for details on the connection of this input. When the Stop Input signal is interrupted, the control input signals must be removed and reapplied to restart the motor operation.

10 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

Sink/Source Switch

The PowerFlex series of drives include a DIP Switch that will allow the drive input signals to be wired as “sink” or “source”. This switch should be set to the sink mode on all Alliance Laundry equipment made at the time of this publication. Setting this switch in the source mode will cause the drive to not operate and be mistaken as a failed drive.

PowerFlex 40 and 400 Drive Control Logic

0-10V/0-20m A Switch

The PowerFlex series of drives include a DIP switch that will allow the drive analog input signals to be wired as a 0-10V/0-20 mA switch.This switch should be set to the 0-10V mode on all Alliance Laundry Equipment made at the time of this publication. Setting this switch in the 0-20 mA mode may cause the drive to not operate and be mistaken as a failed drive.

Fault Code Display

Refer to Fault Display and Troubleshooting Information.

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

11 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Control Terminal Block

Designations

Control Wiring Block Diagram |

|

|

|

|

|

|

|

|

|

|

||

|

Enable |

|

|

|

|

|

|

|

|

|

|

Typical |

|

Jumper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stop |

|

|

|

SNK Wiring |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

01 |

|

|

|

|

|

|

|

|

|

|

|

|

02 |

FWD |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

03 |

REV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

SNK |

SRC |

|

|

04 |

Digital Common |

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

05 |

Digital Input 1 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

06 |

Digital Input 2 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

07 |

Digital Input 3 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

08 |

Digital Input 4 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

09 |

Bal Common |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

+24V |

|

|

+ 24V DC |

|

|

|

||

|

|

|

|

|

|

11 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

+10V |

12 |

+ 10V DC |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

13 |

0-10V ( or ± 10V) Input |

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

14 |

Analog Common |

|

||||

|

|

|

|

|

|

|

|

|

|

Pot must be |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay N.O. |

R1 |

|

|

|

|

15 |

4-20mA Input |

|

1-10k ohm |

|||

|

|

0-10V |

|

|

|

|

|

1 Watt Min. |

||||

|

|

|

|

|

|

|

|

|

|

|

||

Relay Common |

|

+ |

|

|

|

|

|

Analog Output |

|

|

||

R2 |

- |

0/4-20mA |

16 |

|

|

|||||||

|

|

|

|

|

|

Common |

||||||

|

|

|

|

|

|

|

|

Bal Output |

|

|||

Relay N.C. |

R3 |

|

|

|

|

17 |

|

24V |

||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

18 |

Opto Output 2 |

|

|

|||

|

30V DC |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

50mA |

|

|

|

|

|

RS485 Shield |

|

|

|||

|

Non-inductive |

|

|

19 |

|

|

||||||

|

|

|

|

|

|

|

|

|||||

|

0-10V |

Analog Output Select |

|

|

|

ENBL |

Enable |

|

||||

|

|

|

|

|

|

|

|

|

Jumper |

|

||

|

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

|

|

|

|

|

|

|||||||||

|

0-20mA |

|

|

|

|

|

|

|

|

|

|

|

R1 R2 R3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

SNK |

|

|

|

|

|

|

|

|

|

|

RS485 |

|

|

|

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

|

|

|

|

(DSI) |

|||||||||

|

SRC |

|

|

|

|

|

|

|

|

|

|

|

PHM780N

Figure 10

Control Input/Output Terminal Block

Torque |

|

0.5-0.8 N-m (4.4-7.0 lb-in) |

|

|

|

Max Wire Size |

|

1.3 mm2 (16 AWG) |

Min Wire Size |

|

0.13 mm2 (26 AWG) |

|

Table 7 |

|

12 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 400 Control Terminal Block

Designations

Control Wiring Block Diagram

ENBL

#1 Relay N.O.

#1 Relay Common

#1 Relay N.C.

#2 Relay N.O.

#2 Relay Common

#2 Relay N.C.

