AEG-Electrolux 335D-W-GB, 335DD User Manual

335 D

Extractor Hood

Installation and Operating Instructions

2

Contents

Description of the appliance |

3 |

General details |

3 |

Extractor version |

3 |

Filter version |

4 |

Safety warnings for kitchen unit installer |

4 |

Electrical connections |

5 |

Safety warnings for electrician |

5 |

Safety warnings for user |

7 |

Hood operation |

8 |

Care and Maintenance |

9 |

Grease filter |

9 |

Active carbon filter |

10 |

Cleaning |

10 |

Replacing the lamps |

10 |

Technic details |

11 |

Special Accessories |

11 |

Technical Assistance Service |

11 |

OKO |

|

MADE |

IN |

|

|

S |

YSTEM |

GERMANY |

|

Printed on recycled paper. AEG – putting words into action.

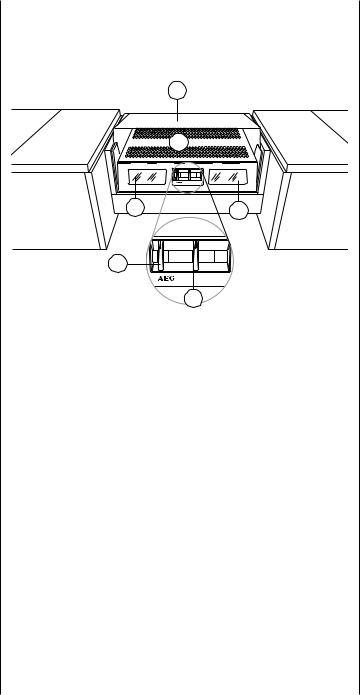

Description of the appliance

1)Pull-out panel

2)Grease filter support grid

3)Hob light

4)Fan speed selector

5)Light switch

1

2

2

3 |

3 |

5

4

General details

The hood is supplied as an extractor version, but may also be used in the recirculating mode by inserting an active carbon filter (Optional extra).

Exhaust vapours are pushed outwards by means of a pipe. |

Extractor |

|

version |

If the exhaust pipe is in a horizontal position, it must be inclined upwards at a angle of 10° so as to guarantee better extraction.

To connect the fan hood to the wall box, we recommend the use of venting hoses E-Nr. 697 000 012 or 647 000 010 (120 mm or 100 mm diameter) which are supplied as optional extras.

3

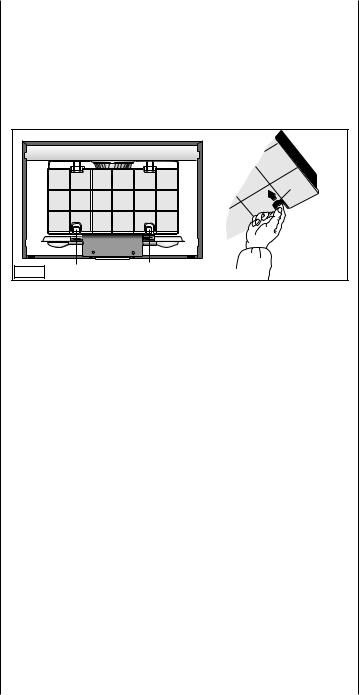

Filter version Exhaust vapours are purified by means of an active carbon filter (Optional extra) and directed back into the room.

To insert the active carbon filter, remove the grease filter grid.

Fit the active carbon filter by inserting it first into the upper hooks and then into the lower ones; then lock into position by using the blocking tabs E (fig. 1).

|

|

E |

1 |

E |

E |

The AEG original KLF 60/80 active filter carbon is necessary for the recirculating mode (see paragraph “Special accessories”).

Safety |

The air outlet must not be connected to chimney flues or combus- |

warnings for |

tion gas ducts. The air outlet must under no circumstances be |

kitchen unit |

connected to ventilation ducts for rooms in which fuel-burning |

installer |

appliances are installed. |

It is advisable to apply for authorization from the relevant controlling authority when connecting the outlet to an unused chimney flue or combustion gas duct.

The air outlet installation must comply with the regulations laid down by the relevant authorities.

When the unit is used as an extractor version, a sufficiently large ventilation hole must be provided, with dimensions that are approximately the same as the outlet hole.

National and regional building regulations impose a number of restrictions on using hoods and fuel-burning appliances connected to a chimney, such as coal or oil room-heaters and gas fires, in the same room.

|

The local decree on fuel-burning systems specifies a maximum |

4 |

depression of 0.04 mbar in such rooms. |

|

Hoods can only be used safely with appliances connected to a chimney if the room and/or flat (air/environment combination) is ventilated from outside using a suitable ventilation hole approximately 500-600 cm2 large to avoid the possibility of a depression being created during operation of the hood.

If you have any doubts, contact the relevant controlling authority or building inspector’s office.

Since the rule for rooms with fuel burning appliances is “outlet hole of the same size as the ventilation hole”, a hole of 500-600 cm2, which is to say a larger hole, could reduce the performance of the extractor hood.

If the hood is used in its recirculation mode, it will operate simply and safely in the above conditions without the need for any of the aforementioned measures.

When the hood is used as an extractor,the following rules must be followed to obtain optimal operation:

—short and straight outlet hose

—keep bends in outlet hose to a minimum

—never install the hoses with an acute angle, they must always follow a gentle curve only

—keep the hose as large as possible (100 or 120 mm Ø min.).

Failure to observe these basic rules will drastically reduce the performance and increase the noise levels of the extractor hood.

Where flexible ducting is fitted the length should be no more than:

—3 metres with one 90° bend

—2 metres with two 90° bends.

Bends of more than 90° will reduce the efficiency of the hood and reduce the air flow.

Electrical connections

Please ensure that the voltage and current indicated on the rating plate agree with the voltage of your electricity supply.

If your appliance has been equipped with a mains lead with a moulded-on type plug, you must comply with the following regulations:

The plug moulded on to the lead incorporates a fuse. For replacement, use a 5 amp BS1362 fuse. Only ASTA approved or

Safety warnings

for electrician

5

Loading...

Loading...