3M 9211, 9210 User Manual

3

Particulate Respirator 9210 and 9211, N95

3062

page 1 of 2

Issue Date 01/01/04

Workers want respirators that are comfortable, lightweight and convenient. That’s why 3M, with its long experience in filtration technologies, designed a family of respirators that provides high levels of comfort and value.

Features & Benefits

NIOSH approved N95

•At least 95% filtration efficiency against solid and liquid aerosols that do not contain oil.* TC-84A-2668 (9211) TC-84A-2669 (9210)

Three-panel respirator with innovative design

•Low profile for better visibility and compatibility with a wide variety of safety equipment.

•Conforms to a wide range of face sizes.

•Offers convenient storage and portability prior to use.

Soft cover web on inner panel

•Feels comfortable against the skin.

Soft nose foam pad, and conformable nose clip

•Adjusts easily.

•Helps provide a custom fit and secure seal.

•Reduces the potential for eyewear fogging.

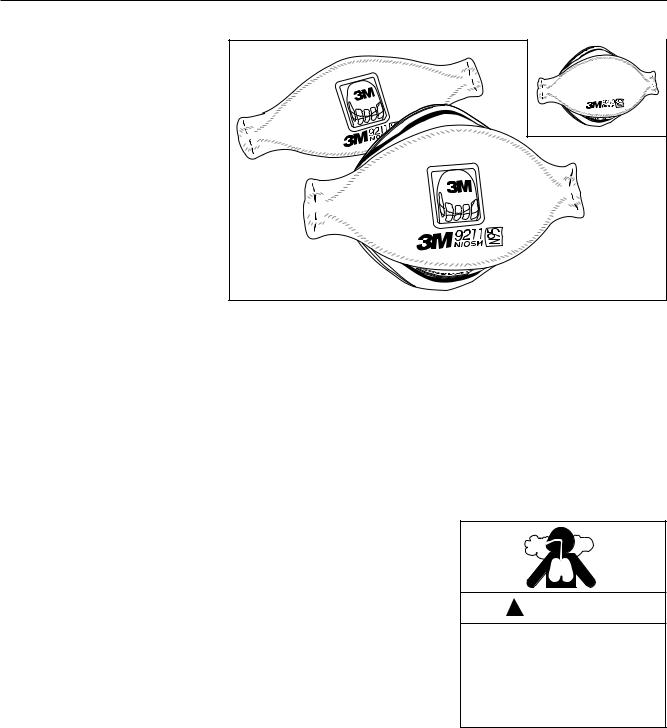

3MTM Particulate Respirator 9211, N95

(Inset photo: 3MTM Particulate Respirator 9210, N95)

Individually packaged

•Helps prevent contamination during storage.

•Helps increase worker acceptance.

•Allows for easy dispensing.

3MTM Cool FlowTM Exhalation Valve — 9211 only

•Patented one-way valve offers easy exhalation and cool, dry comfort.

•Central positioning of the 3MTM Cool FlowTM Exhalation Valve allows for efficient performance.

Lightweight, collapseresistant design

•Promotes greater worker comfort.

•Contributes to increased wear time.

Suggested Applications

•Grinding

•Sanding

•Sweeping

•Bagging

•General maintenance

•Other operations that create dust

! WARNING

These respirators help reduce exposure to certain particles. Misuse may result in sickness or death.

Before use, the wearer must read and understand User Instructions provided as a part of product packaging. Time use limitations may apply. For proper use, see package instructions, supervisor or call 3M OH&ESD Technical Service in U.S.A., 1-800-243-4630. In Canada, call 1-800-267-4414.

*Tested against particles approximately 0.3 micron in size (mass median aerodynamic diameter) per 42 CFR 84.

Loading...

Loading...