1 of 7 Digital Input Circuits |

01 |

|

02 |

Enable |

|

|

|

|

03 |

|

Jumper |

SNK |

|

SRC |

|

||

|

|

|

04 |

|||

|

|

|

|

|

|

|

|

SNK |

|

|

|

05 |

|

|

|

|

|

|

||

|

|

|

|

|

|

06 |

|

SRC |

|

|

|

|

|

|

|

|

|

|

|

07 |

|

|

|

|

|

|

08 |

|

|

|

|

|

|

09 |

|

|

|

|

|

|

10 |

R1 |

|

|

|

|

|

|

|

|

|

|

|

+24V |

|

R2 |

|

|

|

|

|

11 |

R3 |

|

Earth Referenced |

+10V |

12 |

||

|

|

|||||

|

Frames D & E |

|

||||

|

|

0-10V |

|

|||

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

R4 |

|

|

|

|

0-20mA |

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

R5 |

|

|

|

+ |

0-10V |

|

|

|

|

- |

|

15 |

|

|

|

|

|

|

|

|

R6 |

|

|

|

+ |

|

|

|

|

|

- |

|

16 |

|

|

|

|

|

|

|

|

|

|

Isolated |

0-10V |

17 |

||

|

|

|

|

|||

|

|

|

|

0-20mA |

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

19 |

|

|

30V DC |

|

|

|

|

|

|

50mA |

|

|

20 |

|

|

|

Non-inductive |

|

|||

|

|

|

|

|||

|

|

|

|

|

|

RS485 |

|

A01 |

A02 |

AI1 |

|

AI1 |

(DSI) |

|

|

|

||||

10V |

20mA 10V |

20mA 10V |

20mA 10V |

20mA |

|

|

Stop / |

Typical |

|

SNK Wiring |

||

Function Loss |

||

|

||

Start/Run FWD |

|

|

Direction/Run REV |

|

|

Digital Common |

|

|

Digital Input 1 |

|

|

Digital Input 2 |

|

|

Digital Input 3 |

|

|

Digital Input 4 |

|

|

Digital Common |

|

|

Opto Common |

|

+24V DC Source

+10V DC Source

Analog Input 1 (AI1) |

|

Analog Common 1 |

|

|

Pot must be |

Analog Output 1(AO1) |

1-10k ohm |

|

2 Watt Min. |

Analog Output 2 (AO2) |

|

Analog Input 2 (AI2) |

|

Analog Common 2 |

|

Opto Output |

Common |

24V |

|

AS485 Shield |

|

SNK

|

|

|

|

|

|

|

|

|

|

|

SRC |

R1 R2 R3 |

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

RS485 |

R4 R5 R6 |

|

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

|

|

|

|

|

|

|

|

|

|

RS485 |

PHM781N

PHM781N

Figure 11

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

13 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Cabinet Hardmount

“A” control, “B” control, “V” Control and EDC/Netmaster Control

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

|||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

|||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

Control Input |

||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

|||||||||||

|

|

d014 |

|

|

d013 |

|

|||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

InDigital3 (SW3) |

InDigital2 (SW2) |

InDigital1 (SW1) |

TransDB On |

Stop |

(STR)Rev |

(STF)Fwd |

|

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

0 |

0 |

0/1 |

0 |

0 |

|

1/2 Wash Speed Forward |

71 |

H |

H |

L |

L |

H |

L |

*1 |

|

0 |

0 |

1 |

0 |

1 |

0 |

1 |

|

1/2 Wash Speed Reverse |

71 |

H |

H |

L |

L |

L |

H |

0 |

|

0 |

0 |

1 |

0 |

1 |

1 |

0 |

|

Wash Speed Forward |

72 |

H |

L |

H |

L |

H |

L |

*1 |

|

0 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Wash Speed Reverse |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed |

74 |

L |

H |

H |

L |

H |

L |

*1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

1 |

|

Spin 1 |

73 |

H |

L |

L |

L |

H |

L |

*1 |

|

0 |

1 |

1 |

0 |

1 |

0 |

1 |

|

Spin 2 |

76 |

L |

L |

H |

L |

H |

L |

*1 |

|

1 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Spin 3 |

75 |

L |

H |

L |

L |

H |

L |

*1 |

|

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Cabinet Hardmount

Galaxy control, Quantum control and UniMac Software Control

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

||||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

||||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

|

Control Input |

||||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

|||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

||||||||||||

|

|

d014 |

|

|

d013 |

|

||||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

DigitalIn 3 |

DigitalIn 2 |

|

DigitalIn 1 |

TransDB On |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/ H |

H |

H |

0 |

|

0 |

0 |

|

0 |

0 |

0/1 |

0 |

0 |

|

Reduced Wash speed (ccw) |

70 |

H |

H |

H |

L |

L |

H |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

1 |

0 |

|

Reduced Wash Speed (cw) |

70 |

H |

H |

H |

L |

H |

L |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

0 |

1 |

|

Wash Speed (ccw) |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

1 |

0 |

|

Wash Speed (cw) |

72 |

H |

L |

H |

L |

H |

L |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

0 |

1 |

|

Distribution Speed 1 (ccw) |

71 |

H |

H |

L |

L |

L |

H |

0 |

|

0 |

0 |

|

1 |

0 |

1 |

1 |

0 |

|

Extract Speed 1 (ccw) |

76 |

L |

L |

H |

L |

L |

H |

0 |

|

1 |

1 |

|

0 |

0 |

1 |

1 |

0 |

|

Extract Speed 2 (ccw) |

75 |

L |

H |

L |

L |

L |

H |

0 |

|

1 |

0 |

|

1 |

0 |

1 |

1 |

0 |

|

Extract Speed 3 (ccw) |

73 |

H |

L |

L |

L |

L |

H |

0 |

|

0 |

1 |

|

1 |

0 |

1 |

1 |

0 |

|

Extract Speed 4 (ccw) |

77 |

L |

L |

L |

L |

L |

H |

0 |

|

1 |

1 |

|

1 |

0 |

1 |

1 |

0 |

|

Extract Speed 5 (ccw) |

74 |

L |

H |

H |

L |

L |

H |

0 |

|

1 |

0 |

|

0 |

0 |

1 |

1 |

0 |

|

Table 8

14 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Pocket Hardmount - 35 lb through 125 lb Capacity

UniLinc control and M30 control

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

||||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

||||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

|

Control Input |

||||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

|||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

||||||||||||

|

|

d014 |

|

|

d013 |

|

||||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

DigitalIn 4 |

|

DigitalIn 3 |

DigitalIn 2 |

|

DigitalIn 1 |

TransDB On |

Stop |

Rev |

Fwd |

|

Action |

Preset |

|

|

|

|

|

|

|

|

|

|

|||||||

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|||

|

Parameter # |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/ H |

H |

H |

0 |

|

0 |

0 |

|

0 |

0 |

0/1 |

0 |

0 |

|

Reduced Wash Speed (cw) |

70 |

H |

H |

H |

L |

H |

L |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

0 |

1 |

|

Reduced Wash Speed (ccw) |

70 |

H |

H |

H |

L |

L |

H |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

1 |

0 |

|

Wash Speed (cw) |

72 |

H |

L |

H |

L |

H |

L |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

0 |

1 |

|

Wash Speed (ccw) |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed (cw) |

71 |

H |

H |

L |

L |

H |

L |

0 |

|

0 |

0 |

|

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 1 (ccw) |

76 |

L |

L |

H |

L |

H |

L |

0 |

|

1 |

1 |

|

0 |

0 |

1 |

0 |

1 |

|

Extract Speed 2 (ccw) |

75 |

L |

H |

L |

L |

H |

L |

0 |

|

1 |

0 |

|

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 3 (ccw) |

73 |

H |

L |

L |

L |

H |

L |

0 |

|

0 |

1 |

|

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 4 (ccw) |

77 |

L |

L |

L |

L |

H |

L |

0 |

|

1 |

1 |

|

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 5 (ccw) |

74 |

L |

H |

H |

L |

H |

L |

0 |

|

1 |

0 |

|

0 |

0 |

1 |

0 |

1 |

|

Pocket Hardmount - 150 Capacity

Terminator control Control

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

||||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

||||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

|

Control Input |

||||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

|||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

||||||||||||

|

|

d014 |

|

|

d013 |

|

||||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

DigitalIn 4 |

|

DigitalIn 3 |

DigitalIn 2 |

|

DigitalIn 1 |

TransDB On |

Stop |

Rev |

Fwd |

|

Action |

Preset |

|

|

|

|

|

|

|

|

|

|

|||||||

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|||

|

Parameter # |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

|

0 |

0 |

0/1 |

0 |

0 |

|

Reduced Wash speed (ccw) |

70 |

H |

H |

H |

L |

L |

H |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

1 |

0 |

|

Reduced Wash Speed (cw) |

70 |

H |

H |

H |

L |

H |

L |

0 |

|

0 |

0 |

|

0 |

0 |

1 |

0 |

1 |

|

Wash Speed (ccw) |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

1 |

0 |

|

Wash Speed (cw) |

72 |

H |

L |

H |

L |

H |

L |

0 |

|

0 |

1 |

|

0 |

0 |

1 |

0 |

1 |

|

Distribution Speed (ccw) |

71 |

H |

H |

L |

L |

L |

H |

0 |

|

0 |

0 |

|

1 |

0 |

1 |

1 |

0 |

|

Very Low Extract (ccw) |

76 |

L |

L |

H |

L |

L |

H |

0 |

|

1 |

1 |

|

0 |

0 |

1 |

1 |

0 |

|

Low Extract (ccw) |

75 |

L |

H |

L |

L |

L |

H |

0 |

|

1 |

0 |

|

1 |

0 |

1 |

1 |

0 |

|

Medium Extract (ccw) |

73 |

H |

L |

L |

L |

L |

H |

0 |

|

0 |

1 |

|

1 |

0 |

1 |

1 |

0 |

|

High Extract (ccw) |

77 |

L |

L |

L |

L |

L |

H |

0 |

|

1 |

1 |

|

1 |

0 |

1 |

1 |

0 |

|

Very High Extract (ccw) |

74 |

L |

H |

H |

L |

L |

H |

0 |

|

1 |

0 |

|

0 |

0 |

1 |

1 |

0 |

|

Table 9

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

15 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Pocket Hardmount

“V” control and “A” control - Designs 7 and 8

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

|||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

|||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

Control Input |

||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

|||||||||||

|

|

d014 |

|

|

d013 |

|

|||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

DigitalIn 3 (SW3) |

InDigital2 (SW2) |

InDigital1 (SW1) |

TransDB On |

Stop |

(STR)Rev |

(STF)Fwd |

|

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

0 |

0 |

0/1 |

0 |

0 |

|

1/2 Wash Speed Forward |

71 |

H |

H |

L |

L |

H |

L |

*1 |

|

0 |

0 |

1 |

0 |

1 |

0 |

1 |

|

1/2 Wash Speed Reverse |

71 |

H |

H |

L |

L |

L |

H |

0 |

|

0 |

0 |

1 |

0 |

1 |

1 |

0 |

|

Wash Speed Forward |

72 |

H |

L |

H |

L |

H |

L |

*1 |

|

0 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Wash Speed Reverse |

72 |

H |

L |

H |

L |

L |

Ha |

0 |

|

0 |

1 |

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed |

74 |

L |

H |

H |

L |

H |

L |

*1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

1 |

|

Spin 1 Extract |

73 |

H |

L |

L |

L |

H |

L |

*1 |

|

0 |

1 |

1 |

0 |

1 |

0 |

1 |

|

Spin 2 Extract |

76 |

L |

L |

H |

L |

H |

L |

*1 |

|

1 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Spin 3 Extract |

75 |

L |

H |

L |

L |

H |

L |

*1 |

|

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Pocket Hardmount

WE-6 control - Design 5 and Earlier

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

|||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

|||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

Control Input |

||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

|||||||||||

|

|

d014 |

|

|

d013 |

|

|||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

InDigital3 (SW3) |

InDigital2 (SW2) |

InDigital1 (SW1) |

TransDB On |

Stop |

(STR)Rev |

(STF)Fwd |

|

|

|

|

|

|

|

|

|

|

|

||||||||

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

0 |

0 |

0/1 |

0 |

0 |

|

1/2 Wash Speed Forward |

74 |

L |

H |

L |

L |

H |

H |

*1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

1 |

|

1/2 Wash Speed Reverse |

74 |

L |

H |

H |

L |

L |

H |

0 |

|

1 |

0 |

0 |

0 |

1 |

1 |

0 |

|

Wash Speed Forward |

72 |

H |

L |

H |

L |

H |

H |

*1 |

|

0 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Wash Speed Reverse |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed |

71 |

H |

H |

L |

L |

H |

L |

*1 |

|

0 |

0 |

1 |

0 |

1 |

0 |

1 |

|

Medium Extract/Spray Rinse |

76 |

L |

L |

H |

L |

H |

H |

*1 |

|

1 |

1 |

0 |

0 |

1 |

0 |

1 |

|

High 1 Extract |

75 |

L |

H |

H |

L |

H |

L |

*1 |

|

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|

High 2 Extract |

73 |

H |

L |

L |

L |

H |

L |

*1 |

|

0 |

1 |

1 |

0 |

1 |

0 |

1 |

|

High 3 Extract |

77 |

L |

L |

L |

L |

H |

L |

*1 |

|

1 |

1 |

1 |

0 |

1 |

0 |

1 |

|

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Table 10

16 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

F232120 |

|

|

|

|

|

|

PowerFlex 40 and 400 Drive Control Logic |

|||||||||||

Pocket Hardmount |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WE-6 control - Design 6, 7 and 8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

|||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

|||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

Control Input |

||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

|||||||||||

|

|

d014 |

|

|

d013 |

|

|||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

DigitalIn 3 (SW3) |

DigitalIn 2 (SW2) |

DigitalIn 1 (SW1) |

TransDB On |

Stop |

(STR)Rev |

(STF)Fwd |

|

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

0 |

0 |

0/1 |

0 |

0 |

|

1/2 Wash Speed Forward |

70 |

H |

H |

H |

L |

H |

L |

*1 |

|

0 |

0 |

0 |

0 |

1 |

0 |

1 |

|

1/2 Wash Speed Reverse |

70 |

H |

H |

H |

L |

L |

H |

0 |

|

0 |

0 |

0 |

0 |

1 |

1 |

0 |

|

Wash Speed Forward |

72 |

H |

L |

H |

L |

H |

L |

*1 |

|

0 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Wash Speed Reverse |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed |

71 |

H |

H |

L |

L |

H |

L |

*1 |

|

0 |

0 |

1 |

0 |

1 |

0 |

1 |

|

Medium Extract/Spray Rinse |

76 |

L |

L |

H |

L |

H |

L |

*1 |

|

1 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Extract Speed 1 |

75 |

L |

H |

L |

L |

H |

L |

*1 |

|

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 2 |

73 |

H |

L |

L |

L |

H |

L |

*1 |

|

0 |

1 |

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 3 (default) |

77 |

L |

L |

L |

L |

H |

L |

*1 |

|

1 |

1 |

1 |

0 |

1 |

0 |

1 |

|

Extract Speed 3 (maximum) |

74 |

L |

L |

H |

L |

H |

L |

*1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

1 |

|

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Table 11

F232120 |

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT |

17 |

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Cabinet Freestanding

WE-6 control

H – Signal Voltage High (approximately 24V DC) |

|

|

|

|

|

|

|

|

0 = No signal received |

|

|

||||||

L – Signal Voltage Low (less than 1V DC) |

|

|

|

|

|

|

|

|

|

1 = Signal received |

|

|

|||||

|

|

Digital |

Digital |

Digital |

Stop |

Rev |

Fwd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

In 3 |

In 2 |

In 1 |

|

Digital Input |

Control Input |

||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Status – Parameter |

Status – Parameter |

||||||||

DC Volt Meter Red Probe Terminal Location |

07 |

06 |

05 |

01 |

03 |

02 |

|||||||||||

|

|

d014 |

|

|

d013 |

|

|||||||||||

DC Volt Meter Black Probe Terminal Location |

04 |

04 |

04 |

04 |

04 |

04 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

Frequency |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

Terminal |

*DigitalIn 4 |

|

InDigital3 (SW3) |

InDigital2 (SW2) |

InDigital1 (SW1) |

TransDB On |

Stop |

(STR)Rev |

(STF)Fwd |

|

Action |

Preset |

#07 |

#06 |

#05 |

#01 |

#03 |

#02 |

|

|

|

|

|

|

|

|

|

|

|

Parameter # |

(SW3) |

(SW2) |

(SW1) |

(Stop) |

(STR) |

(STF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

N/A |

H |

H |

H |

L/H |

H |

H |

0 |

|

0 |

0 |

0 |

0 |

0/1 |

0 |

0 |

|

1/2 Wash Speed Forward |

74 |

L |

H |

H |

L |

H |

L |

*1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

1 |

|

1/2 Wash Speed Reverse |

74 |

L |

H |

H |

L |

L |

H |

0 |

|

1 |

0 |

0 |

0 |

1 |

1 |

0 |

|

Wash Speed Forward |

72 |

H |

L |

H |

L |

H |

L |

*1 |

|

0 |

1 |

0 |

0 |

1 |

0 |

1 |

|

Wash Speed Reverse |

72 |

H |

L |

H |

L |

L |

H |

0 |

|

0 |

1 |

0 |

0 |

1 |

1 |

0 |

|

Distribution Speed |

71 |

H |

H |

L |

L |

H |

L |

*1 |

|

0 |

0 |

1 |

0 |

1 |

0 |

1 |

|

Medium Extract |

76 |

L |

L |

H |

L |

H |

L |

*1 |

|

1 |

1 |

0 |

0 |

1 |

0 |

1 |

|

High 1 Extract |

75 |

L |

H |

L |

L |

H |

L |

*1 |

|

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|

High 2 Extract |

73 |

H |

L |

L |

L |

H |

L |

*1 |

|

0 |

1 |

1 |

0 |

1 |

0 |

1 |

|

High 3 Extract |

77 |

L |

L |

L |

L |

H |

L |

*1 |

|

1 |

1 |

1 |

0 |

1 |

0 |

1 |

|

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Table 12

PowerFlex 400 Drive Control Logic Chart

Cabinet Freestanding (250 Model Only)

WE-6 control

H – Signal Voltage High (greater than 10V DC) |

|

|

|

|

|

|

|

|

0 = No signal received |

|

|